Abstract

The study of sessile droplet evaporation has attracted widespread interest due to the plethora of industrial and every day applications ranging from inkjet printing, to DNA micro-array chips, to spray cooling.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

1 Introduction

The study of sessile droplet evaporation has attracted widespread interest due to the plethora of industrial and every day applications ranging from inkjet printing, to DNA micro-array chips, to spray cooling [1, 2]. To date, the bulk of this research has been constrained to single sessile droplet evaporation, which is rarely present in real applications. Hence, to fully reap the benefits of such research and thus optimise the above-mentioned applications, it is crucial to also study evaporation of multiple droplets in close proximity and the interplay between them.

Experimental observation of a pair of evaporating sessile droplets placed in the vicinity of each other has revealed interesting behaviours, such as asymmetric and suppressed evaporation and contact line deformation, in addition to buckling and arching of colloidal droplets [3, 4]. The presence of a neighbouring droplet alters the vapour field around the droplets, thereby disturbing the normal evaporation phenomenon [4]. Droplets placed in close proximity induce a saturation of the vapour field around the liquid–vapour interface, resulting in suppressed evaporation [4]. Moreover, in the case of organic solvent evaporation and/or liquid desiccants, the presence of relative humidity was found to have a strong impact on droplet evaporation or on the droplet growth due to absorption–adsorption and/or condensation onto the droplets [5]. Then, besides the non-uniform distribution of the organic solvent vapour evaporating around the droplets, the distribution of the water vapour field also varies, having a strong influence on the evaporative behaviour.

Due to the complexity of multi-drop systems, current research has been largely focused on the liquid–vapour interactions between neighbouring drops. The present work, however, aims to not only further the understanding of the physical mechanisms driving the liquid–vapour interactions of such complex droplet systems, but also investigate both the liquid–liquid and solid–liquid interactions of a pair of droplets.

2 Methodology

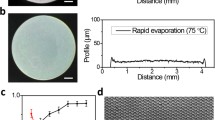

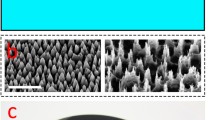

Double micro-droplets comprising both pure liquids (water and ethanol) and more complex fluid mixtures (binary mixtures of ethanol and water) are tested on microdecorated silicon substrates coated in parylene. Evaporation rate and top view images of the droplets lifetime are recorded. Thin-film interactions are monitored for binary fluid droplets that are able to adopt the hemi-wicking state on such substrates. In the hemi-wicking state, a droplet sits on a composite solid/liquid surface, where a film imbibes the microstructures. Additionally, the effect of surface topography is addressed by varying the pillar shape and interpillar distance. Four pillar shapes will be tested: circular, square, star-shaped and triangular pillars (Fig. 1). An infrared camera will provide insight into the liquid–solid interactions.

3 Results

The obtained results will provide further insight into three important interactions of a pair of neighbouring droplets, namely, liquid–vapour, liquid–liquid and liquid–solid.

Droplet composition allows for control over the contact angle and as such will provide the means to establish and analyse the interaction of droplets in varying wetting regimes: sessile droplets, hemi-wicking droplets and wicking films. In the case of pure water sessile droplets, the interactions between a pair of droplets take place mainly in the gas phase above the structured substrate, thus suppressing evaporation (Fig. 2a).

In the case of binary droplet mixtures (consisting of ethanol and water) exhibiting the hemi-wicking behaviour, two scenarios are possible (Fig. 2b). For films that are finite in size and that pin at their periphery shortly after deposition, coalescence of neighbouring films does not take place. In this case, it is expected that the saturation of the vapour field would predominantly take place within the microstructures and near the film, with the gas phase interactions between droplets diminishing greatly given their relatively large distance from each other. Experimental observation of single hemi-wicking droplets on the same substrates demonstrated that the wicking films can reach diameters of up to 10 mm. Therefore, to supress the coalescence of two nearby films, the droplets must be relatively distant from each other when compared to the characteristic length of the droplets. Alternatively, when the distance between the two hemi-wicking droplets is reduced, the films will coalesce and mix, thereby inducing a saturation of the vapour field around the liquid–vapour interface. Thus, the experimental data obtained from hemi-wicking droplets will establish the interactions through mass transfer for both the liquid and the vapour phases.

Lastly, in the case of pure ethanol, only the wicking fronts will become saturated and interact with each other (Fig. 2c). In cases where the films are in very close proximity, the pair of wicking films will coalesce and mix.

Additionally, solid–liquid interactions of droplet pairs through heat transfer will be established on surfaces exhibiting a range of microstructures. Variations in surface topography allow for systematic control of surface roughness and wettability, and short time evaporation dynamics are heavily influenced by the surface structure. The influence of pillar shape and pillar-to-pillar spacing on the evaporation of two droplets in close proximity to each other will be determined. Potential application such as evaporation and condensation phase change heat transfer, droplet manipulation and microfluidics will be sought.

4 Conclusions

This research will offer a more encompassing insight into multi-drop evaporation phenomena, as well as the universal features of multi-drop systems, by addressing the vapour, liquid and gas interactions. Emphasis will be placed on the above in the context of custom microdecorated surfaces.

References

M. Yoshino, T. Matsumura, N. Umehara, Y. Akagami, S. Aravindan, T. Ohno, Engineering surface and development of a new DNA micro array chip. Wear 260, 274–286 (2006)

T. Kokalj, H. Cho, M. Jenko, L.P. Lee, Biologically inspired porous cooling membrane using arrayed-droplets evaporation. Appl. Phys. Lett. 96, 163703 (2010)

L. Chen, J.R.G. Evans, Arched structures created by colloidal droplets as they dry. Langmuir 25, 11299–11301 (2009)

A.J.D. Shaikeea, S. Basu, Insight into the evaporation dynamics of a pair of sessile droplets on a hydrophobic substrate. Langmuir 32, 1309–1318 (2016)

Y. Kita, Y. Okauchi, Y. Fukatani, D. Orejon, M. Kohno, Y. Takata, K. Sefiane, Quantifying vapor transfer into evaporating ethanol drops in a humid atmosphere. Phys. Chem. Chem. Phys. 20, 19430–19440 (2018)

Acknowledgements

The present work is supported by the UK Engineering and Physical Sciences Council (EPSRC). The substrates used in the experimental work were fabricated at the Scottish Microelectronics Centre (SMC) at the University of Edinburgh.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Kubyshkina, V., Sefiane, K., Orejon, D., Dover, C.M. (2021). Droplet Interplay on Microdecorated Substrates. In: Wen, C., Yan, Y. (eds) Advances in Heat Transfer and Thermal Engineering . Springer, Singapore. https://doi.org/10.1007/978-981-33-4765-6_14

Download citation

DOI: https://doi.org/10.1007/978-981-33-4765-6_14

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-4764-9

Online ISBN: 978-981-33-4765-6

eBook Packages: EngineeringEngineering (R0)