Abstract

Thermal stress evaluations in a hot and humid work environment also require estimating the metabolic heat generated from a human body. The estimation of this metabolic heat depends on the physical work activity level and body surface area (BSA) of the targeted audience employed in that particular work environment. Similarly, basal metabolic rate (BMR) provides an estimation for the daily energy expenditure requirements (in Kcal) for maintaining a healthy body weight based on the physical work activity level. In this study, an attempt was made to evaluate the different BSA estimates from a group of 87 metal casting workers. Five different BSA expressions were evaluated based on the anthropometric variables of casting workers and a comparative analysis among these BSA estimates was performed. The respective BSA and BMR estimates were utilized in evaluating the metabolic heat generated during different physical work activities (based on the metabolic rate for specific foundry work activities, according to ISO 8996 standard) and also the energy expenditure requirements. From the results, it was concluded that there was a strong association between the Du-Bois and Mosteller BSA estimates (correlation coefficient (r) = 0.993, at 0.01 significance level). It was observed that there was a strong association among the considered BSA estimates (at significance level of 0.01). Although the BMI index showed a better association (r = 0.785) with the Boyd expression as compared to other BSA expressions. The highest metabolic heat was observed for the hand molding work profile (upper limit (UL) varying between 427.08 watts to 431.66 W) followed by blast furnace work (upper limit (UL) varying between 391.49 and 395.69 W). Also, the average daily energy expenditure requirements based on the BMR estimates were found varying between 2647.18 kcal to 2699.89 kcal. These estimates may be considered as an effective tool in evaluating the metabolic heat and further analyzing the thermal ambiance for a high-heat work environment.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

1 Introduction

Metal casting workers are exposed to hot and humid work conditions due to the high heat industrial work environment, which are mostly subjected to intensive physical workload, having significant thermal stress on the workers’ health (Krishnamurthy et al. 2017). There are several environmental factors (temperature, humidity, air velocity and radiation) and personal factors (clothing worn, muscular activity), which affect the thermal ambiance of a person (The Six Basic Factors 2020). Figure 1 describes the factors affecting heat stress exposure among workers. One such important factor is metabolic rate, which depends on the physical work activity performed by an individual in a particular work environment. Human body produces heat even at relaxed position and the rate at which heat is produced is expressed in terms of metabolic rate (in Met); where 1 met is equal to 58.2 W/m2 (DEA3500 2020). In foundries, there are various work activities such as high-heat furnace work operations, manual material handling, manual molding, and fettling operations, which requires higher level of physical work activity. High-heat work environment imposes thermal stress, which causes thermophysiological effects on the workers body (such as rise in core body temperature, heart rate and increased sweating). An individual involved in an intensive physical work builds up body heat, expressed in terms of metabolic heat (in watts), which may be evaluated by multiplying the metabolic rate with the body surface area (BSA). BSA is the calculated surface area of a human body, which provides a better indication of metabolic mass than considering body weight and body mass index, as it is least influenced by abnormal adipose mass (DuBois and DuBois 1916). BSA estimate is beneficial in evaluating the energy requirements, while performing heat stress analysis for particular environment, with higher ambient temperatures. In high-heat work environment, evaluating BSA yields a better estimation of the thermal environment suitability for the targeted audience; which yearns a better estimation of the heat stress and thermal comfort evaluations (Ioannou et al. 2019; Zamanian et al. 2017). Its application includes evaluating the metabolic heat generated from human body while performing a physical activity (ranging from light to moderate), and evaluating cardiac index (which involves measuring the cardiac output divided by BSA), which, in turn, yields better estimate for the effective cardiac output and other medical investigations (DuBois and DuBois 1916; Gurney 2002). Although there are also few evidence that BSA values are least accurate at certain situations (like extremes of weight, height), where Body Mass Index (BMI) may be a better estimate (Adler et al. 2012). Similarly, basal metabolic rate (BMR) provides an estimation for the daily energy expenditure requirements (in Kcal) for maintaining healthy body weight based on the physical work activity level (McNab 1997; Ballesteros et al. 2018). These estimates may be considered as an effective tool in evaluating metabolic heat energy and further analyzing the thermal ambiance for a work environment. The present study intends to evaluate different BSA estimates from a group of casting workers followed by calculating the metabolic heat.

Furthermore, a comparative analysis between the estimates has also been performed.

2 Methodology

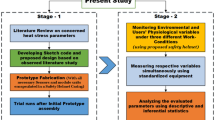

In the present study, an anthropometric survey was conducted among 87 workers employed in small- and medium-scale gray cast iron foundries located nearby Chandigarh region in India, which were further used to evaluate the BSA and BMR estimates using different expressions as described in Table 1. These estimates were utilized in evaluating the metabolic heat generated during different physical work activities and also the energy expenditure requirements for the targeted audience. A descriptive and inferential statistics has been performed using IBM SPSS 26 on the BSA and BMR estimates. Figure 2 describes the work flowchart for the present study.

2.1 Body Surface Area (BSA) and Basal Metabolic Rate (BMR)

There are various mathematical expressions available based on previous research studies that may be utilized in determining the BSA estimates (generally expressed in m2) involving indirect measurements utilizing weight (in kilograms) and height (in centimeters). One such frequently used expression is Du-Bois BSA estimate (DuBois and DuBois 1916). There are few other expressions, which are also commonly used including Mosteller, Gehan-George, Haycock, and Boyd BSA estimates (Mosteller 1987; Haycock et al. 1978; Boyd 1935; Gehan and George 1970; Shuter and Aslani 2000; Fujimoto et al. 1968; Schlich et al. 2010; Lipscombe 2020). Basal metabolic rate presents the energy expenditure requirements based on several factors like age, weight, and height. Most widely used BMR expression is given by Harris-Benedict (Harris and Benedict 1918; Harris 1919), which was further modified by other researchers during later time frame (Roza and Shizgal 1984; Mifflin et al. 1990). Table 1 depicts the different BSA and BMR expressions used in this study.

2.2 Anthropometric Survey

In this current study, an anthropometric survey was conducted among 87 foundry workers to measure anthropometric variables such as stature and weight, which were further utilized to evaluate the BSA using Du-Bois and other available BSA expressions. Similarly, BMR estimations were calculated based on the three BMR expressions. Further, statistical analysis was performed on the evaluated data using descriptive analysis, scatter plots, and Pearson product–moment relationship.

2.3 Metabolic Rate

ISO 8996 standard provides information about the metabolic rate (in W/m2) based on the physical work activities/ job occupations (ISO 8996 2004). From the product of the evaluated BSA estimates and metabolic rate, the metabolic heat generated (in watts) from the analyzed subject may be evaluated. This estimation may be beneficial in performing further heat stress analysis for a particular work environment, yielding better results. Table 2 describes the metabolic rate for workers employed in high heat work environments like iron and steel casting industries, based on the ISO 8996 standard.

3 Results and Discussion

The descriptive analysis was performed using IBM SPSS 26.0 software package. Table 3 depicts the mean and standard deviation for the weight, age, height, BMI, and Du-Bois body surface area. The descriptive statistics results for the evaluated BSA expressions have been shown in Table 4, whereas Table 5 describes the results for three different BMR expressions (in Kcal/min). The average body mass index (BMI) was found to be 23.62 kg/m2 (ranging between 17.52 and 30.76 kg/m2) and workers’ average BSA based on the Du-Bois estimation was found to be 1.7795 m2 ranging between (1.467 and 2.124 m2).

Further, Pearson’s product-moment correlation analysis was performed on the considered BSA and BMR estimates separately (as described in Tables 6 and 7). From the results, it was observed that there was a strong association between the Du-Bois and Mosteller BSA estimates (correlation coefficient (r) = 0.993, at 0.01 significance level). Du-Bois BSA estimate was also found to be strongly correlated with other BSA estimates. Although the BMI index showed a better association (r = 0.785) with the Boyd expression as compared with other BSA expressions. The correlation analysis among various evaluated BMR expressions yielded a better relationship for the widely used Harris-Benedict BMR expression with the revised BMR expressions (i.e. BMR-1984 (r = 0.998); BMR-1990 (r = 0.990); at 0.01 significance level).

The scatterplots and regression line indicating the relationship between Du-Bois and different BSA (in m2) estimates and relationship between different BMR (in Kcal/day) estimates have been shown in Figs. 3 and 4, respectively. The coefficient of determination (R2) value showed a strong goodness of fit between the Du-Bois and Mosteller estimates (R2 = 0.986). Similarly, strong goodness of fit was observed between the Harris-Benedict and revised BMR expression (R2 = 0.996). The respective BSA and BMR estimates were utilized in evaluating the metabolic heat generated during different physical work activities (based on the metabolic rate for specific foundry work activities, according to ISO 8996 standard) and also the energy expenditure requirements (based on moderate physical activity level equal to 1.76) (United Nations University, World Health Organization 2004) for the targeted audience, which may be considered beneficial for conducting thermal stress evaluations in that particular high-heat work environment. Table 8 depicts the calculated metabolic heat (in watts) for different work profiles based on the evaluated BSA estimates, whereas Table 9 shows the energy expenditure requirements (at moderate level activity) for different BMR expressions. From the results, it may be concluded that the highest metabolic heat was observed for the hand molding and foundry man work profiles (upper limit (UL) varying between 427.08 and 431.66 W) followed by blast furnace work (upper limit (UL) = 391.49 to 395.69 W) based on Du-Bois expression. However, Boyd BSA expression yielded the highest metabolic heat values among all work profiles. Similarly, based on the BMR expressions, the average daily energy expenditure requirements to maintain healthy body weight were found varying between 2647.18 kcal and 2699.89 kcal for moderate-level physical activity (Table 9).

4 Conclusions

The current study intended to perform a comparative analysis for four different BSA estimates with the widely used Du-Bois BSA estimate and also evaluating the daily energy expenditure requirements based on the basal metabolic rate (BMR) among workers employed in small-scale foundries. From the results, it was concluded that there was a strong association between the Du-Bois and Mosteller BSA estimates (correlation coefficient (r) = 0.993, at 0.01 significance level). Although the BMI index showed a better association (r = 0.785) with the Boyd expression as compared to other BSA expressions. From the results, it was observed that there was a strong association between the various BSA estimates (at significance level of 0.01). The highest metabolic heat was observed for the hand molding work profile (upper limit (UL) varying between 427.08 and 431.66 W) followed by blast furnace work (upper limit (UL) = 391.49 and 395.69 W) based on the Du-Bois BSA expression, whereas Boyd BSA expression yielded the highest metabolic heat values as compared to other BSA expressions. Similarly, based on the BMR expressions, the average daily energy expenditure requirements to maintain healthy body weight were found varying between 2647.18 and 2699.89 kcal. These BSA and BMR estimates may provide a better indication of the metabolic heat generated and daily energy requirements for workers involved in high work-load activities, particularly high heat work environments. These estimates may be helpful in; conducting in-depth thermal stress analysis for high-heat work environments, CFD-based thermal comfort studies for an industrial work environment and so on, which, in turn, yields better evaluation of particular thermal environment suitability for the targeted audience.

References

Adler AC, Nathanson BH, Raghunathan K, McGee WT (2012) Misleading indexed hemodynamic parameters: the clinical importance of discordant BMI and BSA at extremes of weight. Crit Care 16(6):471

Ballesteros FJ, Martinez VJ, Luque B, Lacasa L, Valor E, Moya A (2018) On the thermodynamic origin of metabolic scaling. Sci Rep 8(1):1–10

Boyd E (1935) The growth of the surface area of the human body. University of Minnesota Press, Minneapolis

DEA3500 (2020) Ambient environment: thermal regulation notes. Cornell University Ergonomics Web. Website: http://ergo.human.cornell.edu/studentdownloads/DEA3500notes/Thermal/thregnotes.html. Accessed on 12 March 2020

DuBois D, DuBois EF (1916) A formula to estimate the approximate surface area if height and weight be known. Arch Int Med 17:863–871

Fujimoto S, Watanabe T, Sakamoto A, Yukawa K, Morimoto K (1968) Studies on the physical surface area of Japanese. Nippon Eiseigaku Zasshi (Jap J Hygiene) 23(5):443–450

Gehan EA, George SL (1970) Estimation of human body surface area from height and weight. Cancer Chemother Rep 54:225–235

Gurney H (2002) How to calculate the dose of chemotherapy. Br J Cancer 86(8):1297–1302

Harris JA (1919) Biometric studies of basal metabolism in man. Publication 279:233–250

Harris JA, Benedict FG (1918) A biometric study of human basal metabolism. Proc Natl Acad Sci USA 4(12):370

Haycock GB, Schwartz GJ, Wisotsky DH (1978) Geometric method for measuring body surface area: A height weight formula validated in infants, children and adults. J Pediatr 1(93):62–66

Ioannou LG, Tsoutsoubi L, Mantzios K, Flouris AD (2019) A free software to predict heat strain according to the ISO 7933: 2018. Industrial health, 2018–0216.

ISO 8996 (2004) Ergonomics of the thermal environment—determination of metabolic rate

Krishnamurthy M, Ramalingam P, Perumal K, Kamalakannan LP, Chinnadurai J, Shanmugam R, Venugopal V (2017) Occupational heat stress impacts on health and productivity in a steel industry in southern India. Safety Health Work 8(1):99–104

Lipscombe T (2020) Body surface area formula based on geometric means. Med Internacia Revuo-Int Med Rev 29(114):11–18

McNab BK (1997) On the utility of uniformity in the definition of basal rate of metabolism. Physiol Zool 70(6):718–720

Mifflin MD, St Jeor ST, Hill LA, Scott BJ, Daugherty SA, Koh YO (1990) A new predictive equation for resting energy expenditure in healthy individuals. Am J Clin Nutr 51(2):241–247

Mosteller RD (1987) Simplified calculation of body surface area. N Engl J Med 317(17):1098

Roza AM, Shizgal HM (1984) The Harris Benedict equation revaluated: resting energy requirements and the body cell mass. Am J Clin Nutr 40(1):168–182

Schlich E, Schumm M, Schlich M (2010) 3D-Body-Scan als anthropometrisches Verfahren zur Bestimmung der spezifischen Körperoberfläche. Ernährungs Umschau 57(4):178–183

Shuter B, Aslani A (2000) Body surface area: Du bois and Du bois revisited. Eur J Appl Physiol 82(3):250–254

The Six Basic Factors (2020) HSE. Website: https://www.hse.gov.uk/temperature/thermal/factors.html. Accessed on 15 March 2020

United Nations University, & World Health Organization (2004) Human energy requirements: report of a joint FAO/WHO/UNU expert consultation: Rome, 17–24 October 2001 (vol 1). Food & Agriculture Org. Website: http://www.fao.org/3/a-y5686e.pdf. Accessed on 20 July 2020

Zamanian Z, Sedaghat Z, Hemehrezaee M, Khajehnasiri F (2017) Evaluation of environmental heat stress on physiological parameters. J Environ Health Sci Eng 15(1):24

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sharma, M., Suri, N.M., Kant, S. (2022). Analysing Metabolic Heat Among Metal Casting Workers Using Different Body Surface Area Estimates: A Comparative Study. In: Rana, N.K., Shah, A.A., Iqbal, R., Khanzode, V. (eds) Technology Enabled Ergonomic Design. HWWE 2020. Design Science and Innovation. Springer, Singapore. https://doi.org/10.1007/978-981-16-6982-8_5

Download citation

DOI: https://doi.org/10.1007/978-981-16-6982-8_5

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-6981-1

Online ISBN: 978-981-16-6982-8

eBook Packages: EngineeringEngineering (R0)