Abstract

SF6 as a gas medium for power switchgear, has outstanding performance on arc suppression and insulation. However, because of the strong greenhouse effect, it is limited to use recently. SF6/N2 mixture is an effective alternative in high voltage power switchgear, which not only reduce the emission of SF6 but also lower the gas liquefaction temperature. Based on a 220 kV disconnector, this paper built a magneto-hydro-dynamic (MHD) model to simulate the arc burning process. The electric field distribution and the critical breakdown voltage within 100 us after current zero (CZ) were calculated to evaluate the arc interruption performance of the SF6/N2 mixture. The model established in this paper is effective and referable in arc simulation and dielectric recovery assessment. The research results in this thesis are significant to the application of SF6/N2 mixture in disconnectors.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

SF6 as a gas medium for power switchgear, has outstanding performance on arc suppression and insulation [1]. But for its strong greenhouse effect, the electrical industry urgently needs to find an environmentally friendly substitute gas. Researchers have conducted extensive and in-depth research in the field of SF6 alternative gases over the years. At present, the widely studied and applied SF6 alternative gases can be divided into four categories. The first is natural conventional gases [2], which are cheap and do little harm to the environment. But their arc interruption and insulation performance are insufficient. The other two are new environmentally friendly gases such as fluorocarbons and new fluoride, which are still being explored [3,4,5]. And the last category is the SF6 mixture [6]. This category of gas can solve the problem of SF6 liquefaction that can occur in cold regions and also helps reduce SF6 use, which has great important engineering significance. One of the most studied gases is the mixture of SF6 and N2 [7, 8].

Researchers have done a lot of research on the breakdown characteristics of the SF6/N2 mixture. Christophorou et al. [9, 10] studied the breakdown characteristics of SF6/N2 mixture under different electrode structures and found an excellent synergistic effect of them. Lu et al. [11] conducted frequency breakdown tests and lighting impulse tests to 30% SF6/N2 mixture at a temperature range from −30 to 20 ℃ based on a 126 kV GIS partial discharge test platform. The results showed that in low temperatures about −30–−10 ℃, the frequency breakdown voltage was significantly influenced by the mixing ratio of SF6; as in the higher temperature of 0–20 ℃, the influence became inconspicuous. Dmitry and Laxminarayan [12] built a two-dimensional axisymmetric fluid model and coupled it with the comprehensive mechanism of plasma chemical reactions, to figure out the influence of the SF6 fraction in the SF6/N2 mixture on the breakdown voltage. It was observed that the breakdown voltage increased by 7–43% when adding only 1% SF6 to N2 depending on the voltage rise time. All the studies mentioned above were carried out on the single electrode structure or simplified electrode model. Therefore, studying the arc-suppressing performance of SF6/N2 mixed gas on specific electric high voltage power switchgear is essential and has great engineering practical research significance.

This thesis aims to evaluate the arc suppressing property of SF6/N2 mixture. Firstly, a magneto-hydro-dynamic (MHD) model of a 220 kV disconnector structure was built up to simulate the arc burning process. Secondly, the electric breakdown in the arc extinguishing room after arc was evaluated. The probability of electrical breakdown in each region of the arc extinguishing room was predicted through the temperature, pressure, and the actual electric field distribution of the mixture, meanwhile, the critical breakdown voltage of the SF6/N2 mixture was calculated. The results revealed the breakdown probability and arc reigniting after current zero (CZ), and effectively evaluate the arc interruption performance of the SF6/N2 mixture. The model established in this paper is effective and referable in arc simulation and dielectric recovery assessment. The research results in this thesis are significant to the application of SF6/N2 mixture in disconnectors.

2 Simulation Model and Calculation Method

In this section, a two-dimension MHD model is built based on ANSYS FLUENT, which is software to simulate the interaction of multiple physical fields during arc burning process [13]. Then the method to calculate the critical breakdown field strength of the mixture and the method of evaluating the electric breakdown in the arc extinguishing room after arc is presented.

2.1 MHD Model

In the process of current interrupting simulation, the arc is regarded as a special fluid, and the arc plasma is considered to be electrically neutral, which is in the state of Local Thermodynamic Equilibrium (LTE) and Local Chemical Equilibrium (LCE). The effect of a thin sheath near the electrode is ignored. The dynamic development of arc and surrounding airflow field is described using the Navier–Stokes equations that reflect the conservation of mass, momentum, and energy, electromagnetic field equations, radiation model, and turbulence model [14].

2.2 The Geometric Model of Disconnector

The geometric model is based on a 220 kV disconnector. It is axisymmetric including half of the disconnector structure, so as to simplify the calculation. Figure 1 shows the disconnector model as the moving contact has moved for 9 ms. Along the axis, there is an evaluation line L1, which is used to calculate the critical breakdown voltage.

The boundary and initial conditions of the model are set as follows:

-

1.

The IRMS and frequency of current is 1.6 kA, 50 Hz. The maximum value of the transient recovery voltage (TRV) is 73 kV.

-

2.

The inflation pressure is 0.6 MPa, the upper part of the chamber is set as the pressure outlet, and the ambient temperature is 300 K. And the separation speed of contact is 5 m/s.

-

3.

There are three proportions of mixture filled in the switch: pure SF6,28%SF6 + 72%N2, and 40%SF6 + 60%N2.

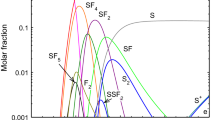

2.3 Calculation of Critical Breakdown Field Strength

During the arc burning process, the gas will decompose and change its properties because of the high temperature and fluctuating pressure. To assess the dielectric strength recovery after arc, The critical breakdown electric field strength \({E}_{cr}\) at high temperatures is calculated. For the mixture, the collision cross sections are acquired using the semi-classical Deutsch-Märk (DM) method. Then, the collision cross sections and gas components are used to calculate \({E}_{cr}\) at different temperatures and pressures by solving the Boltzmann equation [15]. Figure 2 shows the \({E}_{cr}\) of two proportions of mixture. The \({E}_{cr}\) is the function of temperature and pressure, inversely correlated with temperature and positively correlated with pressure.

2.4 Evaluation of the Dielectric Strength Performance of Gas Mixture

To estimate the electrical breakdown of the gas mixture in the arc extinguishing room, the real electrical field distribution and the airflow field are considered. Figure 3 shows that the electrical field \({E}_{a}\) is determined by the transient recovery voltage (TRV) after arc. The distribution of temperature and pressure field in the chamber influences the critical breakdown field \({E}_{cr}\). It is supposed that the gas gap is likely to break down when the critical breakdown field is smaller than the background field. Therefore, the ratio of \({E}_{a}\) to \({E}_{cr}\) represents the probability of electric breakdown in this area.

3 Simulation Results and Analysis

In this section, the post-arc electrical breakdown simulation of the disconnector is carried out after the CZ. After that, the distribution of the physical field and the critical breakdown voltage for three proportions of SF6/N2 mixture are analyzed.

3.1 The Distribution of the Physical Field

Figure 4 shows the temperature contour and \({E}_{a}\)/\({E}_{cr}\) contour of the disconnector in three proportions of SF6/N2 mixture at 100 us after arc. It can be found that the temperature of gas is low at this time, as the highest temperature of the three gases is within 3000 K. Therefore, it is helpful for the recovery of dielectric insulation strength. When analyzing the distribution of the \({E}_{a}\)/\({E}_{cr}\), it is similar in all three cases. The maximum value of \({E}_{a}\)/\({E}_{cr}\) appears at the edge of the contact, because of the large electric field caused by the unsmooth structure. For 28% SF6/N2, the maximum value of it is 0.7, which is less than 1, so the arc is less likely to be re-struck. Although the highest temperature appears at the bottom of the static contact which can lead to the lowest \({E}_{cr}\), as \({E}_{a}\) is much lower, the \({E}_{a}\)/\({E}_{cr}\) value is small. At last, it can be concluded that in the same position, the higher the SF6 concentration is, the smaller the \({E}_{a}\)/\({E}_{cr}\) value is.

3.2 The Calculation of Critical Breakdown Voltage

The critical breakdown voltage along the selected path (shown in Fig. 1) is calculated and shown in Fig. 5. With the decrease of the temperature and the fluctuation of the pressure in the arc extinguishing room, the critical BD voltages all fluctuate in a small amplitude, and show an upward trend overall time. The initial critical BD voltages of 28% SF6/N2 and 40% SF6/N2 mixture are 275.5 and 300 kV, about 56.0 and 61.0% compared to SF6, but still higher than the TRV, the maximum value of which is set as 73 kV. Meanwhile, the presence of N2 in the mixed gas also increases the fluctuation of the critical BD voltages and affects the recovery of dielectric strength. It is indicated that in the first 30 \(\mu s\), the critical breakdown voltage of the two SF6/N2 mixtures fluctuated sharply, and the value was very close. After 30 \(\mu s\), the critical breakdown voltage began to stabilize and because of the effect of SF6, the critical breakdown voltage of 40% SF6/N2 was slightly higher than 28% SF6/N2.

4 Conclusion

To evaluate the arc suppressing property of SF6/N2 mixture, the MHD model was built based on the 220 kV disconnector. The arcing process of SF6 gas and SF6/N2 mixture is simulated and the critical breakdown field strength is calculated as the precondition to evaluate the dielectric recovery performance of SF6 and SF6/N2 mixture. The following conclusions were drawn:

-

1.

The critical breakdown field strength of SF6/N2 mixture is calculated, which decreases when temperature increases and pressure decreases. At the same time, the rise of SF6 ratio in the mixture increases the critical breakdown field strength.

-

2.

The critical breakdown voltage of 28%SF6/N2 and 40%SF6/N2 mixture under 0.6 MPa after current zero is predicted and compared to pure SF6. The calculated critical breakdown voltage is lower than SF6, but it is much higher than the maximum of TRV, without the risk of breakdown.

Therefore, SF6/N2 mixture has perfect arc suppressing performance and can be used as the substitution for SF6 in the power switchgear. The simulation results in this thesis are helpful to the application of SF6/N2 mixture in disconnectors and have high engineering significance.

References

Guo Z, Li X, Su H et al (2017) Interrupting characteristics of paralleled SF6 circuit breakers with a highly coupled split reactor. In IEEE Transactions on components, packaging and manufacturing technology 7(5):768–776

Seeger M, Avaheden J, Pancheshnyi S et al (2017) Streamer parameters and breakdown in CO2. J Phys D: Appl Phys 50(1):5207

Zhang B, Zhou R, Wang K et al (2023) Arc interruption performance of C4F7N-CO2 mixture in a 126 kV disconnector. IEEE Transact Pow Deliv 38(2):1197–1207

Lin X, Zhang J, Xu J et al (2022) Dynamic dielectric strength of C3F7CN/CO2 and C3F7CN/N2 mixtures in high voltage circuit breakers. IEEE Transact Power Deliv 37(5):4032–4041

Alonso ML, Alonso RM, Lombraña JI et al (2021) Exploring the Decomposition Products of 1,3,3,3-Tetrafluoropropene and Perfluoro-(3-methylbutan-2-one) mixtures in medium-voltage electrical switchgear as alternatives to SF6. ACS Omega 6(33):21534–21542

Ou X, Wang L, Liu J et al (2020) Numerical simulation of streamer discharge development processes with multi-component SF6 mixed gas. Phys Plasmas 27:073504

Geng J, Yang J, Shu T et al (2023) Stability of breakdown phenomenon in N2, SF6, and their mixture under impulse voltages. AIP Adv 13:035033

Wang L, Ou X, Zheng Y et al (2019) Numerical simulations of the SF6-N2 mixed gas streamer discharge development process. AIP Adv 9:055320

Christophorou LG, Olthoff JK, VanBrunt RJ (1997) Sulfur hexafluoride and the electric power industry. IEEE Electric Insulat Magaz 13(5):20–24

Christophorou LG, Olthoff JK, Green DS (1997) Gases for electrical insulation and arc interruption: possible present and future alternatives to pure SF6. NIST Techn Note 1425:1–44

Lu G, Su Z, Xu O et al (2016) Experimental study on performance of SF6+N2 mixed gas insulation. In: 2016 international conference on mechatronics, manufacturing and materials engineering (MMME 2016),63,03017

Dmitry L, Laxminarayan LR (2023) Computational analysis of electrical breakdown of SF6/N2 mixtures. J Appl Phy133:053301

Guo Z, Liu S, Pu Y et al (2019) Study of the arc interruption performance of CO2 gas in high-voltage circuit breaker. IEEE Transact Plasma Sci 47(5):2742–2751

Jiang X, Li X, Zhao H et al (2013) Analysis of the dielectric breakdown characteristics for a 252-kV gas circuit breaker. IEEE Transact Pow Deliv 28(3):1592–1599

Zhao H, Li X, Jia S et al (2013) Dielectric breakdown properties of SF6–N2 mixtures at 0.01–1.6 MPa and 300–3000 K. J Appl Phys 113:143301

Acknowledgements

This work was supported by the Science and Technology Program of Guizhou Power Grid Co. Ltd. (GZKJXM20220057).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 Beijing Paike Culture Commu. Co., Ltd.

About this paper

Cite this paper

Yang, W., Wang, Z., Wang, D., Chen, Q., Zhao, S., Zhuo, R. (2024). Arc Interruption Performance of SF6/N2 Gas and Dielectric Recovery in Disconnector. In: Dong, X., Cai, L. (eds) The Proceedings of 2023 4th International Symposium on Insulation and Discharge Computation for Power Equipment (IDCOMPU2023). IDCOMPU 2023. Lecture Notes in Electrical Engineering, vol 1102. Springer, Singapore. https://doi.org/10.1007/978-981-99-7405-4_17

Download citation

DOI: https://doi.org/10.1007/978-981-99-7405-4_17

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-7404-7

Online ISBN: 978-981-99-7405-4

eBook Packages: EnergyEnergy (R0)