Abstract

In case of smoke occurrence in the cockpit on civil aircraft, whether the cockpit can readily evacuate smoke directly influence safety of the pilots and passengers. The airworthiness regulation CCAR25.831 (d) puts forward requirements for cockpit smoke evacuation. However, the provision does not provide explicit indexes or instructions and cannot be directly used for aircraft design or validation. This paper mainly investigates CCAR25.831 (d) and related advisory circular, based on which the validation method is proposed in detail and put into practice. Through theoretical research and flight test, it provides ideas and methods for design and airworthiness validation for cockpit smoke evacuation on civil aircraft.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

During flight of civil aircraft, smoke may appear in cockpit or cabin in case of fire, explosion and system failure, etc. Smoke in cockpit or cabin will influence respiration of the crew and passengers, affect eye-sight of the pilots and weaken their ability to operate in emergency cases, endangering safety of the aircraft and passengers. Therefore, cockpit smoke evacuation capability is very important and it is one of the main concerns in airworthiness regulations. The civil aviation authorities such as FAA, EASA and CAAC are paying high attention to the smoke handling capacity of civil aircraft, and the major aircraft manufacturers also take smoke evacuation and smoke protection capacity as an important indicator for design of civil aircraft.

In airworthiness provisions, there is 25.831(d), 25.795(b)(1), 25.795(b)(2) regulations for smoke evacuation and protection of cabin and cockpit. This paper mainly focuses on 25.831 (d) [1], which is a requirement for ventilation system. A well-designed ventilation system can guarantee cockpit smoke evacuation capacity. We investigate into main terms in 25.831(d) and its related advisory notices, analyzes the precautions and provides compliance ideas and validation methods for 25.831(d).

2 CCAR25.831(d) Regulation

CCAR25.831(d) is quoted as follows: If accumulation of hazardous quantities of smoke in the cockpit area is reasonably probable, smoke evacuation must be readily accomplished, starting with full pressurization and without depressurizing beyond safe limits.

3 25.831(d) Regulation Interpretation

We can see from 25.831(d) that there are no specific indexes in the regulation, which brings uncertainty to aircraft design and validation. We need to investigate into the key terms first.

-

1)

‘Reasonably possible’. In aircraft safety assessment, function failure cases are divided into five categories based on severity of consequences: catastrophic, hazardous, major, minor and no safety effect. For each category, there is a probability defined for the failure event. The more severe the consequence is, the less probable it is allowed to happen. For smoke evacuation regulation 25.831(d), reasonably possible means we only consider smoke evacuation in the cases with a probability greater than10–5 [2]. Therefore, during smoke evacuation, the ventilation system, the anti-fire system and other systems all functions normally. We do not consider combined failure cases which happen at a probability much less than 10–5.

-

2)

‘Hazardous quantities of smoke’. In the test, we use smoke generator to simulate smoke in the cockpit. According to advisory notice AC25-9A [3] chapter 12 e (2): ‘When the cockpit instruments are obscured (dial/panel indicator numbers or letters become indiscernible), smoke generation should be terminated, and the appropriate AFM and operations manual (if applicable) fire and smoke procedures should be initiated.’ However, if the applicant wants to demonstrate protection for a continuous source in the cockpit, the smoke should be generated continuously. It’s not mandatory.

-

3)

‘Starting with full pressurization’. According to the provisions of AC25-9A chapter 8.b:

Section 25.831 allows the use of depressurization within safety limits to evacuate smoke from the cockpit and passenger compartment. Aircraft manufacturers have developed smoke evacuation procedure and tested that. Those techniques have been found to be effective for the specific airplane models that utilize them.

Reducing cabin pressure can speed up smoke evacuation. Therefore, ‘full pressurization’ defines the initial status of cabin pressure before smoke evacuation starts and should be understood as ‘starting from maximum pressurization’.

-

4)

‘Without depressurizing beyond safe limits’. This restriction includes two aspects: cabin pressure altitude and cabin pressure change rate.

Cabin pressure altitude is mainly based on the constraints of human physiological endurance, aircraft structure and mass. According to CCAR25.841a, “Pressurized cabin and compartments to be occupied must be equipped to provide a cabin pressure altitude of not more than 2,400 m (8000 ft) at the maximum operating altitude of the airplane under normal operating conditions. (1) If certification for operating above 7600 m (25000 ft) is requested, the airplane must be designed so that occupants will not be exposed to cabin pressure altitude in excess of 15000 ft after any probable failure in the pressurization system.”

In addition, the rate of pressure change needs to be considered to prevent negative impact on the eardrum. Normally, the rate of pressure change is related to flying height, the rate of aircraft ascending or descending, which is specified in pressurization system design specification.

-

5)

‘Smoke evacuation must be readily accomplished’. According to AC25-9A chapter 12 a (1): Cockpit smoke evacuation test verify that smoke from sources within or contiguous with the cockpit, can be readily evacuated as required by 25.831(d). Typical commercial large transport airplanes are capable of evacuating dense cockpit smoke within approximately 90 s after the AFM fire and smoke emergency procedures are initiated. Three minutes is an acceptable maximum time to evacuate smoke from any transport category airplane cockpit.

Based on this, we define three minutes as the maximum acceptable time for cockpit smoke evacuation. The faster the smoke evacuation is, the better the pilot can recover from ability degradation, and the less the impact will be caused on flight safety.

4 Validation for CCAR25.831(d)

For validation of CCAR25.831(d), we conduct ground test and flight test to show cockpit smoke evacuation capacity on the ground and in the air. Smoke in flight has a greater impact on aircraft safety and it is more difficult to carry out, therefore this paper mainly focuses on flight test.

The objective of in-flight smoke evacuation test is to demonstrate that the AFM emergency fire and smoke procedures provide means to clear the cockpit of dense smoke at an acceptable rate. This test should also demonstrate that the flight crew can use the procedures without introducing any additional hazard. Refer to Table 1 for the test cases.

The flight test procedure for cockpit smoke evacuation is as follows:

-

a)

Adjust the flying height, air bleed mode and air conditioning system settings according to Table 1, turn on all lights in the cockpit (non-emergency lights), turn off cargo ventilation.

-

b)

Crew on board shall wear protective breathing apparatus (or oxygen mask) as required, and confirm that the interphone communication functions normally.

-

c)

Turn on the smoke generator. Stop generating smoke when the cockpit instrument becomes obscure. Meanwhile the aircraft starts to descend from the initial altitude at normal descent rate. Record the time when the smoke generator shuts down and smoke removal completes (the standard for smoke evacuation completion is that remained smoke will not affect crew operation).

-

d)

Emergency pressure relief can be conducted as required during the test. If emergency pressure relief is carried out, related status message and alarms will appear in the cockpit, which can be ignored. This information should be transferred to the pilots before the test to avoid any confusion.

In addition, the aircraft should get out of cabin depressurization mode before it reaches the value when emergency oxygen module will automatically drop down due to low cabin pressure.

-

e)

Level off the airplane when smoke evacuation test finishes as required.

Here are more explanations for the test procedures.

According to AC25-9A chapter 12 section e, when the cockpit instruments are obscured (dial/panel indicator numbers or letters become indiscernible), smoke generation should be terminated, and the appropriate AFM and operations manual (if applicable) fire and smoke procedures should be initiated.

In the test, we follow above instructions. There were two pilots in the cockpit and both of them judge whether the instruments become obscured. When the pilots indicate the instruments are clear again, the test stops. It’s a common practice and highly reliable. Therefore, the pilots’ subjective judgements are the criteria for the test to start and stop.

When the test starts, smoke begins to accumulate with smoke generators on. When the pilot indicates panels are obscured, smoke generation stops. During the whole process, the air conditioning system functions normally and therefore smoke will be extracted outboard through ventilation system. However, if the applicant wants to demonstrate protection for a continuous source in the cockpit, the smoke should be generated continuously. It’s not mandatory.

5 Test Configuration and Devices

In smoke evacuation test, the smoke is generated by a smoke generator. In AC25-9A chapter 9 section b [3], it provides acceptable smoke generator types for smoke evacuation test.

Before the cockpit smoke evacuation test, the cockpit is equipped with test devices.

-

a)

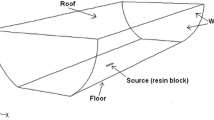

A smoke generator is installed in the cockpit, as shown in Fig. 1;

-

b)

A total of three portable cameras are prepared in the cockpit: one is fixed on the right rear panel of the cockpit to take an overall view of the cockpit, the second one behind the observer seat, and the third one is hand-held by the crew.

The test equipment is shown in Table 2.

-

c)

We use stopwatch to keep record of time.

6 Test Results and Analysis

In 2022, flight test for cockpit smoke evacuation was carried out at the height of 39000 ft and 31000 ft.

a) 39000 ft

At 12:15, the aircraft maintained a level flight at 39000 ft. The aircraft configuration was set in accordance with test condition 1 in Table 1.

At 12:15:32, the crew gave instructions and smoke generator was turned on. The overall view of the cockpit right before smoke generation is shown in Fig. 2.

20 s later (at 12:15:52), the smoke filled in the cockpit and smoke generation was stopped (Fig. 3).

28 s later (at 12:16:20), both pilots reported that they could see the instrument panel clearly without affecting the flight operation (Fig. 4).

The cockpit smoke evacuation took 28 s, satisfying the test criteria of 3 min.

During smoke evacuation, cabin altitude and fly altitude status are shown in Fig. 5 Status of engine bleed, packs, trim air, cargo ventilation, pressure control mode are shown in Figs. 6, 7, 8 and 9. As we can see, during smoke evacuation, both engine bleed were on, L &R packs on, cargo ventilation off, trim air automatically on, cabin pressure manual mode off (means automatic mode on) and emergency pressure relief uninitiated.

b) 31000 ft

The test procedure at the height of 31000 ft is basically the same as 39000 ft. The only difference is that we use only one pack for ventilation.

At 12:28, the aircraft maintained a level flight at 31000 ft. The aircraft configuration was set in accordance with test condition 2 in Table 1. The right pack was closed at 12:27:40.

At 12:28:23, the crew gave instructions and smoke generator was turned on (Fig. 10).

27 s later (at 12:28:50), the smoke filled in the cockpit and smoke generation was stopped (Fig. 11).

34 s later (at 12:29:24), both pilots reported that they could see the instrument panel clearly without affecting the flight operation (Fig. 12).

In this test condition, the cockpit smoke evacuation took 34 s, satisfying the test criterion of 3 min. Figures 13, 14, 15, 16 and 17 show status of the main systems during the test.

7 Conclusion

This paper mainly focuses on CCAR 25.831 (d) and related advisory circular, investigating into the main terms of probability of smoke occurrence, amount of hazardous smoke, safety cabin pressure limits and acceptable smoke evacuation time limit.

Based on above analysis, the validation method of flight test is proposed and put into practice. Through theoretical research and flight test, it provides ideas and methods for design and airworthiness validation for cockpit smoke evacuation on civil aircraft.

References

CCAR-25-R3 China Civil Aircraft Regulation 25 Rev.3

AC25.1309 System Design and Analysis

AC25–9A, SMOKE DETECTION, PENETRATION, EVACUATION TESTS AND RELATED FLIGHT MANUAL EMERGENCY PROCEDURE

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Wu, D., Yang, Z., Yan, X., Shi, Z. (2024). Investigation into Provisions and Validation for Cockpit Smoke Evacuation on Civil Aircraft. In: Jing, Z., Zhan, X. (eds) Proceedings of the International Conference on Aerospace System Science and Engineering 2023. ICASSE 2023. Lecture Notes in Electrical Engineering, vol 1153. Springer, Singapore. https://doi.org/10.1007/978-981-97-0550-4_1

Download citation

DOI: https://doi.org/10.1007/978-981-97-0550-4_1

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-97-0549-8

Online ISBN: 978-981-97-0550-4

eBook Packages: EngineeringEngineering (R0)