Abstract

Advancement to the performance of humidity sensor is an importance subject due to its diverse role in multitude of applications. The trend shows that researchers are using various approaches to tackle the performance issues of humidity sensor. This paper reviews recent progress on the improvement of titanium dioxide-based humidity sensor performance through structural modification, doping and composite effect. These three approaches have seen tremendous success in elevating the humidity sensing performance of titanium dioxide-based humidity sensor in term of higher sensitivity, shorter response/recovery time, and higher stability. The main advantages of the modified nanostructures are that they offer huge surface area which is beneficial for the adsorption of water molecules and directional pathway for the flow of charge carrier. Meanwhile, doping and formation of composite have contributed by having a positive synergistic effect in term of hydrophilicity, electrical conductivity, surface reactivity etc. In this work, efforts to improve the humidity sensing performance by various researchers working on this material are presented and discussed.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The importance of metal oxide semiconductors is growing with each passing year. Materials such as ZnO, NiO, SnO, MgO etc. are constantly at the centre of research subject from researcher from all over the world. This is due to the advantageous properties of metal oxides namely their non-toxicity, high chemical stability, intrinsic high sensing characteristic, low cost, and their abundance in nature. These compounds are formed when the electron from metal element is released to the oxygen atom resulting in oxides with different bonds and electronic structures [1].

One such metal oxide is titanium dioxide (TiO2) or titania. TiO2 is semiconductor with bandgap energy of 3.0–3.2 eV [2]. Since the discovery of its photocatalytic capability in 1972 [3], interest in this compound continue to rise. Furthermore, in 1988, Gratzel et al. [4] have introduced a new type of solar cell which utilizes TiO2 as the photoanode in dye-sensitized solar cell. Nowadays, TiO2 have found its way in various type of application such as pollutant degradation photocatalyst [5], photochemical water splitting, UV photosensor [6], biosensors [7], and chemical sensors [8].

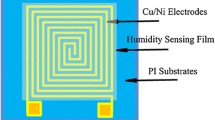

One of the important chemical sensors is the humidity sensor. It is a device which can detect the level of water molecules in the air. It is used in wide variety of fields such as home appliances, agricultural, weather forecasting, and health monitoring. In the light of recent advancement in Internet of Things (IoT) and fourth industrial revolution (IR 4.0), the trend of application is shifting toward interconnected sensors and wearable devices. Depending on the transduction mechanism, humidity sensor can be divided into several types namely resistive, capacitive, and optical [9]. Humidity is often expressed in term of relative humidity (RH). It can be defined as the ratio of the amount of water vapour present in the atmosphere to the maximum amount that the atmosphere can hold [10]. RH is usually stated in unit of percentage.

Experimental works and analyses are being carried out by numerous groups with the aim to promote the performance of TiO2-based humidity sensor mainly in term of sensitivity, response/recovery time, hysteresis, linearity and stability with various degree of success. However, a comprehensive review on this subject remained scarce. Herein, recent progress on the TiO2-based humidity sensor is presented and discussed. Emphasis is placed on efforts which were based on structural modification, doping process and composite formation with other materials.

2 Effect of Different Types of Nanostructures

It is widely considered that humidity sensing mechanism are largely influenced by the structural or the shape of the material [11]. Herein, various kind of structures and their effects to the performance of humidity sensor are discussed.

2.1 TiO2 1-D Nanostructure

1-D nanostructured material refers to a material with one of its dimensions is larger than the other two dimensions. These materials usually are associated a very high aspect ratio. Examples of these type of structure includes nanorods [12], nanowires, nanotubes, and nanofibers. This type of structure offers good carrier transport along its structural axis. The direct pathway of the movement of electron or hole enable faster response with high sensitivity.

Jyothilal et al. [13] have reported on the fabrication of humidity sensor using slanted TiO2 nanorods produced using electron beam evaporation. They have achieved high sensitivity with fast response and recovery time of 145 and 120 ms respectively. It is suggested that the morphology has helped increase the carrier concentration leading to improved protonic conduction. Their sensor also showed promising potential as breath analyzer.

TiO2 nanotube structure have been tested by Farahani et al. [14] as the humidity sensor. They have claimed that the structure is super-hydrophilic, allowing full absorption of water molecules. Their sensor recorded responsivity of 300%.

Meanwhile, Li et al. [15] have experimented with humidity sensor made of TiO2 nanowires. Sensitivity of 280 pF/% RH was recorded at low RH (7% RH to 33% RH). It is supposed that the cross-linked nanowire structure improves charge conduction leading to the increase in sensitivity at low RH environment.

2.2 TiO2 2-D Nanostructure

2-D nanostructures are made of with thin layer structure. Nanosheet, nanowall, nanobelt, nanodisk, and nanoflakes are some of the examples of 2-D nanostructure. These types of structures were also being utilized to increase the performance of humidity sensor. For example, 2-D graphene [16, 17], NiO [18], WS2 [19] and MoS2 [20] have shown promising result as humidity sensor.

However, the use of TiO2 2-D structure for the application of humidity sensor remained scarce. One report on TiO2 nanosheet-based ultrasensitive humidity sensor have been published by Gong et al. [21]. The ultrathin petal-like structure shortened transporting paths and increase contact area between sensing material and electrodes. The self-assembled TiO2 nanosheet yielded a nanoporous structure with high specific surface area. It is also argued that the ultrathin structure is rich with oxygen vacancy defect which is beneficial for humidity absorption. Up to 10 times improvement in sensitivity value was observed from the fabricated device.

2.3 TiO2 3-D Nanostructure

3-D nanostructures usually encompassed three categories which are 3-D spatial ensembles of 1-D or 2-D nanostructure, 3-D nanoporous structures and 3-D hierarchical nanostructured materials [22]. Examples of this type of structure are nanoflower [23], nanoball, nanocube and interconnected pores. They are usually credited as having the largest surface area. Zhang et al. [24] reported on the quartz crystal microbalance (QCM) type humidity sensor using hollow ball, nanosphere and nanoflower TiO2. The hollow ball structure which has the largest surface area showed the highest sensitivity of 33.8 Hz/%RH.

Similar nanoflower structure was also reported by Jeong et al. [25] who have fabricated resistive type humidity sensor with sensitivity of 485.7 RH%−1. Urchin-like structure have been reported by Wang et al. [26]. Figure 1 shows the examples of different types of TiO2 nanostructures, and Table 1 gives a summary of TiO2 nanostructure-based humidity sensor.

3 Effect of Doping

Doping is the act of adding specific amount of impurity into a host material in order to improve its properties. In the case of TiO2, the doping could be divided into metal and non-metal doping. Dopant properties such as atomic radius and electronegativity would influence the effectiveness of a doping process [30].

3.1 Metal Doping

Li et al. [31] reported on the doping of niobium (Nb) into TiO2. The pentavalent Nb5+ ion is a donor and will donate electron based on the following equation:

This type of reaction would increase the electron concentration of TiO2. Since electron conduction is responsible for the humidity detection mechanism, this has resulted in improved sensitivity of up to 13,705 pF/%RH in a capacitive-type humidity sensor.

Quartz crystal microbalance (QCM)-type humidity sensor made of Ru-doped TiO2 nanofiber have been reported by Farzaneh et al. [32]. Using density functional theory (DFT) calculation, they have managed to show that the Ru-doped TiO2 have significantly larger surface reactivity compared to undoped TiO2. This have helped increase the water absorption ability, leading to the increase in sensitivity.

Meanwhile, Li et al. [33] presented Co as the dopant for TiO2 for the application of resistive-type humidity sensor. Substitution of Ti4+ with Co2+ creates many defect sites and reduces the grain size, effectively increasing the humidity sensing performance.

3.2 Non-metal Doping

Humidity sensing properties could also be improved by doping with non-metal elements. Li et. al. [34] has reported on the N doping of ordered mesoporous TiO2. Through XPS analysis, the resulting material showed the presence of Ti3+ defect sites. The defect sites would react with water molecules, releasing additional electron to the structure which would improve the sensitivity.

The sensitivity of optical-type humidity sensor could also be increased through non-metal doping as demonstrated by Ghadiry et al. [35] who added graphene oxide (GO) in TiO2 solution which were then drop-casted on waveguides. GO helps in the diffusion of water molecules which bring significant changes to the refractive index. Table 2 shows the summary of doping effect on TiO2-based humidity sensor.

4 Effect of Composite

Another approach to improve the performance of humidity sensor is through the formation of TiO2 composite. Since it is quite challenging to simultaneously produce all the desired properties in a single material, synthesis of composite material has been gaining considerable attention [36]. Among the composite types which are commonly used are layered, core–shell, random mixture, and decoration structure. Composite materials are interesting as they often exhibit improved physical and chemical properties compare to each of the material alone.

Araujo et al. [37] have reported on the TiO2/ZnO composite-based humidity sensor. Their result showed improved performance in term of increased sensitivity. Both metal oxides complimented each other properties. TiO2 compensated the low hydrophilicity of ZnO while ZnO nanostructure improve the overall surface area of the sensor. TiO2 naturally have high hydrophilicity because of the presence of Ti3+/Ti4+ interface sites which is associated with dissociative transfer of water molecules [38].

Polymer is another material capable of forming beneficial composite with TiO2. Mallick et al. [39] formed TiO2 composite with polyvinylidene fluoride (PVDF) for the application of humidity sensor. They reported that the addition of TiO2 increases the hydrophilicity of the sensor. Moisture absorption and settling were reported to increase at a more hydrophilic surface, leading to increase in the sensitivity of capacitive humidity sensors [40].

Some researcher worked with TiO2 and organic-inorganic hybrid nano-composites, VOPcPhO [41]. Formation of this composite helped produced uniform voids across the surface of the material which are favourable for the absorption of moisture content. These voids also increase the surface porosity as evidenced through atomic force microscopy (AFM) result.

Adding a p-type semiconductor to n-type TiO2 could form heterojunction structure as shown by Lu et al. [11]. Carrier transportation could be increased significantly through the decrease of electron current path at the heterogenous interface. Si et al. [36] reported a similar result when using TiO2/NaNbO3 nanocomposite. In their work, detection of humidity was achieved through the reduction of potential barrier height of the heterojunction due to the transfer of electrons from NaNbO3 to TiO2 upon exposure to moisture. Table 3 shows the summary of TiO2 composite-based humidity sensor.

5 Conclusion

A review on the recent progress of the development of TiO2-based humidity sensor have been presented. Engineering the shape of TiO2 nanostructures into 1-D, 2-D and 3-D could bring advantageous properties to the performance of humidity sensor. In addition, doping process and formation of composite have also been shown to contribute to the increased performance of humidity sensor. Clearly TiO2 have a very good potential to become a very efficient humidity sensing material thanks to the commendable effort by researcher on this subject. However, there are still gaps to be explored to further improve the performance of the device.

References

Victor NS, Leão ESA (2019) Metal oxide heteronanostructures prepared by electrospinning for the humidity detection: fundamentals and perspectives. J Mater Sci Chem Eng 7:43–54

Kalb J, Folger A, Zimmermann E, Gerigk M, Trepka B, Scheu C, Polarz S, Schmidt-Mende L (2019) Controlling the density of hydrothermally grown rutile TiO2 nanorods on anatase TiO2 films. Surf Interfaces

Fujishima A, Honda K (1972) Electrochemical photolysis of water at a semiconductor electrode. Nature 238(5358):37–38

O’Regan B, Grätzel M (1991) A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 353(6346):737–740

Tayel A, Ramadan AR, El Seoud OA (2018) Titanium dioxide/graphene and titanium dioxide/graphene oxide nanocomposites: synthesis, characterization and photocatalytic applications for water decontamination. Catalysts 8(11)

Yusoff MM, Mamat MH, Abdullah MAR, Ismail AS, Malek MF, Zoolfakar AS, Al Junid SAM, Suriani AB, Mohamed A, Ahmad MK, Shameem Banu IB, Rusop M (2020) Coupling heterostructure of thickness-controlled nickel oxide nanosheets layer and titanium dioxide nanorod arrays via immersion route for self-powered solid-state ultraviolet photosensor applications. Measurement 149:106982

Shetti NP, Bukkitgar SD, Reddy KR, Reddy CV, Aminabhavi TM (2019) Nanostructured titanium oxide hybrids-based electrochemical biosensors for healthcare applications. Colloids Surf B 178:385–394

Barreca D, Carraro G, Comini E, Gasparotto A, Maccato C, Sada C, Sberveglieri G, Tondello E (2011) Novel synthesis and gas sensing performances of CuO–TiO2 nanocomposites functionalized with Au nanoparticles. J Phys Chem C 115(21):10510–10517

Yusoff SFAZ, Lim CS, Azzuhri SR, Ahmad H, Zakaria R (2018) Studies of Ag/TiO2 plasmonics structures integrated in side polished optical fiber used as humidity sensor. Results Phys 10:308–316

Blank TA, Eksperiandova LP, Belikov KN (2016) Recent trends of ceramic humidity sensors development: a review. Sens Actuators B Chem 228:416–442

Lu J, Liang K, Xu C, Wang X, Haibo O, Huang J, Feng L (2019) Humidity sensor based on heterogeneous CoTiO3/TiO2 film with vertically aligned nanocrystalline structure. Vacuum 163:292–300

Musa M, Mamat MH, Othman MA, Shameem IB, Vasimalai N, Malek MF, Rusop M (2020) Enhanced sensitivity of humidity sensor prepared using vertically aligned v-doped TiO2 nanorods array. J Electr Electron Syst Res 17:68–73

Jyothilal, Shukla G, Walia S, Kundu S, Angappane S (2020) Humidity sensing and breath analyzing applications of TiO2 slanted nanorod arrays. Sens Actuators A Phys 301:111758

Farahani E, Mohammadpour R (2020) Fabrication of flexible self-powered humidity sensor based on super-hydrophilic titanium oxide nanotube arrays. Sci Rep 10(1):13032

Li N, Jiang Y, Zhou C, Xiao Y, Meng B, Wang Z, Huang D, Xing C, Peng Z (2019) High-performance humidity sensor based on urchin-like composite of Ti3C2 MXene-derived TiO2 nanowires. ACS Appl Mater Interfaces 11(41):38116–38125

Saqib M, Khan SA, Ur Rehman, HMM, Yang Y, Kim S, Rehman MM, Kim WY (2021) High-performance humidity sensor based on the graphene flower/zinc oxide composite. Nanomaterials (Basel) 11(1)

Hassan G, Sajid M, Choi C (2019) Highly sensitive and full range detectable humidity sensor using PEDOT: PSS, methyl red and graphene oxide materials. Sci Rep 9(1):15227

Parimon N, Mamat MH, Shameem Banu IB, Vasimalai N, Ahmad MK, Suriani AB, Mohamed A, Rusop M (2020) Fabrication, structural, optical, electrical, and humidity sensing characteristics of hierarchical NiO nanosheet/nanoball-flower-like structure films. J Mater Sci Mater Electron 31(14):11673–11687

Dwiputra MA, Fadhila F, Imawan C, Fauzia V (2020) The enhanced performance of capacitive-type humidity sensors based on ZnO nanorods/WS2 nanosheets heterostructure. Sens Actuators B Chem 310:127810

Ze L, Yueqiu G, Xujun L, Yong Z (2017) MoS2-modified ZnO quantum dots nanocomposite: synthesis and ultrafast humidity response. Appl Surf Sci 330–336

Gong M, Li Y, Guo Y, Lv X, Dou X (2018) 2D TiO2 nanosheets for ultrasensitive humidity sensing application benefited by abundant surface oxygen vacancy defects. Sens Actuators B Chem 262:350–358

Zhao H, Lei Y (2020) 3D nanostructures for the next generation of high-performance nanodevices for electrochemical energy conversion and storage. Adv Energy Mater 10(28):2001460

Musa MZ, Mamat MH, Vasimalai N, Shameem Banu IB, Parimon N, Hassan H, Malek MF, Rusop M (2021) Humidity sensing performance of V: TiO2 3D nanostructure-based humidity sensor. IOP Conf Ser Earth Environ Sci 682(1):012073

Zhang D, Chen H, Li P, Wang D, Yang Z (2019) Humidity sensing properties of metal organic framework-derived hollow ball-like TiO2 coated QCM sensor. IEEE Sens J 19(8):2909–2915

Jeong H, Noh Y, Lee D (2019) Highly stable and sensitive resistive flexible humidity sensors by means of roll-to-roll printed electrodes and flower-like TiO2 nanostructures. Ceram Int 45(1):985–992

Wang Z, Xiao Y, Cui X, Cheng P, Wang B, Gao Y, Li X, Yang T, Zhang T, Lu G (2014) Humidity-sensing properties of urchinlike CuO nanostructures modified by reduced graphene oxide. ACS Appl Mater Interfaces 6(6):3888–3895

Bindra P, Hazra A (2019) Selective detection of organic vapors using TiO2 nanotubes based single sensor at room temperature. Sens Actuators B Chem

Wang X, Li J, Li Y, Liu L, Guan W (2016) Emulsion-templated fully three-dimensional interconnected porous titania ceramics with excellent humidity sensing properties. Sens Actuators B Chem 237:894–898

Musa MZ, Mamat MH, Vasimalai N, Shameem Banu IB, Malek MF, Ahmad MK, Suriani AB, Mohamed A, Rusop M (2020) Fabrication and structural properties of flower-like TiO2 nanorod array films grown on glass substrate without FTO layer. Mater Lett 273:127902

Umar AA, Saad SKM, Umar MIA, Rahman MYA, Oyama M (2018) Advances in porous and high-energy (001)-faceted anatase TiO2 nanostructures. Opt Mater 75:390–430

Li TY, Si R, Sun J, Wang S, Wang J, Ahmed R, Zhu G, Wang C (2019) Giant and controllable humidity sensitivity achieved in (Na+Nb) co-doped rutile TiO2. Sens Actuators B Chem 293:151–158

Farzaneh A, Esrafili MD, Mermer Ö (2020) Development of TiO2 nanofibers based semiconducting humidity sensor: adsorption kinetics and DFT computations. Mater Chem Phys 239:121981

Li Z, Haidry AA, Gao B, Wang T, Yao Z (2017) The effect of co-doping on the humidity sensing properties of ordered mesoporous TiO2. Appl Surf Sci 412:638–647

Li Z, Haidry AA, Dong B, Sun L, Fatima Q, Xie L, Yao Z (2018) Facile synthesis of nitrogen doped ordered mesoporous TiO2 with improved humidity sensing properties. J Alloy Compd 742:814–821

Ghadiry M, Gholami M, Lai CK, Ahmad H, Chong WY (2016) Ultra-sensitive humidity sensor based on optical properties of graphene oxide and nano-anatase TiO2. PLoS ONE 11(4):e0153949

Si R, Xie X, Li T, Zheng J, Cheng C, Wang C (2020) TiO2/NaNbO3 heterojunction for boosted humidity sensing ability. Sens Actuators B Chem 309:127803

Araújo ES, Libardi J, Faia PM, Oliveira HPD (2017) Humidity-sensing properties of hierarchical TiO2:ZnO composite grown on electrospun fibers. J Mater Sci Mater Electron 28(21):16575–16583

Poonia E, Mishra PK, Kiran V, Sangwan J, Kumar R, Rai PK, Tomer VK (2018) Aero-gel assisted synthesis of anatase TiO2 nanoparticles for humidity sensing application. Dalton Trans 47(18):6293–6298

Mallick S, Ahmad Z, Touati F, Shakoor RA (2019) Improvement of humidity sensing properties of PVDF-TiO2 nanocomposite films using acetone etching. Sens Actuators B Chem 288:408–413

Najeeb MA, Ahmad Z, Shakoor RA (2018) Organic thin-film capacitive and resistive humidity sensors: a focus review. Adv Mater Interfaces 5(21):1800969

Azmer MI, Aziz F, Ahmad Z, Raza E, Najeeb MA, Fatima N, Bawazeer TM, Alsoufi MS, Shakoor RA, Sulaiman K (2017) Compositional engineering of VOPcPhO-TiO2 nano-composite to reduce the absolute threshold value of humidity sensors. Talanta 174:279–284

Mallick S, Ahmad Z, Touti F, Bhadra J, Shakoor SA, Al-Thani NJ (2018) PLA-TiO2 nanocomposites: thermal, morphological, structural, and humidity sensing properties. Ceram Int 44(14):16507–16513

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Musa, M.Z. et al. (2022). Recent Progress on Titanium Dioxide-Based Humidity Sensor: Structural Modification, Doping, and Composite Approach. In: Abdul Sani, A.S., et al. Enabling Industry 4.0 through Advances in Manufacturing and Materials. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-2890-1_48

Download citation

DOI: https://doi.org/10.1007/978-981-19-2890-1_48

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-2889-5

Online ISBN: 978-981-19-2890-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)