Abstract

Bio-composite materials, which are a serious alternative to synthetic-based fibre and matrix materials due to their high characteristics and biodegradability, cause difficulties and uncertainties for usage conditions due to their high sensitivity to climatic conditions. Scientific studies have shown that climatic factors such as temperature, humidity, radiation, UV rays, and acid rain that act synergistically in natural weathering conditions, cause degradation and changes in the bio-composite material's characteristics. Examining the material's behaviour under natural weathering conditions provides the most realistic and reliable results in terms of determining the shelf life of the material and knowing its behaviour in the usage environment. In this study, changes in thermal, mechanical, and aesthetic properties of bio-composite materials exposed to natural ventilation conditions were investigated. It has been observed that natural weathering induces dramatic decreases in thermal and mechanical properties of bio-composite materials, especially with the effect of prolonged exposure times, and causes changes in colour, surface deterioration and changes in shape.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Deterioration of the environment's natural equilibrium, increasing natural disasters, and environmental awareness on governmental and personal basis have led to increased sustainability awareness. Therefore, the search for environment-friendly products used in industrial and daily life has been launched. One of the areas where environment-friendly material applications are used is the field of composite material production. In this respect, it has begun to search for green composite materials that can be an alternative to synthetic fibre and synthetic matrix composite materials with a wide range of use and superior properties.

Within the scope of the search for sustainable materials, it is seen that the use of biobased plastics and their composites (bio-composites) is on a significant growth trend. Bio-composites produced from local and renewable sourced materials contribute to sustainability by increasing ecological efficiency, contributing to the establishment of green chemistry and green industry, and paving the way to produce new generation materials, processes and products (Bharath and Basavarajappa 2016). In reducing the carbon footprint caused by traditional composite materials, bio-composite materials can be an alternative, and these materials can also help reduce the strain on the environment (Chang et al. 2020).

Bio-composite materials can be evaluated in two main classes: green composites or partly eco-friendly composites, depending on the fibres and matrix's sustainability. While the matrix and fibres of green composites are entirely obtained from renewable resources, either the matrix or fibres of partly eco-friendly composites are obtained from environmentally friendly sustainable sources (Mohanty et al. 2005; Mitra 2014; Peças et al. 2018; Akderya et al. 2020).

Natural fibre-reinforced bio-composites are additives that are used as reinforcement elements, obtained from natural sources. When compared with synthetic fibres, they have superior characteristic properties such as renewability, abundance, biodegradability, affordability, flexibility during the production process, specific stiffness, low carbon footprint and low density (Nabi Saheb and Jog 1999; Akil et al. 2011; Mukherjee and Kao 2011; Faruk et al. 2012; and Hiremath 2020; Chaudhary et al. 2020). The classification of natural fibres is schematised in Fig. 1, and accordingly, natural fibres can be divided into two main classes, organic and non-organic. Organic natural fibres can be examined in two different groups, plant-based and animal-based. As an example of plant-based natural fibres as a reinforcement element; jute (Rahman et al. 2014), flax (Li et al. 2009), hemp (Popa et al. 2013), kenaf (Kamal et al. 2014), ramie (Krasowska et al. 2010), banana (Rodríguez et al. 2018), coir (Sanal 2016), kapok (Sellivam et al. 2016), bamboo (Astadini et al. 2020; del Pilar Fajardo Cabrera de Lima et al. 2020; Hung et al. 2012; Chaowana and Barbu 2017), rice (Wang et al. 2010; Chen et al. 2015), palm (Abu-Sharkh and Hamid 2004), straw (Yaacab et al. 2016), broom (Nouar et al. 2020) can be given. Human hair (Verma and Singh 2016), alpaca hair (Fortunati et al. 2015), sheep wool (Aluigi et al. 2014), chicken feather (Akderya et al. 2020) can be used as a reinforcement element from animal-based fibres. Non-organic mineral-based natural fibres can be evaluated in three groups: asbestos, ceramic fibres, and metal fibres. Chrysotile, amosite, tremolite, actinolite, crocidolite, and anthophyllite are examples of asbestos class (Lang et al. 1986; Rinaudo et al. 2005), glass wool, glass quartz, aluminium oxide, boron carbide, and silicon carbide are in the ceramic fibre class, and in addition to those, aluminium fibre can be given as an example of metal fibre class (Chandramohan and Marimuthu 2011; Sapuan et al. 2017).

Classification of natural fibres and their origins (Riedel and Nickel 2002; John and Thomas 2008; Tridico 2009; Chandramohan and Marimuthu 2011; Akil et al. 2011; Azwa et al. 2013; Pandey et al. 2015; Bharath and Basavarajappa 2016; Sapuan et al. 2017; Mayandi et al. 2018; and Hiremath 2020; Hiremath and Sridhar 2020)

There has been a noticeable increase in the trend of use of bio-composite materials in recent years. In this direction, scientific studies are carried out to detect the changes in bio-composites’ properties in outdoor conditions to determine their shelf life. There are harsh environmental conditions that all materials can be exposed to in outdoor conditions. These conditions include acid rain, variable temperatures, high and low temperatures, wind, solar radiation, oxygen, biotic factors, and humidity. Natural weathering environment conditions are illustrated in Fig. 2. External conditions may cause degradation in the material and leakage of additives in its structure and entry of additives that are not in its structure. (Yew et al. 2009; Badji et al. 2018a; Liu et al. 2020; González-López et al. 2020).

Some researchers focused on the behaviour of natural fibre-reinforced bio-composite materials in different environmental conditions. Duigou et al. (2011) conducted a study to determine how to protect the external layers of flax/poly (l-lactic acid) (PLLA) bio-composite material from seawater ageing. Another study was carried out by Duigou et al. (2014) to obtain the effects of long-term seawater ageing on the flax/poly (lactic acid) (PLA) bio-composite. Ogunsona et al. (2017) investigated the behaviour of biocarbon reinforced nylon bio-composites under accelerated hydrothermal ageing conditions. Lila et al. (2019) conducted a study in which they examined the behaviour of bagasse fibre/PLA bio-composites under accelerated thermal ageing. The study on the differences between the bio-composite properties using pineapple leaf and palm fibre as reinforcement elements and polypropylene as a matrix was carried out by Chollakup et al. (2017). When the results of these studies were examined, it is seen that bio-composites degraded due to reasons such as matrix cracking, swelling, hydrolysis, debonding of fibre/matrix, and high-water uptake as a result of exposure to severe environmental conditions.

2 Natural Weathering Conditions

The high sensitivity of bio-composites to climatic conditions constitutes uncertainty and obstacle for their usage conditions. A limited number of scientific studies (Badji et al. 2018a, b, c; Abdullah et al. 2019) have been conducted to gain insight into bio-composites’ durability and behaviour under natural weathering conditions with different climatic conditions (Badji et al. 2018d). With natural weathering, more than one external environmental factors synergistically affect the material at the same time. In the natural weathering environment, it cannot be precisely known what factor causes the dramatic changes in the material's properties (Badji et al. 2018d). The biggest reason for the application of natural weathering technique on materials is to obtain reliable and realistic results for the behaviour of the material in real-life conditions (Pospíšil et al. 2006; Lv et al. 2015; González-López et al. 2020).

The most influential factors that cause degradation of both polymer matrix and natural fibre in bio-composite materials exposed to natural weathering environment are high temperatures or oxidative processes caused by free radicals due to ultraviolet (UV) rays, and degradation phenomena bring about decrease in physicochemical properties of bio-composites (Stark and Matuana 2004; Fabiyi et al. 2008; Badji et al. 2018d). The polymer matrix undergoes Norrish type I and II reactions chain scissions (Parikh et al. 2006) during natural weathering exposure and transforms into lower molecular weight products (Stark and Matuana 2004; Fabiyi et al. 2008; Thirmizir et al. 2011; Badji et al. 2018d). In addition to Norrish type reactions, degradation phenomena cause effects in the matrix, such as absorption of UV rays by the lignin substance, photo-yellowing effect, and quinoid structure formation. Moreover, degradation phenomena cause chromophoric groups’ formation in plant-based natural fibres (Beg and Pickering 2008; Azwa et al. 2013; and Hiremath 2020; Siakeng et al. 2020).

3 Results

3.1 Effects on Mechanical Properties

Having knowledge about the mechanical behaviour of materials gives a chance to intervene with a proactive approach to prevent malfunctions and errors that can potentially occur in engineering applications. Few scientific studies have been done to reveal the behavioural changes in bio-composites' mechanical properties in natural weathering environments.

Changes in some bio-composites' mechanical properties after exposure to natural weathering such as flexural strength, flexural modulus, tensile strength, tensile modulus, elongation at break, hardness and impact strength are given in Table 1. According to this table, most of the mechanical properties have decreased with natural weathering environments. The decrease in hardness values results from polymer chain scissions due to surface cracks and embrittlement occurring in natural weathering environment (Du et al. 2010). With the extension of the natural weathering duration, the number of chain scissions increase. Increasing the number of chain scissions results in the formation of shorter polymer chains and therefore, a decrease in overall mechanical properties (Fabiyi et al. 2008). Stark and Matuana (Stark et al. 2004; Stark and Matuana 2006) attributed the decrease in flexural strength values the fact that the crystallinity of composites increases at the beginning of the exposure period due to UV light and water exposure encountered in the natural weathering environment and decreases with the prolongation of this period. At the beginning of the exposure, the shorter and more mobile chains recrystallise. With the prolongation of the exposure, the chain scissions continue, and thus, the crystal regions are affected, and the crystallinity decreases.

The decrease in mechanical strength properties has been associated with the deterioration of the composite material's structure and properties. Natural weathering environment causes the composite materials to deteriorate, thus weakening the matrix-filler interfacial bonding. The swelling and shrinkage of natural fibres or particles with hydrophilic capability by absorbing and desorbing moisture cause the quality of the matrix-filler interface bonding to decrease (Beg and Pickering 2007, 2008). Stress concentration and chain scissions forming a brittle layer on the matrix surface, and the degradation of fillers led to an increase in composite materials' brittleness. Natural fibres deteriorating due to long-term natural weathering causes chromophoric groups to form in the composite material. These groups increased the photooxidation of composites. Moreover, thanks to photodegradation, additives with lignin in their structure have led to the formation of free radicals. Free radicals have had a detrimental effect on the structure of the matrix material by increasing chain scissions' speed (Beg and Pickering 2007; Naumann et al. 2012; Zhou et al. 2016).

The decrease in matrix-fibre interfacial bonding success of naturally weathered and therefore degraded composite materials may be caused by the inability to distribute the energy generated at the moment of impact through vibration and the inability to spread this energy in weak matrix-fibre regions (Oksman et al. 2009; Rahman et al. 2011).

3.2 Effects on the Thermal Properties

Exposure to natural weathering conditions has caused some changes in the thermal properties of composite materials. These changes are given in Table 2, as revealed by some scientific studies. The decrease in the first melting temperature of naturally weathered composites indicates the degradation of the matrix's lamellar fold surfaces, and the decrease in the second melting temperature indicates the effect of decaying molecules on crystal phase formation. The smaller and more defective molecules in the crystals formed during the recrystallisation process are the reason for the decrease in the second melting temperature (Rabello and White 1996, 1997; Butylina et al. 2012). Under natural weathering conditions, changes occurring on the matrix's lamellar structure due to cross-linking with UV rays' effect may affect the mechanical properties, while the melting temperatures may remain unchanged if they do not affect the bulk properties of the matrix. In case of exposure to high energy levels such as gamma-ray or electron irradiation, chain scissions and cross-linking in the amorphous phase cause changes in the bulk crystal structure of the composite material, and thus a decrease in the peak melting temperature is observed (Mitomo et al. 1994; Bergmann et al. 2007; Wei and McDonald 2016; Chan et al. 2019).

Photodegradation appears to be more predominant in the amorphous phase whose molecular chain is susceptible to further crystallisation; however, the crystallinity's overall decrease indicates that the crystalline phase is generally affected (Stark and Matuana 2006; Homkhiew et al. 2014; Badji et al. 2018a). One of the reasons for the decrease in crystallinity may be the impurities caused by factors such as dust and moisture accumulating in the composite material during exterior natural weathering exposure or the presence of smaller and more defective molecules in the material (Butylina et al. 2012; Soccalingame et al. 2016). The increase in the degree of crystallinity under natural weathering conditions may result from the change in molecular weight due to degradation of the polymer of the composite leading to chain breakage and subsequent secondary crystallisation (Fabiyi and McDonald 2014).

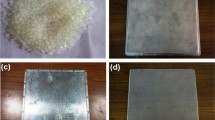

3.3 Effects on the Aesthetics

Some alterations in lightness and colours have been observed as a result of factors such as high temperature, UV rays and rain, with the exposure of composite materials to natural weathering conditions for specific periods. Total colour change is calculated by taking the lightness, redness and yellowness values of the composite into consideration. The changes in the visual properties of composites under natural weathering conditions are given in Table 3. When Rahman et al. (2011) exposed the polyethylene reinforced with 30% rice husk powder composite to natural weathering environment for four months, it caused a colour change in the composite as a result of photooxidation on the sample surfaces. Rain, which is one of the factors of natural weathering environment, accelerates the erosion process on the composite material's surface and is a source of moisture that can cause dimensional changes. Typical surface erosion spreads faster in materials such as wood-based materials with low density, and the surface of the material becomes rougher as a result of this spread. Surface erosion spread is a slowly progressing process and does not show itself in short periods (Rahman et al. 2011).

4 Future Perspective

Bio-composite materials are new trend materials that are being used as an alternative to traditional materials in a wide variety of industrial and engineering applications. Increased awareness and interest in long-term sustainability and environmental sensitivity, as well as superior properties such as high specific strength, high hardness values, higher fatigue strength, impact absorption, superior resistance to corrosion, recyclability, non-toxicity, and low-cost cause bio-composites to be evaluated in the class of engineering materials, and it is predicted that their frequency of use will increase in the future. Static and dynamic failures such as matrix cracking, fibre breakage and layer delamination, high sensitivity to climatic conditions and the inability to predict the mechanical behaviour of natural fibre reinforced composites present challenges in predicting the reliable performance of bio-composites. In order for the components of bio-composite materials to be selected correctly, long-term reliable performance must be determined. For this purpose, real-time experimental studies in natural weathering environment and accelerated weathering studies on bio-composites are mandatory to carry out. There is a need to develop new combined evaluation criteria in both macro and nano scale by demonstrating consistency between these studies.

5 Conclusion

Bio-composites encounter factors such as humidity, high and low temperatures, radiation and UV rays in natural environments. These factors cause deterioration in the mechanical, and thermal properties and aesthetics of bio-composite materials. Mechanical properties such as flexural strength, tensile strength, modulus of elasticity, elongation at break, impact resistance change with influences such as chain scissions and reduction of fibre-matrix interfacial bonding success. Thermal properties such as crystallinity and melting temperature deteriorate with recrystallisation, resulting in the formation of smaller and more defective molecules. Aesthetic properties such as lightness, surface roughness and shape also change with effects such as photooxidation, moisture absorption and photodegradation.

References

Abdullah AH, Bakar AA, Ismail H et al (2019) The effects of accelerated weathering on the tensile properties of kenaf reinforced biocomposites. In: IOP conference series: materials science and engineering. Institute of Physics Publishing

Abu-Sharkh BF, Hamid H (2004) Degradation study of date palm fibre/polypropylene composites in natural and artificial weathering: mechanical and thermal analysis. In: Polymer degradation and stability. Elsevier Ltd, pp 967–973

Akderya T, Özmen U, Baba BO (2020) Investigation of long-term ageing effect on the thermal properties of chicken feather fibre/poly(lactic acid) biocomposites. J Polym Res 27. https://doi.org/10.1007/s10965-020-02132-2

Akil HM, Omar MF, Mazuki AAM et al (2011) Kenaf fiber reinforced composites: a review. Mater Des 32:4107–4121

Aluigi A, Tonetti C, Rombaldoni F et al (2014) Keratins extracted from Merino wool and Brown Alpaca fibres as potential fillers for PLLA-based biocomposites. J Mater Sci 49:6257–6269. https://doi.org/10.1007/s10853-014-8350-9

Astadini NA, Widiastuti I, Harjanto B et al (2020) Natural weathering effect on mechanical and physical properties of recycled high-density polyethylene composite with bamboo reinforcement. In: Lecture notes in mechanical engineering. Springer, pp 659–666

Azwa ZN, Yousif BF, Manalo AC, Karunasena W (2013) A review on the degradability of polymeric composites based on natural fibres. Mater Des 47:424–442

Badji C, Beigbeder J, Garay H et al (2018a) Correlation between artificial and natural weathering of hemp fibers reinforced polypropylene biocomposites. Polym Degrad Stab 148:117–131. https://doi.org/10.1016/j.polymdegradstab.2018.01.002

Badji C, Beigbeder J, Garay H et al (2018b) Natural weathering of hemp fibers reinforced polypropylene biocomposites: relationships between visual and surface aspects, mechanical properties and microstructure based on statistical approach. Compos Sci Technol 167:440–447. https://doi.org/10.1016/j.compscitech.2018.08.036

Badji C, Beigbeder J, Garay H et al (2018c) Under glass weathering of hemp fibers reinforced polypropylene biocomposites: impact of volatile organic compounds emissions on indoor air quality. Polym Degrad Stab 149:85–95. https://doi.org/10.1016/j.polymdegradstab.2018.01.020

Badji C, Beigbeder J, Garay H et al (2018d) Exterior and under glass natural weathering of hemp fibers reinforced polypropylene biocomposites: impact on mechanical, chemical, microstructural and visual aspect properties. Polym Degrad Stab 148:104–116. https://doi.org/10.1016/j.polymdegradstab.2017.12.015

Beg MDH, Pickering KL (2008) Accelerated weathering of unbleached and bleached Kraft wood fibre reinforced polypropylene composites. Polym Degrad Stab 93:1939–1946. https://doi.org/10.1016/j.polymdegradstab.2008.06.012

Beg MDH, Pickering KL (2007) The effects of residual lignin content on wood fibre reinforced polypropylene composites. In: Advanced materials research. Trans Tech Publications, pp 323–326

Bergmann A, Teßmar J, Owen A (2007) Influence of electron irradiation on the crystallisation, molecular weight and mechanical properties of poly-(R)-3-hydroxybutyrate. J Mater Sci 42:3732–3738. https://doi.org/10.1007/s10853-006-1411-y

Bharath KN, Basavarajappa S (2016) Applications of biocomposite materials based on natural fibers from renewable resources: a review. Sci Eng Compos Mater 23:123–133

Butylina S, Hyvärinen M, Kärki T (2012) A study of surface changes of wood-polypropylene composites as the result of exterior weathering. Polym Degrad Stab 97:337–345. https://doi.org/10.1016/j.polymdegradstab.2011.12.014

Chan CM, Pratt S, Halley P et al (2019) Mechanical and physical stability of polyhydroxyalkanoate (PHA)-based wood plastic composites (WPCs) under natural weathering. Polym Test 73:214–221. https://doi.org/10.1016/j.polymertesting.2018.11.028

Chandramohan D, Marimuthu, (2011) A review on natural fibers. Int J Res Rev Appl Sci 8:194–206

Chang BP, Mohanty AK, Misra M (2020) Studies on durability of sustainable biobased composites: a review. RSC Adv 10:17955–17999

Chaowana P, Barbu MC (2017) Bamboo: potential material for biocomposites. In: Lignocellulosic fibre and biomass-based composite materials: processing, properties and applications. Elsevier Inc., pp 259–289

Chaudhary V, Bajpai PK, Maheshwari S (2020) Effect of moisture absorption on the mechanical performance of natural fiber reinforced woven hybrid bio-composites. J Nat Fibers 17:84–100. https://doi.org/10.1080/15440478.2018.1469451

Chen RS, Ab Ghani MH, Ahmad S et al (2015) Rice husk flour biocomposites based on recycled high-density polyethylene/polyethylene terephthalate blend: effect of high filler loading on physical, mechanical and thermal properties. J Compos Mater 49:1241–1253. https://doi.org/10.1177/0021998314533361

Chollakup R, Askanian H, Delor-Jestin F (2017) Initial properties and ageing behaviour of pineapple leaf and palm fibre as reinforcement for polypropylene. J Thermoplast Compos Mater 30:174–195. https://doi.org/10.1177/0892705715598356

del Pilar Fajardo Cabrera de Lima L, Santana RMC, Rodríguez CDC (2020) Influence of coupling agent in mechanical, physical and thermal properties of polypropylene/bamboo fiber composites: under natural outdoor aging. Polymers (basel) 12. https://doi.org/10.3390/POLYM12040929

Du H, Wang W, Wang Q et al (2010) Effects of pigments on the uv degradation of wood-flour/HDPE composites. J Appl Polym Sci 118:1068–1076. https://doi.org/10.1002/app.32430

Fabiyi JS, McDonald AG (2014) Degradation of polypropylene in naturally and artificially weathered plastic matrix composites. Maderas Cienc y Tecnol 16:275–290. https://doi.org/10.4067/S0718-221X2014005000021

Fabiyi JS, McDonald AG, Wolcott MP, Griffiths PR (2008) Wood plastic composites weathering: visual appearance and chemical changes. Polym Degrad Stab 93:1405–1414. https://doi.org/10.1016/j.polymdegradstab.2008.05.024

Faruk O, Bledzki AK, Fink HP, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37:1552–1596

Fortunati E, Aluigi A, Armentano I et al (2015) Keratins extracted from Merino wool and Brown Alpaca fibres: thermal, mechanical and biological properties of PLLA based biocomposites. Mater Sci Eng C 47:394–406. https://doi.org/10.1016/j.msec.2014.11.007

González-López ME, Martín del Campo AS, Robledo-Ortíz JR et al (2020) Accelerated weathering of poly(lactic acid) and its biocomposites: a review. Polym Degrad Stab 179

Hiremath SS (2020) Natural fiber reinforced composites in the context of biodegradability: a review. In: encyclopedia of renewable and sustainable materials. Elsevier, pp 160–178

Hiremath A, Sridhar T (2020) Use of bio-fibers in various practical applications. In: encyclopedia of renewable and sustainable materials. Elsevier, pp 931–935

Homkhiew C, Ratanawilai T, Thongruang W (2014) Effects of natural weathering on the properties of recycled polypropylene composites reinforced with rubberwood flour. Ind Crops Prod 56:52–59. https://doi.org/10.1016/j.indcrop.2014.02.034

Hung KC, Chen YL, Wu JH (2012) Natural weathering properties of acetylated bamboo plastic composites. Polym Degrad Stab 97:1680–1685. https://doi.org/10.1016/j.polymdegradstab.2012.06.016

John MJ, Thomas S (2008) Biofibres and biocomposites. Carbohydr Polym 71:343–364

Kamal I, Beyer G, Saad MJ et al (2014) Kenaf For biocomposite: an overview. J Sci Technol 6:41–66

Krasowska K, Brzeska J, Rutkowska M et al (2010) Environmental degradation of ramie fibre reinforced biocomposites. Polish J Environ Stud 19:937–945

Lang PL, Katon JE, O’Keefe JF, Schiering DW (1986) Identification of fibres by infrared and Raman microspectroscopy

Le Duigou A, Bourmaud A, Davies P, Baley C (2014) Long term immersion in natural seawater of Flax/PLA biocomposite. Ocean Eng 90:140–148. https://doi.org/10.1016/j.oceaneng.2014.07.021

Le Duigou A, Deux JM, Davies P, Baley C (2011) Protection of Flax/PLLA biocomposites from seawater ageing by external layers of PLLA. Int J Polym Sci 2011. https://doi.org/10.1155/2011/235805

Li X, Panigrahi S, Tabil LG (2009) A study on flax fiber-reinforced polyethylene biocomposites. Appl Eng Agric 25:525–531. https://doi.org/10.13031/2013.27454

Lila MK, Shukla K, Komal UK, Singh I (2019) Accelerated thermal ageing behaviour of bagasse fibers reinforced Poly (Lactic Acid) based biocomposites. Compos Part B Eng 156:121–127. https://doi.org/10.1016/j.compositesb.2018.08.068

Liu P, Zhan X, Wu X, et al (2020) Effect of weathering on environmental behavior of microplastics: properties, sorption and potential risks. Chemosphere 242

Lv Y, Huang Y, Yang J et al (2015) Outdoor and accelerated laboratory weathering of polypropylene: a comparison and correlation study. Polym Degrad Stab 112:145–159. https://doi.org/10.1016/j.polymdegradstab.2014.12.023

Mayandi K, Rajini N, Manojprabhakar M, et al (2018) Recent studies on durability of natural/synthetic fiber reinforced hybrid polymer composites. In: Durability and life prediction in biocomposites, fibre-reinforced composites and hybrid composites. Elsevier, pp 1–13

Mitomo H, Watanabe Y, Ishigaki I, Saito T (1994) Radiation-induced degradation of poly(3-hydroxybutyrate) and the copolymer poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Polym Degrad Stab 45:11–17. https://doi.org/10.1016/0141-3910(94)90173-2

Mitra BC (2014) Environment friendly composite materials: biocomposites and green composites. Def Sci J 64:244–261. https://doi.org/10.14429/dsj.64.7323

Mohanty AK, Misra M, Drzal LT et al (2005) Natural fibers, biopolymers, and biocomposites: an introduction. In: Natural fibers, biopolymers, and biocomposites. CRC Press, pp 1–36

Mukherjee T, Kao N (2011) PLA based biopolymer reinforced with natural fibre: a review. J Polym Environ 19:714–725. https://doi.org/10.1007/s10924-011-0320-6

Nabi Saheb D, Jog JP (1999) Natural fiber polymer composites: a review. Adv Polym Technol 18:351–363. https://doi.org/10.1002/(SICI)1098-2329(199924)18:4%3c351::AID-ADV6%3e3.0.CO;2-X

Naumann A, Stephan I, Noll M (2012) Material resistance of weathered wood-plastic composites against fungal decay. Int Biodeterior Biodegrad 75:28–35. https://doi.org/10.1016/j.ibiod.2012.08.004

Nouar Y, Zouaoui F, Nekkaa S et al (2020) Effect of chemical treatment on thermophysical behavior of Spanish broom flour-reinforced polypropylene biocomposite. J Polym Eng. https://doi.org/10.1515/polyeng-2020-0073

Ogunsona EO, Misra M, Mohanty AK (2017) Accelerated hydrothermal aging of biocarbon reinforced nylon biocomposites. Polym Degrad Stab 139:76–88. https://doi.org/10.1016/j.polymdegradstab.2017.03.013

Oksman K, Mathew AP, Långström R et al (2009) The influence of fibre microstructure on fibre breakage and mechanical properties of natural fibre reinforced polypropylene. Compos Sci Technol 69:1847–1853. https://doi.org/10.1016/j.compscitech.2009.03.020

Pandey JK, Nagarajan V, Mohanty AK, Misra M (2015) Commercial potential and competitiveness of natural fiber composites. In: Biocomposites: design and mechanical performance. Elsevier Inc., pp 1–15

Parikh A, Parikh H, Parikh K (2006) Norrish Type I an II Reaction (Cleavage). Name reactions in organic synthesis. Foundation Books, Delhi, pp 325–329

Peças P, Carvalho H, Salman H, Leite M (2018) Natural fibre composites and their applications: a review. J Compos Sci 2:66. https://doi.org/10.3390/jcs2040066

Popa MI, Pernevan S, Sirghie C et al (2013) Mechanical properties and weathering behavior of polypropylene-hemp shives composites. J Chem. https://doi.org/10.1155/2013/343068

Pospíšil J, Pilař J, Billingham NC et al (2006) Factors affecting accelerated testing of polymer photostability. In: Polymer degradation and stability, pp 417–422

Rabello MS, White JR (1997) Crystallization and melting behaviour of photodegraded polypropylene-II. Re-Crystal Degrad Mol Polym (guildf) 38:6389–6399. https://doi.org/10.1016/S0032-3861(97)00214-0

Rabello MS, White JR (1996) Photodegradation of talc-filled polypropylene. Polym Compos 17:691–704. https://doi.org/10.1002/pc.10661

Rahman MM, Afrin S, Haque P (2014) Characterization of crystalline cellulose of jute reinforced poly (vinyl alcohol) (PVA) biocomposite film for potential biomedical applications. Prog Biomater 3. https://doi.org/10.1007/s40204-014-0023-x

Rahman WAWA, Sin LT, Rahmat AR et al (2011) Comparison of rice husk-filled polyethylene composite and natural wood under weathering effects. J Compos Mater 45:1403–1410. https://doi.org/10.1177/0021998310381545

Riedel U, Nickel J (2002) Applications of natural fiber composites for constructive parts in aerospace, automobiles, and other areas. In: Biopolymers online. Wiley

Rinaudo C, Gastaldi D, Belluso E, Capella S (2005) Application of Raman Spectroscopy on asbestos fibre identification. Neues Jahrb Fur Mineral Abhandlungen 182:31–36. https://doi.org/10.1127/0077-7757/2005/0030

Rodríguez LJ, Orrego CE, Ribeiro I, Peças P (2018) Life-cycle assessment and life-cycle cost study of banana (Musa sapientum) fiber biocomposite materials. In: Procedia CIRP. Elsevier B.V., pp 585–590

Sanal I (2016) Coir fiber-reinforced composites. In: Green approaches to biocomposite materials science and engineering. IGI Global, pp 247–275

Sapuan SM, Tamrin KF, Nukman Y et al (2017) Natural fiber-reinforced composites: types, development, manufacturing process, and measurement. In: Comprehensive materials finishing. Elsevier Inc., pp 203–230

Sellivam RKCP, Husseinsyah S, Leng TP et al (2016) Effect of Adipic acid content on properties of soy protein Isolate/Kapok Husk biocomposite films. Procedia Chem 19:891–896. https://doi.org/10.1016/j.proche.2016.03.131

Siakeng R, Jawaid M, Asim M (2020) Polymers accelerated weathering and soil burial effect on biodegradability, colour and textureof. Polymers (basel) 458:1–15

Soccalingame L, Perrin D, Bénézet JC, Bergeret A (2016) Reprocessing of UV-weathered wood flour reinforced polypropylene composites: study of a natural outdoor exposure. Polym Degrad Stab 133:389–398. https://doi.org/10.1016/j.polymdegradstab.2016.09.011

Stark NM, Matuana LM (2004) Surface chemistry changes of weathered HDPE/wood-flour composites studied by XPS and FTIR spectroscopy. Polym Degrad Stab 86:1–9. https://doi.org/10.1016/j.polymdegradstab.2003.11.002

Stark NM, Matuana LM (2006) Influence of photostabilizers on wood flour-HDPE composites exposed to xenon-arc radiation with and without water spray. Polym Degrad Stab 91:3048–3056. https://doi.org/10.1016/j.polymdegradstab.2006.08.003

Stark NM, Matuana LM, Clemons CM (2004) Effect of processing method on surface and weathering characteristics of wood-flour/HDPE composites. J Appl Polym Sci 93:1021–1030. https://doi.org/10.1002/app.20529

Thirmizir MZA, Ishak ZAM, Taib RM et al (2011) Natural weathering of Kenaf Bast fibre-filled poly(Butylene Succinate) composites: effect of fibre loading and compatibiliser addition. J Polym Environ 19:263–273. https://doi.org/10.1007/s10924-010-0272-2

Tridico SR (2009) Natural animal textile fibres: structure, characteristics and identification. In: Identification of textile fibers. Elsevier Ltd., pp 27–67

Verma A, Singh VK (2016) Human hair: a biodegradable composite fiber–a review. Int J Waste Resour 6. https://doi.org/10.4172/2252-5211.1000206

Wang W, hong, Bu F hua, Zhang Z ming, et al (2010) Performance of rice-hull-PE composite exposed to natural weathering. J for Res 21:219–224. https://doi.org/10.1007/s11676-010-0036-9

Wei L, McDonald AG (2016) Accelerated weathering studies on the bioplastic, poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Polym Degrad Stab 126:93–100. https://doi.org/10.1016/j.polymdegradstab.2016.01.023

Yaacab ND, Ismail H, Ting SS (2016) Potential use of paddy straw as filler in poly lactic acid/paddy straw powder biocomposite: thermal and thermal properties. Procedia Chem 19:757–762. https://doi.org/10.1016/j.proche.2016.03.081

Yew GH, Chow WS, Mohd Ishak ZA, Mohd Yusof AM (2009) Natural weathering of poly (Lactic Acid): effects of rice starch and epoxidized natural rubber. J Elastomers Plast 41:369–382. https://doi.org/10.1177/0095244309103663

Zhou X, Huang S, Chen L (2016) Effect of antiaging agents on the outdoor natural weathering of bamboo powder/polypropylene foamed composites. J Vinyl Addit Technol 22:311–319. https://doi.org/10.1002/vnl.21433

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Akderya, T., Bilir, C., Baba, B.O. (2022). Effects of Natural Weathering on Aesthetics, Thermal and Mechanical Properties of the Bio-composites. In: Muthukumar, C., Krishnasamy, S., Thiagamani, S.M.K., Siengchin, S. (eds) Aging Effects on Natural Fiber-Reinforced Polymer Composites. Composites Science and Technology . Springer, Singapore. https://doi.org/10.1007/978-981-16-8360-2_8

Download citation

DOI: https://doi.org/10.1007/978-981-16-8360-2_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-8359-6

Online ISBN: 978-981-16-8360-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)