Abstract

Vehicle frontal low-speed impact creates vehicle frontal component damage and driver injuries. In conventional vehicle frontal impact protection system, the frontal foam and reinforcing bar reduce the amount of damage and the degree of injuries, and it is the fact that heavier opponent needs stiffer structure and lighter opponent need less stiff structure but those structural components behave similarly in every crash situation. This work deals with using controlled pneumatic actuator as low speed and adaptable impact absorber in vehicle frontal impact absorption system in order to create dynamic behaviour of impact absorber and achieve sufficient damping during the event of crash. In this work, air spring dynamic property is simulated using ABAQUS simulation software and all controlling electrical and electro-pneumatic components behaviour is animated by using both Proteus 8 Professional and ARDUINO. To control the system, different electrical sensors, controllers and actuators are used. At the back of the air spring, the pressure sensor is mounted to control the amount of pressure needed in the air spring and the compressor control system is coded to pre-conditions to maintain the amount of pressure needed and to make idle the control system when the situation is in crash situation. The microcontroller is coded with the ARDUINO software by studying the real-time scenarios and it uses the input from the ultrasonic sensor to measure the distance between cars. In line with the ultrasonic sensing, the vehicle speed is sensed, and then the microcontroller compares the distance and the speed of the car and decides whether the car can achieve 0 kph within this distance or not. The result of electro-pneumatic shows a sufficiently good agreement with the physical parameter taken and the controlled system is able to execute and take action within 15 µs which is less than the impact duration for low-speed frontal crash and stiffer air spring column is maintained when the severity of crash is higher by comparing speed and distance between cars and less stiff air spring column is maintained when the severity of crash is minimum.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Vehicle collision is a big challenge being faced by automotive field. In the design of an automobile, the most important task is to minimize the occurrence and consequences of automobile accidents. Automotive safety can be improved by “active” as well as “passive” measures. Active safety refers to technology which assists within the prevention of a crash. Passive safety includes all components of the vehicle that help to scale back the aggressiveness of the crash event. Crash protection priorities are directly proportional to the speed of the car when crash occurs: at speeds up to 15 km/h, the main goal is to minimize repair costs, at speeds between 15 and 40 km/h, the first aim is to protect pedestrians; at speeds over 40 km/h, the most important concern is to guarantee occupant protection [1,2,3].

The term “Crash Management System” is usually wont to describe the structural module consisting of the bumper and therefore the related attachments which hook up with the longitudinal beams of the car. Front bumpers are connected to the front chassis rail by a separate deformation element (“crash box”). Energy absorbers are loaded in compression or tension also because the bumper moves from a designed outer position toward the vehicle body and are operative to soak up the energy of the impact. After impact, these energy absorbers recover at various rates to return related to bumper assembly toward its original pre-impact position. Most of crash boxes are mechanical impact absorbers they did not return to their original position and shape after impact [4,5,6].

Pneumatic actuators are devices and they use controlled compressed air to create mechanical motion. It gives both linear movement and angular rotation with simple and continuously variable operational speed of the car. And also, it can be used as impact absorbers by controlled restricted flow [7,8,9].

2 Methodology

This work is done with the main objective of developing adaptive low-speed electro-pneumatic frontal impact absorption system for crossover vehicles. The air spring with various controlling electrical components is used. Air spring is simulated by using ABAQUES simulation software. Then, all the system components including mechanical components installation are done with the help of Proteus software. The controlling code is written in ARDUINO programming. After all the Arduino code is loaded in to Proteus microcontroller.

The response of the system simulated by varying different parameters such as

-

The distance between cars

-

Vehicle speed

-

Air spring internal pressure.

2.1 Development of Electro-Pneumatic Impact Absorption System

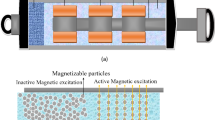

Low-speed electro-pneumatic frontal impact absorption system is a system designed to reduce the occupant injuries and vehicle components damage during low-speed collision (30 kph). The system uses controllable damping element called air spring and controlling element called microcontroller by receiving the input data through sensors and send signals to the actuators.

2.1.1 Air Spring

Air springs consisting of actuators made of rubber or fabric and are supported by a compressed air column. These air springs are generally used as vibration isolators and as pneumatic actuators. Air springs do not consist of pistons, connecting rods, dynamic seals, etc. like pneumatic cylinders. This behaviour is good to make them suitable to handle various impacts and even off-centre impacts.

Air springs make use of the fact that air has elastic or springiness when compressed. Air springs are normally noise-free because of the virtue of their construction. Material properties of air spring are stated in Table 1.

2.1.2 Terms in Air Spring

- Assembly.:

-

Assembly of air spring includes the flexible member like rubber body, top plate and bottom plate.

- Assembly volume.:

-

Air spring assembly volume is working volume exclusive of any external working volume.

- Compression stroke.:

-

Compression stroke in air spring is reduction of height from its designed operational height.

- Design load.:

-

Maximum static load expected to be acting on the spring under normal conditions.

- Design height. :

-

The overall height of the air spring.

- Effective area.:

-

The working area perpendicular to air spring output force. It is not the actual cross-sectional area of the air spring.

- Reservoir volume.:

-

It is the volume of the reservoir which is located externally to the air spring and supplying the air for functioning of the air spring.

Vertical parameters to describe air spring vertical parameter.

-

The elastic part is described by \({K}_{ez}\)

$$ K_{ez} = \left( {\frac{1}{{\frac{{p_{0} A_{e} 2^{n} }}{{V_{b0} + V_{r0} }} + P_{g} \frac{{{\text{d}}A_{e} }}{{{\text{d}}z}}}} + \frac{1}{{K_{{{\text{aux}}}} }}} \right)^{ - 1} $$(1) -

Viscous part is described by \({K}_{vz}\), Czβ, β and M.

$$ K_{vz} = \left( {\frac{1}{{\frac{{p_{0} A_{{e^{2} }} n}}{{V_{b0} }} + P_{g} \frac{{{\text{d}}A_{e} }}{{{\text{d}}z}}}} + \frac{1}{{K_{{{\text{aux}}}} }}} \right)^{ - 1} - K_{ez} $$(2) -

Mass (M) to describe the inertia of air in the surge pipe

$$ M = 1_{s} A_{s} P\left( {\frac{{A_{e} }}{{A_{s} }}\frac{{V_{r0} }}{{(V_{b0} + V_{r0} )}}} \right)^{2} $$(3) -

Nonlinear viscous damper Czβ, β

$$ C_{Z\beta } = C_{s} K_{wz}^{1 + \beta } = C_{s} \left( {\frac{{A_{e} }}{{A_{s} }}\frac{{V_{r0} }}{{(V_{b0} + V_{r0} )}}} \right)^{1 + \beta } $$(4) -

equilibrium internal absolute air pressure is

$$ P_{0} = \frac{{m_{b} g}}{{A_{e} }} + P_{a} $$(5)

2.2 Modelling of Air Spring Using Abacus

The air spring modelled in abacus is cylindrical in shape with inner diameter of 100 and 150 mm outer diameter. The idealization of the air spring consists of two metal discs of circular shape connecting with each other with a component made of rubber. The radius of the lower disc is 70 mm and the radius of upper disc is 72 mm and they are coaxial with a distance of 70 mm between them.

The fluid cavity is modelled using the surface-based fluid cavity capability, and to define cavity completely and ensure proper calculation in three-dimensional models, surface elements are defined along the bottom and top rigid disc boundaries of the cavity, even though no displacement element exists along those surfaces. Since two-dimensional surface elements are provided by abacus, structural elements were used instead of surface elements for modelling the rigid disc boundaries.

The rubber component is modelled as shell element, and the circular top and bottom plates are modelled as rigid element.

Boundary conditions and materials

-

Fluid cavity inflated to a pressure at step one

-

For bottom plate—U1 = U2 = U3 = UR1-UR2 = UR3 = 0

-

For top plate—U1 = UR2 = UR3 = 0

-

For top plate—U3 = UR1 = UR2 = 0

-

For top plate—U2 = 30 cm

-

Top plate and rubber body has tie contact

-

Rubber body and bottom plate has tie at centre and surface-to-surface contact with the others (adjust slave surface to its initial position)

-

Contact property between rubber body and bottom plate is rough

-

Top plate is modelled as rigid body (adjust point to centre of mass at start of analysis)

-

Bottom plate is modelled as rigid body.

2.3 System Control and Components

Ultrasonic sensors are a type of sensors used to measure the distance of an object from the point the sensor is placed. Ultrasonic waves are sound waves with frequencies higher than 20 kHz which cannot be heard.

Pressure sensor: Pressure is one of the most important physical parameters in fluid operation, and it is the force exerted on a unit of area.

Speed sensor uses the principle of variable reluctance magnetic sensing. In this, there is a coil wire wound around a cylindrical permanent magnetic core and is mounted on stationary hub carrier.

Quick exhaust valves work by providing a rapid exhaust of controlled air when placed directly onto an air cylinder after the control valve.

3 Results and Discussion

Speed has been identified as a key risk factor in road traffic injuries, influencing both the risk of a road crash as well as the severity of the injuries that result from crashes. Controlling vehicle speed can prevent crashes happening and can reduce the impact when they do occur, but collision occurs unintentionally so building a system to reduce the consequence is important.

It is the fact that injuries and damages during collision are directly proportional to the amount of kinetic energy generated during the motion of the vehicle, to minimize risk of injury and damage, and it is important to remove the kinetic energy as slowly and evenly as possible.

Kinetic energy is directly proportional to the mass and the square of the speed of the vehicle, so at different speed the vehicle will have different amount of kinetic energy. To remove this varying kinetic energy, it is important to develop adaptive kinetic energy removing system to reduce injuries and damages happen during collision. Figure 1a, b shows the undeformed and deformed shapes of air spring.

In simulation of air spring using abacus, an incompressible Mooney–Rivlin (hyper-elastic) material with c10 = 80, c01 = 80, d1 = 0 and temp = 25, and the steel with E = 210.0 Gpa and v = 0.3 is used. Figure 2a, b shows the material distribution in the model.

The simulation result in Fig. 3 shows the von Mises stress concentration on the inflated air spring when the spring is compressed about 30 cm in the negative y-direction, and as the graph Fig. 4 indicates the stress concentration is below the Tresca stress and we can say it is safe.

As the graph in Fig. 5 shows all the stress components during the simulation of air spring lies below the Tresca line, so it is safe to use the air spring with this range which is proportional with the required range.

As indicated in the parameter, the air spring is first inflated to the required pressure level and then compressed in 30 cm in the negative y-direction, so the graph in Fig. 6a, b shows the characteristics in both steps. The effective area of the air spring change is negligible; pressure is directly proportional to the applied force so as the compression force increases the pressure also increases.

3.1 Spatial Displacement

When the air spring is compressed to 30 cm in the negative y-direction, the rubber body compressed in the same direction is shown in Fig. 7. The following result in Figs. 8, 9, 10, 11 and 12 shows the magnitude and the direction of displacement.

4 Conclusion

To reduce the damage in the vehicle components and occupant injuries, adaptive electro-pneumatic system is used, and this designed system is mounted in the vehicle frontal structure. Then, the system operation is animated in Proteus 8 Professional result of electro-pneumatic shows a sufficiently good agreement with the physical parameter taken and the controlled system able to execute and take action within 15 µm which is less than the impact duration for low-speed frontal crash.

In this paper, the timely response of the system is observed. Air column unit can able to perform efficiently for low-speed crash impact load and the required amount of stiffness is achieved by varying the air pressure inside the air column unit, and impact energy damping is achieved by controlling the quick exhaust valve diameter.

To check the response and operation of the system, the following dynamic operation condition is simulated and the result is as follow:

-

When both the speed and distance between colliding cars are minimum in this condition, the probability of crash between the cars is very low so the valve condition remains closed.

-

When speed of the car is maximum and the distance between colliding cars is maximum, in such scenario, the vehicle is at 50 kph and the distance between the cars is 11 m apart then this condition is not enough to trigger the valve so the valve remains closed and the signal voltage reading is 0 V.

-

When speed of the car is maximum and the distance between colliding cars is minimum, the system is checked by suddenly decreasing the distance between the car to 4 cm, and the speed of the car was at constant speed which is 50 kph and quick exhaust valve opens about 40%.

-

When speed of the car is minimum and the distance between colliding cars is maximum in this extreme condition, the speed of the car suddenly drops to 8 kph and the distance between the car rises to 11.1 m at this condition the system compares the actual condition and the pre-condition set and maintain the valve condition in closed state because the vehicle in motion has sufficient distance to bring the vehicle to 0 kph.

-

When distance is constant but speed varies even if the speed of the car is increasing but the distance between the cars is constant or in a safe distance to bring the car to 0 kph, the valve remains in closed command.

References

Wakjira A, Nallamothu RB (2013) Microcontroller based rear-end anti-collision warning systems for vehicles. Glob J Eng Design Technol 2(6):14–21

Nagel G, Thambiratnam D (2002) Energy absorption and performance of a vehicle impact protection system. School of Civil Engineering, Queensland University of Technology, Australia, Physical Infrastructure Centre

Chen H, Yang Y, Wang L (2015) Vehicle Front structure energy absorbing optimization in frontal impact. College of Automotive Engineering, Shanghai University of Engineering Science, Shanghai

Ghasemnejad H, Hadavinia H, Marchant D, Aboutorabi A (2008) Energy absorption of thin-walled corrugated crash box in axial crushing

Witteman W (1999) Adaptive frontal structure design to achieve optimal deceleration pulses. Technische Universiteit Eindhoven Mechanics of Materials/Vehicle Safety the Netherlands Paper Number 05-0243

Jie L, Lin D (2014) Influence of material properties on automobile energy-absorbing components crashworthiness. College of Civil Engineering, Heilongjiang University, Harbin

Wykes NJ, Edwards MJ, Adrian Hobbs C (2004) Compatibility requirements for cars in frontal and side impact. Transport Research Laboratory United Kingdom Paper Number 98-S3-O-04

Jain S, Sreekumar M (2016) The preliminary design of a collision energy absorption system. Indian Institute of Information Technology Design and Manufacturing, Kancheepuram Melakottaiyur, Chennai

Nunes T (2017) Multi-objective design optimization of a frontal crash energy absorption system for a road-safe vehicle. Instituto Superior T´ecnico, Universidade de Lisbon, Portugal

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ameneshewa, K., Nallamothu, R.B., Nallamothu, A.K., Nallamothu, S.K. (2021). Design and Simulation of Adaptive Low-Speed Electro-Pneumatic Frontal Impact Absorption System for Crossover Vehicles. In: Joshi, P., Gupta, S.S., Shukla, A.K., Gautam, S.S. (eds) Advances in Engineering Design. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-33-4684-0_46

Download citation

DOI: https://doi.org/10.1007/978-981-33-4684-0_46

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-4683-3

Online ISBN: 978-981-33-4684-0

eBook Packages: EngineeringEngineering (R0)