Abstract

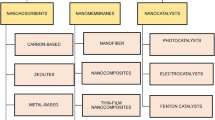

Nanomaterials are widely used for practical application in environmental chemical engineering and water purification technologies. The non-reagent methods (adsorption, catalysis, membrane technology, etc.) attracts the attention as the most prospect approaches for liquid radioactive waste treatment and waste water purification. Nanostructured metal oxides materials showed the enhanced characteristics for preparation of mesoporous adsorbents for selective radionuclides removal, heterogeneous catalysts for harmful organic pollutants degradation Fenton-like processes, as well as ceramic membranes for microfiltration water treatment. The chapter described the novel results for preparation, characterization and practical application of nanomaterials based on various metal oxides for water purification. The main factors affected on regularities between synthesis conditions, structure and functional properties were studied. The obtained results have significant impact for advancement in water purification by nanomaterials.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Nanostructured metal oxides

- Mesoporous adsorbents

- Fenton-like catalysts

- Microfiltration membrane

- Water treatment

18.1 Introduction

Intensive operation of nuclear power facilities is certainly accompanied by the formation and accumulation of large volumes of liquid radioactive waste (LRW). In accordance with the IAEA regulatory documents on the safe management of LRW, this waste is subject to mandatory processing before subsequent disposal. LRW most often have a complex chemical and radionuclide composition; in particular, it contains long-lived isotopes 137Cs (τ1/2 = 30.2 years), 60Co (τ1/2 = 5.3 years), and 90Sr (τ1/2 = 28.8 years). According to the literature data, 90Sr radionuclide poses a serious hazard to humans and the environment (Pathak and Gupta 2020).

One of the main disadvantages of classical methods of LRW treatment, including ion exchange, membrane technology, and precipitation, is the lack of the possibility of selective removal of the 90Sr radionuclide from multicomponent aqueous solutions containing competing ions of alkali and alkaline earth metals (Okoshi and Momma 2015). At the same time, sorption technology makes it possible to use efficient sorption materials with unique selectivity. Such sorption materials include manganese oxides, which exhibit exceptional selectivity toward 90Sr radionuclide even in the presence of Na+, K+, Ca2+, and Mg2+ ions (Pakarinen et al. 2010; Ivanets et al. 2019a, b). High sorption characteristics, such as unique selectivity, high sorption capacity, and fast sorption kinetics, can be assumed to be due to a number of factors. First, selectivity is related to the presence and availability of micropores and is due to the layered (interlayer space ≤10 Å) or channel structure (channel size 4.6–7.0 Å). Second, the sorption capacity and sorption kinetics depend on the availability of active sites for the 90Sr radionuclide in micropores and their good communication with mesopores, which play the role of transport channels and improve electrolyte diffusion toward active sites.

Currently, pharmacologically active compounds (PhACs) and their metabolites are found everywhere in wastewater, groundwater, and surface and even drinking water, posing a great threat to human health and the aquatic ecosystem (Majumder et al. 2019). The high stability, low volatility, accumulative and mutagenic properties, contamination with antibiotics, hormonal and nonsteroidal anti-inflammatory drugs leads to irreversible negative consequences for humans and the environment. The main sources of environmental pollution by these pollutants are agriculture, wastewater from pharmaceutical enterprises, garbage disposal, etc. Also, many PhACs are not completely destroyed in the process of metabolism by humans and animals and are found in domestic and agricultural wastewater (Michael et al. 2014). The Fenton reaction is one of the most studied varieties of advanced oxidation processes (AOPs), which produces OH radicals. Of particular interest as heterogeneous Fenton catalysts are metal ferrites with the general formula M2+Fe3+2O4, where M: Mg2+, Mn2+, Co2+, Ni2+, Cu2+, characterized by high stability, developed surface, small particle size, and high catalytic activity (Kefeni and Mamba 2020; Amiri et al. 2019; Ivanets et al. 2020).

Due to their high chemical and thermal stability, ceramic membranes are widely used in wastewater treatment processes (Goh and Ismail 2018). The use of ceramic membranes is limited by their low productivity compared to polymer membranes and the high sintering temperature of traditional metal oxides (Al2O3, ZrO2, TiO2) used for their production (Zuo et al. 2020). This is why researchers are interested in finding more affordable materials for creating ceramic membranes. The use of natural minerals and industrial waste is most attractive (Abdullayev et al. 2019), which reduces the cost of ceramic precursors and the temperature of heat treatment of membranes. Previously, the possibility of obtaining ceramic microfiltration membranes based on natural silicon oxide was shown. The main factors that determine the mechanical and transport characteristics are the nature and concentration of the binder and pore-forming additives, as well as the chemical and phase composition of natural quartz sand, which significantly varies depending on the deposit (Ivanets et al. 2016a; Ivanets and Agabekov 2017).

18.2 Mesoporous Manganese Oxides for 85Sr Radionuclide Adsorption

Manganese oxides are widely used as effective sorption materials for heavy metal ions and radionuclides (85,90Sr, 137Cs, etc.) (Aminul Islam et al. 2018; Voronina et al. 2020). This is due to the presence of more than 14 polymorphic modifications and, accordingly, the characteristic features of its crystalline and chemical structure, which largely determine high sorption and selective properties (in the presence of competing ions Na+, Ca2+, etc.) toward 90Sr radionuclide. In a negatively charged manganese-oxygen framework, MnO6 octahedra can form tunnel (cryptomelane, todorokite, etc.) or layered (birnessite, etc.) structures that are capable of accommodating positively charged cations and/or water molecules, stabilizing their structure. In this work, mesoporous manganese oxides were obtained using a template-free solgel synthesis method. An aqueous solution of potassium permanganate was used as a precursor; hydrogen peroxide and a manganese (II) salt were used as reducing agents. In addition, the adsorption properties (removal efficiency, distribution coefficient) of the obtained oxides toward 85Sr radionuclide were studied (Ivanets et al. 2015, 2016b).

The gas adsorption-textural properties of obtained manganese oxides were determined by using the low-temperature adsorption/desorption of N2 analysis (Fig. 18.1). The type IV of sorption isotherms was determined by the presence of the loops of the capillary-condensation hysteresis for obtained manganese oxides (samples 1–8), which also indicates the presence of a mesoporous structure by the IUPAC classification (Thommes et al. 2015).Different shapes of hysteresis loops indicate the formation of mesopores of various shapes. So, on the isotherms of samples 1–3 (reducing agent (RA), H2O2; processing temperature (PT), 80, 200, and 400 °C), there is H2 hysteresis, which is characteristic of bottle-like and wide-neck mesopores, for which the size of the cylindrical necks is greater than the half-width of spherical voids (Fig. 18.1a, b). The pores of sample 4 (RA, H2O2; PT, 600 °C) were equivalent to the cylindrical pores according to H1 hysteresis (Fig. 18.1b). The hybrid shape of hysteresis loops (Fig. 18.1a, c) consists of H2 (at p/p0 ≤ 0.60), and H3 (at p/p0 ≥ 0.60) is typical for obtained samples 5, 6, and 8 (RA, MnCl2; PT, 80, 200, and 600 °C) and indicates the presence of slit-shaped mesopores, observed in plate-like structures. For sample 7 (RA, MnCl2; PT, 400 °C), the mesopores are mainly bottle-like according to the H2 hysteresis (Fig. 18.1c). Based on an analysis of the differential curves of the pore distribution size (PDS) for obtained samples 1–3, quite homogeneous structure was determined (Fig. 18.1a, b). As the temperature increased to 600°С, the intensity of dV/dlogD on the distribution curves decreased. The distribution of mesopores in sample 4 (PT—600 °C) was characterized by the presence of hysteresis in the range р/р0 0.42–0.96 (Fig. 18.1b).

Adsorption/desorption isotherms of N2 and pore distribution curves of manganese oxide sorption materials (The samples were marked according to Table 18.1)

For obtained samples 1–3 and sample 4, the dominant bottleneck size was measured as the abscissa of the maximum on the PSD curve and amounted to ~5–8 nm and ~39 nm, respectively (Dpr; Fig. 18.1, Table 18.1). Close values (DBJHads and Dpr) only confirm that the structure of the obtained manganese oxides (samples 1–3) is homogeneous. The PSD curves of samples 5, 6, and 8 (RA, MnCl2; PT, 80, 200, and 600 °C) had two segments: (1) with well-discernible mode at Dpr ~ 3–4 nm and (2) with indistinguishable, diffuse peak maxima in the range of Dpr ~ 5–100 nm (at р/р0 0.58–0.96).

This configuration of the distribution curves reflected the morphological properties of mesopores that differ in the shape, size, and volume (Table 18.1). Thus, the difference in mesopore shapes (from bottle-like pores with a homogeneous neck to slit-like pores with a wide scatter in thicknesses) indicates a significant effect of the processing temperature on phase transformations during obtaining.

When comparing the specific surface areas (Table 18.1), it was shown that for crystalline samples (2, 3 and 6, 7, respectively), it is significantly higher than for X-ray amorphous samples (1 and 5) and decreased at 600 °С due to the sintering process (samples 4 and 8). Analysis of XRD data indicates the formation of mixed phases with different compositions at the processing temperature range of 200–600 °С. The specific pore volumes changed in a more complex way.

During the synthesis of manganese oxides at the processing temperature (80 °С), particles of a dispersed phase are formed with an almost spherical shape diameter (200 nm), regardless of the choice of the reducing agent (Fig. 18.2).

Thus, the adsorption properties and morphology of manganese oxides obtained by the solgel method using reducing agents hydrogen peroxide and manganese chloride depend on the chemical processes at the stages of the conversion of sol into gel and subsequent heat treatment at the temperature range 80–600 °С. The factors responsible for the formation of crystalline nuclei in amorphous xerogel particles as the dominant of its internal rearrangement serve as the mechanism that triggers the subsequent phase transformations of xerogel. The X-ray amorphous samples (PT—80 °C) had a dense pore structure and low specific surface areas (32–120 m2/g). At higher temperatures (200–600 °C), obtained xerogels crystallized into mixed phases with different compositions (excluding sample 4). The transformation of manganese oxide is important for its formation; variation of the treatment temperature allows to control over its phase composition and mesoporous structure.

The second stage of the work was the study of the sorption-selective properties of the obtained sorption materials based on manganese oxides toward 85Sr radionuclide in static conditions at V/m ratio = 250 cm3/g. The activity of initial model solutions (A0, kBq∙cm3) and after sorption (Ae, kBq∙cm3) was carried out on a gamma beta spectrometer of MKS-AT1315 (Belarus). It was also investigated the effect of competing ions (Na+, Ca2+) presented in the model solution (with addition of 0.1 M NaCl, 0.05 M CaCl2) onto 85Sr radionuclide removal efficiency (Ivanets et al. 2016b).

To assess the efficiency of the obtained sorption materials based on manganese oxides, the removal efficiency (S) and the distribution coefficient (Кd) of 85Sr radionuclide in the presence of NaCl and CaCl2 electrolytes (Table 18.2) were calculated, which amounted to 70–100% and (0.72–3.67) × 105 cm3/g, respectively. Manganese oxide samples 1 and 5 demonstrated the lowest removal efficiency of 85Sr radionuclide regardless of properties of initial sols (Table 18.2). Apparently this is due to small degree of samples’ crystallinity and absence of the regular layer or channel structure forming micropores, as well as the lowest specific surface area of mesopores among the studied sorption materials. Introduction of the competing Na+ ions into the model solution by adding 0.1 M NaCl led to significant decrease of the removal efficiency and distribution coefficient for all samples (Table 18.2). The highest removal efficiency of 85Sr radionuclide in the presence of Na+ ions was shown by samples 3–4 (RA, H2O2; PT, 400 and 600 °C). For these samples the Kd reached (1.06–4.74) × 104 cm3/g. For all other samples the Kd value didn’t exceed 1.56 × 103 cm3/g.

In the case of using a model solution, containing Ca2+ ions, there was a further decrease in the efficiency of removing 85Sr radionuclide by obtained sorption materials based on manganese oxides (Table 18.2).

The highest distribution coefficients of 85Sr radionuclide in the presence of Ca2+ ions were shown by samples 3–4 (RA, H2O2; PT, 400 and 600 °C). For these samples the Kd reached 1.5–4.6 × 102 cm3/g and 1.1–8.7 × 102 cm3/g, respectively. The obtained results demonstrated that sorption-selective properties of the synthesized materials were compared with the widely using aluminasilicates, titanosilicates, and silicaantimonate adsorbents.

Thus, it was established that obtained manganese oxides using different types of the reducing agents (H2O2, MnCl2) are effective sorption materials toward 85Sr radionuclide and its Kd reached (0.72–3.67) × 105 cm3/g. Presence of 0.1 M NaCl in model solution leads to decrease of Kd up to (4.74–1.06) × 104 cm3/g. For comparison, the introduction of 0.05 M CaCl2 to model solution of 85Sr radionuclide was accompanied by an even stronger decrease of Kd up to (1.1–8.7) × 102 cm3/g. It was found the influence of a reducing agent onto sorption properties, which are much higher when using H2O2 than MnCl2. Samples of manganese oxides obtained at processing temperature of 400–600 °C demonstrated the highest sorption-selective properties in the presence of 0.1 M NaCl and 0.05 M CaCl2.

18.3 Ibuprofen Degradation onto Nanostructured Magnesium Ferrite

Despite toxicological studies of the side effects of drugs on human and animal health, the potential environmental consequences of pharmaceutical production only became a topic of scientific interest in the 2000s. The presence of PhACs in wastewater and surface water was reported as early as the 1970s in the United States, which did not cause much concern at the time. Later, it was discovered that even small amounts of PhACs metabolites affect the environment and living organisms. The continuous increase in the population over the past few decades, its marked aging in many countries, globalization, and increased investment in health care have led to a significant increase in the use of pharmaceuticals. It is important to note that most medicines are not removed during the treatment of wastewater and domestic water, due to the low efficiency of treatment facilities in the removal of PhACs and their metabolites. This makes it necessary to develop new materials and technologies for natural and wastewater treatment (Rodriguez-Narvaez et al. 2017).

Catalytic degradation of organic compounds that are resistant to chemical and biological degradation, including PhACs, is one of the most promising methods for their removal. In this regard, in the last two decades, active research has been conducted on the development and application of AOPs, which involve the use of chemically stable, nontoxic, and highly active to a wide range of organic pollutants catalytic systems based on nanostructured metal oxides. Nanoparticles of magnesium ferrite were selected as the object of research due to its low toxicity and safety for living organisms in comparison with transition metal ferrites, which allows it to be used for solving a wide range of environmental problems (Ivanets et al. 2019c).

Figure 18.3a shows that the catalyst is a crystalline magnesium ferrite (MgFe2O4). The parameter a of the crystal lattice was 8.393 Å, which slightly differs from the reference value of 8.370 Å and indirectly indicated the presence of defects in the crystal structure of the studied catalyst. The crystallite size calculated by the Scherrer formula was 8.2 nm. It is obvious that the real structure was formed from agglomerates of the abovementioned crystallites, which lead to the formation of a mesoporous structure. This fact was confirmed by the presence of a hysteresis loop, which allows the isotherm, shown in Fig. 18.3b, to be classified as type IV according to the IUPAC classification (Thommes et al. 2015). The H1 hysteresis is typical for cylindrical pores formed by agglomerates of spherical particles-globules that are uniformly packed and close in size. The specific surface area calculated by the single-point BET method was 14 m2/g, the pore volume was 0.03 cm3/g, and the average pore size was 8 nm. The MgFe2O4 sample consists of spherical agglomerates <1 μm in size (Fig. 18.3c), consisting of primary particles (crystallites) of 16–26 nm in size (Fig. 18.3d).

According to Fig. 18.4, the conditions of the catalytic process (the concentration of the catalyst and H2O2, pH of the solution) in the studied ranges did not significantly affect the efficiency of ibuprofen degradation. Thus, the degree of catalytic degradation of ibuprofen according to HPLC data for 40 min reached 98–100%, while the minimum residual concentration of ibuprofen under optimal conditions was below the detection limit. Despite the high efficiency of the process (Fig. 18.4a), reducing the concentration of catalyst of less than 0.2 g/L is impractical due to the complexity of the real aim of the amount of material in a given volume of treated solution, which corresponds to the ratio V(solution)/m(catalyst) more than 5000 L/g.

To ensure the highest efficiency of ibuprofen degradation under the specified conditions, the concentration of H2O2 should be at least 20.0 mmol/L (Fig. 18.4b). The pH range of the model solution varies from acidic (4.0) to slightly alkaline (8.0), which corresponds to conditions close to real wastewaters (Fig. 18.4c). It is important to note that the degree of ibuprofen degradation practically corresponded to the degree of mineralization calculated from the values of the residual total organic carbon. This indicates that it is possible to treat wastewater from pharmaceutically active compounds by completely mineralizing them without forming by-products and toxic products using a Fenton-like catalyst based on MgFe2O4 nanoparticles.

According to Fig. 18.5a, complete oxidative degradation of ibuprofen (100%) was achieved within 40 min of interaction. The dependence of the degree of destruction on time was monotonous, and the kinetics of the catalytic process was described with a high degree of confidence (R2 0.99) by a first-order model (Fig. 18.5b). The calculated value of the apparent rate constant was 4.01 × 10−2 min−1, which corresponded to the most effective catalysts described in the literature (Davarnejad et al. 2018).

Thus, it was shown the efficiency (degree of mineralization reached 100%) of catalytically active materials based on MgFe2O4 nanoparticles in the catalytic destruction of nonsteroidal anti-inflammatory drug ibuprofen. The conducted research showed the prospects of practical application of the developed Fenton-like heterogeneous catalyst for wastewater treatment from pharmaceutically active compounds.

18.4 Microfiltration Membranes Based on Silicate Ceramic

Ceramic membranes usually have an asymmetric structure: the top thin layer determines the separation properties and a large-pore base, which provides mechanical strength and increased permeability. In this case, as a rule, multistage sintering is used, which negatively affects the mechanical and transport properties and complicates the process of manufacturing membranes. The use of powders with the same chemical composition and different dispersion to obtain a porous base and membrane layers allows to ensure high adhesion and the necessary performance characteristics of ceramic membranes (Ivanets et al. 2016a).

The initial raw material for the production of ceramic membranes was natural quartz sand from the Henan deposit (China), which, according to X-ray analysis, consisted of quartz with a high degree of crystallinity, as evidenced by the calculated values of the quartz unit cell, and did not contain other impurities of crystalline compounds (Fig. 18.6). When creating porous materials from quasi-spherical particles, the size of the initial particles should exceed the pore size by four to five times. Therefore, to obtain a ceramic substrate with a pore size of 50–100 μm, it is advisable to use a fraction of 200–630 μm, which is more than 97 wt.% of natural quartz raw (Table 18.3).

Microfiltration membrane layers were applied using a suspension of fine crystalline silicon oxide in an aqueous solution of an aluminosilicate binder (5.0–15.0 wt.%): the intermediate layer was formed using particles of 10–40 μm and the membrane layer 0.5–2.0 μm.

The nature and content of the binder and pore-forming agent have a significant impact on the physical and chemical properties of silicate ceramics. To determine the effect of the binder and pore-forming agent concentration on the porosity and mechanical strength of silicate ceramics, a series of samples with a content of sodium aluminosilicate of 7.0–15.0 wt.% and burning additives of 2.0–25.0 wt.% were prepared (Fig. 18.7).

Figure 18.7a shows that with an increase in the content of the aluminosilicate binder from 7.0 to 13.0 wt.%, if there was a linear increase in mechanical strength, a further increase in concentration leads to a slight decrease in strength. This was due to the formation of a complete and optimal thickness of the binder film on the surface of the frame-forming silicon oxide particles, which provided high mechanical characteristics of ceramic samples. The mechanical strength decreased with increasing content of the pore-forming agent, which was due to a decrease in the number of interparticle contacts of the formed porous solid (Fig. 18.7b). However, only the samples containing 5.0–10.0 wt.% of the burning additive met the mechanical characteristics required for porous ceramics for filtration purposes.

Porosity is the most important parameter that determines the permeability and transport characteristics of porous ceramics. In this case, an increase in porosity is usually accompanied by a decrease in mechanical characteristics. Therefore, the choice of the optimal composition should be carried out when comparing the specified mechanical and transport characteristics of the resulting materials (Fig. 18.7c, d). For example, an increase in the binder content from 7.0 to 11.0 wt.% practically did not affect the porosity and was 35–40%, which is sufficient for their practical use in the filtration of liquid media. A further increase in the binder concentration leads to a sharp decrease in porosity, which was due to the filling of the binder in the porous space of the ceramic (Fig. 18.7c). The porosity of ceramics was expected to increase with an increase in the content of the pore-forming agent. In this case, samples containing a burning additive of 10–15 wt.% were characterized by porosity of 25–45% (Fig. 18.7d).

SEM images of ceramic samples with different binder and burning additive contents were shown in Fig. 18.8. The surface of samples with a binder content of 15.0 wt.%, as well as with the lowest pore-forming agent content of 2.0 wt.% had an undeveloped porous structure, which was fully consistent with the data on the effect of the ceramic composition on the porosity of ceramic samples.

Preliminary studies have shown that during the formation of intermediate and microfiltration layers on the surface of a large-pore substrate, optimal mechanical and transport characteristics are achieved when using a suspension with a concentration of 15.0 wt.% of an aluminosilicate binder and the content of silicon oxide of 30.0 wt.%. Figure 18.9a shows that the thickness of the intermediate layer was 50–100 μm, while during the deposition of a suspension of silicon oxide, it partially penetrated into the porous space. The surface of the sample with an intermediate layer was not completely covered with fine particles of ground quartz sand, while the SEM image clearly identified the presence of a significant number of particles with size of ~40 μm, which formed the largest pores during sintering. Smaller particles were located in the interparticle space between large particles (Fig. 18.9b). The formations of a microfiltration layer lead to a slight increase in the thickness of the membrane, which did not exceed 150–200 μm (Fig. 18.9c). The surface of the microfiltration layer was uniform and defect-free (Fig. 18.9d).

Membrane transport characteristics and pore size determine its selectivity and performance. The performance of membranes is an integral characteristic that depends on the porosity, size, and morphology of the pores (tortuosity, shape, closed or open pores, etc.). According to Table 18.4, a coarse-pore substrate was characterized by an average pore size of 22 ± 3.02 μm, a water capacity of 54 ± 5.0 m3/(h × m2 × bar), and a tensile strength of 9.0 ± 0.6 bar.

At the same time, the formation of an intermediate layer leads to a natural decrease in the average pore size to 9.2 ± 0.5 μm, water productivity to 38 ± 2.0 m3/m2 × h × bar, and mechanical tensile strength to 7.8 ± 0.4 bar. The prepared microfiltration ceramic membranes with an average pore size of 2.3 ± 0.2 μm, a water capacity of 26 ± 1.0 m3/(h × m2 × bar), and a tensile strength of 6.5 ± 0.3 bar correspond to the most effective analogues.

18.5 Conclusions

In this chapter we present the results of systematic investigations of the main factors which influence on the physicochemical properties of mesoporous manganese oxide obtained via solgel method and demonstrate its effectiveness for sorption of 85Sr radionuclide from model solutions with different chemical composition. This allowed obtaining the efficient adsorbents for the removal of 85Sr radionuclide from aqueous media, to find out the optimal conditions of their production and to establish the relationship between the chemical and phase compositions, the parameters of porous structure, and sorption activity of developed sorbents.

A glycine-nitrate method was used to synthesize a Fenton-like catalyst consisting of MgFe2O4 nanoparticles with a parameter a 8.393 Å and crystallite size 8.2 nm, characterized by a mesoporous structure (ABET 14 m2/g, Vads 0.03 cm3/g, and Ddes 8 nm), and consisting of agglomerates less than 1 μm in size formed by particles of 16–26 nm. The prepared catalysts have considerable interest for wastewater treatment from pharmaceutically active compounds.

The main factors affecting on the physicochemical properties of microfiltration ceramic membranes based on natural quartz sand were studied. Large-porous support with a content of aluminosilicate binder of 11.0 wt.% and burning additive of 10.0 wt.% was characterized by average pore size of 22 ± 3.02 μm, water capacity of 54 ± 5.0 m3/(h × m2 × bar), and tensile strength of 9.0 ± 0.6 bar. The optimal conditions for membrane layers coating were determined that allowed to obtain microfiltration ceramic membranes with average pore size of 2.3 ± 0.2 μm, water capacity of 26 ± 1.0 m3/(h × m2 × bar), and tensile strength of 6.5 ± 0.3 bar. The developed membranes are promising material for wastewater treatment.

References

Abdullayev A, Bekheet MF et al (2019) Materials and applications for low-cost ceramic membranes. Membranes 9(9):105–136. https://doi.org/10.3390/membranes9090105

Aminul Islam M, Morton DW, Johnson BB et al (2018) Manganese oxides and their application to metal ion and contaminant removal from wastewater. J Water Process Eng 26:264–280. https://doi.org/10.1016/j.jwpe.2018.10.018

Amiri M, Eskandari K, Salavati-Niasari M (2019) Magnetically retrievable ferrite nanoparticles in the catalysis application. Adv Colloid Interf Sci 271:101982. https://doi.org/10.1016/j.cis.2019.07.003

Davarnejad R, Soofi B, Farghadani F et al (2018) Ibuprofen removal from a medicinal effluent: a review on the various techniques for medicinal effluents treatment. Environ Technol Innov 11:308–320. https://doi.org/10.1016/j.eti.2018.06.011

Goh PS, Ismail AF (2018) A review on inorganic membranes for desalination and wastewater treatment. Desalination 434:60–80. https://doi.org/10.1016/j.desal.2017.07.023

Ivanets AI, Agabekov VE (2017) Ceramic microfiltration membranes based on natural silica. Pet Chem 57:117–126. https://doi.org/10.1134/S0965544117020037

Ivanets AI, Kouznetsova TF, Prozorovich VG (2015) Sol-gel synthesis and adsorption properties of mesoporous manganese oxide. Russ J Phys Сhem A 89:481–486. https://doi.org/10.1134/S0036024415030140

Ivanets AI, Azarova TA, Agabekov VE et al (2016a) Effect of phase composition of natural quartz raw material on characterization of microfiltration ceramic membranes. Ceram Int 42(15):16571–16578. https://doi.org/10.1016/j.ceramint.2016.07.077

Ivanets AI, Prozorovich VG, Kouznetsova TF et al (2016b) Mesoporous manganese oxides prepared by sol-gel method: synthesis, characterization and sorption properties towards strontium ions. Environ Nanotechnol Monit Manag 6:261–269. https://doi.org/10.1016/j.enmm.2016.11.004

Ivanets AI, Milutin VV, Prozorovich VG et al (2019a) Adsorption properties of manganese oxides prepared in aqueous-ethanol medium toward Sr(II) ions. J Radioanal Nucl Chem 321(1):243–253. https://doi.org/10.1007/s10967-019-06557-y

Ivanets AI, Milutin VV, Prozorovich VG et al (2019b) Sorption of 90Sr onto manganese oxides prepared in aqueous-ethanol media. Radiochemistry 61:707–713. https://doi.org/10.1134/S1066362219060110

Ivanets A, Roshchina M, Srivastava V et al (2019c) Effect of metal ions adsorption on the efficiency of methylene blue degradation onto MgFe2O4 as Fenton-like catalysts. Colloids Surf A 571:17–26. https://doi.org/10.1016/j.colsurfa.2019.03.071

Ivanets A, Prozorovich V, Roshchina M et al (2020) Heterogeneous Fenton oxidation using magnesium ferrite nanoparticles for Ibuprofen removal from wastewater: optimization and kinetics studies. J Nanomater 2020:8159628. https://doi.org/10.1155/2020/8159628

Kefeni KK, Mamba BB (2020) Photocatalytic application of spinel ferrite nanoparticles and nanocomposites in wastewater treatment: review. Sustain Mater Technol 23:e00140. https://doi.org/10.1016/j.susmat.2019.e00140

Majumder A, Gupta B, Gupta AK (2019) Pharmaceutically active compounds in aqueous environment: a status, toxicity and insights of remediation. Environ Res 176:108542. https://doi.org/10.1016/j.envres.2019.108542

Michael I, Vasquez MI, Hapeshi E et al (2014) Metabolites and transformation products of pharmaceuticals in the aquatic environment as contaminants of emerging concern. In: Lambropoulou DA, Nollet LML (eds) Transformation products of emerging contaminants in the environment. Wiley, pp 425–470. https://doi.org/10.1002/9781118339558.ch14

Okoshi M, Momma T (2015) Radioactive waste treatment technologies. In: Nagasaki S, Nakayama S (eds) Radioactive waste engineering and management. Springer, Japan, pp 119–151. https://doi.org/10.1007/978-4-431-55417-2

Pakarinen J, Koivula R, Laatikainen M et al (2010) Nanoporous manganese oxides as environmental protective materials—effect of Ca and Mg on metals sorption. J Hazard Mater 180(1–3):234–240. https://doi.org/10.1016/j.jhazmat.2010.04.019

Pathak P, Gupta DK (eds) (2020) Strontium contamination in the environment. Springer International Publishing. https://doi.org/10.1007/978-3-030-15314-4

Rodriguez-Narvaez OM, Peralta-Hernandez JM et al (2017) Treatment technologies for emerging contaminants in water: a review. Chem Eng J 323:361–380. https://doi.org/10.1016/j.cej.2017.04.106

Thommes M, Kaneko K et al (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl Chem 87:1051–1069. https://doi.org/10.1515/pac-2014-1117

Voronina AV, Noskova AY, Semenishchev VS et al (2020) Decontamination of seawater from 137Cs and 90Sr radionuclides using inorganic sorbents. J Environ Radioact 217:106210. https://doi.org/10.1016/j.jenvrad.2020.106210

Zuo H-R, Shi P, Duan M (2020) A review on thermally stable membranes for water treatment: material, fabrication, and application. Sep Purif Technol 236:116223. https://doi.org/10.1016/j.seppur.2019.116223

Acknowledgments

The authors are grateful to Artsiom Radkevich (Joint Institute for Power and Nuclear Research—Sosny NAS of Belarus) for conducting experiments with 85Sr radionuclides.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Ivanets, A., Prozorovich, V., Kouznetsova, T. (2022). Advancement in Water Purification by Nanomaterials. In: Thakur, A., Thakur, P., Khurana, S.P. (eds) Synthesis and Applications of Nanoparticles. Springer, Singapore. https://doi.org/10.1007/978-981-16-6819-7_18

Download citation

DOI: https://doi.org/10.1007/978-981-16-6819-7_18

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-6818-0

Online ISBN: 978-981-16-6819-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)