Abstract

This study presents a mixed-method approach for the problem of supplier selection in the context of public procurement. A recent tender invited by BLW, a unit of Indian Railways producing ‘diesel-electric’ and electric locomotives for Indian Railways and export market for the propulsion system (the costliest and most important item in the assembly of the locomotive), has been considered in this work. Initially, the criteria for evaluation of vendors are identified through the survey of experts from Indian Railways, who are engaged in procurement for the organization. These criteria are used to calculate the inter-se ranking of the offers received against the procurement tender. For the purpose of evaluation, the weights of the attributes are calculated using the Analytic Hierarchy Process (AHP) by taking the inputs for relative comparison of the attributes from experts through a questionnaire-based survey. Then, the ranking of the offers, as well as the relative importance of offers, is calculated using the TOPSIS method. Further, a mixed-integer programming (MIP) problem has been formulated to ensure the optimal order allocation in the multi-sourcing environment with an objective of maximizing the total value of the purchase. The model is populated with constraints that limit the order quantity, like selection of suppliers, the order quantity, minimum order quantity, and minimum number of suppliers to be selected. Results of the case are presented considering various scenarios. As a result of the study, it has revealed that the multi-sourcing of the suppliers for a specific item in given situation has an additional penalty on the organization. The effective and optimal use of the resources can be ascertained with the help of the proposed study. The biggest advantage of the study is engagement of potential suppliers, evaluators, and the end user. Continual system improvement is additional and inherent advantage reaped through proposed model.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Supplier is the most important entity of any business and right selection of supplier is always a vital issue for the management. The selection of suppliers is a cumbersome process attempting to identify, and evaluate various parameters associated with supply chain and enter into agreement with suppliers for procurement of goods or service [1]. The appropriate supplier decision has long-term financial and strategic implications on the success of a business. The primary objective in the supply selection process is to make a purchase decision in a manner that all the challenges of supply chain management are effectively mitigated. Various risks associated with supplier’s performance such as cost of failure in supply chain and cost associated with quality of the product/service being purchased need to be taken care, while making decisions for supplier’s selection. In recent years, the business environment has undergone a fundamental change incorporating various factors (both internal and external) in the purchase process. Therefore, the criticality of the decision of supplier selection has become a point of concern in the business decision process.

Out of all the procurement practices employed in the business, public procurement is a special type of purchase exercise, where taxpayer’s money is used to purchase goods and services. By definition the public procurement is the purchase done by the government and state-owned enterprises of goods, services, and works. Public procurement is a necessary evil for any public agency or department. For the limited sectors where the government produces final goods and services like railways and defense, procurement of raw material is essentially vital. In fact, procurement of goods and services is the primary channel through which money is passed on to private hands. The procurement in this case is accomplished through taxpayers’ money and the high standards of conduct and impartial selection of the vendor become critical in ensuring high quality of services or goods being procured. That is why it is prone to misconduct and malpractices [2]. It is very frequently seen that the possibility of favoritism and manipulations thrives in the public procurements. The quality of the procurement is one of an inextricable area of leverage and possible misconducts and malpractices in public procurements. This makes the process of public procurement not only complex, but also marred with lack of transparency and technical inability for appropriate assessment of the quality of procurement. The complex environment and lack of responsibility have potential to promote the propensity for malpractices. Given all these factors in the play, the procurement decisions need to be taken with utmost care to prevent fraud, waste of money, corruption, or local protectionism. To prevent such possibilities, the government take numerous measures to ensure fairness in public procurement and the public procurement is regulated through various laws and regulations issued from time to time. These laws envisage procurement agencies to issue a public notice declaring the intention of the agencies to exercise the procurement process in an impartial manner and without any prejudice.

In public procurement the end user and the purchaser are usually different parties with different and even sometimes with conflicting priorities. The accountability of the procurement personnel is limited to the procurement exercise. Further, the parameters governing the procurement process and the ability of the suppliers are assessed by a different and unconnected agency. These factors influence the procurement process at basic level and develop tendencies for indulgence in compromises resulting in various complications in the entire process. Therefore, to avoid any biased to creep in, it demands a quantitative basis for the decision-making process which can be monitored, quantified, and improved as per the organizational goal. It calls for a systematic approach or a tailor-made decision support system to facilitate the supplier selection process. Present work is an attempt to develop such a support system for public procurement for one of the manufacturing units of Indian Railways to promote free and fair process with equal opportunity to every eligible supplier. This study proposes a mixed-method approach for the problem of supplier selection in the public procurement. In this study, we have solicited and incorporated the opinions of experts to identify the important criteria for supplier selection. To evaluate the weight of such identified criteria again a survey was conducted engaging experts from the field. AHP was applied for calculating the weights of these criteria identified in the survey. The weights so calculated are used with TOPSIS method to find the inter-se ranking of the offers received in response to a tender. Finally, a mix-integer linear program is used to decide the quantity to be placed on the firm, with compliance to government guidelines. Applicability of the proposed framework is demonstrated in the setting of procurement system of locomotive in Banaras Locomotive Works. Thus, we contribute to the practice of the supplier selection in public procurement. Although there are several studies that have adopted a mixed-method approach for supplier selection, to the best of our knowledge, this is the first attempt to do so for a very practical problem faced by the Indian Railways. The use of AHP, TOPSIS, and mixed Integer linear programming for solving complex problem with compliance to intricate Government’s policy is the novelty of this study.

The rest of the article is organized as follows. A review of the extant literature is presented in Section “Literature Review”. The problem description is given in Section “Problem Description”. Section “Optimization Program for Multi-supplier Selection Through Open Tender” contains the mathematical model for optimization of total value of the procurement. The procedure to calculate inter-se ranking of the offer and relative weight is given in Section “Estimating Relative Vendor Ranking”. A case study of the Banaras Locomotive Works is shown with experimental results in Section “The Case Study”. Finally, Section “Conclusions” concludes the work.

Literature Review

Supplier selection has always been a topic of interest and a crucial decision parameter in supply chain decisions. The research on various aspects of supplier selection can be traced back to the early 1960s. This literature was summarized by Weber et al. [3]. Ghodsypour and O’Brien [4] have provided insightful research in supplier selection. Karpak et al. [5] discussed one of the ‘user-friendly’ alternative multiple criteria decision support systems—visual interactive goal programming (VIG). Nag [6] has examined issues, such as organizational structure, procurement organization, source selection methodology, procurement oversight and regulation and their impact on the economy, efficiency, transparency, and accountability aspects of procurement in Indian Railways. Various studies have been conducted to identify and include various parameters for supplier selection in different situations. Abdolshah [7] has presented a review of decision criteria reported in the literature for supporting the supplier selection process. Ellram [8] has studied the situation where the firm is considering partnership type of the relation. They have developed four categories of the factors for evaluating the supplier’s potential. Goffin et al. [9] have stated that supplier management is one of the key issues of supply chain management because the cost of raw materials and component parts constitutes the main cost of a product and most of the firms must spend a considerable amount of their sales revenues on purchasing. Kilincci and Onal [10] have noticed that the selection is the one of the most significant decisions in the supply chain. For selection methodology, there have been numerous studies conducted on various areas. Ghobadian et al. [11] have proposed a computer-based vendor rating system. Segura and Maroto [12] have proposed a multiple criteria supplier segmentation using outranking and value function methods. An expert Systems with Applications was proposed by An et al. [13]. Önüt et al. [14] has proposed an analytical approach to supplier selection and used AHP as a selection tool. Deng et al. [15] have proposed supplier selection using AHP methodology extended by D numbers (D-AHP). Dweiri et al. [16] have designed a decision support system for supplier selection using AHP for the automotive industry in developing countries. Similarly, Önüt et al. [17] have used combined ANP and TOPSIS for long-term supplier selection problem in telecommunication company in GSM sector under the fuzzy environment where vagueness and subjectivity are handled with linguistic terms parameterized by triangular fuzzy numbers. Liao and Kao [18] proposed integrated fuzzy techniques for order similarity to ideal solution, TOPSIS and Multi-choice goal programming approach to solve supplier selection problem. A Fuzzy-Racsh-based COPRAS-G method was proposed by Chatterjee and Kar [19] for supplier selection in telecom industry. Multi-criteria analysis of supply chain risk management using interval valued fuzzy TOPSIS was proposed by [20]. Extension of TOPSIS and VIKOR methods was proposed by Si et al. [21]. Sharma et al. [22] have used multi-criteria decision-making techniques for prioritizing stations of Indian Railways. A Delphi-AHP TOPSIS-based framework for prioritization of intellectual capital indicators was proposed by Sekhar et al. [23]. Ramos et al. [24] propose to apply a multi-criteria decision model based on the FAHP (Fuzzy Analytic Hierarchy Process) method for the selection of suppliers in a food company. Polat [25] has used AHP and PROMETHEE for selection of subcontractors in an international project. Mohanty and Mohanty [26] have proposed an efficient hybrid model for selection of best car models. The hybrid model constitutes Fuzzy AHP and PROMETHEE II techniques as both are best MCDM techniques for solving decision problems efficiently and economically. Kubt [27] has proposed a model for supplier selection using genetic algorithms and fuzzy-AHP. The proposed work is inspired from the various works cited above.

However, it is distinct from them in the following ways. (1) The criteria for evaluation have been identified after consultation from the experienced personnel having wide experience of procurement and technical evaluation of tender offers. (2) The calculation of the weights for these identified criteria is also done through surveys engaging the expert in the field of public procurement. (3) The study offers a mixed-integer program through which various regulations and guidelines form the government from time to time can be complied. Additionally, (4) It offers insight into the implications of various guidelines and their application cost on the procurement agencies. Therefore, the study may also be used as a tool for decision-making on application of various rules and ability to tweak the decision based on the mathematical model and helps in making informed decisions.

Problem Description

These challenges of free and fair procurement to ensure the best quality and genuine suppliers are always uphill task for the government agencies. These challenges become more pronounced for the simple reason of a non-incentivized procurement system for the persons engaged in procurement. The current system is marred with the lack of administrative capacity to handle these challenges. In practice while evaluating the offer, various methods are adopted such as Quality-Based Selection, Quality-Cost-Based Selection, and Least Cost Selection [28]. The least cost selection is the most popularly adopted method for general finalization of the tender called for procurement of goods and services. In recent years, the systems of procurement have been improved by incorporating concepts of vendor approval based on technical ability and capacity/capability assessments done by authorized agencies [6]. But this concept also inherits certain drawbacks and is crippled with its susceptibility for human judgments and manipulations to favor one or another supplier. Quantification of the subjective responses like numbers of failures, post-supply performance, and warranty obligation, while evaluating technical capability of the firm, have always been the bone of contention. The subjectivity has always manifested itself through compromise on the quality of the procurement or with the ability of the suppliers to dominate the process by finding a path to circumvent the rules and procedures. The parties involved in the process including supplier and the rating agencies evaluating the vendors, also have their limitations, on ability to distinguish the fine variations of the parameters in consideration. Other methods for ensuring free procurement of goods and services adopted in recent years are two packet systems and reverse auction systems, Indian [29]. These systems are effectively being used to ensure the targeted procurement with transparent methods to effect the best quality purchase. However, in both systems technical assessment and final decision for placing order to specific vendor depend on the human judgment. In many cases, decisions have been challenged through litigations and legal battles ensued. In certain cases, the concerned authorities have been subjected to legal scrutiny and derision. The subjectivity of technical evaluations and the inability to translate the technical parameters in quantifiable data have always been a question. However, it is noticed in recent years that the use of technology has proved to be an effective business tool which has improved performance, productivity, and effectiveness. But, the greatest challenge in adopting and implementing technological advancement includes preference of procurement personnel for legacy systems, issues in change management, and distrust on the ability of technological implementations. The intricacies of the latest systems and lack of opportunity to adopt the technological tools only aid in disregarding the utilization of the same. This necessitates a decision support system that will assist the supplier selection and order allocation in the public procurement.

In this work, we are proposing a mathematical model for optimization of intended procurement and its value with no human intervention. Wherever any human judgment is employed in the process of evaluation, it is collection of many individuals’ judgments clubbed together with the idea to minimize individual influence on the final decision outcome to ensure free fair procurement. The proposed optimization program is presented in the next section.

Optimization Program for Multi-supplier Selection Through Open Tender

Sets and indices

- \(I\) :

-

Set of Suppliers indexed by i.

Parameters

- \(V_{i}\) :

-

The capacity of the ith supplier indexed by \(i\).

- \(R_{i}\) :

-

The rating of the supplier indexed by \(i\).

- D :

-

The demand for the item being procured.

- n :

-

Minimum number of suppliers to be selected.

- \(\alpha\) :

-

Limit for minimum order quantity.

- M :

-

A large positive number.

Decision Variable

- \({\text{X}}_{{\text{i}}}\) :

-

The Quantity of the order placed to \(i{\text{th}}\) Supplier.

Model

Objective Functions

Constrains

The Objective function maximizes the total value of purchase. Constraint (6.2) ensures that total order quantity allotted to suppliers must meet the total demand of the item. Constraint (6.3) is to ascertain that order allocation to a supplier is possible only if the supplier is selected. Constrain (6.4) ensures the compliance of the regulation that in the case the order is placed on the firm, it should be above a certain percent \((\alpha )\) of the total tender quantity. In this study, we have assumed the minimum limit to be 10% and it varies from organization to organization. Constraint (6.5) restricts the order allocation with respect to supplier capacity. Constraint (6.6) is requirement imposed to promote the competition and avoid the eventual crises in case of the supplier’s inability to supply owing to their internal or external factors. This number of minimum vendors for the item can be strategically decided by the procuring agency taking various parameters in consideration. Constraint (6.7) imposes the limit on the integrality of the distribution as in most of the cases a fraction of item is not desired and in certain cases it is not possible to purchase a part product. Constraint (6.8) indicates the nature of the decision variable.

Estimating Relative Vendor Ranking

Identification of the Criteria for Vendor Evaluation

The model presented in this work uses the criteria identified for selection of vendors through consultation and survey of the all-possible criteria for evaluation of performance of the vendor in respect of a single item already supplied to the procuring agency in the past. In fact, interrelation between the criteria identified should encompass all the performance parameters that the purchasing firm is expecting from the supplier. In practice they make a list of suppliers who are approved based on technical ability and continuous evaluation is done to keep the performance under check. However, there is always a subjective discretion available with decision-makers particularly in a situation where the difference in various evolutionary parameters is insignificant. The quantifiable attributes in such situations are ignored and the decision process becomes prone to favoritisms.

For identification of most relevant parameters governing the overall performance of a vendor, a survey was conducted among the officers of government of India who are engaged in purchase activity and in technical evaluation of the bid received through tender.

These evaluation criteria are:

-

A1. Cost of the item being offered by the vendor.

-

A2. In service failure of the item per unit item already in service.

-

A3. ‘On time Delivery’ performance of the vendor in the past orders.

-

A4. Compliance of warranty obligation and post-delivery performance of the vendor.

Calculation of Weightage of Criteria

In our study, the ranking of the vendor is calculated in terms of these parameters and their contribution on actual values of the attributes. These attributes are gathered from the literature and further refined to fit into the context by a survey.

The attributes listed above are used to calculate the inter-se ranking of the offers received against the procurement tender. We first calculate the weights of the attributes using the Analytic Hierarchy Process (AHP) proposed by [30]. The inputs (for relative comparison of the attributes) are taken from the experts through a questionnaires-based survey. The subjective judgments of the officers are quantified using a linear scale suggested by [31] to calculate weights of the attributes. The eigenvalue method of AHP is used for calculating the individual weights given by the experts. The individual weights are then aggregated to obtain final normalized weights for attributes. The weights obtained for criteria A1, A2, A3, and A4 using AHP are 0.41268955, 0.38512504, 0.11817148, and 0.084014, respectively.

Calculation of Relative Ranking and Absolute Values for Vendor Performance on Offer

In the next step, the data is the collection of data through the offers (quotations) received and normalization. Each element of the normalized decision matrix is multiplied by the weight of criteria obtained using AHP to obtain the weighted normalized decision matrix. Having calculated the weighted normalized decision matrix, the ranking of the vendor’s offers, as well as the relative quantity of importance of offers, needs to be calculated. For this purpose, we use a multi-attribute decision-making technique—‘Techniques for Order of Preference Similarity to the Ideal Solution’ abbreviated as TOPSIS originally proposed by [32]. The steps of the TOPSIS method are described as calculation of the Zenith (an Ideal point) and Nadir (anti-ideal point) points for each criterion, calculating the distance for each criterion point to Zenith and Nadir points and calculation of the relative closeness coefficient, i.e., importance indexes are followed as reported in the literature [32].

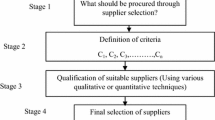

The final ranking and the relative importance for case in consideration are depicted in Table 6.4. A summary of overall procedure is presented in Fig. 6.1.

The Case Study

Case Description and Numeric Problem

The data for the case study has been collected form the recent tender invited by Banaras locomotive works, a unit of Indian Railways producing diesel and electric locomotives for Indian Railways and for export market. The item under study is an extremely critical item, i.e., the propulsion system which is the brain and heart of the locomotive. It is the costliest item in the complete assembly of the locomotive and costs around 20% of the total cost of the locomotive. The propulsion system is a technically complex and intricate item where firms with high caliber and proven track records are permitted to participate in the bid. The item is used with both goods and passenger locomotives. Therefore, the importance of the item is further multiplied because it impacts the safety of passengers. The propulsion system controls the functioning of complete operation and performance of the locomotive, including the braking system.

At present the supplier selection is based on the vendor directory methods, where suppliers are evaluated and enlisted as potential source for specific item, if they are found technically competent to produce the item [33]. The registration in the vendor directory is done only after successful completion of development, testing, and completion of mandatory trial without any major technical problem. Once registered, the supplier is groomed with hand-holding to bring the quality and capability to the level of expectation of Indian Railways by providing partial order for pre-defined developmental quantity. Many times, a separate tender is also called to promote more vendors for specific items where the number of approved suppliers is less than a certain number stipulated in the policy. However, there are constant disputes about the deliberations on various evaluation parameters and the procedure of evaluation of the vendors. For instance, the evaluation criterion of ‘On Time Delivery’ is seriously debatable. Though the vendors are penalized for delay in supplying the item, the fine is not commensurate with the consequential cost the organization has to bear for the delay. Further, the delay in supply is completely ignored while evaluating the performance of the vendor on other technical parameters. So, the criteria become a disincentive to the vendors, who are sincere and partnering with the organization at a cost to produce and deliver the items as per schedule of supply. The criteria like this are quantified in above study and evaluation is made considering the relative importance of the criteria as already explained in item no 3. Indian Railways is one of the world’s largest public sector organizations, and it is the world’s third largest railroad network under a single administration. It is the world’s second largest railway passenger transport organization, carrying 7 billion passengers annually. It produces around 650 locomotives annually at its two manufacturing units at Chittaranjan and Varanasi. The total worth of this single item and its criticality is enough testimony for various possibilities of compromises in public procurement. The indicative data is selected for the purpose of study and to demonstrate the applicability of the concept proposed in this paper (Table 6.1).

The offer received and the data collected

For calculation of weights Analytic Hierarchy Process (AHP) is used with eigenvalue method as explained in Section “Calculation of Weightage of Criteria”. The weights obtained for criteria A1, A2, A3, and A4 using AHP are 0.41268955, 0.38512504, 0.11817148, and 0.084014.

Calculation of Rank Through TOPSIS

-

a.

Normalization of the metrics

The performance, i.e., the actual data against each attribute criteria needs to be normalized in order to be able to compare the measure on the different units, e.g., cost in Cr. Rupees and failure are per unit items in service. The most popular method for normalization is the distributive normalization. In this method, the performances are divided by the square root of the sum of each squared element in a column (Table 6.2).

-

b.

Calculation of Nadir and zenith points from weightage normalized metrics. Weighted normalized matrix is obtained by multiplying the weights in each element of a column. These weighted scores will be used to compare each option to an ideal and anti-ideal option in the matrix (Table 6.3).

Table 6.3 Weighted normalized matrix Table 6.4 Closeness coefficient and ranking of the offers

-

c.

Collect the data of the best and worst performance on every criterion of the normalized decision matrix. For the ideal performance we have

$$ X^{ + } = \left( {v_{1}^{ + } ,v_{2}^{2} \ldots \ldots \ldots \ldots \ldots v_{m}^{ + } } \right) $$where \(v_{i}^{ + } = \mathop {\max }\limits_{a} \left( {v_{ai} } \right) \), if the criterion is to be maximized and \(v_{i}^{ + } = \mathop {\min }\limits_{a} \left( {V_{ia} } \right)\), if the criterion is to be minimized.

-

d.

The distance for each performance to the ideal action.

$$ d_{a}^{ + } = \sqrt {\left( {v_{i}^{ + } - v_{ia} } \right)^{2} } ,\quad a = 1 \ldots , \, m $$For the anti-ideal or zenith points

$$ d_{i}^{ - } = \sqrt {\left( {v_{i}^{ - } - v_{ia} } \right)^{2} } ,\quad a = \, 1 \ldots m $$ -

e.

Calculate the relative closeness of each performance:

The closeness coefficient is always between 0 and 1, where 1 is the preferred performance. If a performance is closer to the ideal than the anti-ideal, then \(c_{a}\) approaches 1 and if the performance is closer to the anti-ideal then to the ideal, \( c_{a}\) approaches 0.

The relative values are taken as the indication of measures of performance of offer on various attributes (Table 6.4).

Result Discussion and Analysis

In the case of public procurement, the government issues instructions from time to time to promote multi-sourcing to discourage monopoly and encourage fair competition among the bidders. Therefore, the problem becomes complex while deciding the quantity of the orders to be placed on any firm to maximize the purchase value and promote the firms with equal opportunity to ensure compliance of the government’s guidelines. The quantity of the procurement made in public procurement is also so large that it is normally not feasible for a single firm to supply the entire demand quantity. In our study, we have assumed both the situation and tried to demonstrate various possibilities in the case when the firm is competent to supply the complete demand or otherwise, with possible variations in the minimum numbers of the suppliers on which orders can be placed. ‘n’ is the number of suppliers on which the orders are finally placed in accordance with government guidelines or else to promote competition among the suppliers.

Scenario I

In case the capacity of all the suppliers is higher than the demand, the production capacity as quoted against the tender say 370 in this case.

Scenario II

In case the capacity of the suppliers is less than the demand. In above example, the capacity is assumed to be as mentioned in Table 6.5 (Fig. 6.2; Table 6.6).

Conclusions

From above discussion in both the scenarios where the supplier is either able to supply the desired quantity or not, the impact of variation of the number of suppliers is seen till the number is limited to 3. The best results are found for the cases where the suppliers are not able to fulfill the requirement and the number of orders is limited to 2 vendors. The objective value remains same for a single supplier and two supplier’s scenario and deteriorates sharply afterward. To promote competition and fair practice in procurement, multi-sourcing is a proven tool in the supply chain. However, the study indicates that multi-sourcing has an associated cost and compromises need to be made to support it. The benefits of multi-sourcing are obviously proven to be overriding the marginal penalty which this program reflects to be making while selecting more than one vendor.

In real-life practice, multi-sourcing is not only a tool but also a compulsion to be accepted because of the size of the procurement by the public sector. The compromise being indicated in the study can be used as guiding tool for the policy-makers, while deciding the policy framework for multi-sourcing. The study may be quite insightful for the suppliers also, if their performance data is shared with them. The data-driven decision by supplies may also encourage improvement in performance on various parameters as indicated.

The study is an insightful exercise because it reveals the inability of procurement agencies to account for the associate performance of the firm like warranty obligation, on time delivery of the item, etc. These performance measures certainly have a cost implication for the suppliers, who tends to cut corners on the quality front to save money. Disregarding these indicators is proved to be a potential compromise. The results show that the application of a structured decision-making technique is vital, especially under the complex conditions that include both qualitative and quantitative criteria. The study is applicable in various fields of procurement and government agencies. The model can be used as the foundation for the development of complete support software for decision-making, eliminating or minimizing the human interventions in the procurement process. This way other related menaces in the system can be minimized ensuring saving on public money and best quality of procurement.

Future Research

This study further reveals that the weights associated with the parameters are critical in nature and detailed study on the impact of the variation of the weights on decision needs to be studied. In this study, the optimization program section offers the handy tool to accommodate and implement the government’s rules and guidelines issued from time to time. The linear program has potential to be improved for more pragmatic situations, where running evaluation of multi-item through multi-vendor offers can be incorporated as future study.

As the potential of future extension of the study, sensitivity analysis of various factors such as weights associated may be conducted to find out the robustness of the support system being proposed through this study. Similarly, the sensitivity analysis of the various factors being considered may also be done to prove the impact of individual factors on overall performance of the vendor in specific tender offered, which can also act as advisory tool for the vendor to understand the focus performance area in the offer to remain competitive with respect to the other offers.

References

Taherdoost, H., & Brard, A. (2019). Analyzing the process of supplier selection criteria and methods. Procedia Manufacturing, 32, 1024–1034. https://doi.org/10.1016/j.promfg.2019.02.317

Lenderink, B., Halman, J. I. M., & Voordijk, H. (2019). Innovation and public procurement: From fragmentation to synthesis on concepts, rationales and approaches. Innovation, 1610. https://doi.org/10.1080/13511610.2019.1700101

Weber, C. A., Current, J. R., & Benton, W. C. (1991). Vendor selection criteria and methods. European Journal of Operational Research, 50(1), 2–18. https://doi.org/10.1016/0377-2217(91)90033-R

Ghodsypour, S. H., & O’Brien, C. (1998). A decision support system for supplier selection using an integrated analytic hierarchy process and linear programming. International Journal of Production Economics, 56–57, 199–212. https://doi.org/10.1016/S0925-5273(97)00009-1

Karpak, B., Kumcu, E., & Kasuganti, R. R. (2001). Purchasing materials in the supply chain: managing a multi-objective task. European Journal of Purchasing and Supply Management, 7(3), 209–216. https://doi.org/10.1016/S0969-7012(01)00002-8

Nag, B. (2012). Public procurement: a case study of the Indian railways. MPRA Paper

Abdolshah, M. (2013). A review of quality criteria supporting supplier selection. Journal of Quality and Reliability Engineering, 2013. https://doi.org/10.1155/2013/621073

Ellram, L. M. (1990). The supplier selection decision in strategic partnerships. Journal of Purchasing and Materials Management, 26(4), 8–14. https://doi.org/10.1111/j.1745-493x.1990.tb00515.x

Goffin, K., Marek, S., & New, C. (1997). Managing suppliers: When fewer can mean more. International Journal of Physical Distribution and Logistics Management, 27(7), 422–436

Kilincci, O., & Onal, S. A. (2011). Fuzzy AHP approach for supplier selection in a washing machine company. Expert Systems with Applications, 38(8), 9656–9664. https://doi.org/10.1016/j.eswa.2011.01.159

Ghobadian, A., Stainer, A., Liu, J., & Kiss, T. (2016). A computerised vendor rating system. Developments in Logistics and Supply Chain Management, 103–112. https://doi.org/10.1057/9781137541253_10

Segura, M., & Maroto, C. (2017). A multiple criteria supplier segmentation using outranking and value function methods. Expert Systems with Applications, 69, 87–100. https://doi.org/10.1016/j.eswa.2016.10.031

An, M., Qin, Y., Jia, L. M., & Chen, Y. (2016). Aggregation of group fuzzy risk information in the railway risk decision making process. Safety Science, 82, 18–28. https://doi.org/10.1016/j.ssci.2015.08.011

Narasimhan, R. (1983). An analytical approach to supplier selection. Journal of Purchasing and Materials Management, 19(4), 27–32. https://doi.org/10.1111/j.1745-493x.1983.tb00092.x

Deng, X., Hu, Y., Deng, Y., & Mahadevan, S. (2014). Supplier selection using AHP methodology extended by D numbers. Expert Systems with Applications, 41(1), 156–167. https://doi.org/10.1016/j.eswa.2013.07.018

Dweiri, F., Kumar, S., Khan, S. A., & Jain, V. (2016). Designing an integrated AHP based decision support system for supplier selection in automotive industry. Expert Systems with Applications, 62, 273–283. https://doi.org/10.1016/j.eswa.2016.06.030

Önüt, S., Selin S. K., & Elif I. (2009). Long term supplier selection using a combined fuzzy MCDM approach: A case study for a telecommunication company. Expert Systems with Applications, 36(2 PART 2), 3887–3895. https://doi.org/10.1016/j.eswa.2008.02.045

Liao, C. N., & Kao, H. P. (2011). An integrated fuzzy TOPSIS and MCGP approach to supplier selection in supply chain management. Expert Systems with Applications, 38(9), 10803–10811. https://doi.org/10.1016/j.eswa.2011.02.031

Chatterjee, K., & Kar, S. (2018). Supplier selection in telecom supply chain management: A fuzzy-rasch based COPRAS-G method. Technological and Economic Development of Economy, 24(2), 765–791. https://doi.org/10.3846/20294913.2017.1295289

Chatterjee, K., & Kar, S. (2016). Multi-criteria analysis of supply chain risk management using interval valued fuzzy TOPSIS. Opsearch, 53(3), 474–499. https://doi.org/10.1007/s12597-015-0241-6

Si, A., Das, S., Kar, S. (2020). Extension of TOPSIS and VIKOR methods for decision-making probelm with picture fuzzy number. Advances in Intelligent Systems and Computing, 1112. https://doi.org/10.1007/978-981-15-2188-1_20

Sharma, H. K., Roy, J., Kar, S., & Prentkovskis, O. (2018). Multi criteria evaluation framework for prioritizing indian railway stations using modified rough AHP-Mabac method. Transport and Telecommunication, 19(2), 113–127. https://doi.org/10.2478/ttj-2018-0010

Sekhar, C., Patwardhan, M., & Vyas, V. (2015). A delphi-AHP-TOPSIS based framework for the prioritization of intellectual capital indicators: A SMEs perspective. Procedia—Social and Behavioral Sciences, 189, 275–284. https://doi.org/10.1016/j.sbspro.2015.03.223

Ramos, M. O., Rodrigues, F., Junior, L. (2019). Suppliers selection model based on FAHP method : A case study in the food supply chain

Polat, G. (2016). Subcontractor selection using the integration of the AHP and PROMETHEE methods. Journal of Civil Engineering and Management, 22(8), 1042–1054. https://doi.org/10.3846/13923730.2014.948910

Mohanty, S., & Mohanty, S. (2018). An efficient hybrid MCDM based approach for car selection in automobile industry. In Proceedings of the 2018 3rd IEEE international conference on research in intelligent and computing in engineering, RICE 2018, no. Promethee (pp. 1–5). https://doi.org/10.1109/RICE.2018.8509053

Kubt, C., Yuce, B. (2006). Supplier selection with genetic algorithm and fuzzy AHP. In Proceedings of 5th international symposium on intelligent manufacturing systems (pp. 1382–1401)

Kumar, R. (2010). Supplier selection criteria—an overview

Indian Railways (2019). Guidelines_ReverseAuction_18102019.Pdf. file:///C:/Users/DELL/Desktop/RS(M)_Guidelines_ReverseAuction_18102019.pdf

Saaty, T. L. (1990). How to make a decision: The analytic hierarchy process. European Journal of Operational Research, 48(1), 9–26. https://doi.org/10.1016/0377-2217(90)90057-I

Saaty, T. L. (1977). A scaling method for priorities in hierarchical structures. Journal of Mathematical Psychology, 15(3), 234–281. https://doi.org/10.1016/0022-2496(77)90033-5

Lai, Y. J., Liu, T. Y., & Hwang, C. L. (1994). TOPSIS for MODM. European Journal of Operational Research, 76(3), 486–500. https://doi.org/10.1016/0377-2217(94)90282-8

Banaras Locomotive Works (2021). 2021

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Tripathi, G., Tanksale, A.N. (2023). A Decision Support System for Supplier Selection in Public Procurement: A Case of Banaras Locomotive Works, Varanasi. In: Gunasekaran, A., Sharma, J.K., Kar, S. (eds) Applications of Operational Research in Business and Industries. Lecture Notes in Operations Research. Springer, Singapore. https://doi.org/10.1007/978-981-19-8012-1_6

Download citation

DOI: https://doi.org/10.1007/978-981-19-8012-1_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-8011-4

Online ISBN: 978-981-19-8012-1

eBook Packages: Business and ManagementBusiness and Management (R0)