Abstract

The use of metal coagulants in water treatment generates huge amounts of sludge. Effective management to mitigate the challenges associated with the increasing amount of WTS remains a significant concern. This paper provides an overview of the beneficial reuses of water treatment sludge (WTS) as coagulant and adsorbent. Recent advancements in coagulant and adsorbent synthesizing techniques are discussed. Recovered coagulant (RC) and adsorbent have been successfully removed several pollutants in both water and wastewater, reducing the need for new coagulant production and disposal of sludge. Coagulant and adsorbent from sludge have potential to be utilized in both water and wastewater treatment processes and, hence promoting sustainability. Sulfuric acid is commonly used to recover contaminated coagulant. Calcination, activation, or impregnation have been studied in adsorbent production. Recovered coagulant/adsorbent could be as effective as or even better than fresh coagulants/adsorbent.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The coagulation–flocculation process plays an extremely vital role in water and wastewater treatment due to its low capital cost and easy operation [5, 21]. The use of these chemicals can result in the generation of sludge as a byproduct, which contains contaminants such as organic matter, heavy metals, and pathogens. It is crucial to properly manage this sludge to prevent environmental issues and health risks to public community. However, disposal of water treatment sludge (WTS) in the environment has been restricted for several reasons, including reduction in access to landfill site, expensive disposal prices, high transportation costs, and regulatory constraints. These issues have led to the exploration of potential reused of the WTS in various application.

Several studies have investigated the effectiveness of WTS as a coagulant and adsorbent for various contaminants and under different treatment conditions. These studies have shown promising results, indicating that sludge can be an effective coagulant and adsorbent for a wide range of contaminants [11,12,12] and this paper aimed to expand the knowledge through latest publications.

2 WTS as Coagulant

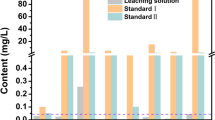

Acid recovery method widely used for coagulant recovery from WTS because of its high efficiency with superior quality [6]. Among different chemicals used, sulfuric acid showed better results from both practical and cost viewpoints [19]. This can be observed in Table 1 that most study using sulfuric acid for their recovery method. There were also other types of acid used such as nitric acid [3,4,4] and hydrochloric acid [10].

Water treatment sludge recovery using acidification methods reported to efficiently remove pollutants in wastewater. Mora-León et al. [10] compared the effectiveness of recovered polyaluminum chloride (PAC) coagulant using sulfuric and hydrochloric acid with that of commercial PAC and ferric coagulant. The authors found that the RC showed better turbidity removal of up to 96%, and at the optimal dose of RC, 89% total suspended solid (TSS), 62% total chemical oxygen demand (tCOD), 90% total phosphorus (tP), and 97% soluble phosphorus (sP) were removed from the wastewater. However, Chakraborty et al. [2] found that fresh coagulant outperformed recovered ferric-based coagulant, with RC showing a decrease in TSS, COD, and total nitrogen (tN) removal efficiency and a corresponding 10% increase in these pollutant’s concentration in the treated wastewater compared to fresh coagulant; might be due to lower ionic strength of RC.

In comparison, there are studies that directly use WTS to treat wastewater without any recovery method. Kang et al. [7] studied the use of aluminum-based WTS as a substitute for conventional chemicals in animal farm wastewater treatment and found that the removal of TSS, PO \(_{4}^{3 - }\), and total organic carbon (TOC) was 87.8%, 96.9%, and 62.1%, respectively. Khedher et al. [8] studied the use of WTS as a coagulant aid to improve the dissolve organic matter (DOC) in natural surface water. The researchers found that the addition of WTS at a concentration of 3 g/L can reduce the optimum dose of fresh alum sulfate required up to 50% to achieve similar removal efficiency of DOC (70%). They also found that the addition of WTS reduced the sludge produced by approximately 50% compared to when it was not.

Several studies have also utilized sludge from water treatment plants to treat raw water, employing an acidification method to recover the coagulant from the sludge before use. Hamzah et al. [4] investigated the percentage recovery of aluminum-based coagulant by nitric acid and its performance in removing turbidity from raw water. The study found that at the optimal dosage, the RC can remove the raw water turbidity up to 99.47%, which is better or comparable to the fresh coagulant. Dahasahastra et al. [3] performed the same recovery method and showed that RC has potential for use as a substitute for commercial alum in water treatment. The finding was that 1 mL/L of RC has a similar removal of turbidity efficiency (74%) to 0.6 mL/L of 1% (w/v) commercial alum solution. The same result was found by Ruziqna et al. [14], where slightly higher doses of RC were required to achieve the quality of pure coagulant in removing turbidity in raw water. They found that 25 ppm of recovered coagulant achieved similar reduction of turbidity of pure alum at 93.26%.

3 WTS as Adsorbent

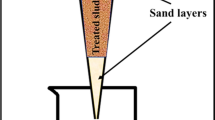

Although activated carbon is a popular adsorbent for water and wastewater treatment, it can be expensive due to operation and regeneration costs, as reported by Azreen and Zahrim [1]. Thus, many studies have explored the use of adsorbents synthesized from waste materials like WTS as an effective and affordable solution. Among the various synthesis methods available, physicochemical methods have emerged as the most commonly used approach due to their effectiveness and ease of synthesis; needing only heat treatment. Methods such as calcination, activation, or impregnation have been studied to modify the properties of the WTS and create adsorbents with high adsorption capacity. Studies by Shahin et al. [16] and Truong and Kim [18] have demonstrated the high recovery efficiency and good quality of adsorbents synthesized using calcination and pyrolysis. Other synthesizing method also include chemical and physicochemical activation such as impregnation of AlCl3 + Starch and calcination + H3PO4/KOH, respectively [9, 20]. These adsorbents have been found to effectively remove heavy metals, dyes, and organic pollutants from wastewater.

WTS has shown great potential as an effective and low-cost adsorbent for various pollutants. Table 2 summarizes some recent studies on the use of WTS as an adsorbent for contaminants in various solutions. The type of pollutant influences the adsorption capacity and removal performance of the adsorbent. Shahin et al. [16] used calcined powder adsorbent synthesized through physical aerobic calcination to remove copper. They obtained a high adsorption capacity of 35 mg/g and a removal performance of 90%. Separate studies found that phosphate achieve removal performance of 86–99% [18, 20], and endocrine disruptors achieving almost 100% [19].

It is worth noting that the adsorption capacity and removal performance of WTS as an adsorbent are generally comparable to or even higher than those of other commercial adsorbents. Zeng et al. [22] compared the adsorption capacity of granular adsorbent synthesized through physical methods with chitosan solution to that of commercial activated carbon and raw sludge for arsenic removal. They found that their adsorbent is able to remove As (V) at 14.95 mg/g adsorption capacity and solves the concern on the application in fixed beds system and the recovery and reuse of adsorbents resulting in lower operation cost. Similarly, Siswoyo et al. [17] compared the adsorption capacity of alum sludge to that of commercial activated carbon for heavy metal removal. They found that the adsorption capacity of alum sludge was comparable to that of commercial activated carbon.

The use of WTS as adsorbents for heavy metal removal has gained increasing attention due to their cost-effectiveness, eco-friendliness, and mainly high removal rate. Studies have shown that the effectiveness of WTS as an adsorbent for heavy metal at optimized condition where a study conducted by Siswoyo et al. [17] showed that WTS can achieve a removal rate of up to 95% for Cd. Furthermore, the removal performance of WTS for copper (Cu) and arsenic (As) achieved 90% and 85%, respectively [17, 22].

WTS as adsorbent has the potential to be utilized in water and wastewater treatment process in removal of pollutants. Further studies on hybridization of adsorbent should also be carried out. For instance, a study by Safie and Zahrim [15], where they studied on the combination of adsorbents to produce higher adsorption capacity which includes zeolites, chitosan, and biochar, and in line with this study, WTS-based adsorbent can be hybridized to achieve higher adsorption capacity.

4 Conclusion

The use of RC and sludge adsorbent shows the potential to provide a cost-effective and sustainable solution for water treatment. The acid sulfuric recovery process is widely used due to its high recovery efficiency and good quality. Most studies show that recovered coagulant is as effective as or even better than commercial coagulants, but at a higher dose. The recovered coagulants have been applied in removing pollutants in water treatment, especially in treating wastewater, where it efficiently removes contaminants such as turbidity, TSS, tP, and sP up to 90%. Physical methods have emerged as the most commonly used approach to synthesize adsorbents with high adsorption capacity. Most studies also show that the removal pollutant in wastewater using WTS adsorbent up to more than 90%. Further research should explore the economic potential of these materials in reducing the total operational cost of water and wastewater treatment processes. Multiple-objective optimization on the basis of ratio analysis could be employed to discretely measure multiple response characteristics of various coagulant and adsorbent as a function of assessment value.

References

Azreen I, Zahrim, AY (2018) Overview of biologically digested leachate treatment using adsorption. Green Energy Technol 123–148

Chakraborty T, Balusani D, Smith S, Santoro D, Walton J, Nakhla G et al (2020) Reusability of recovered iron coagulant from primary municipal sludge and its impact on chemically enhanced primary treatment. Sep Purif Technol 231:115894

Dahasahastra AV, Balasundaram K, Latkar MV (2022) Turbidity removal from synthetic turbid water using coagulant recovered from water treatment sludge: a potential method to recycle and conserve aluminium. Hydrometallurgy 213:105939

Hamzah N, Roshisham MAF, Zakaria MF, Basri MHH, Akbar NA (2022) Performance of recovered coagulant from water treatment sludge by acidification process. Environ Ecol Res 10(1):21–30

Ibrahim A, Yaser AZ, Lamaming J (2021) Synthesising tannin–based coagulants for water and wastewater application: a review. J Environ Chem Eng 9:105007

Jung KW, Hwang MJ, Park DS, Ahn KH (2016) Comprehensive reuse of drinking water treatment residuals in coagulation and adsorption processes. J Environ Manage 181:425–434

Kang C, Zhao Y, Tang C, Addo-Bankas O (2022) Use of aluminum–based water treatment sludge as coagulant for animal farm wastewater treatment. J Water Process Eng 46:102645

Khedher M, Awad J, Donner E, Drigo B, Fabris R, Harris M et al (2022) The potential reuse of drinking water treatment sludge for organics removal and disinfection by–products formation control. J Environ Chem Eng 10:108001

Martins DS, Estevam BR, Perez ID, Américo-Pinheiro JHP, Isique WD, Boina RF (2022) Sludge from a water treatment plant as an adsorbent of endocrine disruptors. J Environ Chem Eng 10(4):108090

Mora-León AG, Castro-Jiménez CC, Saldarriaga-Molina JC, García AEF, Correa-Ochoa MA (2022) Aluminium recovered coagulant from water treatment sludge as an alternative for improving the primary treatment of domestic wastewater. J Clean Prod 346:131229

Nayeri D, Mousavi SA (2022) A comprehensive review on the coagulant recovery and reuse from drinking water treatment sludge. J Environ Manag 319:115649

Nguyen MD, Thomas M, Surapaneni A, Moon EM, Milne NA (2022) Beneficial reuse of water treatment sludge in the context of circular economy. Environ Technol Innov 28:102651

Quang HHP, Phan KT, Dinh NT, Thi TNT, Kajitvichyanukul P, Raizada P et al. (2022) Using ZrO2 coated sludge from drinking water treatment plant as a novel adsorbent for nitrate removal from contaminated water. Environ Res 212:113410

Ruziqna DP, Suwartha N, Moersidik SS, Adityosulindro S (2020) Aluminium recovery from water treatment sludge as coagulant by acidification. IOP Conf Ser Earth Environ Sci 448:012045

Safie NN, Zahrim AY (2021) Recovery of nutrients from sewage using zeolite-chitosan-biochar adsorbent: Current practices and perspectives. J Water Process Eng 40:101845

Shahin SA, Mossad M, Fouad M (2019) Evaluation of copper removal efficiency using water treatment sludge. Water Sci Eng 12(1):37–44

Siswoyo E, Qoniah I, Lestari P, Fajri JA, Sani RA, Sari DG et al (2019) Development of a floating adsorbent for cadmium derived from modified drinking water treatment plant sludge. Environ Technol Innov 14:100312

Truong VT, Kim DJ (2021) Phosphate removal using thermally regenerated Al adsorbent from drinking water treatment sludge. Environ Res 196:110877

Vaezi F, Batebi F (2021) Recovery of iron coagulants from Tehran water–treatment–plant sludge for reusing in textile wastewater treatment. Iranian J Public Health 30(4):135–138

Wu HF, Wang JP, Duan EG, Hu WH, Dong YB, Zhang GQ (2020) Phosphorus removal by adsorbent based on poly-aluminum chloride sludge. Water Sci Eng 13(3):193–201

Zahrim AY (2018) Current progress on removal of recalcitrance coloured particles from anaerobically treated effluent using coagulation–flocculation. Green Energy Technol 149–163

Zeng H, Yu Y, Wang F, Zhang J, Li D (2020) Arsenic removal by granular adsorbents made from water treatment residuals materials and chitosan. Colloids Surf A Physicochem Eng Asp 585:124036

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Yaser, A.Z., Haqim, A.I., Mijong, J.R. (2024). Water Treatment Sludge as Coagulant and Adsorbent: A Recent Review. In: Zhang, Y. (eds) Proceedings of the 5th International Symposium on Water Pollution and Treatment—ISWPT 2022, Bangkok, Thailand. ISWPT 2022. Lecture Notes in Civil Engineering, vol 366. Springer, Singapore. https://doi.org/10.1007/978-981-99-3737-0_1

Download citation

DOI: https://doi.org/10.1007/978-981-99-3737-0_1

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-3736-3

Online ISBN: 978-981-99-3737-0

eBook Packages: EngineeringEngineering (R0)