Abstract

Power utilities worldwide face capacity expansion challenges due to costs, land availability, and environmental sustainability. Increased demand and the need to build a reliable and resilient network have compelled power utilities to organize competitively distributed generators to compensate for any supply surge. These distributed power generation units are small and dispersed, making control difficult. To find a solution that is both economical and sustainable, a virtual power plant is formed from diesel generators with a capacity of 5.6 MW, a waste-to-energy (WtE) power generating plant with a capacity of 1 MW, a wind power plant with a capacity of 0.6 MW, and a photovoltaic (PV) power plants with a capacity of 0.4 MW. The distributed generators were optimally integrated into a virtual power plant and for the best integration solution, a Deming wheel, also known as the plan, do, check, and act (PDCA) method and mixed integer linear programming (MILP) were used in an Excel solver. The simulation results show that the total VPP power generated from the sources is 6.33 MW, with renewable energy sources accounting for 1.6 MW (25% of the total) and a cost estimate of 0.5$/kW. Diesel and wind contribute the least in comparison with their capacities, while others contribute the most (100% of the capacities).

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Virtual power plant

- Mixed integer linear programming

- Waste to energy

- Distributed generator

- Renewable energy

1 Introduction

With the current decentralization, deregulation, and environmental concerns in the electrical power sector, there has been a massive integration of diverse sources of electrical power into the system, making management difficult. Because they must be close to the source, most of these resources have limited capacity and are dispersed. Power system operators are investigating various options for integrating such resources, and virtual power plants (VPP) can play a significant role in integrating these dispersed low-capacity power plants into a single entity that is both secure and market competitive. This commitment should allow small players to enter the power sector [1]. However, VPPs may be required to operate at lower load factors, posing the risks of high per kWh GHG emissions and high cost per unit production, resulting in low competitiveness [2] and sector coordination. It will become even more critical in the coming years, as more renewable energies (RE) are expected to be added to the electricity grid between now and 2050 [3].

Like all other power systems, a virtual power plant schedules generators and loads in a way that allows the system operator to achieve cheap and reliable operation while maintaining competitiveness and cost. However, this is frequently challenged due to their lack of competitive capacity, remoteness, and sporadic nature [4]. More can be accomplished in a VPP by optimizing the integration of various distributed energy resources. Several researchers have conducted studies on the optimal integration of distributed energy resources in a VPP, as shown in [5,6,7,8]. VPP has been classified into two broad categories, as described in [9, 10]: commercial and technical virtual power plants (CVPP and TVPP), each with its own application and scope. Examples of these applications include reserve power, price stabilization, and so on. Zhang et al. [11] investigated optimization of VPPs, whereas [12] investigated dynamic integration and performance of dispersed resources in a VPP using both linear and nonlinear programming.

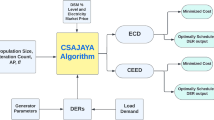

The goal of this research is to integrate distributed resources into a VPP and investigate the performance of a VPP plant to ensure adequate resource allocation to maximize capacity output while keeping costs low. The PCDA method and a mixed integer linear program (MILP) method are used in this study to optimize distributed sources. Figure 1 depicts the basic VPP configuration for the studies.

Figure 1 depicts the distributed resources, which include PV, diesel power generators, a waste-to-energy power plant, and a wind power plant. The management and resource allocation center coordinate these resources, and the power generated is fed to the various load units, as shown in Fig. 1.

To optimally integrate the distributed resources, this study employs the PDCA (Demming wheel) method Fig. 2 and a mixed integer linear program (MILP) solution. PDCA allows for significant “improvements” in performance (“breakthroughs”) [13]. While MILP is a mathematical model used to reduce risks (e.g., cost, energy loss, errors, etc.) or maximize opportunities (e.g., profit, quality, efficiency, etc.), it is subject to some constraints [14]. The study’s findings are expected to be used by policymakers to encourage more participation from distributed energy resources in the power sector in a profitable and sustainable manner, reflecting the anticipated contributions from VPP plants to a sustainable energy system.

2 Proposed Method

2.1 Topology of the VPP

The VPP under consideration is a collection of distributed diesel generators (dg) and renewable energy sources (RES) units (PV and wind). WtE stands for waste-to-energy electrical generator. The goal is to create a VPP portfolio that can manage the technical capability of its distributed energy resources at the lowest possible cost. Other generalized assumptions made in the formulation of the VPP for this study include the fact that all structural capabilities of active, passive, and storage resources in terms of size and location were determined during the VPP planning stage and cannot be changed in the short term, keeping in mind that decisions made during the planning stage considered all environmental and efficiency principles in terms of energy sources and conversion technologies, particularly when using fossil fuels.

2.2 Load Profile and Distribution

Figure 3 depicts the load profile. According to the data, demand ranges from a high of 16 MW between 18:00 and 21:00 h and a low of 4 MW between 01:00 and 06:00 h and 14:00 to 17:00 h.

2.3 PDCA Implementation Framework

Figure 4 depicts the detailed framework used in the study’s implementation. The PDCA cycle is a never-ending cycle of planning, doing, checking, and acting. The framework in Fig. 4 has been broken down into smaller steps or development stages of the activities, and ways to improve each one has been explored.

2.4 Distributed Resources

As previously stated, the distributed resources considered for the VPP fall into two categories: (1) fossil fuel-based (diesel generators) and (2) renewable energy resources (PV, wind, and WtE). Figure 5 depicts the daily generator availability. The yellow shaded area represents low sunshine for a PV generator, amber represents low wind speed, light red indicates an emergency shutdown, dark red indicates a generator is on reliability maintenance, and blue indicates a generator is scheduled for planned maintenance.

2.5 Equations

Each unit is expected to be either available or unavailable (u = 1 or 0). The generated power (Pi) is between the minimum and maximum capacities. Although fossil fuel generators have a higher capacity, renewable energy is expected to contribute significantly due to low GHG emissions. The main goal is to have a power supply mix with a variety of capacities and characteristics that can contribute to demand at a low cost and in a sustainable manner. The mix should be in a proportion that strikes a balance between RE and fossil-based generation, allowing GHG emissions to be kept to a minimum. The goal is to maximize output while keeping supply mix costs as low as possible.

-

(a)

Objective Function and Variables

The objective function is made of two power components. The first power component is determined by the availability of the plant based on Fig. 5, i.e., if a unit is in operation or not at the time of the decision. The second power component is the contribution of renewable generators. They are also dependent on the amount of power generated at that period, greatly impacted by weather conditions as in Fig. 5. The objective function is formulated as in Eq. (1).

The optimization problem is presented in (1) and it is expected to maximize the total power from all generating plants. Unlike renewables and WtE, the total power expected is given in Eq. (2). Power generation for all other sources is at maximum when it is available except for diesel generators whose generation is usually between the maximum and minimum capacity as shown in (3). Constraints associated with the solution are given in Eqs. (4–6).

where

- Pdg:

-

diesel power (kW)

- Preg:

-

renewable power (kW)

- PWtE:

-

WtE power (kW)

- U(t):

-

availability index (1 or 0).

-

(b)

Constraints

The optimization is subject to the following constraints.

where

- \(P_{\max }^{{{\text{dg}}}}\):

-

Maximum diesel power (kW)

- \(P_{\min }^{{{\text{dg}}}}\):

-

Minimum diesel power (kW)

where

- Ppv:

-

PV power (kW)

- Pwind:

-

Wind power (kW).

3 Results and Discussion

Results from the simulation are presented in tables. In the simulation, total power generation, VPP contribution, and renewable penetration are presented based on the constraints given. After modeling and simulation, Table 1 gives the optimal power contribution from VPP and the contribution from respective generation modes.

Table 2 gives the power distribution, renewable energy penetration, and cost. It is shown that wind and diesel contribution has been capped because of the cost constraint, while other sources were maximized. The wind has about 75% of its rated capacity as slack and diesel has about 21% as slack.

In Table 3, sensitivity analysis of the simulation showed that while some generation sources have room to adjust costs and still have an optimal condition, other sources have absolutely no room for that. The reduced costs tell us how much the objective can be increased or decreased before the optimal solution changes.

Table 4 gives the sensitivity analysis of constraints on this table, the shadow price is an important function to reckon with. The shadow prices tell us how much the optimal solution can be increased or decreased by changing the value of the constraints with one unit.

3.1 Optimal Power Solution

According to the simulation results in Tables 1 and 2, the VPP’s ideal power is 6.33 MW, with a 1.6 MW RE penetration. Due to its size, the diesel contribution is more than predicted, but not all of its capacity is used. Table 2 gives that 1.23 MW, or about 20% of the overall capacity for diesel generators, as well as roughly 75% of the wind capacity, are underutilized. The best power is obtained by completely utilizing other sources. This scenario can be linked to the need to keep costs at a specific level and the higher cost of power from the two sources.

3.2 Sensitivity Analysis

It is optimal to have 0.4 MW of PV generation, 0.2 MW of wind generation, 1 MW of WtE generation, and 4.73 MW of diesel generation. This solution gives the maximum VPP generation of 6.33 MW (see Table 1). This solution uses all the resources available for PV and wind at 100% (0.4 MW of capacity and 1 MW of capacity) and 33% of wind (capacity and 78% of diesel capacity).

-

Reduced Cost: Table 3 gives how much the objective coefficients can be increased or decreased before the optimal solution changes. Only wind generator units can be increased by (0.22) based on the results, while other sources can only be decreased before the optimal value changes. As a result, if there is a need to increase any output while still maintaining the optimal solution, it may be possible to do so solely through wind generation capacity.

-

Shadow Price: The shadow prices indicate how much the optimal solution can be increased or decreased if the constraint values (RE contribution and cost) are changed by one unit. According to Table 4, the shadow price is only valid between “22.2 – 0.42 and 22.2 + 0.11,” and anything outside of this range will cause the optimal solution to change.

4 Conclusion

This research has investigated the optimal integration of distributed resources into a VPP plant successfully. The Deming wheel (PDCA) method was used in model formulation, and the optimization was solved using mixed integer linear programming (MILP). It is demonstrated that optimal integration is possible by optimizing power and constraining cost at a specific value. The two elements that were constrained in the solution were RE penetration and contribution. The optimal solution generates 6.33 MW of power from the VPP, with a RE contribution of 1.6 MW and a cost of 0.5 $/kW. Diesel and wind were found to contribute less to total VPP power, with wind contributing only 33% and diesel contributing 78%.

References

Akasiadis C, Chalkiadakis G (2016) Decentralized large-scale electricity consumption shifting by prosumer cooperatives. In: ECAI. August 2016, pp 175–183

Vale Z, Pinto T, Morais H, Praça I, Faria P (2011) VPP’s multi-level negotiation in smart grids and competitive electricity markets. In: 2011 IEEE power and energy society general meeting. IEEE. July 2011, pp 1–8

Elwan AA, Habibuddin MH (2021) Techno-economic analysis of a grid-connected waste to energy gasification plant: a case study. Energy Eng 118(6):1681–1701

Yang Q, Wang H, Wang T, Zhang S, Wu X, Wang H (2021) Blockchain-based decentralized energy management platform for residential distributed energy resources in a virtual power plant. Appl Energy 294:117026

Abujarad SY, Mustafa MW, Jamian JJ (2017) Recent approaches of unit commitment in the presence of intermittent renewable energy resources: a review. Renew Sustain Energy Rev 70:215–223

Emovon I (2020) A fuzzy multi-criteria decision-making approach for power generation problem analysis. J Eng Sci 7(2):E26-31

Kanagasabai L (2021) Heat transfer and simulated coronary circulation system optimization algorithms for real power loss reduction. J Eng Sci 8(1):E1–E8

Sikorski T, Jasiński M, Ropuszyńska-Surma E, Węglarz M, Kaczorowska D, Kostyła P, Leonowicz Z, Lis R, Rezmer J, Rojewski W, Sobierajski M (2019) A case study on distributed energy resources and energy-storage systems in a virtual power plant concept: economic aspects. Energies 12(23):4447

Wang X, Liu Z, Zhang H, Zhao Y, Shi J, Ding H (2019) A review on virtual power plant concept, application and challenges. In: 2019 IEEE innovative smart grid technologies-Asia (ISGT Asia). May 2019, pp 4328–4333

Teixeira R, Cerveira A, Baptista J (2021) Optimized management of renewable energy sources in smart grids in a VPP context. In: 2021 international conference on electrical, computer and energy technologies (ICECET). IEEE. December 2021, pp 1–6

Zhang G, Jiang C, Wang X (2019) Comprehensive review on structure and operation of virtual power plant in electrical system. IET Gener Transm Distrib 13(2):145–156

Othman MM, Hegazy YG, Abdelaziz AY (2015) A review of virtual power plant definitions, components, framework, and optimization. Int Electr Eng J 6(9):2010–2024

Schmidt H (2019) Explosive precursor safety: an application of the Deming cycle for continuous improvement. J Chem Health Saf 26(1):31–36

Alauddin N, Yamada S (2019) Overview of Deming criteria for total quality management conceptual framework design in education services. J Eng Sci Res 3(5):12–20

Acknowledgements

This work was supported/funded by the Ministry of Higher Education under Fundamental Research Grant (Grant FRGS/1/2018/TK07/UTM/02/6).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Elwan, A.A., Habibuddin, M.H., Arief, Y.Z., Sharan, S.N.A.M., Mokhtar, A.S.B., Idris, R.B.M. (2024). Optimization of Distributed Generators in a Virtual Power Plan Using Mixed Integer Linear Programming Method. In: Malik, H., Mishra, S., Sood, Y.R., Iqbal, A., Ustun, T.S. (eds) Renewable Power for Sustainable Growth. ICRP 2023. Lecture Notes in Electrical Engineering, vol 1086. Springer, Singapore. https://doi.org/10.1007/978-981-99-6749-0_22

Download citation

DOI: https://doi.org/10.1007/978-981-99-6749-0_22

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-6748-3

Online ISBN: 978-981-99-6749-0

eBook Packages: EnergyEnergy (R0)