Abstract

Energy is essential for living and vital for the development of any country. Of the three main fossil fuels available—coal, petroleum and natural gas, petroleum is the most versatile and without which life may come to a standstill. Thus, there is a need for proper extraction, transportation and storage of petroleum. The accidental spilling of diesel or petrol from oil storage tanks at oil refilling sites is quite possible. In such situations due to leakage, the hydrocarbons present in oil may percolate into the subsurface and interact with the soil minerals thereby changing their properties. In the present study, interaction of hydrocarbon with fine grained soil was undertaken. The soil from an oil refilling station and the petroleum oil stored in the tank of that station were collected. The Atterberg’s limits, compaction and shear strength characteristics for the contaminated and uncontaminated soil were examined. The amount of oil added was 5, 10 and 15% of the dry weight of the soil sample. The results showed a significant influence of petroleum oil on the properties of clayey soil studied. The Atterberg’s limits, optimum moisture content, maximum dry density and undrained shear strength showed a decreasing trend with the increase in hydrocarbon content. The effective angle of internal friction (ϕ′) for uncontaminated soil samples exceeded the ϕ′ values of uncontaminated soils by 8°.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Petroleum is an extremely important fossil fuel which is crucial for the growth and development of any nation. The need for proper extraction, transportation and storage of petroleum is thus very important. According to the Report of the Working Group on Petroleum and Natural Gas Sector for the XI plan, by the Ministry of Petroleum and Natural Gas [8], the Indian hydrocarbon industry is currently passing through a challenging phase. Increasing concern for energy security, increasingly stringent environmental regulations, emergence of natural gas and soaring prices of crude oil and natural gas have thrown up both enormous challenges and opportunities to the Indian oil and gas industry. The prognosticated resources of hydrocarbon in India are about 28 billion tones as on 1.4.2006. The amount of recoverable balance of hydrocarbon is 1856 MMT. World oil use is expected to grow from 80 million barrels per day (mbpd) to 118 mbpd in 2030. The loss of petroleum by various ways has become an important issue which needs immediate attention for the survival of mankind. As much as 8 percent of total petroleum is lost during explorations, from oil vessels during transportation and accidents involving tankers. Among the sources of loss of petroleum, 33% comes from oil vessels during transportation, 2% during exploration and 12% from accidents involving oil tankers, which highlights a vital requirement for reducing the loss of oil during extraction, transport and storage.

An oil spill is an event resulting in the release of liquid petroleum into the ocean or land, mainly due to human activity. Some of the sources of oil spills are sinking or leakage of oil-carrying vessels or oil pipelines, leakage from oil storage units, illegal dumping by industries, terrorist activities and natural disasters. Crude oil after extraction is transported to oil filling stations for processing where it is stored in oil tanks. In case of accidental spilling the oil percolates into the soil, interacts with the soil minerals and changes the characteristic of the soil, which may become detrimental to the structure constructed or to be constructed over a particular soil deposit [6, 7, 10]. It is thus important to investigate the properties of oil-contaminated soil for assessment of its characteristics. Oil spills affect the surface of groundwater, covering it with a thick film of oil thereby affecting marine life. Oil spill affects the geotechnical properties of soil by reducing water content at liquid and plastic limits and tends to reduce the shear strength of the soil [9] which is unfavourable for geotechnical projects.

With this background, an oil refilling station of Hindustan Petroleum Corporation Limited in Budge Budge, South 24 Parganas District, West Bengal where oil spilling was evidenced from different containers at various time intervals was chosen as a test site. The objective of this study was to assess the impact of oil on the geotechnical properties of the locally available soil at the site and predicting the impact with varying the degree of contamination.

2 Materials and Methodology

Petroleum samples from the oil containers at the test site were collected. Soil samples up to a depth of 5 m were collected to determine the following index properties of the soil at the location:

-

Moisture content

-

Bulk density

-

Atterberg’s limits

-

Particle size distribution

-

Optimum moisture content

-

Permeability (falling head).

3 Experimental Procedure

Particle size distribution of soil sample was determined by standard hydrometric analysis. Hydrometer conforming IS-2720-Part IV-1985 was used for the test. Liquid limit and plastic limit of the oven dried soil samples were determined according to IS-2720 (Part V)-1985. Falling head permeability test was carried out for determining the permeability of soil as per IS-2720-Part-17-1986 (Reaffirmed-1997). The specific gravity of the soil samples was determined by adopting standard procedure. The soil sample was dried in oven dried for 24 h and pulverized. The sample was then poured into a specific gravity bottle and topped up with distilled water. The specific gravity bottle was stirred and heated to eliminate air bubbles. The weight of the specific gravity bottle was recorded along with the temperature of the sample. For a falling head test arrangement, the specimen was connected through the top inlet to selected stand pipe. The bottom outlet was opened and the time interval required for the water level to fall from a known initial head to a known final head as measured above the centre of the outlet was recorded. Three successive observations were taken to the determination of permeability. Standard proctor tests were carried out in the laboratory as per IS-2720-Part VII-1985 in order to determine optimum moisture content corresponding to maximum dry density of soil. The triaxial test as described by Bishop and Henkel [1] typically consisting of three main stages, saturation, consolidation and shearing, were conducted. To determine the shear strength characteristics, CU (consolidated undrained) triaxial tests were conducted. The amount of oil added was 5, 10 and 15% of dried weight of the soil sample.

4 Results and Discussions

The liquid limit and plastic limit of soil were 45% and 25%, respectively, and the physio-chemical properties are given in Table 1.

The test results of oil (Petrol) analysis are presented in Table 2.

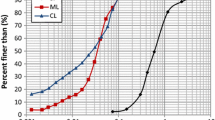

The soil was primarily cohesive in nature with high silt content (57%) and low permeability. Particle size analysis of the soil established that the clay content of the soil tested was 39% (see Fig. 1).

Using A-line chart, the soil was classified as clayey soil having medium plasticity (CM) (see Fig. 2).

The increase in the percentage of oil contamination led to decrease in the Atterberg’s limits. The liquid limit and plastic limits reduced significantly with the liquid limits for 5, 10 and 15% oil contamination being 41%, 36% and 32%, respectively. The plastic limits were found to be 22, 20 and 19% for same percentages of contamination. The plasticity of the soil thus reduced with increasing hydrocarbon content. This behaviour is evident in Fig. 2 where the soil when contaminated with 15% oil is classified as clayey soil with low plasticity (CL). The variation in Atterberg’s Limit with oil content is depicted (see Fig. 3).

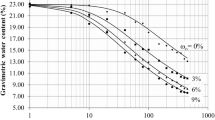

The maximum dry density (MDD) of the soil reduced with increasing oil content. The MDD value of uncontaminated soil was 18.5kN/m3. The MDD values decreased to 17.9, 17.3 and 17.1 kN/m3 corresponding to 5, 10 and 15% oil contamination. The optimum moisture content (OMC) of the soil also showed a decreasing trend with increase in percentage of oil contamination. The OMC for 5, 10 and 15% oil contamination were 16.48%, 15.04% and 14.59%, respectively. The hydrocarbons present in petrol is a non-polar liquid and thus displaces the water (which is polar in nature) around the clay minerals thereby reducing the thickness of water film surrounding the clay minerals. This reduces the bonding between the clay particles as water acts a binding agent hence reducing the plasticity and water retaining capacities of cohesive soils. The variation in compaction characteristics of the cohesive soil due to oil contamination are presented below (see Fig. 4).

The results of the triaxial compression CU (consolidated undrained) tests conducted at effective confining pressures of 100 kPa and 200 kPa are presented in Fig. 5a, b, respectively. The maximum deviator stress for uncontaminated soil is appreciably more than contaminated soils for both confining pressures. For an effective confining pressure of 100 kPa, the peak deviator stress of uncontaminated, 5, 10 and 15% oil-contaminated soils was 92 kPa, 73 kPa, 63 kPa and 54 kPa, respectively. The corresponding peak deviator stresses for effective confining pressure of 200 were 179, 152, 135 and 126 kPa. The results of CU tests obtained are presented (see Fig. 5).

The effective stress parameters determined from Mohr’s circles which gives the effective cohesion c’ value as zero with only internal friction contributing to the strength as the soils studied are normally consolidated in nature. The (ϕ′) value decreases with the increase in petrol content thus indicating a reduction in shear strength. This is due to the reduction in water which acts as a binding agent between clay minerals. There is a significant decrease in shear strength as the (ϕ′) value reduces significantly for oil-contaminated soil. The (ϕ′) value for uncontaminated soil was found to be 27.5° and for 15% contaminated soil was 19°. The variations of effective angle of internal friction (ϕ′) with petrol percentage are presented (see Fig. 6).

5 Conclusions

-

1.

Petroleum oil has a significant influence on geotechnical properties of clay soil.

-

2.

The Atterberg’s limits and the plasticity of the soil reduce with increase in oil content.

-

3.

The maximum dry density, optimum moisture content and the shear strength of clay soil decrease with increase in oil contamination content. A significant drop in shear strength was evidenced with a difference of 8° in the effective angle of internal friction (ϕ′) values of uncontaminated and contaminated soil samples.

References

Bishop AW, Henkel DJ (1962) The measurement of soil properties in triaxial test. Edward Arnold

IS: 2720 (Part 4)—1985-Specification for methods of test for soils-code of practice

IS: 2720 (Part 5)—1985-specification for methods of test for soils-code of practice

IS: 2720 (Part 7)—1985-specification for methods of test for soils-code of practice

IS: 2720 (Part 17)—1985-specification for methods of test for soils-code of practice

Khamehchiyan M, Charkhabi Amir H, Tajik M (2007) Effects of crude oil contamination on geotechnical properties of clay and Sand soils. Eng Geol Sci Dir 89:220–229

Konečný F, Boháček Z, Müller P, Kovářová M, Sedláčková I (2003) Contamination of soils and groundwater by petroleum hydrocarbons and volatile organic compounds—case study: ELSLAV BRNO. Bull Geosci 78(3):225–323

Ministry of Petroleum and Natural Gas (2006) Report of the working group on petroleum and natural gas for the XI plan (2007–2012)

Rahman ZA, Hamzah U, Ahmad A (2010) Geotechnical characteristics of oil-contaminated granatic and metasedimentary soils. Asian J Appl Sciences 3(4):237–249

Tuncan A, Pamukeu S (1992) Predicted mechanism of crude oil and marine clay interactions in salt water. In: Conference on environmental geotechnology-CSME/Turkey, 109–112

Acknowledgements

I would like to thank the concerned authorities of the oil refilling station of Hindustan Petroleum Corporation Limited in Budge Budge, South 24 Parganas District, West Bengal, for allowing the collection of necessary samples required for carrying out this study.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Chowdhury, A. (2022). Evaluation of Geotechnical Properties of Mineral Oil-Contaminated Clay Soil. In: Dey, A.K., Mandal, J.J., Manna, B. (eds) Proceedings of the 7th Indian Young Geotechnical Engineers Conference. IYGEC 2019. Lecture Notes in Civil Engineering, vol 195. Springer, Singapore. https://doi.org/10.1007/978-981-16-6456-4_24

Download citation

DOI: https://doi.org/10.1007/978-981-16-6456-4_24

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-6455-7

Online ISBN: 978-981-16-6456-4

eBook Packages: EngineeringEngineering (R0)