Abstract

Since the composition of solid waste varies depending on a community’s socioeconomic status this paper is an attempt toward the management of kitchen waste for Jorhat, Assam, India. With rapid growth in population, the environment in the country is facing a massive challenge and disposal of waste causes huge environmental impacts along with health issues. The energy from the waste is one of the most crucial treatments of solid waste. The present study is aimed to identify the optimum food to microorganisms (F/M) ratio for maximum methane production using Biochemical Methane Potential (BMP) test. The findings obtained from the experiments will serve as a baseline for the other researchers to select optimum F/M. The production of biogas from anaerobic digestion (AD) of food waste is analyzed where cow dung is used as inoculum. To check the potential of food waste to be used as substrate for AD process, initial characterization of food waste has been done. Along with this, characterization of inoculum (cow dung) is also performed. The food waste has been collected from Jorhat, Assam, India and the experiments have been conducted for four different F/M ratios viz. 1:1, 1.5:1, 2:1 and 2.5:1. The methane production is found to be highest while maintaining the F/M ratio at 2:1. This investigation is very relevant for this region as no previous study has been reported explaining the characterization/production of biogas for Jorhat, Assam, India.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

7.1 Introduction

According to the Food and Agricultural Organization (FAO) of United Nations, the food waste (FW) is any healthy or edible substance, such as fresh vegetables, fruit, fish, meat, bakery and dairy products, etc., which is wasted, lost, or degraded at every stage of the food supply chain (Yang et al. 2018; Pecar et al. 2020; Chen et al. 2017). Out of the total food produced in the world, around one-third (amounting to 1.3 billion tonnes) gets wasted every year. This accounts for nearly US$ 680 billion in industrialized countries and US$ 310 billion in developing countries (Barua et al. 2018; FAO 2011). Most of the generated is either directly dumped in landfills or used as feedstock in animal husbandries; but these practices have created serious environmental and health issues (Mir et al. 2016).

The physiochemical characteristics of FW are affected by its composition. For instance, the FW comprising of rice, pasta and vegetables is enriched with carbohydrates, while the FW consisting of meat, fish and eggs has abundant amount of proteins (Pecar et al. 2020). But in general, FW can be considered to have moisture content (MC) of around 74–90%, volatile solids (VS) of around 85 ± 5%, and mean pH of around 5.1 ± 0.7 (Pecar et al. 2020; Fisgativa et al. 2016; Zhang et al. 2007). The high MC and perishable nature of FW makes the treatment by traditional methods (incineration, pyrolysis and composting) to be less effective (Li et al. 2018; Zhao et al. 2019). However, AD involves multiphase and multistage chains of complex biological process and produces biogas from organic waste (Zhao et al. 2019; Ren et al. 2018; Xu et al. 2018). It has emerged as a promising technique where FW can be used to produce large amount of energy.

Of late, India has emerged as world’s second largest LPG importer after China and the demand for LPG is projected to rise 34% from 2014 to 2025. LPG is used by 59% of Indian houses for their cooking needs (Apte et al. 2013). However, the importance of non-conventional energy resources is slowly increasing because of sharp rise in energy demand and depletion of conventional resources of the country at a large scale. Further, replacing even 20% of LPG by biogas produced from FW as feedstock can result in significant saving of foreign exchange, thereby upgrading the economy of the nation (Desai and Jadhav 2016). Biogas is a clean renewable energy resource that can be obtained through biological degradation of organic waste during AD process (Mir et al. 2016; Appels et al. 2011). The biogas obtained through this process mostly contains 60–75% of methane and 20–40% of carbon dioxide as well as traces of other gases. Further, the several operating parameters such as solid concentration, temperature, pH, and retention period influence the typical gas yield during AD.

The AD is a biological process that produces biogas by degrading and stabilizing complex organic matter in an anaerobic environment with the help of a consortium of microbes (Akyol 2020). According to various studies, AD proceeds through four steps: hydrolysis, acidogenesis, acetogenesis and methanogenesis as shown in Fig. 7.1 (Senthilkumar et al. 2016; Deepanraj et al. 2015; Achinas and Euverink 2019). During hydrolysis, conversion of complex organic molecules (proteins, polysaccharides and fat) into simpler ones (peptides, saccharides and fatty acids) occurs with the help of exoenzymes (cellulose, protease, lipase) produced by hydrolytic and fermentative bacteria. In acidogenesis, the products of hydrolysis are broken down into smaller molecules of low molecular weight (organic acid alcohols, carbon dioxide, hydrogen and ammonium), which are then converted into acetic acid, hydrogen and carbon dioxide by acetate bacteria. The products of the acetogenesis are converted into methane gas in the final step by two groups of microbes-acetoclastic methanogens. It converts the acetate into carbon dioxide, methane and hydrogen-utilizing methanogens, which reduces the hydrogen and carbon dioxide into methane (Mir et al. 2016).

It is critical to have prior understanding of the methane potential of the feedstock for any digestion facility to work properly in the long run (Deepanraj et al. 2015; Koch and Drewes 2014; Koch et al. 2017). The Biochemical Methane Potential (BMP) test was developed by Owen et al. (Owen et al. 1979), and is an important tool for the study of potential of methane generation from different wastes as this test determines the maximum quantity of methane that can be produced from a substrate (Elbeshbishy et al. 2012; Owens and Chynoweth 1993; Wang and Barlaz 2016; Krause et al. 2018). Castellón-Zelaya et al. (Castellón-Zelaya and González-Martínez 2021) studied the effects of solids concentration and substrate to inoculum ratio on production of methane from organic municipal solid waste. The methane production from fermented organic fraction of municipal solid waste was found to be increased by 32% when compared to fresh organic fraction of municipal solid waste. Furthermore, the substrate to inoculum ratio for optimum production of methane from the fermented organic part of municipal solid waste was reported to be 1.0.

7.1.1 Motivation

Figure 7.2 shows the scenario of the unmanaged landfill site at Garmur, Jorhat, Assam, India. The waste generated in the town is dumped directly into this landfill and burnt, situated alongside Tocklai rivulet which falls in the Bhogdoi river, Assam without any treatment process, like incineration or composting. The condition is deplorable with stray animals, foul odors, and flies, thereby raising serious concerns among the residents. Also, there is a municipality water supplier plant nearby. As a result, these wastes have the potential to damage all of the living environment’s essential components: air, land and water. The Jorhat Municipal Board (JMB) operates and handles waste from 19 wards in the town, which spreads across 9.25 km2. The total waste generated per day in the town is around 60 tonnes, which is picked up every day from 121 collection points located across the town. FW makes up a large component of the municipal solid waste organic fraction, which can be easily separated at the source (residences, restaurants, school canteens, etc.) and treated anaerobically to produce energy-rich biogas. This will not only help in managing food waste efficiently, but will also provide an alternative source of energy to meet the increasing energy requirements coupled with rapidly depleting coal and petroleum resources.

7.1.2 Present Objective

Considering the energy deficit and waste management problem in Jorhat, Assam, an attempt has been made to determine the potential of kitchen waste to produce biogas through AD. The present study aims to optimize the F/M ratio in order to obtain maximum methane gas, during AD of FW using cow dung as inoculum. This kind of investigation is unique because no such study has been reported for Jorhat, Assam, India. For this, initial characterization of the kitchen waste and inoculum (cow dung) has been done to evaluate the MC, volatile matter content, ash content, fixed carbon content and calorific value. Further, BMP test is conducted on different Food to Microorganisms ratios (F/M) viz. 1:1, 1.5:1, 2:1 and 2.5:1 to identify the optimum F/M ratio for maximum production of methane using cow dung (CD) as inoculum.

7.2 Materials and Methods

7.2.1 Initial Characterization of Substrate and Inoculum

In the present study, FW is used as the substrate and fresh cow dung is used as the inoculum. Cow dung is found to be the best inoculum, as reported by Dhamodharan et al. (2015). The FW was collected from hostels of Jorhat Engineering College, Jorhat, Assam, India as shown in Fig. 7.3, while fresh cow dung is sourced from a nearby goshala in Jorhat, Assam, India. The FW used mainly consists of cooked rice, vegetables, chapattis and uncooked vegetables peels. The waste is mixed thoroughly and grinded in a mixer grinder. The homogenously mixed samples of substrate and inoculum is then evaluated for determination of basic characteristics, viz. Moisture content (MC), Total solids (TS), Volatile solid (VS), Ash content (AC), Fixed carbon content (FC) and pH. The hot air oven and furnace for initial characterization are shown in Fig. 7.4. APHA (APHA 2005) standards were used to measure MC, TS and VS. AC is measured using standard procedure as per ASTM D 2974–87 (ASTM D 2974–87 1993). The pH meter is used to determine the pH of the samples.

7.2.2 Data Measurement

7.2.2.1 Moisture Content (MC) and Total Solid (TS)

At first a known weight of the sample was dried in hot air oven at 105 ± 5 °C for 24 h. The weight of the oven dried sample is measured.

7.2.2.2 Volatile Solid (VS)

The oven dried sample was then covered with a lid and heated in a furnace at 550 ± 10 °C for around 2 h.

7.2.2.3 Ash Content (AC)

Oven dried sample is uncovered and heated in a furnace at 440 ± 10 °C until the specimen is completely ashed.

7.2.2.4 Fixed Carbon (FC)

7.2.3 BMP Test Setup

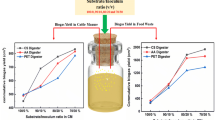

The methodology employed for carrying out the BMP test is followed as described by Owen et al. (Owen et al. 1979). The overall testing has been conducted for 35 days, using four different F/M ratios (VS basis), namely 1:1, 1.5:1, 2:1, 2.5:1 and a control (cow dung only). On the basis of VS content, the different quantities of FW and cow dung to be mixed to get the required F/M ratios is as shown in Table 7.1. The accurately weighed samples were put in 1000 mL reagent bottles. The level of all the batch reactors was maintained 600 ± 10 mL by adding distilled water. To maintain the anaerobic state, nitrogen gas was purged into the reactor bottles. The bottles were made air-tight using rubber corks, and then connected to aspirator bottles as shown in Fig. 7.5. To measure the amount of biogas production water displacement method has been used. In place of water, the aspirator bottles are filled with 1.5 N NaOH solution, so that the CO2 produced reacts with NaOH to form sodium carbonate (Na2CO3), and thus can be separated from methane gas (Saha et al. 2018; Walker et al. 2009). Thus, the amount of solution displaced in the aspirator bottles indicates the volume of methane gas produced. At different stages of anaerobic digestion, the pH value varies because of change in concentrations of volatile fatty acids (VFA), bicarbonates, alkalinity and CO2 (Mir et al. 2016). With increase in the amount of VFA produced, the pH drops and below a pH = 6.0, the methane production is significantly inhibited. During this study, NaHCO3 has been added to keep the pH value in the range of 6.5–7.5 (Owen et al. 1979; Saha et al. 2018; Singh et al. 2017).

7.2.4 Analysis of Different Parameters

The volume of methane production has been measured on daily basis using water displacement method. In place of water, 1.5 N NaOH was used to separate CO2 from methane. When the biogas generated passed from the reagent bottles into the aspirator bottles containing NaOH, the CO2 reacted with NaOH, and the pressure of the methane gas displaced the NaOH solution out of the aspirator bottles. The volume of NaOH displaced has been measured by using a measuring cylinder and this indicated the amount of methane gas produced (Saha et al. 2018). The MC, TS, VS are examined weekly according to the method described in APHA (APHA 2005) standards. At first, a known weight of the sample is dried in hot air oven at 105 ± 5 °C for 24 h. The weight of the oven dried sample expressed as a percentage of the original weight is the TS. The loss in weight due to drying in hot air oven is expressed as a percentage of the original weight is the MC. The oven dried sample is then covered with a lid and heated in a furnace at 550 ± 10 °C for around 2 h. The loss in weight is expressed as a percentage of the weight of the oven dried sample indicated the VS. The room temperature is measured on daily basis using a thermometer.

7.3 Results and Discussion

7.3.1 Characterization of Food Waste and Inoculum (Cow Dung)

The characterization of FW and inoculum (cow dung) is enumerated in Table 7.1 and 7.2, respectively and the results obtained in the present study are compared with the results reported by Zhang et al. (Zhang et al. 2007) (for FW) and Saha et al. (Saha et al. 2018) (for cow dung). The MC, TS, VS, AC, FC, VS/TS ratio, and pH of the FW and inoculum (cow dung) are listed in the Table 7.2 and 7.3, respectively. The MC of FW is found to be high (around 71.1%) which makes it a potential feedstock for AD. The VS/TS percentage of both FW and cow dung is high, indicating that their consumable organic fraction is high, thereby producing more energy (Dhamodharan et al. 2015). The pH value of the FW is obtained to be slightly acidic (pH = 6.02) while the pH value of cow dung is 7.11.

7.3.2 Biogas / Methane Production

In AD, the most vital parameter to be optimized is the quantity of methane gas production, which depends on various factors like inoculum source and quantity, TS, VS, VFA and temperature etc. (Dhamodharan et al. 2015). In the present study, the BMP test of different F/M ratios (g VS FW/g VS CD), namely 1:1, 1.5:1, 2:1, 2.5:1 and a control (only CD) is done, to determine the optimum F/M ratio, corresponding to the maximum production of methane gas. The daily methane production and the cumulative methane production from each of the ratios have been plotted in Fig. 7.6. The experimental observation showed that for AD of FW with cow dung as inoculum, the F/M ratio of 2:1 yielded the maximum amount of methane, with ratios 2.5:1 and 1.5:1 following it. At F/M = 2:1, the total methane yield is 3428 mL for a period of 35 days, while for F/M = 2.5:1 and 1.5:1, the methane yields are 2850 mL and 2582 mL, respectively. Further, F/M = 1:1, the cumulative methane yield is 2210.5 mL and in the control, it was around 1789 mL. From the methane production trend, it can be observed that as the F/M is increased from 1 to 2, the methane production also increased. After F/M = 2:1, the methane production started decreasing. Thus, the optimum order of F/M ratios with respect to methane gas production from AD of FW is 2:1 >2.5:1 >1.5:1 >1:1.

7.3.3 Volatile Solids

From Fig. 7.7, it can be observed that for all F/M ratios, VS follows a decreasing pattern over time. These decreasing trends of VS indicate the decreasing mass, which can be correlated to biogas production. The inoculum activity and its adaptability toward the substrate influence the VS reduction. Therefore, in order to improve the microbial activity, it is necessary to maintain a balanced combination between inoculum and substrate (Dhamodharan et al. 2015). In the present BMP test, at F/M ratio of 2:1, a maximum of 40% VS reduction is observed. At F/M ratios of 2.5 and 1.5, the VS reduction of 36.15% and 33.36% respectively is observed. Further, the F/M = 1:1 is having a VS reduction of 32.32%, followed by control having 26.81%. This order of VS reduction (2:1 >2.5:1 >1.5:1 >1:1) is found to be in order with the cumulative methane production.

7.3.4 Variation of Room Temperature Outside the Digester

The operating temperature has a vital role for sustaining the microorganisms of AD. The microorganisms that are taking part in AD process can be classified into three categories (Singh et al. 2017):

-

Cryophiles (Psychrophiles), occupying the area of cryophilic digestive regime (operating temperature range 12–24 °C).

-

Mesophiles, occupying the area of mesophilic digestive regime (operating temperature range 22–40 °C).

-

Thermophiles, occupying the area of thermophilic digestive regime (operating temperature range 50–60 °C).

Figure 7.8 depicts the variation of room temperature outside the digesters during the test period of 35 days. As the BMP test is performed during the month of March, the operating temperature was on a lower side. The temperature fluctuated in between 17 °C and 29 °C, which lies in between cryophilic and mesophilic conditions. As the thermophilic condition has high conversion rate and biogas productivity, so higher methane yield can be expected during summer when temperature is higher.

7.4 Conclusions

Pollution is caused by wastes, and the form and extent of pollution is determined by the nature of the wastes. It also aids in the selection of the required management application, engineering design, and technology. Furthermore, the composition of waste is influenced by community’s socioeconomic status, living style, composition pattern and cultural behavior. Here, an effort has been made to tackle the increasing problem of waste management in Jorhat, Assam, India. The production of biogas from AD of FW has been investigated using cow dung as inoculum. To check the potential of FW to be used as substrate for AD process, initial characterization of FW has been done. Along with this, characterization of inoculum (CD) is also performed. The moisture content and volatile solid content of FW is found to be high and thus suitable for biological degradation. On the basis of VS of the substrate and inoculum, four F/M ratios varying from 1.0 to 2.5 are chosen, and BMP test have been carried out for these ratios for five weeks. The daily methane production, cumulative methane production, and weekly VS degradation are discussed.

From the experiments, the F/M ratio of 2:1 has been found to be most suitable for AD of FW with cow dung. At this F/M ratio a volume of 3428 mL methane gas has been produced at duration of 35 days. Thus, with around 60 tonnes/day of waste material, the Jorhat town has a good potential of biogas generation. It can be used in cooking, biogas-based small-scale electricity generation system. For F/M ratios lower and higher than 2:1, the methane yield is observed to be decreased. As the temperature during the study was fluctuating in between 17 °C and 29 °C (in between cryophilic and mesophilic conditions), therefore, the biogas yield was found to be slightly low. Future studies can be performed taking F/M ratio of 2:1 as optimum, by maintaining high temperature bath, so as to observe the enhanced methane production at high temperature. In addition, the effect of pre-treatment of the FW on biogas production can be analyzed. Based on the composition of the biogas produced, future study may be pursued on purification of the FW so as to remove the impurities and increase the methane percentage and thus, obtain higher calorific value of the gas. The co-digestion of the FW with other potential feed stocks can also be studied.

Abbreviations

- AC :

-

Ash Content

- AD :

-

Anaerobic Digestion

- BMP :

-

Biochemical Methane Potential

- CD :

-

Cow Dung

- CV :

-

Calorific Value

- F/M :

-

Food to Microorganisms ratio

- FW :

-

Food Waste

- MC :

-

Moisture Content

- TS :

-

Total Solid

- VFA :

-

Volatile Fatty Acid

- VS :

-

Volatile Solid

References

Achinas S, Euverink GJW (2019) Effect of combined inoculation on biogas production from hardly degradable material. Energies 12(217):1–13

Akyol C (2020) In search of the optimal inoculum to substrate ratio during anaerobic co-digestion of spent coffee grounds and cow manure. Waste Manage Res 00:1–6

APHA (2005) Methods for the examination of water and wastewater, twentieth ed., American Public Health Association, American Water Works Association, and Water Environment Federation, Washington DC, USA

Appels L, Assche AV, Willems K, Degreve J, Impe JZ, Dewil R (2011) Peracetic acid oxidation as an alternative pre-treatment for the anaerobic digestion of waste activated sludge. Biores Technol 102:4124–4130

Apte A, Cheernam V, Kamat M, Kamat S, Kashikar P and Jeswani H (2013) Potential of using kitchen waste in a biogas plant. Int J Environ Sci Develop 4(4)

ASTM D 2974–87 (1993) Standard test methods for moisture, ash, and organic matter of peat and other organic soils. Am Soc Test Mater 31–33.

Barua VS, Rathore V, Kalamdhad AS (2018) Comparative evaluation of anaerobic co-digestion of water hyacinth and cooked food waste with and without pre-treatment. Bioresource Technol Rep 4:202–208

Bouallagui H, Touhami Y, Cheikh RB, Hamdi M (2005) Bioreactor performance in anaerobic digestion of fruit and vegetable wastes. Process Biochem 40:989–995

Castellón-Zelaya MF, González-Martínez S (2021) Effects of solids concentration and substrate to inoculum ratio on methane production from fermented organic municipal solid waste. Multi J Waste Resour Residues 15:3–12

Chen H, Jiang W, Yang Y, Man X (2017) State of the art on food waste research: a bibliometrics study from 1997 to 2014. J Clean Prod 140:840–846

Deepanraj B, Sivasubramanian V, Jayaraj S (2015) Experimental and kinetic study on anaerobic digestion of food waste: The effect of total solids and pH. J Renew Sustain Energy 7:063104

Desai SS, Jadhav VN (2016) Design of small scale anaerobic digester using kitchen waste in rural development countries. Res J Chem Environ Life Sci 4(4S):129–133

Dhamodharan K, Kumar V, Kalamdhad AS (2015) Effect of different livestock dungs as inoculum on food waste anaerobic digestion and its kinetics. Biores Technol 180:237–241

Elbeshbishy E, Nakhla G, Hafez H (2012) Biochemical methane potential (BMP) of food waste and primary sludge: influence of inoculum pre-incubation and inoculum source. Biores Technol 110:18–25

FAO (2011) Swedish Institute for Food and Biotechnology, Global Food Losses and Food Waste Study Conducted for the International Congress

Fisgativa H, Tremier A, Dabert P (2016) Characterizing the variability of food waste quality: a need for efficient valorization through anaerobic digestion. Waste Manage 50:264–274

Koch K, Drewes JE (2014) Alternative approach to estimate the hydrolysis rate constant of particulate material from batch data. Appl Energy 120:11–15

Koch K, Lippert T, Drewes JE (2017) The role of inoculum’s origin on the methane yield of different substrates in biochemical methane potential (BMP) tests. Biores Technol 243:457–463

Krause MJ, Chickering GW, Townsend TG, Pullammanappallil P (2018) Effects of temperature and particle size on the biochemical methane potential of municipal solid waste components. Waste Manage 71:25–30

Li L, Peng X, Wang X, Wu D (2018) Anaerobic digestion of food waste: a review focusing on process stability. Biores Technol 248:20–28

Madigan M, Martin KJ, Porter J (1997) Brock biology of microorganisms Upper Saddle River, 1st edn. Pearson Prentice Hall publisher, NJ

Mir MA, Hussain A, Verma C (2016) Design considerations and operational performance of anaerobic digester: a review. Cogent Eng 3:1181696

Owen WF, Stuckey DC, Healy JB, Young LY, McCarty PL (1979) Bioassay for monitoring biochemical methane potential and anaerobic toxicity. Water Res 13:485–492

Owens J, Chynoweth DP (1993) Biochemical methane potential of municipal solid waste (MSW) components. Water Sci Technol 27:1–14

Pecar D, Smerkolj J, Pohleven F, Gorsek A (2020) Anaerobic digestion of chicken manure with sawdust and barley straw pre-treated by fungi. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-019-00583-2

Ray NHS, Mohanty MK and Mohanty RC (2013) Anaerobic digestion of kitchen waste: Biogas production and pre-treatment waste, a review. Int J Sci Res Publ 3(11)

Ren Y, Yu M, Wu C, Wang Q, Gao M, Huang Q, Liu Y (2018) A comprehensive review on food waste anaerobic digestion: research updates and tendencies. Biores Technol 247:1069–1076

Saha B, Sathyan A, Mazumder P, Choudhury SP, Kalamdhad AS, Khwairakpam M, Mishra U (2018) Biochemical Methane Potential Test for Ageratum conyzoides to optimize ideal F/M ratio. J Environ Chem Eng 6(4):5135–5140

Senthilkumar N, Deepanraj B, Vasantharaj K, Sivasubramanian V (2016) Optimization and performance analysis of process parameters during anaerobic digestion of food waste using hybrid GRA-PCA technique. J Renew Sustain Energy 8:1–11

Singh G, Jain VK, Singh A (2017) Effect of temperature and other factors on anaerobic digestion process, responsible for bio gas production. Int J Theor Appl Mech 12(3):637–657

Walker M, Zhang Y, Heaven S, Banks CM (2009) Potential errors in the quantitative evaluation of biogas production in anaerobic digestion processes. Biores Technol 100:6339–6346

Wang X, Barlaz MA (2016) Decomposition and carbon storage of hardwood and softwood branches in laboratory-scale landfills. Sci Total Environ 557:355–362

Xu F, Li Y, Ge X, Yang L, Li Y (2018) Anaerobic digestion of food waste–challanges and opportunities. Biores Technol 247:1047–1058

Yang Y, Bao W, Xie GH (2018) Estimate of restaurant food waste and its biogas production potential in China. J Clean Prod 211:309–320

Zhang R, El-Mashad HM, Hartman K, Wang F, Liu G, Choate C, Gamble P (2007) Characterization of food waste as feedstock for anaerobic digestion. Biores Technol 98:929–935

Zhao X, Li L, Wu D, Xiao T, Ma Y, Peng X (2019) Modified Anaerobic digestion model no. 1 for modelling methane production from food waste in batch and semi- continuous anaerobic digestions. Biores Technol 271:109–117

Acknowledgements

The authors wish to thank CSIR-North East Institute of Science and Technology for providing some technical support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Talukdar, P.K., Karnani, V., Saikia, P. (2023). Inoculum Ratio Optimization in Anaerobic Digestion of Food Waste for Methane Gas Production. In: Mathew, V.K., Hotta, T.K., Ali, H.M., Sundaram, S. (eds) Energy Storage Systems. Engineering Optimization: Methods and Applications. Springer, Singapore. https://doi.org/10.1007/978-981-19-4502-1_7

Download citation

DOI: https://doi.org/10.1007/978-981-19-4502-1_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-4501-4

Online ISBN: 978-981-19-4502-1

eBook Packages: EnergyEnergy (R0)