Abstract

Fused Deposition Modelling (FDM) has gained its extensive application because of its lower cost, simple machinery and ease in operation. The simplicity of construction has enabled the development and use of several opensource FDM 3D printers. However, the FDM process parameters are difficult to tune as they significantly affect the printability of the material used. Many studies have been made to obtain a relationship between these parameters and print quality. The high non-linearity due to the numerous process variables playing their role complicates this relationship. Artificial neural networks can handle a high number of process variables and aid in studying the effect of these process variables on the fabricated part. This work aims to use a neural network for predicting whether a given set of parameters can lead to a successfully fabricated Polycaprolactone (PCL) part using FDM. A two-layer feed-forward neural network has been developed to predict the printability of PCL based on a given set of process parameters. Various combinations of process parameters were used to fabricate a PCL part using an opensource FDM 3D printer, and a data of 45 such combinations were used to develop the neural network. Three different neural network models with 10, 20 and 30 number of hidden neurons were trained. Finally, a group of process parameters was fed to the network with the best performance, and the network provided the probability of the given group of process parameters to result in the successful fabrication of the PCL part as the output.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

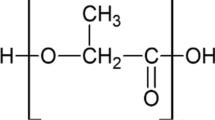

Additive manufacturing (AM) has been emerging in recent years, enabling the fabrication of complex 3D structures from a variety of materials. AM allows fabrication of 3D structures in a layer-wise fashion, allowing control on the internal and external geometry, using three-dimensional computer-aided design (CAD) models. Fused Deposition Modelling (FDM), also referred by Fused Filament Fabrication (FFF), is a widely used AM process because of its low cost and ease in operation. In FDM, a polymer filament is passed through a heated nozzle, which causes the filament to be extruded in a semiliquid state and deposited on a heated bed to manufacture a 3D object in a layer-wise fashion according to CAD data [1]. A wide range of materials such as Polylactic acid (PLA), Polyester, Polyamide, Polyethylene, Polypropylene, Acrylonitrile-Butadiene Styrene (ABS) and Polycaprolactone (PCL) are feasible for use in FDM process. However, FDM is a complex process, which is affected by many parameters. Various process parameters such as extrusion temperature, heated bed temperature, raster orientation, layer thickness, infill pattern, raster width, infill density, and printing speed play a role in making it possible to print a part successfully [2]. Changes in these parameters can influence the part quality and even lead to the failure of the process in manufacturing the part. Many studies have been carried out to investigate the influence of different process parameters on the part quality and its mechanical properties using professional FDM 3D printers [3, 4] as well as low-cost opensource FDM 3D printers [5, 6]. Moreover, many experimental methods have been implemented to optimise the process parameters of FDM, such as Taguchi method [7, 8], factorial designs [9], ANOVA [10, 11], and fuzzy logic [12]. While performing studies involving optimisation of FDM process parameters, especially with materials other than the commonly used ABS and PLA, different process failures like nozzle clogging, filament breakage, warping of part and detachment of part from print bed occur, which fail to manufacture the part. Many times, the FDM parts can have typical defects such as overfilling, cracking and voids. An empirical or theoretical relationship between the FDM process parameters and their effect on the 3D printed part can be useful to mitigate such failures. This relationship between the process parameters and their effect on the fabricated part is often highly non-linear because of the high amount of input variables playing their roles. Unfortunately, such a relationship becomes complicated as the number of parameters taken into account is increased. Neural Network (NN) models can deal with a high amount of input variables and can be applied in studying the effect of process parameters on manufactured part for different AM processes [13,14,15]. NNs are data-driven models that automatically develop the relationship linking the input parameters and output categories based on the data provided. Most studies applying NN models to determine the relationship of FDM process parameters on the fabricated object have used ABS [11, 16,17,18]. ABS and PLA have been commonly used in such studies to determine the effect of FDM process parameters on the part quality. PCL is a material that meets the criteria for medical applications and especially as an implantable material. Although, many studies have focussed on fabrication of scaffolds using PCL, very few have focussed on the effect of FDM process parameters over the print quality and mechanical properties [19,20,21]. Moreover, many process parameters are involved in the successful part fabrication. NNs can handle more variables and provide an output that can assist in predicting the effect of the FDM process parameters in obtaining a successfully fabricated part.

Thus, a neural network has been applied in this study to predict the effect of FDM process parameters on the fabrication of PCL part. In this work, a neural network is developed to predict the probability of a given set of process parameters to result in the successful fabrication of PCL part using the FDM process. A feed-forward neural network is developed by training it with the data recorded in tuning the process parameters to fabricate a PCL part by an FDM 3D printer. This work can assist designers in the biomedical field in predicting the printability of a PCL part by FDM process.

Experimental Section

Materials and Methods

PCL filament having a diameter of 1.75 mm has been used to fabricate the parts using a 3D Jet FDM 3D Printer as shown in Fig. 23.1. In the attempts to determine the parameters to fabricate the PCL part successfully, eight parameters, viz. nozzle diameter, nozzle temperature, heated bed temperature, printing speed, raster width, layer height, infill density and ambient temperature range, were considered. Table 23.1 mentions the values of process parameters used in the study. All the 45 data samples of the parameter values categorised into ‘success’ or ‘failure’ are mentioned in Table 23.2. The combinations were categorised in the ‘success’ category if they resulted in a PCL part with desirable quality as checked by visual inspection. The combinations which led to a PCL part that lacked the desirable quality were categorised in the ‘failure’ category. The combinations numbered as 6, 27, 29, 33, 39, 41, 43, 44 and 45 are repetitions of one of the other 36 unique combinations.

Development of Neural Network Model

A neural network (NN) is a densely interconnected network of simple processing elements called neurons. Any NN consists of three types of layers, the input layer, hidden layer and the output layer [22]. An architecture of NN is shown in Fig. 23.2a. The neurons in the input layer carry the input variables. Similarly, the neurons in the output layer represent the output categories for classification. The hidden layer acts as the processing unit of the NN. Figure 23.2b shows the representation of a hidden layer neuron. Every connection between the neurons has a weight (w), making it a weighted connection, the magnitude of which is equal to the product of the weight and the input value (\(w_{i} x_{i}\)). The weights of these connections are allotted by training the NN in several iterations. These iterations are conducted to reduce the deviation between the true output and the output predicted by using the NN. This deviation is measured in terms of a loss function. The threshold value that offsets the hidden and the output layer is represented by (b). The activation function (f) introduces the non-linear nature of the relationship generated by the NN. All this is brought together by the output from each hidden layer neuron (y) and is given by,

where \(w_{i}\) is the weight of the link, \(x_{i}\) is the ith input variable, b is the threshold value of the neuron, and f is the activation function [23].

In this iterative process, the back-propagation algorithm is the most widely used method to repeatedly alter the weights of the connections in the network to minimise the loss function. The back-propagation algorithm uses a chain rule to train the network [24]. Once the NN has been trained, it can be used to obtain the outputs for new unseen inputs.

A MATLAB code was generated for creating the NN model. The NN has a two-layer feed-forward type network with a hidden layer having a sigmoid activation function and an output layer having a softmax activation function as illustrated in Fig. 23.3.

The sigmoid activation function that introduces non-linearity to the relationship generated using NN is given as,

The softmax activation function, which provides a probability distribution of its inputs proportional to their exponentials, is given by,

where k is the number of classes into which the sample set has to be classified. As the output of the softmax function is a probability distribution of the input variable proportional to its exponential, \(0 \le f\left( {x_{i} } \right) \le 1\) and \(\mathop \sum \nolimits_{j = 1}^{k} f\left( {x_{i} } \right) = 1\).

The deviation between the value predicted by the network and the true value fed to the network is determined in terms of the cross-entropy loss function. The loss function is given as,

where n represents the number of samples, k represents the number of classes, \(p_{ij}\) indicates the true probability of sample i to belong to the class j, and \(q_{ij}\) is the output probability by the network for sample i to belong to class j, which in this NN, is the value provided by the softmax function.

A scaled conjugate gradient back-propagation algorithm is applied for training the neural network used in this work. The data are fed in the form of input data to the network and target data for defining the desired network output. The input data are divided into three different types, viz. training set, validation set and testing set. The samples in the training set are used to train the network so that the network weights are altered repeatedly by the back-propagation algorithm. The validation samples do not take part in the adjustment of the weights. They are used for evaluating the network accuracy to avoid overfitting while training the network. Testing samples do not affect the network but provide a final measure of the network accuracy after training. If the network does not perform satisfactorily, it can be retrained to get more accurate results [25]. In this work, 70% of the data were used for training, 15% for testing and the rest 15% for validation purpose. The NN model was trained nine times with three iterations each for 10, 20 and 30 number of hidden neurons. In order to check for the successful working of the NN, the confusion matrix of each iteration was evaluated, as shown in Fig. 23.3. The diagonal cells of the confusion matrix indicate the number of correctly classified cases and the off-diagonal cells indicate the incorrectly classified cases. The bottom right cell shown in dark grey indicates the total per cent of correctly and incorrectly classified cases in green and red colour, respectively [25]. The confusion matrices of all the iterations are shown in Fig. 23.4.

Confusion matrices of iterations by training the NN (i) hidden neurons: 10, iteration: 1 (ii) hidden neurons: 10, iteration: 2 (iii) hidden neurons: 10, iteration: 3 (iv) hidden neurons: 20, iteration: 1 (v) hidden neurons: 20, iteration: 2 (vi) hidden neurons: 20, iteration: 3 (vii) hidden neurons: 30, iteration: 1(viii) hidden neurons: 30, iteration: 2 (ix) hidden neurons: 30, iteration: 3

Results and Discussion

The 0.8 mm nozzle diameter was the most suitable for proper extrusion. While using a 0.4 mm nozzle diameter, filament buckling caused the print failure. Buckling of the filament was seen frequently, causing the filament to stack between the feed rollers and the entry of the heating element. The buckling of the filament might be due to the higher backpressure on the filament from the heating element side of the feed roller [26]. The nozzle temperature is one of the primary effective processing parameters in FDM. It was noticed that a nozzle temperature of 90 °C resulted in successful fabrication of the PCL part. Temperatures above 90 °C allowed proper extrusion of the material but were too high to allow sufficient solidification of the deposited layer within the printing time. The insufficient solidification of the deposited layer led to deformation of the part as the deposited layers could not retain their shape during the printing of subsequent layers. Nozzle temperatures below 90 °C caused the buckling of the filament due to the insufficient liquefaction. Heated bed temperatures above 50 °C hindered the proper solidification of the deposited layers, thus causing the printed part to deform after subsequent layers were printed. Heated bed temperature below 45 °C caused eventual warping of the printed part, and the part lost its adhesion to the bed, thus getting dragged along with the nozzle.

A low printing speed of 10 mm/s was most suitable for fabricating a PCL part. While using higher printing speeds, the buckling of the filament was observed frequently. This buckling might be due to the increase in the extrusion rate at higher printing speeds, leading to an increment in the backpressure on the filament. A raster width of 0.9 mm was found to be most suitable for successful printing of the PCL part. A higher value of the raster width set in the slicing process resulted in unfused rasters. In contrast, a raster width lower than 0.9 mm caused the unsolidified deposited material to ooze outside the perimeters. It was found that with the proper selection of other parameters, the PCL part could be fabricated successfully with all the three-layer heights considered. A lower layer height of 0.2 mm increased the printing time, which led to higher chances of warping of the part. It was noticed that while using a lower layer height, the insufficiently solidified material of the previous layer got dragged along with the nozzle leading to deformations in part. Higher layer heights of 0.3 and 0.4 mm did not cause any issues while fabrication of the PCL printed part. Although, a higher layer height reduced the printing time. The infill densities of 60, 80 and 100% resulted in successful fabrication of part when the other parameters considered were set in the range feasible for printing. However, higher infill density led to deformations in a few cases. It was observed that the PCL part could not be fabricated with the ambient temperature in the range of 35–40 °C because it led to insufficient solidification of the layers deposited during the FDM process. Ambient temperature in the range of 25–28 °C was suitable for the proper fabrication of the PCL part as it allowed sufficient solidification of the deposited layers.

Every parameter has influenced the FDM process in the printability of the PCL part. Thus, the NN can help in determining the printability of PCL based on a particular set of process parameters. Out of all the iterations with three different values of hidden neurons, the NN with 30 hidden neurons showed better accuracy than other cases as seen in Fig. 23.5. The best accuracy obtained by using 30 hidden neurons was 93.3%.

Thus, the NN with 30 hidden neurons was considered for the proposed application. Finally, a particular set of parameters was fed to the NN model, as shown in Table 23.3. The output provided by the NN was a pair of two values, depicting the probability of the given set of parameters to belong to ‘success’ category and the ‘failure’ category. The probability of the ‘success’ category was 0.9998 and that of the ‘failure’ category was 1.6877 × 10−4. The output predicted by this NN can be interpreted as—the parameters mentioned in Table 23.3 result in a successful print of PCL part. Figure 23.6 shows that the PCL part was fabricated successfully using the parameters shown in Table 23.3.

PCL part fabricated using the parameters mentioned in Table 23.3

Conclusion

In this work, various set of process parameter values were used to fabricate a PCL part by the FDM process. The final values of the process parameters that resulted in the successful fabrication of the part were determined. A data of 45 such combinations with the classification as successful print or print failure were used to develop a neural network model using a MATLAB code. The neural network was trained for three times each, using three different values of hidden neurons (10, 20, and 30). The model, which resulted in the highest accuracy, was considered for final use. A particular set of process parameter values was fed to the network. The neural network provided the probability of the given set of process parameters to result in the successful fabrication of a PCL part by the FDM process. The result predicted by the NN was validated by printing a PCL part with the same set of process parameter values. Form this work, the conclusions that can be drawn are as follows:

-

The set of process parameters that resulted in a successful fabrication of a PCL part in this work are nozzle diameter of 0.8 mm, nozzle temperature of 90 °C, bed temperature in the range of 45–50 °C, printing speed of 10 mm/s, raster width of 0.9 mm, layer height of 0.3–0.4 mm, infill density of 60–100% and under ambient temperature in the range of 25–28 °C.

-

The most common reasons for the failure of the process were filament buckling between the feed rollers and heating element, and deformation of the part because of insufficient solidification.

-

The NN with 30 hidden neurons performed better than other cases with the highest accuracy of 93.3%. It was also noticed that the NN with 10 hidden neurons showed better accuracy than that with 20 hidden neurons. This indicates that a higher number of hidden neurons do not always result in higher accuracy, and it is necessary to train networks with different levels of hidden neurons until a desirable accuracy is obtained.

This neural network model is a useful tool to predict the result of a particular set of FDM process parameters on the printability of PCL.

References

Gibson I, Rosen D, Stucker B (2010) Additive manufacturing technologies. Springer, Boston, MA

Popescu D, Zapciu A, Amza C, Baciu F, Marinescu R (2018) FDM process parameters influence over the mechanical properties of polymer specimens: a review. Polym Testing 69:157–166

Chacón JM, Caminero MA, García-Plaza E, Núñez PJ (2017) Additive manufacturing of PLA structures using fused deposition modelling: effect of process parameters on mechanical properties and their optimal selection. Mater Des 124:143–157

Sun Q, Rizvi GM, Bellehumeur CT, Gu P (2008) Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyping J 14:72–80

Deng X, Zeng Z, Peng B, Yan S, Ke W (2018) Mechanical properties optimisation of poly-ether-ether-ketone via fused deposition modeling. Materials 11:216

Fernandez-Vicente M, Calle W, Ferrandiz S, Conejero A (2016) Effect of infill parameters on tensile mechanical behavior in desktop 3D printing. 3D printing and additive manufacturing 3:183–192

Lee BH, Abdullah J, Khan ZA (2005) Optimisation of rapid prototyping parameters for production of flexible ABS object. J Mater Process Technol 169:54–61

Che CW, Ta-Wei L, Shr-Shiung H (2007) Optimising the rapid prototyping process by integrating the Taguchi method with the Gray relational analysis. Rapid Prototyping J 13:304–315

Mohamed OA, Masood SH, Bhowmik JL, Nikzad M, Azadmanjiri J (2016) Effect of process parameters on dynamic mechanical performance of FDM PC/ABS printed parts through design of experiment. J Mater Eng Perform 25:2922–2935

Srivastava M, Rathee S (2018) Optimisation of FDM process parameters by Taguchi method for imparting customised properties to components. Virtual Phys Prototyping 13:203–210

Sood AK, Ohdar RK, Mahapatra SS (2009) Parametric appraisal of fused deposition modelling process using the grey Taguchi method. Proc Inst Mech Eng Part B: J Eng Manuf 224:135–145

Sahu RK, Mahapatra SS, Sood AK (2013) A study on dimensional accuracy of fused deposition modeling (FDM) processed parts using fuzzy logic. J Manuf Sci Prod 13:183–197

Sood AK, Ohdar RK, Mahapatra SS (2012) Experimental investigation and empirical modelling of FDM process for compressive strength improvement. J Adv Res 3:81–90

Shen X, Yao J, Wang Y, Yang J (2004) Density prediction of selective laser sintering parts based on artificial neural network. In: Yin FL, Wang J, Guo C (eds) Advances in neural networks—ISNN 2004. ISNN 2004. Lecture Notes in Computer Science, vol 3174. Springer, Berlin, Heidelberg, pp 832–840

Rong-Ji W, Xin-hua L, Qing-ding W, Lingling W (2009) Optimising process parameters for selective laser sintering based on neural network and genetic algorithm. Int J Adv Manuf Technol 42:1035–1042

Vosniakos G-C, Maroulis T, Pantelis D (2007) A method for optimizing process parameters in layer-based rapid prototyping. Proc Inst Mech Eng Part B: J Eng Manuf 221(8):1329–1340

Sood AK, Equbal A, Toppo V, Ohdar RK, Mahapatra SS (2012) An investigation on sliding wear of FDM built parts. CIRP J Manufact Sci Technol 5:48–54

Panda BN, Bahubalendruni MVAR, Biswal BB (2015) A general regression neural network approach for the evaluation of compressive strength of FDM prototypes. Neural Comput Appl 26:1129–1136

Zein I, Hutmacher DW, Tan KC, Teoh SH (2002) Fused deposition modeling of novel scaffold architectures for tissue engineering applications. Biomaterials 23:1169–1185

Ceretti E, Ginestra P, Neto PI, Fiorentino A, Da JVL (2017) Multi-layered scaffolds production via fused deposition modeling (FDM) using an open source 3D printer : process parameters optimisation for dimensional accuracy and design reproducibility. In: Shih A, Cao J (eds) 3rd CIRP conferences on biomanufacturing 2017, vol 65. Chicago, U.S., Procedia CIRP, pp 13–18

Yen H-J, Tseng C-S, Hsu S, Tsai C-L (2009) Evaluation of chondrocyte growth in the highly porous scaffolds made by fused deposition manufacturing (FDM) filled with type II collagen. Biomed Microdevices 11:615–624

Goldberg Y (2017) Neural network methods for natural language processing. Synthesis Lect Human Language Technol 10:1–309

Vijayaraghavan V, Garg A, Lam JSL, Panda B, Mahapatra SS (2015) Process characterisation of 3D-printed FDM components using improved evolutionary computational approach. Int J Adv Manuf Technol 78:781–793

Rumelhart DE, Hinton GE, Williams RJ (1986) Learning representations by back-propagating errors. Nature 323:533–536

Beale MH, Hagan MT, Demuth HB (2013) Neural network toolbox TM 7 user’ s guide, Mathworks Inc

Yang Z, Jin L, Yan Y, Mei Y (2018) Filament breakage monitoring in fused deposition modeling using acoustic emission technique. Sensors 18:749

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Narkhede, R., Karumuri, R.T., Prajapati, A.R., Dave, H.K. (2021). Application of Neural Network to Predict Printability of Polycaprolactone Using FDM. In: Kumar, S., Rajurkar, K.P. (eds) Advances in Manufacturing Systems. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-33-4466-2_23

Download citation

DOI: https://doi.org/10.1007/978-981-33-4466-2_23

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-4465-5

Online ISBN: 978-981-33-4466-2

eBook Packages: EngineeringEngineering (R0)