Abstract

This work illustrates the effect of temperature on the performance of dual-metal double-gate Ge pocket TFET with hetero-dielectric. The study reveals that the performance of DM-DG-Ge pocket TFET improves with an increase in temperature. Both the DC and analog/RF parameters improve with increase in temperature, whereas ION/IOFF decreases with an increase in temperature due to higher increase in OFF current than ON current. The improvement in DC and analog/RF parameters makes the device suitable for operation at the higher temperatures.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

TFET has gained huge interest of researchers and industry due to its low-power circuit application, low off-state leakage current, low SS and thus fast switching [1,2,3,4,5,6,7,8]. The main agenda of TFET is to achieve low SS as 60 mV/decade is the thermionic transport limitation of MOSFET. The transport mechanism of TFET is completely different from MOSFET, and it works on band-to-band tunneling mechanism removing SS limitation. TFET is also immune to short-channel effects. The limitation of TFET is low ION and ambipolar current [9]. Researchers have found performance improvement with low band gap material, n+ pocket region, double gate, double metal gate, etc. [5, 10,11,12]. Further, with low k dielectric ambipolar current suppression can be achieved. Dual-metal double-gate Ge pocket TFET (DM-DG-Ge pocket TFET) with hetero-dielectric consists of the advantage of both dual-metal double-gate and hetero-dielectric. This work reports the investigation on performance of DM-DG-Ge pocket TFET at higher temperatures. The study has been done for a wide range of temperatures, viz 250–500 K.

In this work, DC and analog/RF performance parameter such as VTH, ION, ION/IOFF, SS, gm, Cgd, Cgg, fT, GBW, TGF and TFP analysis has been done with variation in temperature for DM-DG-Ge pocket TFET.

2 Device Structure and Simulation models

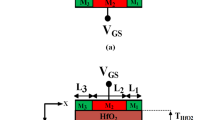

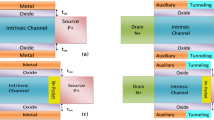

2D cross-sectional structure of DM-DG-Ge pocket TFET with hetero-dielectric is shown in Fig. 1. The source region is of Si0.5Ge0.5, the pocket region is of Ge, and the source and the channel regions are of silicon. With pocket width (Lpocket) 3 nm, tox as 1.2 nm, LG = 20 nm and body thickness (t) is 8 nm. The length of auxiliary gate (Lauxiliary) and tunneling gate (Ltunneling) is LG/2. The oxide material used is HfO2 under tunneling gate and SiO2 under auxiliary gate. Further, the doping in source region is Nsource = 1020 cm−3, in pocket region is Npocket = 4 × 1019 cm−3, in channel region is Nchannel = 1016 cm−3, and in drain region is Ndrain = 1020 cm−3. The work function of gate metal for tunneling gate is (\(\Phi \)tunn = 4.6 eV) and for auxiliary gate is (\(\Phi \)aux = 4.2 eV). Mo, Ta and W metals can be used for tunneling gate metal, and Ti–Ni and IrO2 can be used for auxiliary gate metal.

All simulation has been carried out on Atlas Silvaco device simulator [13]. Silvaco solves Poisson's equation with the current continuity equation self-consistently. Non-local band-to-band tunneling has been considered for precise modeling of tunneling. Kane model has also been considered with default value of material parameters. Band gap narrowing, Shockley–Read–Hall recombination and Fermi–Dirac model have also been considered for precise modeling of device. The body thickness of device is 8 nm; hence, quantum confinement effect has not been considered.

3 Result and Discussion

The property of semiconductor material depends on temperature. Thus, operating temperature indirectly influences the performance of device. The dependence of energy band gap on temperature is as depicted in the following equation:

where Eg(T) is the energy band gap at temperature T K. Eg(0) is the energy band gap at 0 K, and \(\alpha\) and \(\beta\) are fitting parameters of semiconductor material.

Equation 1 shows that the energy band decreases with increase in operating temperature. The carrier transport of device depends on band-to-band tunneling (BTBT) of electron from valence band of source region to conduction band of channel region. Thus, the drain current can be evaluated by Kane model, given by

Here, D, Akane and Bkane are constant parameters and Eg is energy band gap of material. So, drain current is indirectly dependent on temperature. With increase in temperature, energy band gap of semiconductor decreases, and with decrease in energy band gap, the drain current increases as depicted in Eq. (2).

3.1 DC Performance Analysis

With increase in temperature, the drain current increases. Both ION and IOFF increase, but the increase in ON current is less in comparison with the increase in OFF current. Thus, the ION/IOFF decreases with increase in temperature. VTH, gm and SS also improve with increase in temperature. The variation in device parameter with increase in temperature is shown in Table 1. With increase in temperature from 250 to 500 K, the decrease in VTH is 4%, increase in ION is 799.5%, increase in IOFF is ~107, and decrease in ION/IOFF is ~107. Further, the increase in transconductance (gm) is 552.7% and improvement in SS is 10.8%.

3.2 Analog/RF Performance Parameter Analysis

Further, the analog and RF parameter analysis with variation in temperature has been done. Figure 2a shows the ID − VG at VD = 0.5 V for DM-DG-Ge pocket TFET, and it shows the increase in drain current with VGS variation at different temperatures. The ambipolar current is fully suppressed for the DM-DG-Ge pocket TFET as shown in figure. The increase in ID − VG with increase in temperature from 250 to 500 K is 799.5%. Figure 2b shows the ID − VD at VG = 0.5 V for DM-DG-Ge pocket TFET. The figure shows increase in drain current with the drain voltage variation at higher temperatures. The analog analysis is done at 1 GHz frequency. The Cgd and Cgg are shown in Fig. 3a, b, respectively. Capacitance values are also increasing with increase in the temperature.

Further, Fig. 4a, b shows gm and gd with the variation in temperature, respectively. For analog applications of device in OPAMP, differential amplifier, etc., circuit designer needs device to have higher gm in order to get higher amplification (AV = gm/gd = gmRo). The gm of the device increases with increase in temperature and thus suitable for higher gain. Lesser gd value is needed for higher gain. However, gd increases with increase in temperature. This shows that Ro decreases with increase in temperature, giving rise to drain current. Figure 5a, b shows fT and GBW of device with variation in temperature, respectively. The circuit designer needs the device to work as amplifier for higher frequency. Cut-off frequency fT is the maximum frequency at which the gain of device becomes unity. After this frequency, the device could not work as amplifier. fT is defined as fT = gm/2πCgg. The fT of DM-DG-Ge pocket TFET increases with increase in temperature. The GBW is the operating frequency and voltage gain product. GBW is defined as GBW = gm/2π10Cgd. It is a constant value, for a DC voltage gain of 10; the GBW is shown in the figure. It increases with increase in temperature. Figure 6a, b shows TGF and TFP of DM-DG-Ge pocket TFET, respectively. It is defined as TGF = gm/ID = ln(10) /SS. SS value is being low in transition region from ON to OFF. The TGF value achieves its maximum and then again decreases. TFP describes power bandwidth trade-off.

and is important parameter for design of moderate to high-speed circuit. It is defined as TFP = (gm/ID) × fT = TGF × fT. TFP also increases with increase in temperature.

4 Conclusion

An exhaustive analysis of temperature sensitivity of DM-DG-Ge pocket TFET has been presented in this work. The study reports excellent improvement in DC parameter as well as analog/RF performance parameters with increase in temperature. The study shows improvement in gm, fT, GBW, TGF and TFP with operating temperature increase, thus making it suitable for application in higher temperature ranges.

References

Seabaugh AC, Zhang Q (2010) Low voltage tunnel transistors for beyond CMOS logic. Proc IEEE 98(12):2095–2110

Ionescu AM, Riel H (2011) Tunnel field-effect transistors as energy effcient electronic switches. Nature 479(7373):329–337

Ionescu AM, De Michielis L, Dagtekin N, Salvatore G, Cao J, Rusu A et al (2011) Ultra low power: emerging devices and their benefits for integrated circuits. IEDM Tech Dig: 1611–1614

Nigam K, Kondekar P, Sharma D (2016) DC characteristics and analog/RF performance of novel polarity control GaAs-Ge based tunnel field effect transistor. Superlattices Microstruct 92:224–231. ISSN 0749–6036

Boucart K, Ionescu AM (2007) Double gate tunnel FET with high-k gate dielectric. IEEE Trans Electron Devices 54(7):1725–1733

Kumar MJ, Janardhanan S (2013) Dopingless tunnel field effect transistor: design and investigation. IEEE Trans Electron Devices 60(10):3285–3290

Leung G, Chui CO (2013) Stochastic variability in silicon double-gate lateral tunnel field-effect transistors. IEEE Trans Electron Devices 60(1):89–91

Shrivastava V, Kumar A, Sahu C, Singh J (2016) Temperature sensitivity analysis of dopingless charge-plasma transistor. Solid-State Electron 117:94–99

Avci UE, Rios R, Kuhn KJ, Young IA (2011) Comparison of power and performance for the TFET and MOSFET and considerations for P-TFET. In: 11th IEEE international conference on nanotechnology, IEEE, pp 869–872

Saurabh S, Kumar MJ (2009) Impact of strain on drain current and threshold voltage of nanoscale double gate tunnel field effect transistor: Theoretical investigation and analysis. Jpn J Appl Phys 48(6R):064503

Krishnamohan T, Kim D, Raghunathan S, Saraswat K (2008) Double-Gate Strained-Ge Heterostructure Tunneling FET (TFET) with record high drive currents and << 60 mV/dec subthreshold slope. In: IEEE international electron devices meeting. IEEE, pp 1–3

Li W, Woo JC (2018) Optimization and scaling of Ge-pocket TFET. IEEE Trans Electron Devices 65(12):5289–5294

Atlas AUM (2015) Silvaco international. Santa Clara, CA

Acknowledgements

The authors are grateful to the National Institute of Technology, Raipur, India, for providing the computational resources.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Priyadarshani, K.N., Singh, S., Naugarhiya, A. (2021). Impact of Temperature on DC and Analog/RF Performance for DM-DG-Ge Pocket TFET. In: Goyal, V., Gupta, M., Trivedi, A., Kolhe, M.L. (eds) Proceedings of International Conference on Communication and Artificial Intelligence. Lecture Notes in Networks and Systems, vol 192. Springer, Singapore. https://doi.org/10.1007/978-981-33-6546-9_14

Download citation

DOI: https://doi.org/10.1007/978-981-33-6546-9_14

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-6545-2

Online ISBN: 978-981-33-6546-9

eBook Packages: EngineeringEngineering (R0)