Abstract

Distribution system is one of integral part of complex power system. Power losses in distribution system branches are very high rather than power losses in transmission system branches. These higher losses lead to higher operational cost in distribution system. The advancement of technology using distributed generations has been proved to be very important in optimizing network losses, environment pollution, and reliability of power systems. The DG allocation is a mixed-integer optimization problem with nonlinearity associated. In this paper, the work optimal size location and power factor of single and multiple placements of different distributed generators have been presented. Distribution network loss has been minimized for optimal power factor, size, and location of distributed generator to be optimized. Optimum size and minimum loss have been determined. Results thus obtained have been compared with the results in the literature. The proposed method has been validated on the IEEE33-bus test system.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The day-by-day increase in electrical power demand, as load is increasing rapidly, has rendered the existing central generation and transmission network unable to manage such a large burden. This increasing power demand has challenged the power engineer to maintain the power system reliably, securely as well as economically [1]. Hence, it is clear that either increasing the capacity of existing transmission network or production and supply in a small—scale near the load center can cope up with these issues. Power production of small generation units dispersed across the power grid or networks is defined as distributed generation [2]. These power producing technologies have led the multidimensional research opportunities in the field of distribution system planning and operation [3]. Apart from traditional very large scale power generation utility, distributed generator installation near load center requires very less capital cost, operation cost, and maintenance cost. Distributed generators are also environment friendly, when they are used as different renewable energy technology. Renewable energy technologies which are not very new include solar generation, micro-hydro power plants, wind, geothermal generation, power from municipal waste, landfill gas, and biomass. Emerging major power source of renewable technologies comes from sea waves and tidal stream. These energy sources possess the property of lower energy density compared to fossil fuels, which leads to smaller, economic, and geographically spread power plants [4]. Benefit of effective integration of DGs includes reduced generation of central power plants, enhanced utilization of available transmission/distribution network capacity, and improved system security, more reliable operation and overall costs and pollutant gas emission reduction.

Being a conventional approach in power industry, distributed generation has a large number of definitions and terms. The term distributed generation is also known by different terminology in literature such as “embedded generation,” “dispersed generation,” and “decentralized generation” based on their geospatial locations. “Dispersed generation” and “embedded generation” are mostly popular in North-American and Anglo-American countries respectively, while Europe and Asian countries use the term “decentralized generation” [5]. According to American council of energy efficient economy sources of electricity generation which are closer to point of use are termed as “decentralized or on-site generation” contrary to large power producing central units [6]. Gas Research Institute acknowledge the term distributed generation for the amount of power production “more than 25 kW but always lesser than 25 MW” [7]. These generations can include PV solar generation, wind generation, combined heat power plant, and others. Distributed generation changes the flow of power in network and hence results in change in network losses, not only in distribution system but also for transmission network. These reductions in losses further result in reduced charges for transmission network uses by utility.

It has been shown that poor power factor size and location of DG results in increased distribution losses compared to losses with optimally located DG [8,9,10]. Lee et al. have presented selection of optimal locations and ratings before the integration of multiple DGs to the power grid so that minimum line losses and maximum benefits of DGs are achieved [11]. Amanifar in his paper has presented particle swarm optimizer (PSO) to achieve the minimum operating and maintenance cost, reduced line losses, and reduction in THD with optimally located and sized DG [12]. The concept of network reconfiguration by opening and closing the tie switches and maintaining the radial structure of the operational distribution network to minimize the losses and voltage deviation has been achieved in [13,14,15,16,17]. Mathematical modeling for reducing network losses with reconfiguration has been established in [18]. Fractal theory-based stochastic search algorithm [19] and water cycle algorithm [20] were applied to obtain a better solution in order to minimize losses while reconfiguring the distribution network in presence of DG sources. In Refs. [21,22,23,24,25], method of analytical expression has been illustrated the optimality in size and location to obtain minimum distribution loss and to improve the system voltages at all nodes.

In this paper, different cases of DG allocation strategy have been presented for optimal location and size problem for minimizing real power losses while satisfying different constraints. Optimal size corresponding to optimal bus for minimum loss has been computed based on repeated load flow method with power factor. In a case where the optimal power factor, optimal location and optimal size have been calculated for minimum loss. The optimal power factor has been calculated by running load flow for different power factor. For calculation of distribution loss, load flow algorithm by backward—forward sweep is utilized [26]. The method proposed in this paper has been implemented on standard 33-bus distribution test system.

2 Problem Formulation

This paper presents the main objective to minimize the total active power losses in distribution network, i.e.,

Subject to constraints:

where \(P_{{\text{L}}}\) is total network loss, \(I_{k}\) and \(r_{k}\) is current and resistance, respectively, of branch \(k,nb\) is maximum number of branches in the network, \(V_{i}\) voltage at ith node. The maximum and minimum limit on voltage is ±5% [27]. dg_loc1, dg_loc2 and dg_loc3 are the 1st, 2nd, and 3rd location of DG placed, respectively, which must not be same in any case.

The total network loss \(P_{{\text{L}}}\) has been calculated by sum of losses in all branches of network (1) using the load flow algorithm using backward–forward sweep as given in Ghosh and Das [26]. To calculate the loss in a branch, the current flowing in that branch is multiplied by the corresponding branch resistance. The current through any particular branch is the addition of the all load currents beyond that particular branch, i.e.,

The current \(I_{{{\text{load}}}} \left( n \right)\) at a particular node \(n\) is calculated by

\(P_{l} \left( n \right)\) and \(Q_{l} \left( n \right)\) are real and reactive power load demand at node \(\left( n \right)\), and \(v\left( n \right)^{*}\) is complex conjugate of voltage \(v\) at node \(n\).

The voltage at receiving end node connected with sending end node by kth branch is calculated by

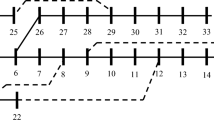

where \(V_{{{\text{rn}},k}}\) and \(V_{{{\text{sn}},k}}\) are voltages at receiving end node and sending end node, respectively, connected by branch \(k\). \(I_{k}\) and \(Z_{k}\) are branch current and branch impedance of kth branch, respectively. Initially, a flat voltage profile has been assumed for each node in the network (Fig. 1).

2.1 Optimal Location and Size of DG

The optimal locations and sizes of DGs play a very crucial role for minimization of distribution network losses. At a bus, the loss is the function of injected power by DG placed at that bus, so starting from minimum DG size, if we increase the size of DG at that particular bus the losses starts decreasing till a particular DG size, which is optimal size of DG corresponding to that particular bus. Beyond this particular optimal DG size, any further increment in DG size leads to higher distribution losses, and it may overtake the losses corresponding to base case losses. Similarly, it is true for all the buses in network. Hence, selection of DG size is very crucial as it may result in higher distribution losses. Also, the size of DG must not be more than maximum load demand and should be consumable within the distribution network boundary, otherwise there will be a large amount of loss because of design of distribution network and decreasing conductor sizes as power in passive distribution system flows in forward direction from substation to load.

DG installation for location size and minimum power loss has been calculated for different cases as below:

-

A single unit of Type-3 DG rated in MVA injecting both active and reactive power has been computed.

-

Losses with multi-DG placed simultaneously injecting only active power has been computed.

3 Methodology

In this section, loss calculation for Type-3 DG has been presented. Load flow has been performed to get the optimal size and location for each power factor, and corresponding loss also has been calculated. Thus, power factor for which loss is minimum has been obtained by comparing losses at other power factor. Power factor has been taken from zero to unity and has been increased in small steps of 0.02. For each power factor, different DG size has been taken into account starting from zero to 4 MW in a small step, and then, load flow has been run to calculate the losses at each bus. And thus optimal DG size, location, and optimal power factor corresponding to minimum loss are stored.

3.1 Procedure

-

Step 1

Run base caseload flow using input system data.

-

Step 2

Start with initial chosen size of DG, initial DG location, and initial power factor as initial solution vector and calculate the system loss.

-

Step 3

Increment the size of DG in a fixed small step to get the corresponding loss.

-

Step 4

If the loss found with DG size in step 3 is lesser than previous loss, update the solution vector else go to step 3 until the maximum DG size is reached.

-

Step 5

Increment the DG location by one.

-

Step 6

Repeat steps 2–6 until all the possible DG location have been checked and update the solution vector and corresponding loss if found lesser than previous.

-

Step 7

Make an increment in previous power factor by a fixed step change.

-

Step 8

Repeat steps 2 to 8 until unity power factor and update the solution vector and corresponding loss if found lesser than previous loss.

-

Step 9

Print the updated solution vector and stop.

Applying the above procedure, it is also possible to get the minimum loss, optimum DG size, and location at any given power factor. In this paper, the work has been extended to obtain the minimum loss, optimal size, and location of multiple DGs injecting only real power, i.e., Type-1 DG. The procedure for placement of multiple units of Type-1 DG is as follows.

3.2 Procedure for Multi-type-1 DG Placement

-

Step 1

Input the system data and run the load flow to obtain the size and location for 1st DG, as stated in previous method for unity power factor, for minimum distribution loss.

-

Step 2

Store the DG size, optimal location, and minimum loss obtained for 1st DG.

-

Step 3

Fix the DG of capacity/size obtained above, at their respective optimal location.

-

Step 4

Repeat steps 1 and 2 to obtain the size and location, corresponding to minimum loss for 2nd DG, and then for 3rd DG also.

4 Results and Discussion

4.1 Size, Location, and Loss

The methodology is tested on standard 33-bus 32 branch test system with 2.3 MVAr and 3.715 MW load at 100 MVA, 12.66 kV [17]. The test system is radial in nature. A MATLAB code has been written in the MATLAB R2018a environment to evaluate the optimal location of DG and its size to calculate the minimum loss in the network.

In Fig. 2, minimum loss at each DG location corresponding to different power factors for 33-bus system is shown. For more clarity, Fig. 2 is redrawn and shown in Fig. 3 in a more clear way for some selected power factors at 0, 0.5, 0.82, 0.9, and unity power factor. For each power factor, it is found that loss corresponding to that power factor occurs at different location and different DG size. Figure 4 is drawn for the minimum loss obtained at each power factor, which exhibits that at 0.82 power factor loss is minimum.

Case 1: For Type-3 DG injecting both real as well as reactive power, load flow for every power factor with varying DG size for each and every bus has been performed, and corresponding minimum loss is calculated which is shown in Fig. 5. It is found that at 0.82 power factor, locating 3.1 MVA capacity of DG at bus no. 6 gives the minimum loss of 61.371 kW. In Fig. 5, optimum DG size and losses corresponding to optimally located DG at each bus is shown for Type-3 DG.

In Fig. 5, optimum DG size and losses corresponding to optimum size of DG placed at each bus is shown for Type-3 DG.

Case 2: As this case has been studied for multiple Type-1 DG placements in distribution network. Three successive DGs of optimum size have been placed one by one at their optimum location found with previously installed DGs, and losses have been computed as shown in Fig. 6. Thus, it is noticed that after placing 1st DG of size 2.6 MW at bus no. 6, the optimal location for 2nd DG is bus no. 16 of DG size 0.4 MW reduces the losses to 93.736 kW. And for 3rd DG, it is found that 0.6 MW DG at bus no. 25 reduces the losses further to 85.989 kW.

Voltage: Voltage profile for all the cases mentioned in this paper has been calculated for each case. In Table 1, the minimum and maximum voltage obtained in each case and corresponding bus with and without DG placement is reported.

In Fig. 7, the voltage profiles for all cases have been drawn, and it is clear that using multiple numbers of Type-1 DG improves the voltage mostly as compared to Type-3 DG. In Table 1, minimum and maximum voltage and corresponding bus with and without DG are also shown.

In Table 2, it is shown that loss is lowest for case 1 using Type-3 DG which reduces losses to 61.371 kW, while using multiple DGs reduces the losses in a great extent but lower than case 1. Type-3 DG reduces the losses by 69.72%, while three numbers of Type-1 DG reduce the losses by 57.57%.

A comparative study of optimal location of multiple Type-1 DG approach for maximum loss reduction is shown in Table 3, which shows that placing DG at nodes 6, 16, and 25 has reduced the losses to 85.989 kW as compared to 96.76 kW loss obtained with the meta-heuristic harmony search algorithm (HSA) [16]. And loss reduction has been improved to 57.57% as compared to 52.26% of HSA. Although it is found that voltage profile with the method applied in this paper experiences a slight decrement compared to HSA [17] but within its acceptable limit.

5 Conclusion

This paper has presented the Type-3 as well as multiple numbers of Type-1 DGs to minimize the real power losses in distribution network by injecting real or reactive power. From above discussion, it can be concluded that Type-3 DG is best suitable for the most loss reduction which is calculated as 69.72% as can been seen in Fig. 6 and Table 2, while improvement of voltage at almost all buses after installing DG at their optimal location is well within the limit of ±5%. Placing a single Type-3 DG improves the voltage significantly which is almost equivalent to placing two Type-1 DGs as can be seen in Fig. 7. A more improved voltage profile has been achieved with three Type-1 DG placement cases.

References

Alhelou HH, Hamedani-Golshan ME, Njenda TC, Siano P (2019) A survey on power system blackout and cascading events: research motivations and challenges. Energies 12(4):1–28. https://doi.org/10.3390/en12040682

Kumar T, Thakur T (2014) Comparative analysis of particle swarm optimization variants on distributed generation allocation for network loss minimization. In: 1st international conference on networks soft computing ICNSC 2014—proceedings, pp 167–171. https://doi.org/10.1109/CNSC.2014.6906682

Dulău LI, Abrudean M, Bică D (2014) Distributed generation technologies and optimization. Procedia Technol 12:687–692. https://doi.org/10.1016/j.protcy.2013.12.550

Jenkins N, Ekanayake JB, Strbac G (2010) Distributed generation. Distrib Gener 1–279. https://doi.org/10.1201/b16747-16

Ackermann T, Andersson G, Söder L (2001) Distributed generation: a definition. Electr Power Syst Res 57(3):195–204. https://doi.org/10.1016/S0378-7796(01)00101-8

ACEEE: Distributed generation. https://www.aceee.org/topic/generation. Last accessed 2021/07/12

Institute GR (1998) Distributed power generation : a strategy for a competitive energy industry. Chicago

Mithulananthan N, Phu LV (2004) Distributed gener ator placement in power distribution system using genetic algorithm to reduce losses. Thammasat Int J Sci Tech 9(3):55–62

Griffin T, Tomsovic K, Secrest D, Law A (2000) Placement of dispersed generations systems for reduced losses. In: Proceedings of the annual Hawaii international conference on system sciences

Jasmon GB, Lee LHCC (1991) Distribution network reduction for voltage stability analysis and loadflow calculations. Int J Electr Power Energy Syst 13(1):9–13. https://doi.org/10.1016/0142-0615(91)90011-J

Lee SH, Park JW (2013) Optimal placement and sizing of multiple DGS in a practical distribution system by considering power loss. IEEE Trans Ind Appl 49(11):2262–2270. https://doi.org/10.1109/TIA.2013.2260117

Amanifar O (2011) Optimal distributed generation placement and sizing for loss and THD reduction and voltage profile improvement in distribution systems using particle swarm optimization and sensitivity analysis. In: 16th electrical power distribution conference EPDC

Moghaddam MJH, Kalam A, Shi J, Nowdeh SA, Gandoman FH, Ahmadi A (2020) A new model for reconfiguration and distributed generation allocation in distribution network considering power quality indices and network losses. IEEE Syst J 14(3):3530–3538. https://doi.org/10.1109/JSYST.2019.2963036

Merlin A, Back H (1975) Search for a minimal—loss operating spanning tree configuration in urban power distribution systems. In: Proceedings of 5th power systems computation conference Cambridge, UK

Srinivasa Rao R, Narasimham SVL, Ramalinga Raju M, Srinivasa Rao A (2011) Optimal network reconfiguration of large-scale distribution system using harmony search algorithm. IEEE Trans Power Syst 26(3):1080–1088. https://doi.org/10.1109/TPWRS.2010.2076839

Rao RS, Ravindra K, Satish K, Narasimham SVL (2013) Power loss minimization in distribution system using network reconfiguration in the presence of distributed generation. IEEE Trans Power Syst 28(1):317–325. https://doi.org/10.1109/TPWRS.2012.2197227

Baran ME, Wu FF (1989) Network reconfiguration in distribution systems for loss reduction and load balancing. IEEE Trans Power Deliv 4(2):1401–1407

Mahdavi M, Alhelou HH, Hatziargyriou ND, Al-Hinai A (2021) An efficient mathematical model for distribution system reconfiguration using AMPL. IEEE Access 9:79961–79993. https://doi.org/10.1109/ACCESS.2021.3083688

Tran TT, Truong KH, Vo DN (2020) Stochastic fractal search algorithm for reconfiguration of distribution networks with distributed generations. Ain Shams Eng J 11(2):389–407. https://doi.org/10.1016/j.asej.2019.08.015

Muhammad MA, Mokhlis H, Naidu K, Amin A, Franco JF, Othman M (2020) Distribution network planning enhancement via network reconfiguration and DG integration using dataset approach and water cycle algorithm. J Mod Power Syst Clean Energy. 8(1):86–93 (2020). https://doi.org/10.35833/MPCE.2018.000503

Shojaei F, Rastegar M, Dabbaghjamanesh M (2021) Simultaneous placement of tie-lines and distributed generations to optimize distribution system post-outage operations and minimize energy losses. CSEE J Power Energy Syst 7(2):318–328. https://doi.org/10.17775/CSEEJPES.2019.03220

Wang C, Nehrir MH (2004) Analytical approaches for optimal placement of distributed generation sources in power systems. IEEE Trans Power Syst 19(4):2068–2076. https://doi.org/10.1109/TPWRS.2004.836189

Acharya N, Mahat P, Mithulananthan N (2006) An analytical approach for DG allocation in primary distribution network. Int J Electr Power Energy Syst 28(10):669–678. https://doi.org/10.1016/j.ijepes.2006.02.013

Gözel T, Hocaoglu MH (2009) An analytical method for the sizing and siting of distributed generators in radial systems. Electr Power Syst Res 79(6):912–918. https://doi.org/10.1016/j.epsr.2008.12.007

Hung DQ, Mithulananthan N, Bansal RC (2010) Analytical expressions for DG allocation in primary distribution networks. IEEE Trans Energy Convers 25(3):814–820. https://doi.org/10.1109/TEC.2010.2044414

Ghosh S, Das D (1999) Method for load-flow solution of radial distribution networks. IEE Proc Gener Transm Distrib 146(6):641–646. https://doi.org/10.1049/ip-gtd:19990464

Lee Willis H (2004) Power distribution planning reference book, 2nd edn. CRC Press, Boca Raton

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Barnwal, A.K., Singh, S., Verma, M.K. (2022). Optimal Location and Size of Multi-distributed Generation with Minimization of Network Losses. In: Mahajan, V., Chowdhury, A., Padhy, N.P., Lezama, F. (eds) Sustainable Technology and Advanced Computing in Electrical Engineering . Lecture Notes in Electrical Engineering, vol 939. Springer, Singapore. https://doi.org/10.1007/978-981-19-4364-5_6

Download citation

DOI: https://doi.org/10.1007/978-981-19-4364-5_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-4363-8

Online ISBN: 978-981-19-4364-5

eBook Packages: Computer ScienceComputer Science (R0)