Abstract

In case of sheet metal blanking, inadequate trimmed condition of such a blanked material may produce fit concerns in the assembly. Cracks may form due to uneven surfaces, leading to a loss of exterior smoothing and improved efficacy. Four underlying parameters are selected after punching: shear angle, punch penetration, burr height, fracture angle as decision-making input parameters to measure quality of clean-cut surface. The fracture depth is determined by gradually increasing the punch penetration. Experiments are conducted with uni-punch tool on the power press, and sheet metal material is IS277GI. This research aims to assess the cut surface quality using surface roughness value, which is categorized into three groups. To measure the efficiency of the cut surface, a classification model is developed adopting the machine learning decision tree classifier technique. The model's reliability is 93% of the Gini and Entropy index.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The metal forming business is facing challenges worldwide due to new materials and processing processes. Because the process necessitates the employment of several resources, a computerized method for assessing the blanking procedure is required. Improved approaches for studying the behavior of the sheet metal forming sector are in high demand.

Automation is required to increase production. Given the automation level, deploying software applications in the sheet metal processing industry is advantageous. Different sensing techniques for fault diagnosis and the re-use of damaged component replace systems rapidly appearing as automation develops. However, a suitable process model is required to manage the complexity of sheet metal.

The next industrial revolution is being ushered in by advancements in automation. There has been growing research in sensing systems for defect detection and identifying significant parameters. The intricacy of the sheet metal working method, on the other hand, makes building a self-learning model challenging. With advent of mechanization, the industrial positioning in assessing defect is rapidly moving toward developing self-sustained systems. However, a suitable process model is required to manage the complexity of sheet metal processing.

While studying the process parameters in machining, research is conducted utilizing ANN modeling to increase the precision of intellectual structures [14, 21, 23] and as well as sheet metal blanking [11, 16, 17, 19]. The approach has been influenced by sheet thickness and tool wear [6, 7].

Classification model is proposed using decision tree modeling in current work, for IS277GI material for predicting fracture surface quality.

2 Literature Review

2.1 Blanking Process Setup

The process model of blanking consists of blanking die, sheet metal, blank holder, and punch as shown in Fig. 1. Suitable clearance is selected between blank and punch for obtaining smooth fracture surface. A punch with velocity shears the work-piece placed between blank holder and die. In this way, a slug, called blank, separates from the work-piece.

Blanking procedure system [18]

Figure 2 depicts blank part after shearing and the clean-cut surface. Strain at rupture is the most crucial element in determining when a fracture will begin and the propagation circumstances. From the inside die corner to the punch corner, a fracture line develops as a result of shearing. As per literature, the clearance is defined in terms of percentage of sheet thickness. Figure 3 shows mechanism of metal fracture at punch and die. Smooth sheared surface is obtained when the crack path joins the fracture line.

Slug work-piece [18]

Diagonal fracture line diagram [16]

The previous studies on clearance identification for sheet metal employed FEM [9, 11] and FEM simulation findings were consistent with experimental investigations. They concluded that surface roughness improves when the cracks beginning at the punch and die coincides [9]. However, punch velocity and heat production during processing have a significant role on metal behavior [16]. Investigations were done into how the punch geometry affected the features of the cut surface and the cutting forces [21].

where Dm—die diameter, Dp—punch diameter, t—sheet thickness.

ANN is powerful methodology for studying the behavior of the turning process [12, 23], as well as the bending of sheet metal [3, 23]. The simulated system uses an algorithm that replaces the conventional judgment system. The NN is chosen to construct suitable model for predicting optimal punch-die clearance. A backpropagation neural network was used for the prediction of optimal clearance [16,17,18]. The data on experimental fracture angles was utilized to train the algorithm, and model is developed for a given data. While assessing the defects in sheet metal forming, [5] uses a CART, MLP, SVM, RF techniques for predicting the coil back, and utmost thinning result achieved the accurateness varying from 87.39 to 94.98%.

2.2 Decision Tree Classifier (DTC)

The decision tree (DT) algorithm is a supervised machine learning technique to solve classification and regression problems. This approach aims to develop a model that predicts the value of a targeted variable; for that, the decision tree solves the issue using the tree representation, where the leaf node belongs to a class label, and characteristics are expressed on the inner node of the tree. A classification strategy continually separates data using decision rules. Data is classified at each node for optimization of decision-making for information gain:

where N represents the total number of data points for node j, n represents the number of data points for node j of the expected class, D represents node values, and H represents impurities [5]. The formula for impurity Gini Index is as follows:

where pi share of sample for node.

where pi—the proportion node fitting to a class [2]. If all node samples are of the same kind, then entropy is zero. This step is followed until the same label remains in a sample from each terminating node. A stop condition can also be established to avoid over fitting.

3 Methodology

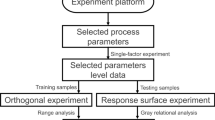

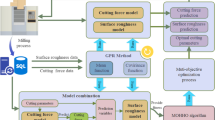

For investigating the quality of surface, decision tree classifier is employed. The independent factors dependent, and categorical variable is chosen. Figure 4 depicts a correlation analysis using Python code to investigate the association between the independent variables through heat map generation.

The control factors are derived though literature and total of 140 data points (training and testing) and 42 (validation) data points. This study develops a DTC model by splitting data: 70% for training and 30% for testing. An estimator with a variable maximum depth is used to train the resulting model, while parameter adjustment is applied. At the depth of 5, we obtained highest accuracy for accuracy measurements in terms of training and testing, recall, precision, f1-score, and confusion matrix. At each node, we employed Gini and Entropy as impurity indices, with a maximum depth of 5 and minimum sample leaf 5. The research flowchart is shown in Fig. 5.

During training phase, progressive categorization of samples and visualization of the decision tree is developed using Python code for the detailed functioning of the Gini and progressive calculation Entropy indexes.

Figure 6 shows gradual classification of samples based on Gini index, and Fig. 7 shows iterative steps till samples are classified based on entropy.

The outcome of classification is approved if the validation (experimental) provides consistent results; the findings are directed to the DTC model training and testing for parametric optimization.

4 Discussion and Result

Experiments are carried out for blanking operation using power press with a punch (hallow circular). Table 1 displays the input parameter and properties of ‘IS277GI’ for the experiment. Engineering strain and real strain are calculated using material characteristics [5].

We trained the DTC model using the Gini and Entropy index of impurity criterion, and both models obtained 93% accuracy. Figure 8 depicts a comparison of prediction performance with various classes.

Confusion matrix is an another approach employed for measuring the accuracy of model as shown in Fig. 9, to validate the performance of DTC model. During the testing phase, class 3 has all of its sample points properly identified; however, classes have a deviance of sample points (one and two).

One more performance measure for the model is receiver operating characteristic (ROC), which presents graphically performance of classification. Two variations are plotted: the true positive rate (TPR) and the false positive rate (FPR), as shown in Fig. 10. The probability for the ROC curve of class 2 is 0.85, which is less than the probability for classes 1 and 3, which are 0.93 and 0.92, respectively.

5 Conclusion

The machine learning approach (decision tree classifier method) is used to estimate quality of the fracture surface. The result shows that punch penetration has a direct impact on burr height creation and surface roughness. When employing DTC, we discovered that both the Gini as well as Entropy index impurities provide precise model correctness for the training, testing, and validation sets. The precision metric for class one is 1, whereas the recall measure for class two is 1. With k-fold cross-validation, additional sample points would imply greater model accuracy. Other classification models, such as support vector machines and random forest, can also be investigated using the significant data points.

Current study provides sheet metal production engineers with a decision-making solution for selecting the underlying factors for calculating precision for right fit requirement for processing IS277GI.

References

Bautista-Monsalve F, García-Sevilla F, Miguel V, Naranjo J, Manjabacas MC (2021) A novel machine-learning-based procedure to determine the surface finish quality of titanium alloy parts obtained by heat assisted single point incremental forming. Metals 11(8):1287

Cheng PJ, Lin SC (2000) Using neural networks to predict bending angle of sheet metal formed by laser. Int J Mach Tools Manuf 40(8):1185–1197

Dib M, Ribeiro B, Prates P (2018) Model prediction of defects in sheet metal forming processes. In: International conference on engineering applications of neural networks. Springer, Cham, pp 169–180

Djavanroodi F, Pirgholi A, Derakhshani E (2010) FEM and ANN analysis in fine-blanking process. Mater Manuf Process 25(8):864–872

Faura F, Lopez J, Sanes J (1997) Criterion for tool wear limitation on blanking 18–8 stainless steel strips. Rev Metal 33(5):304–310

Fang G, Zeng P, Lou L (2002) Finite element simulation of the effect of clearance on the forming quality in the blanking process. J Mater Process Technol 122(2–3):249–254

Hambli R (2005) Optimization of blanking processes using neural network simulation. Arab J Sci Eng 30(1):3–16

Hernández JJ, Franco P, Estrems M, Faura F (2006) Modelling and experimental analysis of the effects of tool wear on form errors in stainless steel blanking. J Mater Process Technol 180(1–3):143–150

Lee BY, Tarng YS (2000) Cutting-parameter selection for maximizing production rate or minimizing production cost in multistage turning operations. J Mater Process Technol 105(1–2):61–66

Mackensen A, Golle M, Golle R, Hoffmann H (2010) Experimental investigation of the cutting force reduction during the blanking operation of AHSS sheet materials. CIRP Ann 59(1):283–286

Maiti SK, Ambekar AA, Singh UP, Date PP, Narasimhan K (2000) Assessment of the influence of some process parameters on sheet metal blanking. J Mater Process Technol 102(1–3):249–256

Mia M, Dhar NR (2016) Response surface and neural network based predictive models of cutting temperature in hard turning. J Adv Res 7(6):1035–1044

Onwubolu GC, Buryan P, Lemke F (2008) Modeling tool wear in end-milling using enhanced GMDH learning networks. Int J Adv Manuf Technol 39(11):1080–1092

Özel T, Karpat Y (2005) Predictive modeling of surface roughness and tool wear in hard turning using regression and neural networks. Int J Mach Tools Manuf 45(4–5):467–479

Patil VP, Patil PP, Ingale NE (2019) Experimental investigations of optimum sheet metal blanking clearance for IS2062 HR steel using artificial neural network (ANN). In: 2019 9th annual information technology, electromechanical engineering and microelectronics conference (IEMECON). IEEE, pp 12–16

Patil PP, Patil VP, Ramaswamy R (2020) Prediction of optimum sheet metal blanking clearance for IS513CR steel using artificial neural network. In: Proceedings of international conference on intelligent manufacturing and automation. Springer, Singapore, pp 221–230

Patil P, Patil V, Date H, Nehete R (2021) Investigation of blanking clearance for IS277GI by artificial neural network (ANN). In: 2021 4th Biennial international conference on Nascent technologies in engineering (ICNTE). IEEE, pp 1–6

Patill V, Patil P, Ingale N, Date H (2021) Methodology for identification of quality of clean-cut surface for IS2062HR sheet metal blanking using random forest. In: 2021 5th conference on information and communication technology (CICT), IEEE, pp 1–5

Ranganathan A (2004) The levenberg-Marquardt algorithm. Tut LM Algor 11(1):101–110

Şenol Ö, Esat V, Darendeliler H (2014) Springback analysis in air bending process through experiment based artificial neural networks. Proc Eng 81:999–1004

Shahbaz M, Ali S, Guergachi A, Niazi A, Umer A (2019) Classification of Alzheimer’s disease using machine learning techniques. In: Data, pp 296–303

Thipprakmas S, Sontamino A (2020) Fabrication of cleancut surface on high strength steel using a new shaving die design. J Mech Sci Technol 34(1):301–317

Zuperl U, Cus F, Mursec B, Ploj T (2004) A hybrid analytical-neural network approach to the determination of optimal cutting conditions. J Mater Process Technol 157:82–90

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Patil, P., Patil, V. (2023). Investigation of Quality of Clean-Cut Surface for Sheet Metal Blanking Using Decision Tree. In: Vasudevan, H., Kottur, V.K.N., Raina, A.A. (eds) Proceedings of International Conference on Intelligent Manufacturing and Automation. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-7971-2_10

Download citation

DOI: https://doi.org/10.1007/978-981-19-7971-2_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-7970-5

Online ISBN: 978-981-19-7971-2

eBook Packages: EngineeringEngineering (R0)