Abstract

A conventional Fused Deposition Modeling (FDM) machine builds an object layer by layer on a horizontal platform from bottom to top fashion. The major drawback of the FDM machine is limited number of degree of freedom (only 3). Industrial robots with six degrees of freedom are capable to move its end effector in 3D space with high resolution and repeatability. A robot with an extruder as an end effector has the capability to print the objects on multiple planes. In this work, an attempt is made to simulate the FDM process with an industrial robot. Simulation of printing of a cube on horizontal and inclined planes is presented. Tool path for each sliced layer is developed using polygon-filling algorithm. The simulation of printing of 3D objects using 6-axis industrial robot is carried out using ABB RoboStudio simulation software.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Fused deposition modeling (FDM) is an additive manufacturing process where the material is deposited in horizontal layers one on another to create a three-dimensional object. The digital model, i.e., CAD model is the input for this process. Software, hardware, and materials work together to get the desired final product. Initially, this process is used for creating prototypes rather than end functional products. But due to the availability of newly developed materials and higher precise machines, objects are produced with very close or same mechanical and material properties of the end functional products. Nowadays, this technology has a very broad area of applications in almost every field [1, 2].

Manufacturing Industries aims to produce better quality products in the least time. The product quality is mainly dependent on the skill of the worker and the product cost is prohibitively high. In order to reduce the cost and increase the quality robot manipulators are introduced in the manufacturing industries. These robots can do repetitive tasks once they are accurately programmed. Reprogramming can also be done within less time. So these robots are so flexible systems to incorporate in manufacturing industries. High precision, speed, endurance, repeatability and having many numbers of degrees of freedom are the main advantages in the case of an industrial robot. Many numbers of end effectors were developed to meet the requirements in the industry. Autonomous robots are also being developed so that they can interact with the environment and take their own decisions based upon the situations [3].

Integrating robotic and 3D printing technologies will be so advantageous in the field of manufacturing. Because of the higher degrees of freedom, the robot arm can freely move in huge workspace compared to the conventional fused deposition modeling machines. Printing with the extruder in different orientations and over multiple planes is possible if the extruder acts as an end effector of the robot. Tse and Chen [4] explored the new application of robot in the subtractive manufacturing process. A milling tool was used to machine a prototype out of a material block using a CAD model. A number of complex surfaces were also produced using this method. Barnett and Gosselin [5] used a cable suspended robot having 6 degrees of freedom as a large scale 3D printer. In this work polyurethane foam was used as the object material and shaving foam as the supporting material.

The important factors needed to be considered in fusion deposition modeling using the industrial robot are categorized into two groups mainly process parameter and process planning parameters. Layer thickness, deposition speed, and flow rate are the important process parameters are needed to be chosen carefully to ensure good material deposition of layers. Orientation, support structure, slicing, and tool path generation are the process planning parameters that affect the overall product’s surface quality and strength of the product [6]. Process parameters directly influence the dimensional accuracy of parts that are fabricated using the fused deposition modeling process. Orientation angle has an impact on repeatability and strength of parts [7]. Layer thickness and road width affect more on the surface quality and part accuracy, compared to raster angle. As well as the air gap has more impact over dimensional accuracy and has a low impact on surface quality [8]. In conventional FDM machines, while generating the tool path, it uses standard G and M codes for movement across the plane. For FDM with the robot, a translator is required to convert these instructions into standard robotic commands so that the robot can be moved accordingly [9].

In this paper, a new procedure is developed for combining additive manufacturing and robotics to print 3D objects. The industrial robot with extruder as end effector has more degrees of freedom than the conventional fused deposition modeling machine. The additional degrees of freedom help to print complex surfaces in multi-planes. The simulation of the 3D printing process with an industrial robot for a simple cube over the flat base and the inclined base is presented in this paper. The simulation work is carried out in ABB RoboStudio simulation software. The methodology adopted and simulation results are presented in this paper.

2 Methodology

In this section, the procedure for printing 3D objects using the industrial robot is presented. Generally, in conventional fused deposition modeling machine, the STL format of a CAD model is taken and then processed to generate a number of slices and tool path for each slice. It depends on various input parameters like nozzle diameter, slice thickness, extruder speed, and feed rate. The tool path generates in terms of G and M codes and it is given to the machine to print the objects. The machine utilizes G and M codes for controlling the motion of the extruder and for the material deposition.

In this work ABB makes IRB 1600 industrial robot is used for 3D printing. ABB robots use rapid programming language to control the movement of the joints. The extruder with the nozzle of diameter 0.5 mm is used end effector for the robot to print the objects. In conventional fused deposition modeling machine, the extruder movement is constrained only in two directions, i.e., x and y. The z movement is provided by the heating bed, i.e., the base plate. Once this extruder is attached to the industrial robot it acts as an end effector and does contain six degrees of freedom. The flowchart indicating the procedure followed to print the objects with an industrial robot is shown in Fig. 13.1. First, the CAD model of the object to be printed is converted into the STL format. In STL format the outer surface of the CAD model is approximated with triangles. To determine boundary points a horizontal plane is used to intersect the triangles. All intersection points are connected to extract the boundary of the layer [10]. After generating the boundary of a layer the horizontal plane is taken with an increment of 0.5 mm and intersected again with the triangles to get the boundary points of the next layer. The same procedure is repeated for the entire height of the solid. For the first layer, the tool path is generated by scanning the boundary using horizontal line either in X or Y direction to determine coordinate points on the boundary. The entire boundary is scanned by a horizontal line with the incremental movement of 0.5 mm which is equal to nozzle diameter.

All the coordinates points are connected by the zig-zag pattern to generate the tool path. Similarly, for the second layer, the tool path is generated by scanning the second layer using a horizontal line but perpendicular to the previous horizontal line. To create better bonding between the layers, the second horizontal scanning line is considered perpendicular to the previous scanning line, so that the strength of the overall component will increase. The same procedure is repeated to generate the tool path for the entire solid by considering alternative perpendicular scan lines for layer to layer. The extracted points on the boundary of the single slice are taken as input parameters for tool path generation. The tool path is generated in such a way that first tool (extruder) has to move along the boundary and then fill inside the boundary. After completing the first layer the same procedure adopted for the second layer. Like that, for the entire object (Cube in the present case) the tool path is generated. The program is developed in ‘C’ programming language to find a sequence of points that the extruder to move for each layer. The output of the program gives motion commands that are suitable for rapid language for ABB robot. These rapid commands are taken as the input for the RoboStudio simulation software. The simulation of 3D printing is executed in RoboStudio software. In this work, MatLab is used for slicing, C programming language for tool path generation and rapid programming languages for simulation are integrated to accomplish this procedure.

3 Simulation of 3D Printing of Cube

In this work, simulation of 3D printing cube of size 50 mm side using an industrial robot is carried out. For simulation, ABB makes IRB 1600 robot having 6 degrees of freedom, 1.45 m range, and 6 kg payload with IRC5 industrial robot controller is used. The position repeatability of this robot is 0.02 mm and the path repeatability is 0.19 mm. The working range of the robot is shown in Fig. 13.2.

First CAD model (as shown in Fig. 13.3) of a cube having 50 mm side is created and then it is converted into an STL file format (as shown in Fig. 13.4). In this format, the surface of the CAD model is approximated by triangles. Now this STL file is sliced using MatLab program and horizontal slices are obtained. The generated horizontal slices are shown in Fig. 13.5.

Now, form the sliced model each slice is extracted separately depending upon the z values. In this work, each slice of a thickness of 0.5 mm is taken along the z-axis. The cross-section of the slice is shown in Fig. 13.6.

For each layer polygon filling algorithm is implemented. The entire area is scanned with scan lines from left to right. For the first or base slice, the coordinate points are obtained by scanning horizontal lines as shown in Fig. 13.7. The intersection points between the boundary and horizontal lines are extracted for tool path generation. For the second slice, i.e., z = 0.5, the area is obtained and it is scanned with scan lines from front to back and intersections are obtained as shown in Fig. 13.8. The intersection points are highlighted with the red circles in both the figures.

For the third layer, i.e., Z = 1, the scanning is done again from left to right similar to the first slice as shown in Fig. 13.5. The same procedure is followed by scanning alternatively for the remaining layers. Alternative scanning provides better bonding between the layers. The incremental movement of each scan line is also taken as 0.5 mm in the present work.

These coordinate points are taken as input data and using these points tool path is generated in C programming for infill within the boundary. The logical statements convert these data points into tool paths and at the same time, these tool paths are converted into the motion commands in rapid programming language for the robot. Mainly these commands consist of MoveL (Move linear) statements. The tool path for one slice is shown in Fig. 13.9. Every slice is printed in such a way that, first the boundary is printed and then infill of the area is done.

Now the output of this C program, i.e., rapid commands are used to simulate the procedure in RoboStudio software. For printing a cube over the horizontal base, a work object is needed to be defined along the corner of the cube. The coordinate axes of the work object are in such a way that the Z-axis is aligned along with the height of the cube. The tool path is parallel to the XY plane of the work object. So deposition is carried out in the planes those are parallel to the XY plane and incremented through the Z-axis of the work object. So the orientation of the extruder (end effector of the robot) is perpendicular to the printing base and moves along the Z-axis for printing the layers.

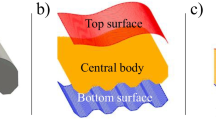

If it is required to print the object over the inclined base, the work object is defined in the same way as the previous case. But in this case, the extruder is oriented with some angle of inclination to the global (or robot’s base coordinate) Z-axis. The angle of inclination is equal to the inclination of the printing base. In this case, also the extruder is perpendicular to the printing base and it moves along the work object’s Z-axis.

4 Results and Discussion

The simulation is done successfully and the end effectors tip, i.e., the extruder tip followed the path that is generated by this procedure. The simulation to print the object on horizontal base is shown in Fig. 13.10. The generated tool path is shown in Fig. 13.11. The simulation of the robot over the inclined base is shown in Fig. 13.12.

Conventional fused deposition modeling machine has the flat horizontal printing base. If an object is needed to be printed over a plane which is inclined, it is impossible, as the extruder can’t move in an inclined path due to its restricted degrees of freedom. By using the extruder as the end effector of the robot it is possible to print over the inclined planes. Simultaneous printing over different planes is possible.

By using the extruder as an end effector of a six-axis industrial robot offers several advantages compared to the conventional fused deposition modeling machine. Having large workspace and more degrees of freedom, multi-plane printing is possible using the six-axis industrial robot. This eliminates the printing of support structures and saves material and time. The conventional fused deposition machine has the limitation of getting staircase effect while printing of curved surfaces. Curved tool paths can minimize this staircase effect. These curved tool paths can be generated by the robot, which is impossible by the conventional fused deposition machine. Adaptive printing can be done using different nozzle diameters to minimize the printing time and power consumption. The material being used in this process is thermoplastic material. It will solidify quickly within a fraction of seconds when it is exposed to the atmosphere. So it will stick to the previous layer when depositing is done in either horizontal or inclined planes. The material won’t drop if the correct parameters are chosen while printing over the inclined plane.

In conventional FDM machines, the horizontal base has to move in a vertically downward direction to build layer by layer and the base should possess high rigidity and strength while printing large-size components. Whereas printing with robot takes place by moving the extruder in vertically upward direction and no need to provide any robust support system and even sometimes robot can build the objects from the ground.

5 Conclusions

In this paper, a new procedure that combines both the additive manufacturing and robotics to print 3D objects is presented. A generalized procedure for 3D printing of objects using a robot is presented in this paper. The industrial robots having the capability to print the objects over entire workspace with high resolution and repeatability. Minimum support system for the printing base is required while printing with the industrial robots.

References

Gibson, I., Rosen, D.W., Stucker, B.: Additive Manufacturing Technologies. Springer (2010). ISBN: 978-1-4419-1119-3

Chee Kai, C., Kah Fai, L., Chu Sing, L.: Rapid Prototyping: Principles and Applications, 2nd edn. (2003). ISBN 981-238-117-1

Tsai, L.W.: Robot Analysis the Mechanics of Serial and Parallel Manipulators (1999)

Tse, W.C., Chen, Y.H.: A robotic system for rapid prototyping. In: Proceedings of the 1997 IEEE International Conference on Robotics and Automation, pp. 1815–1820 (1997)

Barnett, E., Gosselin, C.: Large-Scale 3D printing with a cable-suspended robot. Accepted manuscript Additive Manufacturing. Elsevier (2015)

Ishak, I., Larochelle, P.: Robot arm platform for rapid prototyping: Concept. In: Proceedings in Florida Conference on Recent Advances in Robotics, (2015)

Górski, F., Kuczko, W., Wichniarek, R.: Influence of process parameters on dimensional accuracy of parts manufactured using fused deposition modeling technology. Adv. Sci. Technol. Res. J. 7(19), 27–35 (2013)

Nancharaiah, T., Ranga Raju, D., Ramachandra Raju, V.: An experimental investigation on surface quality and dimensional accuracy of FDM component. Int. J. Emerg. Technol. 1(2), 106–111 (2010)

Swanson, M., Spurgeon, W., Vass, T., Danielewicz, M.: 3D printing robotic arm. Project report, Worcester Polytechnic Institute (2016)

Eragubi, M.: Slicing 3D CAD model in STL format and laser path. Int. J. Innov. Manag. Technol. 4(4) (2013)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sri Harsha, A., Vikram Kumar, C. (2020). Fused Deposition Modeling Using 6-Axis Industrial Robot. In: Shunmugam, M., Kanthababu, M. (eds) Advances in Additive Manufacturing and Joining. Lecture Notes on Multidisciplinary Industrial Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-32-9433-2_13

Download citation

DOI: https://doi.org/10.1007/978-981-32-9433-2_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-32-9432-5

Online ISBN: 978-981-32-9433-2

eBook Packages: EngineeringEngineering (R0)