Abstract

Geocells are interconnected honeycombing geosynthetics used for strengthening the weak soil, pavement base/subgrade, embankment, etc. Considerable numbers of researches are performed; however, till date, an exact behaviour of geocell-reinforced soil is complex enough to predict. Modelling of geocell-reinforced soil, through numerical methods, is a difficult task because of its geometry and soil-reinforcement interaction; however, the modern FEM software are capable to provide considerably good estimate. This study, numerically, compares the behaviour of single and multi-layered geocell-reinforced embankment system with reference to study reported by Krishnaswamy et al. (in Geotech Test J 23:45–54, 2000) and Latha and Rajagopal (in Can Geotech J 44:917–927, 2007). It is observed a splitted (multi-layered) geocell system demonstrates improved performance compared to a single-layer geocell-soil composite of same thickness. In this study, a preliminary verification the concept is performed using PLAXIS2D simulating the work reported by Krishnaswamy et al. (in Geotech Test J 23:45–54, 2000). After satisfactory matching, it is further extended for multi-layer geocell system which is very encouraging for the concept envisaged.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Embankments play major role in providing competent foundation for roadways, railways, earthen dams, etc. In many cases, reinforcing the embankment becomes necessary due to weak nature of the native soil. In practice (and, as a topic of research for decades), strengthening the embankments with different types of geosynthetics (with geocells in many instances) has become a trend. In most of the cases, it is observed that it is fruitful to combine geocell reinforcement [1] with other ground improvement techniques (such as wick drain [3]) is an effective measure for an embankment constructed over soft ground. Cowland and Wang [2] have confirmed that the geocell application is cost-effective over traditional ground improvement methods for construction over soft foundation soil. Inspiring from such field successes, several detailed in-house parametric investigations are performed to improve the application and performance of geocell-reinforced systems in different conditions and configurations. Krishnaswamy et al. [5] studied the behaviour of geocell-reinforced embankments constructed over a soft subgrade through a series of laboratory model tests. The results depicted provision of geocells, at the base, improves the load bearing capacity and deformation behaviour of the embankment. In this study, influence of stiffness of geocell-making geogrid was also verified and found that higher the stiffness, greater was the improvement. However, the performance was independent of the pattern of geocell formation (i.e. chevron and diamond). It was also noticed that the geocell layer can be truncated at the toe of the embankment without any significant reduction in the bearing capacity. Later, Latha and Rajagopal [6] re-investigated the model considered by Krishnaswamy et al. [5] through finite element analyses for rigorous parametric influences. Recently, Khalaj et al. [4] and Tafreshi et al. [4, 7, 8] have conducted series of model plate load tests on multi-layered geocell-reinforced systems. It is concluded that multiple geocell layers, each of a relatively low thickness, are more beneficial than a single-layer geocell.

This paper presents an initial investigation of the behaviour of multi-layered geocell embankment. For the purpose, a validation is made for the model study on the embankment behavior reported by Krishnaswamy et al. [5] through Plaxis2D (a commercially available finite element software package). Henceforth, an embankment is modelled with single layer of geocell [6] and compared that with multi-layered systems.

2 Modelling and Validation

2.1 Simulation of Composite Geocell-Soil Layer

The finite element analysis reported in this paper is performed using the PLAXIS2D. In PLAXIS, soils are modelled using nonlinear elastic–plastic constitutive model following Mohr–Coulomb yield criteria and non-associated flow rule (for a simplified fast analysis with negligible deviation, as per Wulandari and Tjandra [8]). Geocell layers are modelled as an equivalent composite layer as proposed by Latha and Rajagopal [6]. In the method, the geocell-soil layer is simulated as a soil with higher cohesion but unaltered internal friction angle; where, the geocell-induced cohesion is termed as apparent cohesion (cr). With the modified shear parameters, the equivalent stiffness of geocell (Eg) layer is calculated using Eq. 1–3, where Δσ3 is the additional confining pressure due to membrane stress; εa is the axial strain at failure; D0 is the initial diameter; M is the secant modulus of membrane; Kp is the coefficient of passive earth pressure, and Ku is the dimensionless modulus parameter for the unreinforced sand.

2.2 Validation

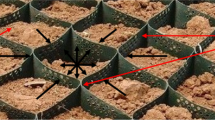

Study reported by Krishnaswamy et al. [5] (Fig. 1a) is validated using PLAXIS2D with the method described above. The load-settlement and deformation behaviour (Fig. 1b) depicted good predictability of the numerical model with the experimental observations reported. Hence, the method is accepted and further extended for the multiple-layer geocell-reinforced embankment system. The geometry of modelled single and multi-layered embankments are presented in Fig. 2.

a Test setup considered by Krishnaswamy et al. [5] and b Deformed mesh from PLAXIS2D analysis

3 Results and Analysis

In the analysis, an embankment of 10 m height above a soft clay of 10 m thick is reinforced with geocell. To verify the advantages of multi-layer geocell, a model with single-layer geocell of thickness 1 m and three models with two layers of geocells are considered. The multi-layer systems are designed in such a way that the total reinforced-soil thickness, including the vertical spacing (z) in between two geocell layers, should be the same. Hence, the height of geocells are as 47.5, 45 and 42.5 cm, with the vertical spacing in between as 5 cm, 10 cm and 15 cm, respectively, are considered.

The models are simulated in PLAXIS2D adopting the soil parameters mentioned by Latha and Rajagopal [6]. Geocell layer was considered as equivalent composite soil as described earlier. The required parameters for geocells for the equivalence are calculated through Eqs. 1–3 [6]. Table 1 presents a brief of the material properties. Plane strain, 15 node element, and drained conditions are selected for the analysis which provided an acceptable matching as shown in Fig. 3a. Plastic calculation is considered to investigate the influence of multi-layer geocells with respect to deflection and stress at the point ‘P’ (Fig. 2). The method is adopted for elastic–plastic deformation analysis in which it is not necessary to take the decay of excess pore pressure with time.

a Comparison of results: PLAXIS simulation and test result of Krishnaswamy et al. [5]; and b Variation of settlement for point ‘P’ at different loading stage for single and multi-layer geocell-reinforced systems

From the analysis, it is observed that multi-layer geocell system gives better result in terms of reduced ‘deformation’ (Fig. 3b) and ‘stress’ at point ‘P’ (Fig. 4). It can be attributed to stress distribution which reduces the stress intensity at the point ‘P’ to increase the overall load bearing capacity of the foundation. Overall, it is found that the multi-layer geocell system is better compared to single-layer geocell system. The study found multi-layer geocell system performed better with a vertical spacing of 10 cm with respect to deflection criteria (Fig. 4); whereas, geocell layers with 5 cm vertical spacing gave better performance in terms of effective Cartesian stress (σyy) (Table 2) (Fig. 5).

4 Conclusions

Present study has investigated the benefits of multi-layered geocell-reinforced embankment system and compared the performance with a single-layer geocell system of same thickness. From the result analysis, it may be concluded that multi-layered system performs better in terms of decreasing the deformation and reducing the effective stress beneath the geocell layers. Hence, the stability and load carrying capacity of the embankment system increases. Besides, it can also be inferred from the geometry considered that adopting multi-layer geocells can optimise the cost with respect to reduction in material (geocell) used.

References

Bush DI, Jenner CG, Bassett RH (1990) The design and construction of geocell foundation mattresses supporting embankments over soft ground. Geotext Geomembr 9:83–98

Cowland JW, Wong SCK (1993) Performance of a road embankment on soft clay supported on a geocell mattress foundation. Geotext Geomembr 12:687–705

Humphrey DN, Holtz RD (1986) Reinforced embankments-a review of case histories. Geotext Geomembr 4:129–144

Khalaj O, Tafreshi SNM, Masek B, Dowson AR (2015) Improvement of pavement foundation response with multilayers of geocell reinforcement: cyclic plate load test. Geomech Eng 9(3):373–395

Krishnaswamy NR, Rajagopal K, Latha GM (2000) Model studies on geocell supported embankments constructed over a soft clay foundation. Geotech Test J 23(1):45–54

Latha GM, Rajagopal K (2007) Parametric finite element analyses of geocell supported embankments. Can Geotech J 44:917–927

Tafreshi SNM, Khalaj O, Dowson AR (2013) Pilot scale load tests of a combined multilayered geocell and rubber-reinforced foundation. Geosynthetic Int 20(3):143–161

Wulandari PS, Tjandra D (2015) Analysis of geotextile reinforced road embankment using PLAXIS 2D. Procedia Eng 358–362

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sarkar, H., Biswas, A. (2022). Behaviour of Multi-layered Geocell-Reinforced Soil Embankment. In: Dey, A.K., Mandal, J.J., Manna, B. (eds) Proceedings of the 7th Indian Young Geotechnical Engineers Conference. IYGEC 2019. Lecture Notes in Civil Engineering, vol 195. Springer, Singapore. https://doi.org/10.1007/978-981-16-6456-4_9

Download citation

DOI: https://doi.org/10.1007/978-981-16-6456-4_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-6455-7

Online ISBN: 978-981-16-6456-4

eBook Packages: EngineeringEngineering (R0)