Abstract

Green Supply Chain Management (GSCM) has received increasing attention, at least in recent decades. During this time, it has become apparent that are significant complexities in its management. From both a practical and research perspective, there is a need to simplify and understand this complexity. To further deepen the understanding of the problem, institutional theory, which consists of three institutional pressures, namely government pressure (coercive pressure), market pressure (normative pressure) and competitive pressure (mimetic pressure), was used to investigate the relationship between institutional pressure and GSCM practices in the manufacturing industry in Malaysia. Data were collected using questionnaires in different Malaysian manufacturing companies. The hypotheses were tested using SmartPLS 3. The results from the 118 respondents showed that the command and control instrument and competitive pressure supported the hypothesis, while the economic incentives instrument and market pressure did not support the hypothesis. Finally, the enactment of stringent environmental regulations by the government was found to be most effective in promoting the adoption of GSCM practices.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Green supply chain management (GSCM)

- Institutional theory

- Institutional pressures

- Sustainable development

- PLS-SEM

1 Introduction

Changes in the industrialization of supply chain management (SCM) are happening very fast, which has a negative impact on the environment and ecology. These issues have led to many climate change agreements between nations to act in a more environmentally friendly manner. In response to the increased pressure to become more environmentally friendly, manufacturing companies are moving away from a traditional profit-driven approach to a more balanced approach where both economic and environmental needs are simultaneously pursued as key business objectives [1]. There is no doubt that implementing environmental objectives in the supply chain requires a holistic approach [2]. Green supply chain management (GSCM) is one of the innovations that should be practiced in the industry to overcome the problem. GSCM is a combination of environmental thinking and SCM that includes product design, material sourcing and selection, manufacturing processes, delivery of the final product to the consumer, and end-of-life management of the product [2, 3]. The goal of green supply chain management is to minimize waste and pollution by integrating environmental thinking into product design [4].

In many countries, green innovation has already taken hold. But how many individual companies are addressing this issue? Are they willing to incur more costs for environmental certification such as ISO 14001? Although GSCM research has come a long way, there are still gaps, including but not limited to the identification of GSCM antecedents, their impact on supply chain performance, and barriers from stakeholders, suppliers, and consumers [5]. Abdullah et al. [6] stated that despite the given value and benefits, manufacturers’ contribution to green practices falls short of expectations. Due to the difficulties involved, many manufacturers are discouraged from engaging in innovation and remain stuck in familiar routines.

External pressure is the main driving force in getting companies to adopt GSCM practices. Based on several previous findings, [7,8,9,10,11,12], GSCM has become more important due to pressure from various stakeholders, such as government regulations, government support, consumers, and competitors. These stakeholders exert pressure and motivate companies to minimize the risk of pollution in the supply chain to become an environmentally responsible company [13].

The findings of [11] show that this pressure encourages the adoption of environmentally friendly practices in China. In Malaysia, the awareness of environmental issues is still at moderate level [6, 14]. Therefore, this study aims to determine the relationship between institutional theory and GSCM practices in the manufacturing industry in Malaysia. This theory consists of three institutional factors, namely coercive pressure which consists of two instruments: first, command and control instrument and second, economic incentive instrument. The second pressure is the normative pressure with market pressure as the variable in this study and finally the mimetic pressure with competitive pressure as the variable [15].

2 Literature Review

2.1 Green Supply Chain Management (GSCM)

Since the early 1980s, when the first concept was introduced, the term SCM has been used to describe the planning and control of raw materials, the flow of information and logistics activities within a company and also externally between companies. Over time, the focus of SCM study has broadened. Originally, SCM focused more on material flows. More recent studies emphasize other aspects of SCM such as performance, risk, and integration. In addition, there is an increasing focus on information flows, internal and external relationship networks, and supply network management [4, 16].

Due to environmental issues, many countries are striving for green innovations, and GSCM is one of the green innovations. In today’s world, GSCM has become an increasingly complex challenge for companies. Suppliers, customers, regulators, stakeholders, and organizations are increasingly demanding solutions and responses from companies that cause significant environmental impacts in their production cycle [17].

There are 22 different definitions of GSCM by Ahi and Searcy [4], but the most commonly used definition in the literature is by Srivastava [18], who defines GSCM as the integration of environmental thinking into SCM, including product design, material sourcing and selection processes, delivery of the finished product to consumers, and end-of-life management of the product after its useful life [17]. Srivastava [18] added that the scope of GSCM ranges from reactive monitoring of general environmental management programs to more proactive practices implemented through various Rs which are reduce, reuse, rework, reclaim, recycle, reprocess, remanufacture, reverse logistics and more.

2.2 Institutional Theory

Institutional theory is concerned with the deeper and more efficient aspects of institutional structure. It looks at the processes by which systems, including schemes, rules, norms and routines, are developed as authoritative social guidelines for behaviour [15]. Organisations are part of a social system with their own unique culture and values, apart from having a production system. Organisational decisions are based on cultural values, norms and behaviours under the influence of the external environment. When all organisations in the same industry adopt the same institutionalised practises and decision-making approaches, it shows that they are trying to become verified. Institutional theory is used to understand the types of external factors that compel an organisation to adopt or apply a new practise [1]. Based on institutional theory, this study assumes that organisational decisions depend on the social structure in which the organisation operates both externally and internally [19].

The pressures for GSCM practises in this study use an institutional theoretical framework of DiMaggio and Powell [15], which consists of three isomorphic pressure factors, namely coercive pressure, normative pressure, and mimetic pressure. Each of these three pressure factors offers testable hypotheses relevant to the study of green supply chain management antecedents. Many researchers have recognised the importance of institutional theory in explaining corporate behaviour. Institutional theory proposes that organisations can improve their ability to grow and survive in a competitive environment by satisfying their stakeholders [5].

Government Pressures as Coercive Pressure

DiMaggio and Powell [15] stated that coercive isomorphism arises from the pressures exerted on a dependent firm by other organisations, as well as the cultural expectations of the society in which it operates [19]. In this research, government legislation is defined as coercive pressure that drives Malaysian GSCM production practises to improve their performance. Coercive pressure is usually an important factor driving the environmental management practises of producers in developing countries like Malaysia. The government is the overarching organisation that can influence the actions of an organisation [20]. Although government legislation can be an encouragement for GSCM practises, managers usually assume that the government exerts the strongest external pressure on the organisation's environmental initiatives. Organisations must comply with these environmental legislation, otherwise they face legal action, penalties or, in the worst case, exclusion from the market [11]. Following Li [5], other researchers show that innovation-friendly rules provide ample incentives to encourage organisational environmental innovation practises. While there is some empirical evidence, the results are mixed [5, 21].

There are two types of instruments that influence government regulation, namely command and control instruments and economic incentives for GSCM practises. In the command and control instrument, the authorities or governments give instructions to the public or organisations through the enactment of laws, the development of behaviours and the use of enforcement machinery to make people comply with the laws. The command and control instrument in environmental policy essentially involves setting standards to protect or improve the quality of the environment [22]. Economic incentive instruments rely on market prices and relative price changes to change the behaviour of public and private polluters in ways that support environmental protection or improvement [23]. Some researchers believe that economic incentive instruments are more effective than command-and-control instruments because they provide more benefits to the organisation. In this case, the basic message is more important than the choice of basic instruments. Other researchers argue that there is no single rule that is suitable for all cases, but that a combination of policy instruments should be made depending on the different circumstances of each instrument. For example, with the implementation of command-and-control policies such as environmental regulations, emission standards, product restrictions and economic incentive instruments such as better taxes, trade permits and subsidies for environmental innovation [5, 21].

Market Pressure as Normative Pressure

According to DiMaggio and Powell [15], normative pressure comes from professional pressure. Normative pressure arises from certain norms and standards that are formalised by the approach based on the expectations of the environmental culture. Various groups can be a source of normative pressure, including educational institutions that teach cognitive behaviour, professionals from industry groups and associations, non-governmental organisations (NGOs) with a special interest in particular industries, and also the general public. In addition, suppliers and customers are also one of the main components of this pressure [1].

Li [5] added, market demand can exert strong pressure on companies’ environmental initiatives and can be an important normative pressure. Customer demand analysis focuses on identifying, understanding and responding to customers' needs and developing products that meet their expectations [24]. Li [5] also noted that previous studies identified two reasons for companies to produce green products. First, there is an increasing demand for green products from end consumers. According to this, retailers who want to green their supply chain take into account customer pressure, and if customer pressure does not affect companies, they may not be willing to practise GSCM. The other reason is the initiatives within the company to protect the environment [11].

Market pressure can come from two types of consumers. First, from the pressure from overseas customers. With the increasing economic globalisation from seller's to buyer’s markets, companies need to adopt environmental practises to meet the demand for exports and sales to overseas customers and partners. This in turn leads to a green multiplier effect, where the requirements for green products and materials must also be adopted by suppliers [25]. Second, domestic customers. Awareness of environmental issues leads domestic customers to want to buy more and more green products, so companies need to take measures to implement GSCM [5].

Competitive Pressure as Mimetic Pressure

Mimetic pressure is a company’s default response to uncertainty [15]. Environmental practises have become an area where companies can gain a competitive advantage over their rivals as more and more companies nowadays have high quality goods, good customer service and other competitive advantages. Other studies have also examined the need for companies to pay more attention to changes in their competitors’ environmental strategies. In order to gain a competitive advantage, more and more environmentally friendly products are being offered in the market nowadays. Many companies are starting to use environmental innovation as an important differentiation tool to improve their efficiency, product quality and green image. However, there are some problems in understanding competitors’ strengths, weaknesses, capabilities and strategies and identifying their technologies to meet the demand of target customers [5].

According to Ye et al. [19], competitive pressure puts pressure on companies to adopt reverse logistics. As reverse logistics management becomes a standard practise and thus an appropriate capability, companies will support and sustain these competitive practises. Moreover, as more companies establish environmentally friendly production facilities, they will put pressure on their upstream suppliers to improve their environmental performance. The growing competition and expectations triggered by the widespread use of reverse logistics and recovery measures will put pressure on top managers to address reverse logistics practises. As reverse logistics is part of the GSCM, this pressure may encourage Malaysian manufacturers to adopt environmentally friendly practises.

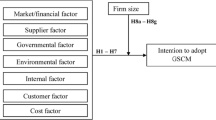

From the above arguments, the framework in Fig. 1 was derived and the following hypotheses were developed to be tested in this study.

- H1a:

-

Government command and control environmental regulations are positively related to green supply chain management practises.

- H1b:

-

Economic incentive instruments are positively related to green supply chain management practises.

- H2:

-

Market pressure is positively related to green supply chain management practises.

- H3:

-

Competitive pressure is positively related to green supply chain management practises.

3 Methodology

In this quantitative study, stratified random sampling was used to collect data. Data was collected through email from various manufacturing companies in Malaysia. The 118 respondents who answered the questionnaire were from 21 different manufacturing industries with green certifications such as ISO 9001, ISO 14001, MyHijau, etc.

The questionnaire consists of three parts, namely demographic information, GSCM practises and institutional pressure. GSCM practises were measured using an already established instrument that has been shown to be reliable and valid in previous research [26]. The instrument consists of fourteen items. Each question was scored on a five-point scale, with 1 representing 'not considered', 2 representing 'considering', 3 representing 'currently considering', 4 representing 'beginning implementation' and 5 representing 'successful implementation'. Three-part questions on government pressure, market pressure and competitive pressure were used to measure the construct "institutional pressure". All questions were in the form of a 5-point numerical Likert scale ranging from 1 (strongly disagree) to 5 (strongly agree) [5, 19]. The hypotheses were analysed using the PLS-SEM method. The decision to accept or reject the hypothesis was made and supported by the researcher based on the t-value.

4 Results

Convergent validity means that a measurement should be positively correlated with alternative measurements of the same construct. The average variance extracted (AVE) and the outer loadings of the indicators were determined to establish the convergent validity of the model [27]. The average variance extracted (AVE) is a leading measure of convergent validity. It measures the unidimensionality of a construct to avoid systematic measurement error [28]. Table 1 shows that all constructs yield a AVE of more than 0.5 and can thus be considered acceptable [28].

A look at Table 2 shows that the moderate and strong relationships with GSCM practises are the command and control instrument CCI (0.434) and competitive pressure CP (0.328). And, the economic incentives instrument, EII (− 0.163) and market pressure, MP (− 0.131) respectively.

To run the PLS-SEM algorithm in SmartPLS, a few parameters need to be set. Figure 2 shows the results after the estimation is complete. The impacts on green supply chain management practises are command and control instrument (CCI) (0.431), economic incentive instrument (EII) (− 0.194), market pressure (MP) (− 0.134) and competitive pressure (0.327). Path coefficients above 0.2 are significant according to the rule of thumb and path coefficients below 0.1 are usually not significant (Hair et al. 2014). The finding that the economic incentive instrument and market pressure provide a direct path to green supply chain management practises that is below 0.1 was of concern, so further analysis such as a multi-group analysis was planned at a later stage to understand the real-life phenomena compared to the theory.

Bootstrapping is used to identify the supported relationships of the structural model. To support the decision, the T-value must be greater than 1.6457. Table 2 shows that two factors support the decision and the relationship with GSCM practises, namely the command and control instrument and competitive pressure. On the other hand, the economic incentive instrument and market pressure do not support the relationships.

5 Discussion

The first research objective was to determine the relationship between government pressure and GSCM practices in the manufacturing industry in Malaysia. As shown in Table 2, H1a (command and control instrument) supports the hypothesis that there is a positive relationship with GSCM practices. This is in line with the findings of Ye et al. [19] who found that command and control instrument is an effective driver of GSCM practices. Esfahbodi et al. [29] found that under institutional pressure, coercion related to compliance due to the influence of those in power is the most important driver of manufacturing firms’ environmental initiatives. However, hypothesis H1b (economic incentive instrument) showed that the hypothesis was not supported. The results are consistent with Li [5] who observed that the economic incentive instrument is not well established in China and remains weak, so it does not provide sufficient incentives for manufacturers to adopt GSCM practices. Abdullah et al. [6] also noted that although the government in Malaysia supports manufacturers through loans, subsidies and grants to encourage firms to adopt environmentally friendly practices, the control and pressure of regulations and incentives are rather inconsistent. This is demotivating for manufacturers.

The second research objective was to determine the relationship between market pressure and GSCM practices in the Malaysian manufacturing industry. As shown in Table 2, hypothesis H2 (market pressure) indicating that there is an insignificant relationship with GSCM practices. The results are also consistent with Vanalle et al. [13], who found no positive relationship between normative pressure (market pressure) and GSCM. Yusuf et al. [24] found that the purchase of an eco-friendly product in Malaysia is not primarily because of the environmental benefits, but consumers purchase the product because it fulfils the desired functions and requirements.

The third research objective was to determine the competitive pressure from GSCM practices in the manufacturing industry in Malaysia. As shown in Table 2, hypothesis H3 (competitive pressure) is supported and shows a positive relationship with GSCM practices. The results are consistent with Hsu et al. [30] who found that competitive pressure also has a positive influence on green product practices. Several other studies have also found that competitive pressure has a direct impact on the adoption of green product practices [5, 11]. Companies’ improvements in the international market are indirectly reflected in the domestic market, as green products are also marketed in Malaysia. This puts pressure on upstream suppliers and their domestic competitors to improve their environmental practices as well [19].

6 Conclusion

The purpose of this study is to determine the relationship between institutional pressure and GSCM practices in the manufacturing industry in Malaysia. The study found that only two factors positively influence the practices, namely command and control pressure as coercive pressure and competitive pressure as mimetic pressure. Malaysian manufacturers seem to adopt green practices when there are strict environmental regulations to avoid being penalized by the government. They will also adopt green practices for competitive reasons to gain a competitive advantage. However, the economic incentives instrument in the form of coercive measures has little influence on the decision to adopt GSCM practices. This could be due to the fact that government regulation and support is rather inconsistent. The same is true for market pressure as normative pressure coming from consumers. Low consumer environmental awareness means that manufacturers do not need to set higher standards for environmentally friendly products. In general, this result will help policy makers to enact strict regulations, researchers to conduct further studies on the causes and drivers of GSCM, and manufacturers in Malaysia to incorporate green features in their traditional products. This will also have an impact on raising awareness of green products among consumers in Malaysia.

References

Saeed A, Jun Y, Nubuor SA, RasikaPriyankara HP, Jayasuriya MPF (2018) Institutional pressures, green supply chain management practices on environmental and economic performance: a two theory view. Sustain 10(5):1–24

Tundys B (2018) Green supply chain—barriers and benefits of implementing the new management strategy—analysis of the empirical research. Eur J Serv Manag

Tronnebati I, Jawab F (2020) The similarities and differences between the green and sustainable supply chain management definitions and factors: a literature review. In: 2020 13th International colloquium of logistics and supply chain management, LOGISTIQUA 2020

Ahi P, Searcy C (2013) A comparative literature analysis of definitions for green and sustainable supply chain management. J Clean Prod

Li Y (2014) Environmental innovation practices and performance: moderating effect of resource commitment. J Clean Prod 66:450–458

Abdullah M, Zailani S, Iranmanesh M, Jayaraman K (2016) Barriers to green innovation initiatives among manufacturers: the Malaysian case. Rev Manag Sci 10(4):683–709

Hajikhani M, Wahiza Binti Abdul Wahat N, Bin Idris K (2012) Considering on green supply chain management drivers, as a strategic organizational development approach, Malaysian perspective. Aust J Basic Appl Sci

Abdullah R, Mat Daud MS, Ahmad F, Shukti AA, Shah MZ (2016) Green logistics adoption among 3PL companies. Int J Supply Chain Manag

Shahlan MZ, Sidek AA, Suffian SA, Hazza MHFA, Daud MRC (2018) An examination on the influence of small and medium enterprise (SME) stakeholder on green supply chain management practices. In: IOP conference series: materials science and engineering

Puspani NS, Hutomo A, Sinaga O (2019) Role of market: How knowledge acquisition impact on investment recovery and reverse logistics towards sustainability performance. J Adv Res Dyn Control Syst

Zhu Q, Sarkis J, Lai K (2013) Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices. J Purch Supply Manag 19(2):106–117

Sarkis J, Gonzalez-Torre P, Adenso-Diaz B (2010) Stakeholder pressure and the adoption of environmental practices: the mediating effect of training. J Oper Manag 28(2):163–176

Vanalle RM, Ganga GMD, Godinho Filho M, Lucato WC (2017) Green supply chain management: an investigation of pressures, practices, and performance within the Brazilian automotive supply chain. J Clean Prod 151(2):250–259

Aldeehani A, Sulaiman S, Aziz FA, Mustapha F (2018) Development of green supply chain management in food industry. In: Proceedings of the International Conference on Industrial Engineering and Operations Management

DiMaggio PJ, Powell WW (1983) The iron cage revisited: institutional isomorphism and collective rationality in organizational fields. Am Sociol Rev 48(2):147–160

Mukhamedjanova KA (2020) Concept of supply chain management. J Crit Rev

de Oliveira UR, Espindola LS, da Silva IR, da Silva IN, Rocha HM (2018) A systematic literature review on green supply chain management: research implications and future perspectives. J Clean Prod

Srivastava SK (2007) Green supply-chain management: a state-of-the-art literature review. Int J Manag Rev

Ye F, Zhao X, Prahinski C, Li Y (2013) The impact of institutional pressures, top managers’ posture and reverse logistics on performance—evidence from China. Int J Prod Econ 143(1):132–143

Zhu Q, Sarkis J, Lai K (2007) Initiatives and outcomes of green supply chain management implementation by Chinese manufacturers. J Environ Manage 85(1):179–189

Jaffe AB, Newell RG, Stavins RN (2004) Technology policy for energy and the environment. In: Jaffe AB, Lerner J, Stern S (eds) Innovation policy and the economy. Volume 4. Cambridge and London, Brandeis U, pp 35–68

Elazegui DD (2002) A law of nature: the command-and-control

Bernstein JD (1993) Alternative approaches to pollution control and waste management: regulatory and economic instruments. In: Alternative approaches to pollution control and waste management. Regulatory and economic instruments

Yusuf MF, Ashari H, Razalli MR, Ramle R (2016) Environmental technological innovation and market demand: is market orientation a missing link? Int J Bus Manag Study 3(2):1–5

Henriques J, Catarino J (2014) Sustainable value and cleaner production—research and application in 19 Portuguese SME. J Clean Prod 1–8

Zhu Q, Sarkis J, Geng Y (2005) Green supply chain management in China: pressures, practices and performance. Int J Oper Prod Manag 25(5):449–468

Hair JF, Hult GTM, Ringle CM, Sarstedt M (2014) A primer on partial least squares structural equation modeling (PLS-SEM). SAGE Publications Inc.

Henseler J, Ringle CM, Sarstedt M (2016) Testing measurement invariance of composites using partial least squares. Int Mark Rev 33(3):405–431

Esfahbodi A, Zhang Y, Watson G, Zhang T (2017) Governance pressures and performance outcomes of sustainable supply chain management—an empirical analysis of UK manufacturing industry. J Clean Prod

Hsu C-C, Tan KC, Zailani SHM, Jayaraman V (2013) Supply chain drivers that foster the development of green initiatives in an emerging economy. Int J Oper Prod Manag 33(6):656–688

Acknowledgements

The authors would like to thank the Ministry of Higher Education for providing financial support under Fundamental Research Grant Scheme (FRGS) No. FRGS/1/2019/SS03/UMP/02/2 and UMP Fundamental Research Grant RDU182202-1.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Yusuf, M., Ramle, R., Abdullah, N. (2022). Pressures on Manufacturing Industry to Practice Green Supply Chain Management in Malaysia. In: Abdul Sani, A.S., et al. Enabling Industry 4.0 through Advances in Manufacturing and Materials. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-2890-1_58

Download citation

DOI: https://doi.org/10.1007/978-981-19-2890-1_58

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-2889-5

Online ISBN: 978-981-19-2890-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)