Abstract

This chapter gives an overview of neutron source facilities existing worldwide, which are used for neutron imaging applications. These facilities are broadly divided into mainly two major categories: reactor-based and non-reactor-based. By large, the neutron imaging facilities that have been catering the in-house research activities as well as worldwide user community, are reactor based. These facilities uses either thermal, cold or ultra-cold neutrons for neutron radiography, tomography as well as advanced neutron imaging techniques such as phase contrast imaging, Time of flight-based energy-resolved imaging, polarized and spin echo imaging, etc. using state-of-the-art systems. Ever since the first neutron radiography was carried out in 1935 soon after the discovery of neutrons, the neutron imaging facilities built worldwide have been utilized in the areas of basic and applied research, industrial application, space research and many more. Most of the facilities, which are close to fifty in numbers, have been built around research reactors. Country wise brief description of reactor-based neutron imaging beamlines with beam characteristics along with imaging modalities offered is presented. In India, the neutron imaging research activity is being pursued since 1995 onwards. Status of imaging beamlines using Indian research reactors Apsara, Cirus and Dhruva, are described. The second category of non-reactor-based sources used for imaging purpose is mainly accelerator based such as spallation neutron source, photo neutron source and linear accelerator-based isotropic neutron source. Besides this, radioactive isotope-based neutron sources have also been used for neutron radiography. Globally, there are few intense spallation neutron sources as well as other accelerator-based neutron sources with lower output of well-collimated beams of moderated neutrons.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

4.1 Introduction: Overview of Neutron Imaging Facilities—Past and Present

Neutron imaging has proven to be very useful in the areas of basic and applied research, industrial application, material research, non-destructive testing (NDT), space research, etc. as represented in Fig. 4.1. Kallmann and Kuhn in Germany [1] carried the first neutron radiography out way back in 1935, soon after the discovery of neutrons. They have used a Ra–Be radioisotope source and low neutron yield accelerator-based neutron source to get a radiograph with exposure of few hours using a vacuum cassette based radiographic converter-film system. For this work, they were awarded a joint US Patent entitled “Photographic Detection of Slowly Moving Neutrons” in January 1940 [2]. Thereafter, the neutron radiography work in Germany (upto World War-II) used intense accelerator-based source to record a neutron radiograph in few minutes [3]. Moreover, limitation of achieving high thermal neutron flux in accelerator-based sources coupled to a thermalizing assembly and realizing the potential of neutron imaging, researchers started looking for alternate intense neutron sources with stable beam started. The first reactor source for neutron imaging in practical applications was used by Thewlis and his co-worker Derbyshire in the mid-1950s, when they utilized a neutron beam with a flux of between ~109 n/cm2 s from the BEPO reactor at Harwell in England [4]. Soon after that, several developments, using reactor sources, were carried out by many researchers during 1960s in neutron imaging. These include intense and collimated beam to produce good quality images with high signal-to-noise ratio as compared to the earlier accelerator-based neutron source radiographs. Simultaneously, the improved detection methods adopted for NDT in neutron imaging provided qualitative as well as quantitative information of the object under examination. Reactor sources thus became the choice for neutron imaging, especially for industrial applications and nuclear fuels. Initially, in late sixties, the neutron radiography program was pursued at Argonne National Laboratory, United States, and at Melusine, Grenoble, France [5,6,7,8,9]. Thereafter, neutron imaging facilities were also developed in many other countries like Canada, Japan, South Africa, Germany, and Switzerland. Nearly 40 installations have come up for neutron radiography by the beginning of 1970 [10, 11]. These facilities were mainly involved in neutron imaging-based investigation of fresh and used nuclear fuel. At the same time, some of the facilities also started offering neutron radiography for commercial services that continue until today. General-Electric Vallecitos Center and the TRIGA type reactor at the Aerotest Operations Incorporated, both in the United States [7], were the first two reactors to offer such services. Similarly, neutron radiography as a service was also provided at the Fontenay-Aux-Roses in France and the Harwell NDT Center in England [7].

Neutron radiography mainly utilized attenuation property of thermal neutrons. However, fast neutron radiography investigations, using a 60-inches. cyclotron at two different neutron energies, at the University of California were also carried out [12]. At the same time, neutron radiography was also investigated using epithermal and cold neutron beam from 5 MW Herald reactor at the Atomic Weapons Research Establishment, England [13, 14].

Neutron imaging from 1970 onwards was focused on developing techniques and instrumentation for quantitative measurement rather than qualitative examination. Efforts were put to standardize neutron imaging in terms of reliability in finding defects and their characterization mainly for critical components such as those used in space programs. Thus, the relationship between standards and the acceptance of new NDT methods were recognized by researchers [15]. In 1969, Association of Neutron Radiographers (ANR) was formed to develop a personnel qualification standard under the authority of the American Society for Non-destructive Testing [16]. This helped in quantifying parts for aerospace industry.

First conference on neutron imaging with a theme of “Radiography with Neutrons,” was held at the University of Birmingham in 1973 [17]. Upto this period neutron imaging facilities were geographically commissioned in the United States, in many European countries and in Japan. Researchers in these facilities were exploring real-time imaging methods and new detectors for investigation [18,19,20]. Efforts were being put in improving the beam quality such as collimation, cadmium ratio for high flux neutron beam along with achieving high spatial resolution. Neutron imaging revolutionized when neutron sensitive image intensifier tube coupled to a vidicon television camera was used as detector for real-time neutron imaging for the first time [19]. Subsequently, this detector system became the choice among the researchers for dynamic imaging through 1990s because of its commercial availability [18,19,20]. Besides this, high-speed neutron radiography was also accomplished using TRIGA reactor by utilizing a reactor pulse and a high-speed camera [21]. New imaging modalities such as computed axial tomography with neutrons were also demonstrated during this period [22, 23] though they were of poor resolution and image quality, compared to the present-day neutron computed tomography (NCT) [24, 25].

Between 1980 and 1990 the progress on neutron imaging facilities and related research did not take noticeable stride. This was due to development of new NDT techniques using portable and less expensive sources along with non-availability of adequate funds for carrying out research at university and national laboratory research reactors. However, since the start of mid-1990s there was a renewed interest in neutron imaging. This was due to the setting up of new improved facilities with upgraded power of reactor sources, setting up of new cold neutron and spallation neutron sources, availability of advanced imaging devices and sensors, availability of high-end computing stations, and image reconstruction software.

4.2 Global Facilities

Neutron imaging has come a long way over seven decades since mid-1950s. It has grown gradually from neutron radiography to advanced imaging such as tomography, phase contrast imaging, polarized neutron imaging, etc. Globally many facilities, built around reactors, spallation sources, have been setup catering the neutron imaging community either for in-house research work or for users as well [10, 11]. Some other neutron imaging facilities have also been reported using radioactive sources, D-T fusion-based neutron sources, and photo neutron sources. A world map of neutron imaging installations is shown in Fig. 4.2. Geographically, the facilities have been widely spread across the globe from developed to developing nations. This section describes the neutron imaging facilities using reactor sources. Both thermal and cold neutron beam facilities are covered. Neutron imaging program in India started in mid-1990 using thermal neutrons from research reactors. A brief history along with the neutron imaging beamlines commissioned in India has been mentioned in a separate section.

World map showing the neutron imaging facilities using reactor and spallation source [26]

4.3 Neutron Imaging at Reactor-Based Sources

Generally, neutron imaging facilities have a common setup as shown in Fig. 4.3. They consist of a collimator placed in the beam tube of the reactor port, a safety shutter, sample manipulator, detector system with a beam dump behind. Neutron beam from the reactor after filtering and collimation is extracted towards the sample position. The image is recorded in transmission mode using scintillator-based high-resolution imaging detector placed in proximity with the sample. A shutter placed in between the collimator and the sample manipulator, allows safe user access during beam operation. For tomographic investigation, the sample is rotated in steps to acquire multiple images and further used for reconstruction the volume image of the sample. The entire setup after the collimator is well shielded for neutron and gamma radiation using proper shielding materials such as high-density concrete, borated wax, high-density borated polythene, steel, and lead. A controlled access from outside the shielding helps user to safely conduct the experiment.

Depending upon the energy of the neutron beam (thermal or cold) extracted from the reactor, the imaging facility is categorized as thermal neutron imaging beamline or cold neutron imaging beamline. A good quality image, on one hand, can be acquired using resolution CCD-based detector system controlled by modern computers and post-processing of image using advanced image processing software. On the other hand, the beam quality also plays an important role in getting a quality image. A useful beam for neutron imaging application should have the following properties:

-

Well collimated neutron beam with high L/D-ratio; L is the collimation length; D is the inlet aperture diameter

-

Large beam size with flat-top beam profile suitable to the sample dimension

-

High neutron beam intensity at the sample position

-

Narrow energy band (thermal or cold), well-known spectral conditions, necessary for quantification. Homogeneous (in space) beam of well thermalized or cold neutrons fitting to the sample and detector size

-

Low background from gamma rays or fast neutrons in the primary beam.

Worldwide, most of the beamlines use thermal neutrons. These beamlines can be put into four major categories namely in-house research, user, under installation, and project as represented in Fig. 4.2. Country-wise description of in-house usage and user facilities is described in the following sections. Technical specifications presented describes the reactor type along with the neutron imaging beamline parameters, detectors available at the facilities and research topics and services offered.

4.3.1 Algeria, Es-SALAM, Centre de Recherche Nucléaire de Birine (CRNB) 15 MW—In-House Usage

The Es-Salam research reactor is located in Birine, Algeria (Fig. 4.4). It is a 15 MW multipurpose heavy water reactor owned by Algeria’s Atomic Energy Commission (COMENA) and operated by the Birine Nuclear Research Centre (CRNB) [10, 27]. The reactor, equipped with several irradiation positions and beam ports, was commissioned in 1992. It provides a high-quality thermal neutron flux that is used for experimental and training tool for nuclear techniques and reactor physics. One of the beam port is dedicated for neutron imaging activities.

Es-SALAM reactor building, Algeria, Africa [27]

Technical Specifications

-

Tank-type research reactor with a power of 15 MW

-

Cooled and moderated by heavy water with a graphite reflector

-

Six horizontal beam ports, including a thermal column and 45 vertical irradiation positions

-

Maximum thermal neutron flux of 2.1 × 1014 cm−2 s−1

-

Radial Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~2.25 × 107

-

L/D collimation ratio ~300

-

Effective Beam size at sample position ~240 mm

-

Detectors—film, scintillator-based CCD camera system

-

Radiography, Non-destructive testing

-

Flow visualization and characterization

-

Neutron Tomography.

4.3.2 Algeria, NUR, CRND, 1 MW—In-House Usage

The NUR research reactor, as shown in Fig. 4.5, is located near Algiers. It is an open pool-type reactor that was commissioned in March 1989 [10, 27]. With a 1 MW of power, the reactor is used for research, development, and training purposes. These include development of nuclear techniques, neutron activation analysis (NAA), Neutron reflectometry, Neutron radiography, small angle neutron scattering (SANS), production of radioisotopes, and radiopharmaceuticals and training of operators.

Nur facility and reactor block, Algeria, Africa [27]

Technical Specifications

-

Pool-type, 1 MW research reactor

-

Materials testing reactor (MTR-LEU) plate-type fuel enriched to 20%

-

Cooled and moderated by light water with a graphite reflector

-

Maximum thermal neutron flux of ~5 × 1013 n-cm−2 s−1

-

Four radial and one tangential beam tubes, two vertical irradiation positions, two fast pneumatic transport systems, one hot cell, and one transfer cell

-

Tangential Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~6 × 106

-

L/D collimation ratio ~113

-

Effective Beam size at sample position ~340 mm dia

-

Detectors—film based.

Applications

-

Research topic—Non-destructive testing, Radiography.

4.3.3 Argentina, RA-6, 1 MW, In-House Usage

RA-6 is a multipurpose open pool type research reactor of 1 MW power [10]. It was commissioned in 1982 and is located in San Carlos de Bariloche, Rio Negro. It is used for research in physics and nuclear engineering. The neutron imaging facility is shown in Fig. 4.6.

Neutron irradiation and imaging facility at RA-6 reactor, Argentina [10]

Technical Specifications

-

Open pool-type, 500 kW/1 MW research reactor

-

Maximum thermal neutron flux of ~2 × 1013 cm−2 s−1

-

Radial Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~2.54 × 106 (with the reactor operating at 500 kW)

-

Filter Options—Sapphire

-

L/D collimation ratio ~100

-

Effective Beam size at sample position ~200 mm × 200 mm

-

Detectors—Scintillator and CCD camera based.

Applications

-

Research topic—Non-destructive testing, Radiography, Hydrogen technology, Cultural Heritage, Aerospace application.

4.3.4 Australia, DINGO, OPAL 20 MW, User Facility

The Open-pool Australian light water reactor (OPAL) is located at the Australian Nuclear Science and Technology Organization (ANSTO) Research Establishment New South Wales, Sydney (Fig. 4.7). It is 20 MW thermal reactor that uses low enriched fuel, heavy water as moderator, and light water as coolant. The reactor went critical on 12th August 2006. OPAL reactor has around nine states of beamlines using thermal and cold neutrons that are utilized in the areas of physical sciences, biology, chemistry, radio isotope production, residual stress measurement, neutron activation analysis, semiconductor material irradiation, and neutron radiography [28].

Technical Specifications

-

Open pool-type, 20 MW research reactor

-

Low enriched plate type fuel

-

Maximum thermal neutron flux of ~4 × 1014 cm−2 s−1

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [cm−2 s−1] ~5.3 × 107 and 1.06 × 107 at two sample positions

-

L/D collimation ratio ~500 and 1000

-

Effective Beam size at sample position ~200 mm × 200 mm

-

Detectors—Scintillator-based CCD camera system

-

Radiography, tomography, phase contrast imaging.

Applications

-

Research topic—Non-destructive testing, Radiography, Fuel Cell research, material science, palaeontology and cultural heritage.

4.3.5 Austria, Atominstitut, Vienna, TRIGA II, 0.25 MW, In-House Usage

TRIGA Mark II research reactor facility, as shown in Fig. 4.8, is located at the Institute of the Technische Universität Wien (TU Wien, Atominstitut in Vienna). TRIGA is an acronym for Training, Research, Isotope Production, General Atomic. It is a swimming pool type reactor giving a continuous and pulsed thermal neutron beam of 250 kW and 250 MW respectively. The reactor is in operation since March 1962 and has been used for basic and applied academic research and teaching purposes. Since this reactor is close to the IAEA headquarters, it is also frequently used by IAEA staff for development and calibration of safeguards instruments [30].

Atominstitut and reactor hall, Vienna, Austria [30]

Technical Specifications

-

Swimming pool type research reactor, 250 kW in continuous mode and 250 MW in pulse mode (prompt pulse lifetime: 40 ms and maximum repetition frequency: 12/h)

-

Maximum thermal neutron flux of ~1 × 1013 n-cm−2 s−1, in continuous mode operation.

-

Radial Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~3 × 105 at NR-I facility and ~1.3 × 105 at NR-II facility

-

L/D collimation ratio ~50 for NR-I facility and 130 for NR-II facility

-

Effective Beam size at sample position ~400 mm diameter for NR-I facility and 90 mm diameter for NR-II facility

-

Detectors—film, scintillator-based CCD camera system, Image plate

-

Radiography, Tomography and timing sequence.

Applications

-

Research topics—Absorber inhomogeneities, hydrogen detection

-

Services for industry—Investigation of steels, borated materials, fuel cells, building materials

-

Methodical developments—Systematic study of secondary effects in neutron transmission, beam hardening correction, NR and NT with weak beams.

4.3.6 Bangladesh, TRIGA MARK II, 3 MW, In-House Usage

TRIGA Mark-II type reactor is located in the capital city Dhaka, Bangladesh. It is a 3 MW research reactor operated under Bangladesh Atomic Energy Commission (BAEC). The reactor has been operating since September 14, 1986 as shown in Fig. 4.9. Utilization of this reactor includes radioisotope production (131 I, 99m Tc, 46 Sc), various R&D activities such as neutron activation, neutron scattering studies, neutron radiography and manpower training [10, 31, 32].

Technical Specifications

-

Swimming pool type, BAEC TRIGA Research Reactor (BTRR) 3 MW

-

Maximum thermal neutron flux of ~5.6 × 1013 cm−2 s−1

-

Tangential Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position (Tangential beam port) [n-cm−2 s−1] ~1.32 × 107

-

Neutron/gamma ratio (n-cm−2 per mGy)—2.23 × 106

-

Cadmium Ratio—10.51

-

Filter options—Bi

-

L/D collimation ratio ~60

-

Effective Beam size at sample position ~300 mm diameter

-

Detectors—film based.

Applications

-

Research topics—Non-destructive testing to study the internal defects and water absorption behaviour of different kinds of objects

-

Services for industry—R&D collaboration with other industry/organization.

4.3.7 Belgium, BR-1, 4 MW, In-House Usage

The BR1, the first Belgian reactor, is an air-cooled reactor with natural metallic uranium as fuel and graphite as moderator (Fig. 4.10). It is located at SCK CEN Institute Mol, Belgium and is operational since 1956. It is a flexible instrument for fundamental research, training and education [10, 33]. The reactor is used for Neutron radiography, calibration and validation, NAA, Production of Neutron Transmutation Doped (NTD) Silicon.

BR-1 reactor, Belgium [33]

Technical Specifications

-

Air-cooled natural metallic uranium fuel, graphite moderator research reactor BR-1

-

Now operated at 0.7 MW/1 MW for short periods

-

Maximum thermal neutron flux of ~2 × 1012 cm−2 s−1

-

Tangential Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [cm−2 s−1] ~4.2 × 105

-

L/D collimation ratio ~75

-

Effective Beam size at sample position ~200 mm dia

-

Detectors—film based

-

Radiography, NDT.

4.3.8 Brazil, ARGONAUTA, 0.2 MW, In-House Usage

The ARGONAUTA research reactor is located at the Nuclear Engineering Institute (IEN), university campus, Rio de Janeiro, Brazil. It is operated under Brazilian Nuclear Energy Commission located at the [10, 34]. “Argonaut” is an acronym for ARGOnne Nuclear Assembly for University Training and mainly refers to a class of small nuclear research and training reactors. The reactor uses U3O8-Al materials testing reactor (MTR) plate-type dispersion fuel type with 20% enriched uranium, giving 500 Wth of maximum power. Besides teaching and training in reactor physics and nuclear engineering, it is mainly used neutron radiography (Fig. 4.11) and neutron activation analysis.

ARGONAUTA research reactor and neutron radiography setup [10]

Technical Specifications

-

Type: Argonaut reactor Research Reactor

-

Maximum thermal neutron flux of ~4.4 × 109 cm−2 s−1

-

Radial Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~4.46 × 105

-

L/D collimation ratio ~70

-

Effective Beam size at sample position ~150 mm × 150 mm

-

Detectors—film, scintillator-based CCD camera system, Image plate

-

Radiography, Tomography.

4.3.9 Brazil, IAE-R1, 5 MW, User Facility

The Brazilian research reactor, IEA-R1, is located at Instituto de Pesquisas Energeticas e Nucleares (IPEN), São Paulo, Brazil. It was commissioned on September 16, 1957 and utilizes 20% enriched uranium fuel giving 5 MWth power [10, 35]. The reactor is widely used in areas of research such as physics, chemistry, biology, and engineering, as well as radioisotopes production for medical and other applications. The other service areas of IAE-R1 reactor utilization include neutron activation analysis, real-time neutron radiography and Tomography (as shown in Fig. 4.12), and neutron transmutation doping of silicon.

Technical Specifications

-

Pool-type, IAE-R1, 5 MW research reactor

-

20% enriched uranium U3O8-Al and U3Si2-Al fuel

-

Cooled and moderated by light water with graphite and beryllium reflectors

-

Maximum thermal neutron flux of ~1013 cm−2 s−1

-

Eight radial and two tangential beam tubes

-

Radial Beam line alignment

-

Thermal/cold neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~5 × 106

-

Cadmium ratio ~5

-

Filter Options—Bi

-

L/D collimation ratio ~90

-

Effective Beam size at sample position ~130 mm diameter

-

Detectors—film, scintillator-based CCD camera system

-

Imaging Options—Radiography, Tomography and time sequence.

Applications

-

Research Topics—Archeology, anthropology, engineering, aerospace, medicine.

4.3.10 Egypt, ETRR-2, 22 MW, In-House Usage

ETRR-2 (Experimental Training Research Reactor-2) reactor was supplied by the Argentine company, Investigacion Aplicada (INVAP). It is located at the Nuclear Research Center in the city of Inshas near Cairo, Egypt and is owned and operated by Egyptian Atomic Energy Authority (EAEA) (Fig. 4.13). The reactor achieved its criticality in 1997 and uses 20% enriched uranium fuel with light water moderator and beryllium reflector [10, 36]. ETRR-2 is widely used in areas of physics, materials/fuel testing, radioisotopes production, NAA, neutron radiography and teaching and training purpose.

ETRR-2 reactor facility, Egypt [27]

Technical Specifications

-

Pool-type, ETRR-2, 22 MW research reactor

-

20% enriched uranium fuel

-

Maximum thermal neutron flux of ~1.2 × 1014 cm−2 s−1

-

Radial Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~1.5 × 107

-

Cadmium ratio ~10

-

L/D collimation ratio ~117

-

Effective Beam size at sample position ~220 mm diameter

-

Detectors—film, scintillator-based CCD camera system

-

Imaging Options—Radiography, Tomography and time sequence.

4.3.11 France, ORPHEE, 14 MW, User Facility

ORPHEE (or the Orpheus) nuclear reactor is located at the Leon Brillouin Laboratory (LLB), CEA-Saclay Centre, Paris, France (Fig. 4.14). LLB is a joint national laboratory between CNRS (French National Center for Scientific Research) and CEA (French Atomic Energy Commission). ORPHEE is a swimming pool-type light water-cooled and heavy water moderated reactor that uses highly enriched fuel. The reactor achieved its criticality in December 1980. This national facility has been aiming three missions (called TGIR in French) such as proper research, service and development, training and education [10, 37]. The large-scale facilities of the reactor are not only open to own research programs but also serves large user community from across the world.

ORPHEE reactor, Saclay Center, France [38]

Technical Specifications

-

Swimming Pool-type, ORPHEE, 14 MW research reactor

-

MTR-type fuel with 93% U-235 enrichment

-

Maximum thermal neutron flux of ~4.4 × 1013 cm−2 s−1

-

Tangential and neutron guide tube* beamline alignment

-

Thermal and cold* neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~5 × 108

-

L/D collimation ratio ~70

-

Effective Beam size at sample position ~150 mm × 25 mm

-

Detectors—film, image plate

-

Imaging Options—Radiography.

* IMAGINE, ORPHEE is a cold neutron imaging beamline that is described in other section.

4.3.12 France, Grenoble, ILL, NeXT, 58 MW, User Facility

The reactor is located at Institut Laue Langevin, Grenoble, France (Fig. 4.15). It is a high flux research reactor with highly enriched fuel, cooled and moderated with heavy water. The reactor achieved its criticality in July 1957. Multidisciplinary beamlines exist in this facility for wide areas of research in physics, chemistry, biology, and engineering along with the production of radioisotopes for medical and other applications. The reactor serves a wide user community across the world with their thermal and cold neutron sources. Neutron and X-ray Tomography (NeXT) beamline is a unique facility that hosts complimentary imaging setup: neutron and X-ray (as shown in Fig. 4.16) [39]. As per reports by Tengattini et al. the measured flux at the end of the H521 guide is 1.4 × 1010 n-cm−2 s−1, which makes this the highest neutron flux in the world [40].

Institut Laue Langevin, Grenoble, France [39]

NeXT beamline, ILL, Grenoble, France [40].

Technical Specifications

-

High flux research reactor, 58 MW research reactor

-

Highly enriched fuel with 93% U-235

-

Maximum thermal neutron flux of ~1.5 × 1015 cm−2 s−1

-

Tangential beamline alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~3 × 108

-

L/D collimation ratio ~330

-

Effective Beam size at sample position ~30 mm diameter

-

Detectors—film, scintillator-based CCD camera system

-

Imaging Options—Neutron and X-ray Radiography and Tomography.

4.3.13 Hungary, DNR, 10 MW, User Facility

Budapest Research Reactor (BRR) is located at KFKI Science Campus in the capital city Budapest, Hungary. The reactor is a Soviet design VVR-type giving 10 MWth power. BRR is a tank-type reactor utilizing enriched uranium fuel, moderated and cooled by light water [10, 41]. It went critical for the first time on March 25, 1959. The reactor is operated by the Centre for Energy Research of the Hungarian Academy of Sciences. Many neutron-research related laboratories located in the KFKI campus participates in research activities under Budapest Neutron Centre (BNC) consortium formed in 1993 (Fig. 4.17). It is not only one of the leading research infrastructure in Hungary but also largest in Central-Europe. The facility has been widely used for neutron scattering investigations, neutron activation analysis and neutron imaging (Fig. 4.18).

KFKI science campus and BRR hall, Budapest [42]

Neutron, gamma and X-ray imaging setup at BRR [10]

Technical Specifications

-

VVR Tank-type, DNR, 10 MW research reactor

-

20% lightly enriched Uranium VVR-M2 type fuel (LEU)

-

Maximum thermal neutron flux of ~2.2 × 1014 cm−2 s−1

-

Radial beamline alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [cm−2 s−1] ~1.8 × 108

-

Neutron/Gamma ratio ~7.82 × 107 (n-cm−2 per mGy)

-

Variable inlet aperture—0.5–25 mm

-

Variable L/D collimation ratio—170–600

-

Variable effective beam size at sample position ~10–220 mm diameter

-

Corresponding beam intensity—7 × 103–6 × 107 cm−2 s−1

-

Detectors—Scintillator-based CCD camera system, image plate, Low lux level TV camera with vidicon

-

Imaging Options—Simultaneous Dynamic Neutron—and Gamma Radiography, time sequences, tomography, X-ray radiography.

Applications

-

Research Topics—Study of the supercritical water, investigation of Fuel Cells in operation.

-

Services for industry—Inspection of refrigerators, test of helicopter rotor blades.

4.3.14 Indonesia, GA Siwabessy MPR, 30 MW, In-House Usage

Reactor–Gerrit Augustinus Siwabessy is a multipurpose research reactor located in the Serpong, Tangerang, Indonesia. The reactor popularly known as BATAN is controlled and operated by BATAN, National Nuclear Energy Agency of Indonesia reactor (Fig. 4.19). It was designed and developed by Interatom GMBH from the Federal Republic of Germany. The reactor went critical in July 1987 and has played important role for nuclear industry development, radioisotope production, nuclear material science, reactor fuel element development, reactor safety, waste treatment, radio-metallurgy, nuclear-mechano laboratories, neutron imaging and teaching and training purpose [10].

BATAN facility and neutron radiography beamline [10]

Technical Specifications

-

Swimming Pool-type, 30 MW MPR research reactor

-

MTR-type enriched fuel

-

Maximum thermal neutron flux of ~3 × 1014 n-cm−2 s−1

-

Tangential beamline alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~107

-

Filter Options—Lead

-

Neutron/Gamma ratio >105 (n-cm−2 per mGy)

-

Cadmium ratio ~6.4

-

L/D collimation ratio ~83

-

Effective Beam size at sample position ~200 mm diameter

-

Detectors—Film, scintillator-based CCD camera system

-

Imaging Options—Radiography, tomography, time sequences.

Applications

Research Topics—Neutron radiography for examining automotive components and archaeological objects.

4.3.15 Israel, IRR-1, 5 MW, In-House Usage

The Israeli Research Reactor-1 (IRR-1) is located in Soreq Nuclear Research Center, Yavane, Israel. The reactor is a 5 MW pool-type light water reactor utilizing highly enriched uranium fuel. Construction on the IRR-1 began in January 1958 and the reactor reached criticality in June 1960. Major uses of this reactor include research and training in nuclear engineering, neutron radiography and tomography [10, 43], and diffraction, activation analysis, and changing colours of semi-precious and precious stones.

Technical Specifications

-

Swimming Pool-type, 5 MW research reactor

-

MTR-type fuel with 93% U-235 enrichment

-

Maximum thermal neutron flux of ~7 × 1013 cm−2 s−1

-

Tangential beamline alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [cm−2 s−1] ~1 × 106

-

L/D collimation ratio ~250

-

Effective Beam size at sample position ~98 mm × 98 mm

-

Detectors—Film, scintillator-based CCD camera system, Image plate, Amorphous Si flat panel detector

-

Imaging Options—Radiography, tomography.

4.3.16 Italy, TRIGA RC-1, 1 MW, In-House Usage

The reactor is located at ENEA institute, Rome, Italy. It is a 1 MW TRIGA Mark-II research reactor that became critical in June 1960. The reactor is used for neutron activation, neutron radiography [10], training purpose.

Technical Specifications

-

Swimming pool type, TRIGA RC-1, 1 MW

-

Radial/Tangential Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [cm−2 s−1] ~2.2 × 105 (radial)

~2.5 × 106 (tangential)

-

Inlet aperture—40 and 200 mm

-

L/D collimation ratio ~108 and 116

-

Effective beam size at sample position ~38 and 180 mm diameter

-

Detectors—Film, scintillator-based CCD camera system

-

Imaging Options—Radiography, Tomography, Time sequences.

4.3.17 Japan, JRR-3, 20 MW—User Facility

The reactor, which comes under Japan Atomic Energy Agency, is located in the Tokai, Naka-gun, Ibaraki, Japan. JRR3 achieved its criticality in 1962 (Fig. 4.20). However, it was modified in 1990 and renamed as JRR-3M. The reactor is a high-performance multipurpose research reactor with thermal power of 20 MW [10, 44]. This is a pool type light water moderated and cooled research reactor using low enriched aluminide fuels. The reactor has been utilized for nuclear research as well as industry. The areas of utilization of JRR-3 include neutron beam experiments, irradiation experiments for nuclear fuel and material, and production of radio isotopes and silicon semiconductors. Cold neutron beams are also available and utilized for research of life phenomena by analyzing the structure of polymer molecules.

Technical Specifications

-

Swimming Pool-type, 20 MW multipurpose research reactor

-

low enriched uranium aluminide fuel

-

Maximum thermal neutron flux at core ~3 × 1014 n-cm−2 s−1

-

Tangential beamline alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~1.5 × 108

-

Inlet aperture—39 and 48 mm

-

L/D collimation ratio ~185 and 154

-

Effective beam size at sample position ~255 and 305 mm diameter

-

Detectors—Scintillator-based CCD camera system, Image plate, Neutron colour image intensifier

-

Imaging Options—Radiography, tomography, time sequences.

Applications

-

Research Topics—Fuel cell, Architecture, Fluid

-

Services for industry—Fuel cell.

4.3.18 South Korea, HANARO, 30 MW—User Facility

The High Flux Advanced Neutron Application Reactor (HANARO) is located at Daejeon, Republic of Korea. It is a 30 MW multipurpose research reactor designed by Korea Atomic Energy Research Institute (KAERI) as a facility for research and development on the neutron science and its applications [10, 45]. The reactor reached its criticality in February 1995. It is an open pool type heavy water moderated and light water-cooled reactor that uses low enriched fuel. HANARO as a national as well user facility (as shown in Fig. 4.21) has played significant role in the area of neutron science, radioisotopes production, material testing, neutron transmutation doping (NTD), neutron activation analysis, and neutron radiography. The installation of a cold neutron source in 2010, has been also serving as a regional and international facility for neutron science.

HANARO reactor building and hall, South Korea [46]

Technical Specifications

-

Open pool-type, 30 MW multipurpose research reactor

-

U3Si, 19.75% enriched

-

Maximum thermal neutron flux of ~4 × 1014 n-cm−2 s−1

-

Tangential beamline alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~2 × 107

-

L/D collimation ratio ~278

-

Effective beam size at sample position ~350 mm × 450 mm

-

Detectors—Film; Scintillator-based CCD camera system

-

Imaging Options—Radiography, tomography.

Applications

-

Research Topics—Fuel cell, Li-Ion Battery, Non-destructive testing for aircraft, Dynamic radiography for heat exchanger

-

Services for industry—Fuel cell and Li-Ion Battery.

4.3.19 Malaysia, TRIGA II PUSPATI, 1 MW—In-House Usage

The PUSPATI reactor, owned by Malaysian Nuclear Agency, is located Selangor, Kajang in Malaysia [10, 47,48,49]. Also known as RTP, the reactor started its operation in 1982 and reached its first criticality in July 1982. It is a 1 MW TRIGA Mark-II pool type reactor that uses light water moderator and coolant, and graphite reflector (Fig. 4.22). The reactor is intended for medical, industrial, and agricultural radioisotope generation, as well as neutron radiography and small angle neutron scattering.

TRIGA II PUSPATI 1 MW facility and reactor hall with neutron imaging beamline, Malaysia [47]

Technical Specifications

-

Pool type, TRIGA II PUSPATI, 1 MW Research reactor

-

Maximum thermal neutron flux of ~1 × 1013 n-cm−2 s−1

-

Radial Beam line alignment

-

Fast and Thermal neutron energy spectrum in the ratio of 1:3

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~1 × 105

-

Neutron/gamma ratio—1.02 × 106 n-cm−2 mR−1

-

Cadmium Ratio—10.51

-

Filter options—Bi

-

L/D collimation ratio ~75

-

Effective Beam size at sample position ~80 and 150 mm diameter

-

Detectors—Film based; Scintillator-based CCD camera system

-

Imaging Options—Radiography, tomography.

Applications

-

Research topics—Non-metallic materials discontinuities assessment, Cultural heritage objects characterization.

4.3.20 Morocco, MA-R1, 2 MW—In-House Usage

The MA-R1 research reactor is located in Morocco’s National Center for Nuclear Energy, Sciences, and Technology’s Maâmora Nuclear Research Centre (CENM) in Rabat (CNESTEN) [10, 27]. As illustrated in Fig. 4.23, it is a 2 MW TRIGA Mark-II pool reactor with a light water moderator and coolant, as well as a graphite reflector. The reactor achieved first criticality in 2007 and has a wide range of capabilities, including radioisotope production for medical, industrial, and environmental applications, metallurgy, chemistry, and the use of nuclear analytical techniques such as NAA and non-destructive neutron radiography examination techniques.

Technical Specifications

-

Pool type, TRIGA II MA-R1, 2 MW Research reactor

-

Maximum thermal neutron flux of ~1.03 × 1013 n-cm−2 s−1

-

Tangential Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~1 × 106

-

Filter options—Bi, Sapphire

-

L/D collimation ratio ~75

-

Effective Beam size at sample position ~80 and 150 mm diameter

-

Detectors—Film based; Scintillator-based CCD camera system

-

Imaging Options—Radiography, tomography.

Applications

-

Research topics—Non-metallic materials discontinuities assessment, Cultural heritage objects characterization.

4.3.21 Poland, Maria, 30 MW—In-House Usage

The Maria research reactor is named after Maria Skodowska-Curie and is located near Warsaw in Wierk-Otwock (Fig. 4.24). It is the sole reactor of Polish design, built by the Institute of Nuclear Research in 1970. In December 1974, the reactor reached criticality. The high flux research reactor is a pool-type reactor with a graphite reflector and pressurized channels that is water and beryllium moderated [10, 50, 51].

Maria is a multifunctional research tool with notable applications in radioisotope production, fuel and structural material testing for nuclear power engineering, neutron transmutation doping of silicon, neutron modification of materials, research in neutron and condensed matter physics, neutron therapy, neutron activation analysis, neutron radiography, and reactor physics and technology training.

Technical Specifications

-

Pool type, 30 MW multifunctional research reactor

-

U3Si2, 20% enriched

-

Maximum thermal neutron flux of ~3 × 1014 n-cm−2 s−1

-

Radial Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~1.5 × 107

-

L/D collimation ratio ~170

-

Effective Beam size at sample position ~180 mm diameter

-

Detectors—Scintillator-based CCD camera system

-

Imaging Options—Radiography, tomography, time sequences.

Applications

-

Research topics—Water migration in porous media (imbibition, drying)

-

Service for industry—Tomography of industrial samples.

4.3.22 Portugal, RPI, 2 MW—In-House Usage

The RPI reactor that is part of Instituto Superior Técnico, is situated in Lisbon, Portugal [10, 52, 53]. It is a 1 MW light water open pool type reactor constructed by AFM Atomics, US (Fig. 4.25). The reactor became critical in April 1961 and has facilities such as radioisotopes production, detector testing, fast neutron irradiation for electronic components, neutron tomography and training in the field of reactor physics and technology.

Technical Specifications

-

Pool type, 1 MW research reactor

-

MTR-type 20% enriched fuel

-

Maximum thermal neutron flux of ~2.5 × 1013 n-cm−2 s−1

-

Radial Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~2 × 105

-

L/D collimation ratio ~40

-

Effective Beam size at sample position ~60 mm diameter

-

Detectors—Scintillator based CCD camera system

-

Imaging Options—Radiography, tomography, real time.

Applications

-

Research topics—Archeological.

4.3.23 Romania, TRIGA 14 MW, INUS and INUM—In-House Usage

The reactor is located in the Institute of Nuclear Research (INR) in Pisteti, Romania, as seen in Fig. 4.26. At the INR, there are two high-intensity neutron sources: the 14 MW TRIGA research reactor and the TRIGA ACPR (Annular Core Pulsed Reactor). Both reactors are open-pool reactors. The reactors have been used for neutron activation studies, neutron scattering, neutron radiography, radioisotope generation, and material research [10].

TRIGA 14 MW reactor facility, Romania [54]

Technical Specifications

-

Pool type, TRIGA 14 MW and TRIGA ACPR

-

U-ZrH fuel, 20% enriched uranium

-

Maximum thermal neutron flux of ~1 × 1012 n-cm−2 s−1

-

Tangential Beam line alignment for INUS and under water for INUM

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~5.4 × 106 in continuous mode

-

L/D collimation ratio ~95 for INUS and ~227 for INUM

-

Effective Beam size at sample position ~290 mm diameter for INUS and ~385 × 100 mm rectangular for INUM

-

Detectors—Film based; Scintillator based CCD camera system

-

Imaging Options—Radiography, tomography.

Applications

Research topics—Archaeological, Fresh and spent nuclear fuel.

4.3.24 Russian Federation, IBR-2 Pulsed Reactor, 2 MW Average—User Facility

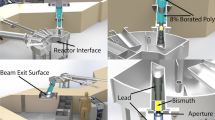

The IBR-2 reactor is a pulsed fast reactor located at Frank Laboratory of Neutron Physics, Dubna, Russia (Fig. 4.27). This reactor is part of one of the laboratories of the Joint Institute for Nuclear Research [10, 55, 56]. It is a 2 MW average power reactor that operates at 5 Hz repetition frequency with pulse duration of 350 µs of thermal neutrons using movable reflector as shown in Fig. 4.28. The reactor has been used for particle physics and condensed matter research, molecular biology, pharmacology, engineering diagnostics and neutron imaging. This reactor’s pulsed operation is appealing not only for conventional neutron imaging application, but also for the development of contemporary energy-selective techniques for time-of-flight measurements.

IBR-2 reactor building, Russia [57]

Core of the IBR-2 reactor with a movable reflector [58]

Technical Specifications

-

Pulsed Fast reactor, 2 MW average power (1850 MW pulsed)

-

PuO2 fuel

-

Maximum thermal neutron flux of ~1013 n-cm−2 s−1 time averaged and 1016 n-cm−2 s−1 burst

-

Radial Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~5.6 × 106

-

Filter options—Bi

-

L/D collimation ratio ~200

-

Effective Beam size at sample position ~200 mm × 200 mm

-

Detectors—Scintillator based CCD camera system

-

Imaging Options—Radiography, tomography, time sequence.

Applications

-

Research topics—Geology, Materials science, Planet science

-

Services for industry—non-destructive testing of various industrial components and products.

4.3.25 Slovenia, Triga, Mark-II, 0.25 MW—In-House Usage

The TRIGA Mark II research reactor is located at Jožef Stefan Institute (JSI) in Ljubljana, Slovenia. It achieved its first criticality on 31st May 1966 (Fig. 4.29). Since then, the reactor has played an essential part in Slovenia’s development of nuclear technology and safety culture. It is one of the country’s few modern technology facilities. The reactor has primarily been used for isotope production, neutron activation analysis, beam applications, neutron radiography, testing and development of a digital reactivity meter, verification of computer codes and nuclear data, primarily criticality calculations and neutron flux distribution studies [10, 59].

TRIGA 0.25 MW reactor hall, Slovenia [60]

Technical Specifications

-

Pool type, TRIGA 0.25 MW

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~4.5 × 105

-

L/D collimation ratio ~65–80

-

Effective Beam size at sample position ~120 mm diameter

-

Detectors—Film based; Image Plate detector

-

Imaging Options—Radiography.

4.3.26 South Africa, SAFARI-1, 20 MW—User Facility

South African Nuclear Energy Corporation (NECSA) owns and operates the SAFARI-1 reactor at its site in Pelindaba, South Africa (Fig. 4.30). It is a 20 MW light water-cooled, beryllium reflected, pool-type high flux research reactor that went critical in March 1965. The reactor is primarily used for commercial production of medical and industrial isotopes, activation analyses, material modification (such as neutron transmutation doping of silicon for the semiconductor industry), and a variety of support services such as neutron radiography and neutron diffraction, which are of both industrial and academic interest [10, 27, 61].

Technical Specifications

-

Pool type, 20 MW high flux research reactor

-

MTR-type 20% enriched fuel

-

Maximum thermal neutron flux of ~1 × 1014 n-cm−2 s−1

-

Radial Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~1 × 107 for L/D: 125

-

Filter options—Bi

-

Variable Inlet aperture—5–21 mm

-

L/D collimation ratio ~525–125

-

Effective Beam size at sample position ~130–300 mm diameter

-

Detectors—Film based, Scintillator based CCD camera system

-

Imaging Options—Radiography, tomography.

Applications

-

Research topics—Archaeology, Paleontology, Porous media Civil Engineering Reverse Engineering Geosciences

-

Service for industry—Geosciences, NDT.

4.3.27 Thailand, TRIGA Mark III, 1 MW—User facility

The Thai Research Reactor1/Modification 1 (TRR-1/M1) that went critical in November 1977, is located in Bangkok, Thailand (Fig. 4.31). It has been a key player in the establishment of the Office of Atomic Energy for Peace (OAEP) as well as nuclear applications in Thailand. The reactor has been used for radioisotope generation, neutron activation analysis, and neutron beam research, such as neutron scattering, prompt gamma analysis, neutron radiography, and training [10].

Neutron radiography facility, Thailand [10]

Technical Specifications

-

Pool type, TRIGA 1 MW, TRR-1/M1

-

Maximum thermal neutron flux of ~3.1 × 1013 n-cm−2 s−1

-

Tangential Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~1.1 × 106

-

Filter Options—Pb, Bi, Graphite

-

L/D collimation ratio ~50

-

Effective Beam size at sample position ~200 mm × 200 mm

-

Detectors—Film based; Scintillator based CCD camera system, Image plate

-

Imaging Options—Radiography, tomography.

Applications

Research topics—Archaeological.

4.3.28 USA, NBSR-NIST, 20 MW—User Facility

Neutron Beam Split Core Reactor (NBSR) at National Institute of Standards and Technology (NIST) in Gaithersburg, MD, USA is a unique multi-user facility as shown in Fig. 4.32. It is heavy water (D2O) moderated and cooled, enriched fuel, tank-type reactor designed to operate at a thermal power level of 20 MW, that went critical in December 1967. The NBSR reactor is utilized for wide-ranging applications such as neutron diffraction and scattering studies both in physical and chemical sciences, residual stress measurement, fuel cell research, NDT, neutron activation, neutron radiography, high-resolution neutron imaging, and detector development [10, 62].

Technical Specifications

-

Tank type, 20 MW reactor

-

MTR-type enriched fuel

-

Maximum thermal neutron flux of ~1 × 1014 n-cm−2 s−1

-

Radial Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal thermal beam intensity at sample position [n-cm−2 s−1] ~3 × 107

-

Filter options—cooled Bi

-

Cadmium ration >20

-

Variable Inlet aperture—10, 15 and 20 mm option circular

10 mm × 1 mm–20 mm × 2 mm rectangular

-

L/D collimation ratio ~600–300 for circular

~6000 × 600–3000 × 300 for rectangular apertures

-

Effective Beam size at sample position ~260 mm

-

Detectors—Scintillator based CCD camera system, flat panel detector, microchannel plate

-

Imaging Options—Radiography, tomography, phase contrast imaging, time sequence.

Applications

-

Research topics—Neutron focusing optics, neutron detection, proton exchange membrane fuel cells, lithium batteries, two-phase flow, porous media, heat pipes, image analysis

-

Service for industry—Free Collaborative beam time access and Proprietary access available via full cost recovery.

4.3.29 US, OSTR, TRIGA Mark II Research Reactor Oregon State, 1.10 MW—In-House Usage

The reactor is located in Corvallis, Oregon, at the Oregon State University Radiation Center. Oregon State University is one of the few educational institutions in the United States with a TRIGA research reactor. The Oregon State TRIGA Reactor (OSTR) is a water-cooled research reactor with a circular grid array of fuel components made of low-enriched uranium/zirconium-hydride. It can operate in both continuous and pulsed modes, with a continuous power output of 1.10 MW and a pulsed power output of 3000 MW [10]. OSTR’s uses include student teaching, research, isotope synthesis, neutron irradiation, and neutron imaging, to name a few.

Technical Specifications

-

Pool type, TRIGA 1.10 MW

-

Tangential Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal thermal neutron flux [n-cm−2 s−1] ~1 × 1013

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~4.4 × 106 at L/D of 101

-

Filter Options—Bi

-

L/D collimation ratio ~86 and 117

-

Effective Beam size at sample position ~44 mm × 52 mm, 172 mm × 229 mm and 360 mm × 440 mm

-

Detectors—Scintillator based CCD camera system, Image plate, Neutron sensitive microchannel plate

-

Imaging Options—Radiography, tomography, time sequences.

Applications

-

Research topics—Two-phased flow determination, Fuel Imaging

-

Services for industry—MMC Material Boron Content.

4.3.30 USA, UC Davis, TRIGA Mark III, 1 MW

The reactor is located at University of California, Davis in the USA. It is a research reactor dedicated mainly for radiographic and irradiation studies. There are dedicated four beamlines neutron radiography [10].

Technical Specifications

-

Pool type, TRIGA Mark III, 1 MW

-

Four beams, All tangential Beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position 4 stations [n-cm−2 s−1] ~6 × 106, 7 × 106, 1.5 × 107, 1.5 × 107

-

Filter Options—Bi

-

L/D collimation ratio ~175, 200 and 300

-

Effective Beam size at sample position ~500 mm diameter, 600 mm diameter and 450 mm square

-

Detectors—Film based, Scintillator based CCD camera system, Image plate

-

Imaging Options—Radiography, tomography.

Applications

-

Research topics—PEM fuel cell design, Geology

-

Services for industry—Turbine blades, pyrotechnical devices.

4.4 Cold Neutron Imaging Facilities

Cold neutron source-based imaging beamlines were setup at very few places across the world. The facilities are mainly located in developed countries. The use of cold neutrons in radiography enhances picture contrast and sensitivity for detecting tiny quantities of water and hydrogen-containing compounds in metal matrixes, for example. The cold neutron beam, on the other hand, may be easily changed using diffraction and neutron optical methods. This permits more advanced measurement techniques to be used in radiography and tomography investigations. These are mainly user-type facilities.

4.4.1 IMAGINE: ORPHEE, France—User Facility

IMAGINE is a cold neutron imaging station builds around ORPHEE reactor at the Laboratoire Léon Brillouin laboratory [10, 63]. As illustrated in Fig. 4.33, the station is intended for high-resolution neutron imaging and tomography. The facility is equipped with a variety of auxiliary equipment that allows for in-situ measurements as well as high-resolution tomographic measurements.

Schematic: IMAGINE cold neutron imaging beamline, France [63].

A highly curved guide (G3bis) that points at an H2 cold source provides the neutrons (20 K). The wavelength spectrum distribution begins at 3 Å because of the high curvature of the guide. The highest flux is at 4 Å, and the flux declines roughly in a 1/λ3 law above this wavelength. The high guide curvature also assures that the final beam used for experiments contains no fast neutrons or gammas coming from the reactor core is at 4 Å and above this wavelength the flux decreases roughly following a 1/λ3 law. The strong guide curvature also ensures that there are neither fast neutrons nor gammas originating from the reactor core in the final beam utilized for experimentation. Cold neutron flux at the sample position is 2 × 107 n/cm2/s with a L/D ratio of ~200 and signal to noise ratio of ~2000. However, L/D ratio can also be increased to ~1000.

4.4.2 Germany, BER II, 10 MW (CONRAD and PONTO Instruments)—User Facility

The BER II, 10 MW research reactor located at Hahn-Meitner-Institut, Berlin was in service for 40 years before it was permanently shut down in 2019. However, it is important to describe this unique multi-disciplinary facility. Imaging at this facility was performed using cold neutron and polarized cold neutron beams (Fig. 4.34).

The CONRAD imaging beamline, Germany [64].

The new cold neutron radiography apparatus CONRAD, as depicted in Fig. 4.35, was a multifunctional facility for radiography and tomography utilizing cold neutrons at the BER II, 10 MW research reactor [10, 64, 65].

The CONRAD-2 instrument setup [65]

The apparatus was constructed in 2005 and is placed at the end of a curved neutron guide that faces the BER-II research reactor’s cold neutron source. The geometry yields a cold neutron beam with wavelengths ranging from 2 to 12 nm. For radiography and tomography studies, there are two measurement locations accessible. The first, which is at the end of the guide, was designed for in-situ investigations that demand a strong neutron flux. At this location, the available flux was ~109 n-cm−2 s−1.

It was built in 2005 and was located at the end of a curved neutron guide, which faces the cold neutron source of the BER-II research reactor. The geometry provides a cold neutron beam with wavelengths between 2 and 12 Å. Two measuring positions are available for radiography and tomography investigations. The first one is placed at the end of the guide and it was optimized for in-situ experiments in which a high neutron flux is required. The available flux at this position was ~109 n-cm−2 s−1. The second position has a pin-hole that allows for better beam collimation (L/D up to 1000) and higher image resolution in the 100 μm range, using CCD-based detector system.

The cold neutron source was changed, and the neutron guide system supporting the instruments in neutron guide hall was entirely rebuilt and upgraded, during the cold neutron instrumentation upgrade at BER-II from October 2010 to October 2012. The CONRAD instrument (now known as CONRAD-2) was moved to a new location in the facility with a 10-m collimation path [65]. The beam divergence was considerably reduced by replacing current neutron guides (m = 1.2) with new supermirror guides (m = 2). The device’s adjustments increased the size of the usable beam and enhanced neutron transport efficiency. Furthermore, the curvature of the guide was improved by reducing its radius from R = 3000 m to R = 750 m in order to improve the distance between the shielding of neighbouring instruments and provide a more spacious experimental and user environment. Neutron tomography, energy-selective imaging, imaging with polarized neutrons, high-resolution radiography, and grating-interferometry were among the imaging modalities accessible at this facility.

At the same facility, the PONTO equipment, as shown in Fig. 4.36, was dedicated to polarized cold neutron radiography and tomography [10, 66]. For a point-to-detector distance of 5 mm, the spatial resolution for un-polarized neutrons was less than 85 µm, and for polarized neutrons, it was less than 300 µm. These resolutions can be used to image magnetic fields in numerous lead samples below the critical temperature for the Meissner phase and magnetic flux pinning.

The PONTO instrument, Germany [66].

4.4.3 Germany, FRM-II (ANTARES), 20 MW—User Facility

The Heinz Maier-Leibnitz neutron source in Germany (Forschungsreaktor München II or FRM II) is one of the most powerful and advanced neutron sources in the world. It is named after physicist Heinz Maier-Leibnitz, who ran a highly successful research programme at the FRM I, its predecessor. It is run by the Technical University of Munich and is located on its Garching campus. FRM-II is a 20 MW reactor with a cold neutron source flux of 8 × 1014 n/cm2/s at 3.5 Å.

The advanced neutron tomography and radiography experimental system (ANTARES) is installed at the FRM-II reactor’s cold neutron beam port SR-4a, as shown in Fig. 4.37 [67]. At the beamport, the facility has a pinhole-based variable collimator that can be used for a variety of high-resolution and high flux imaging applications. In chambers 2 and 3, ANTARES offers two distinct detector positions, which can be selected based on sample size, beam size, neutron flux, and spatial resolution requirements. Built-in options such as a velocity selector, double crystal monochromator, interference gratings, and a Be-filter are also readily available for standard user operation on ANTARES. The L/D ratio can be set anywhere between 100 and 3500. At the sample position, the average cold neutron flux varies from 4 × 105 to 4 × 108 n-cm−2 s−1. The ANTARES neutron imaging facility is designed to produce radiographs and computed tomography of materials. Because neutrons can penetrate metals (such as Fe, Al, and Pb) and have a high sensitivity for hydrogen, they can be used to visualize metal machine parts, as well as liquids, sealants, and polymers within them. Crack and void detection is done with liquid contrast agents. In this beamline, some examples of diverse approaches and their common uses are:

ANTARES facility at FRM II, Garching, Germany [67].

-

Standard neutron radiography: Moisture in sandstone, Rubber gaskets in machine parts, aerospace pyrotechnical components, fuel cells

-

Computed tomography: Geological samples, mineral phases, voids in carbon fiber structures (using contrast agents), machine parts, biological tissues

-

Continuous radioscopy: Real-time radiography

-

Stroboscopic imaging: Visualization of repetitive processes with high time resolution like oil distribution in running combustion engines

-

Phase contrast: Edge enhancement in aluminium foams, interfaces of similar alloys

-

Energy/wavelength scan: Scanning for Bragg edges, phase or material identification for welds investigation

-

Polarized neutron imaging: Metallurgical homogeneity of ferromagnetic materials, fundamental research on ferromagnetic phase transitions, visualization of magnetic field profiles

-

Neutron grating interferometry: Measurement of the spatially resolved SANS or USANS signal of the sample. Detection of microstructures on length scales of 500 nm–10 µm, porous materials, magnetic and superconducting vortex lattice domains.

4.4.4 Hungary, NORMA, 10 MW Cold Neutron Source—User Facility

The 10-MW Budapest Research Reactor has a cold-neutron source (CNS) that has been operational since February 2001 [10]. It involves a ‘direct-cooling’ moderator assembly with the helium cryogenic system [68]. This beamline has two facilities, as shown in Fig. 4.38 [69], Neutron-Induced Prompt Gamma-ray Spectroscopy (NIPS) and imaging—Neutron Optics and Radiography for Material Analysis (NORMA). These can be used separately or in combination with one another. Both conventional PGNAA measurements and Neutron Radiography/Neutron Tomography imaging can be carried out using cold neutrons. More sophisticated investigations using Neutron radiography/Neutron tomography driven PGAI technique can also be performed.

The cold neutron source flux at the sample position is about ~2 × 107 n/cm2/s. High-resolution and high-contrast imaging may be accomplished with an effective square beam size of 40 mm and an L/D ratio of 270. The facility is utilized for a wide range of research, including energy production and conversion, art, geology, and material science, object analysis and imaging, homogeneity of materials, coatings, and elemental characterization.

4.4.5 USA, ORNL, HFIR, 85 MW Cold Neutron Source—User Facility

The High Flux Isotope Reactor (HFIR), which runs at 85 MW, is the highest flux reactor-based source of neutrons for research (Fig. 4.39). It is located in Oak Ridge National Lab, USA, and produces one of the world’s highest steady-state neutron fluxes [10, 70]. The high neutron flux, constant power density, and constant-length fuel cycles are used for neutron scattering studies of condensed matter. As shown in Fig. 4.40, this facility also performs neutron activation, neutron radiography [71, 72], and cold neutron tomography. The L/D ratio for neutron imaging may be set to 480 or 725, with an average cold neutron flux of 7.5 × 106 n-cm2 s at the sample location. This beamline has been utilized in the field of energy storage, biomedical, materials science, engineering, geosciences, and cultural heritage.

(HFIR), Oak Ridge National Lab, USA [70]

Schematic view of neutron imaging facility at HFIR, ORNL [71]

4.5 New Facilities Using Research Reactors in Developing Countries

Radiographic imaging with cold neutrons is being proposed for the China Advanced Research Reactor (CARR). The China Institute of Atomic Energy’s (CIAE) 60 MW CARR attained full capacity in March 2012. It’s a tank-in-pool reactor using a D2O reflector. The expected optimal undisturbed thermal neutron flux of CARR is 8 × 1014 n-cm2 s. However, the expected thermal neutron flux at sample for L/D of 293 and 585 are 2 × 108 n-cm2 s and 5 × 107 n-cm2 s respectively [73]. In the guiding hall, a cold neutron imaging facility will be installed. Its conceptual and practical designs are complete at this moment [74]. The cold neutron imaging facilities will be a flexible and cost-effective tool for non-destructive research in both fundamental science and industry.

4.6 India on Global Map

Neutron imaging facilities in India were built around research reactors. The program of imaging with thermal neutrons was started in mid-1990 initially with a low neutron flux beam at APSARA reactor, BARC and KAMINI reactor, IGCAR, Kalpakkam. Later on, the new and advanced imaging facilities were commissioned at CIRUS and DHRUVA reactor, BARC. The following sections describe the neutron imaging facilities commissioned in India.

4.6.1 Apsara Reactor Imaging Beamline

Apsara, India’s first reactor, was developed at BARC in Mumbai in 1956 to undertake fundamental nuclear physics research (Fig. 4.41). It was light water-cooled and moderated swimming pool type 1 MW thermal reactor that attained criticality on August 4, 1956. The reactor was used for radio isotope production, fundamental nuclear research, shielding experiments, neutron activation analysis, neutron radiography, and neutron detector testing until it was permanently shut down in 2010. This reactor has now been upgraded to 2 MW Apsara-U facility in BARC.

Technical Specifications

-

Swimming pool type, 1 MW research reactor

-

Uranium—aluminium plate type highly enriched fuel

-

Maximum thermal neutron flux of ~1013 n-cm−2 s−1

-

Radial beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~1 × 106

-

L/D collimation ratio ~90

-

Effective Beam size at sample position ~150 mm × 150 mm square

-

Detectors—Scintillator-based Intensified CCD camera system

-

Imaging Options—Radiography, tomography.

This facility was mainly used for radiography, tomography and simulated two-phase flow experiments. Figure 4.42 shows the neutron imaging setup used [75]. An aluminium cylinder having 19 rods of SS and copper inside, its radiography image, 2D tomography and 3D tomography carried out at reactor power of ~400 kW is shown in Fig. 4.43.

4.6.2 KAMINI Reactor Neutron Imaging Beamline

KAMINI is a special purpose research reactor at Indira Gandhi Centre for Atomic Research (IGKAR), Kalpakkam [76]. This reactor was designed and built jointly by BARC and IGCAR. It is a 30 kW thermal reactor that uses metallic Uranium-233 as fuel, light water as moderator and coolant as shown in Fig. 4.44. The reactor achieved criticality on October 29, 1996. Since then, it has been used for neutron radiography, neutron activation analysis and radiation physics research.

KAMINI reactor, IGCAR, Kalpakkam [76]

Technical Specifications

-

Open Tank type, 30 kW research reactor

-

Enriched Metallic Uranium—233 fuel

-

Maximum thermal neutron flux of ~1012 n-cm−2 s−1

-

Radial beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~1 × 107

-

L/D collimation ratio ~160

-

Effective Beam size at sample position ~70 mm × 210 mm square

-

Detectors—Film based

-

Imaging Options—Radiography.

4.6.3 Cirus Reactor Imaging Beamline

Cirus (Canada India Reactor Utility Services) was built in 1954 at BARC, Mumbai in collaboration with Canada as shown in Fig. 4.45. The 40 MW tank-type research reactor used natural metallic uranium as fuel, heavy water as moderator and light water as coolant. It went critical on 10th July 1960 and was the second nuclear reactor to be built in India. The neutron beams produced by the reactor’s core were used extensively in condensed matter research, material irradiation, fuel testing, neutron activation research, neutron radiography, and the production of radioisotopes. CIRUS reactor proved to be an excellent platform for training engineers and scientists and in understanding the intricacies of managing natural uranium, heavy water, reactor systems that eventually evolved into the Indian pressurized heavy water reactor programme. After 50 years of successful operation, it was permanently shut down in December 2010.

Technical Specifications

-

Tank type, 40 MW research reactor

-

Natural metallic Uranium

-

Maximum thermal neutron flux of ~6.5 × 1013 n-cm−2 s−1

-

Radial beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~1 × 106

-

Filter Options—Bi

-

L/D collimation ratio ~90

-

Cadmium ratio ~10

-

Effective Beam size at sample position ~100 mm diameter

-

Detectors—Scintillator-based CCD camera system, Image plate

-

Imaging Options—Radiography, tomography, phase contrast imaging.

The neutron imaging beamline was commissioned at E-12 beamport of Cirus reactor as shown in Fig. 4.46. The shielding hutch and the motorized shielded door were fabricated using borated polythene and lead blocks [77]. This beamline was designed in such a way that conventional neutron radiography and tomography along with phase contrast imaging studies could be performed without any substantial modification of the experimental set-up. Radiography was carried out using main collimator permanently installed in the beamport. In order to carry out phase based neutron imaging a separate collimation insert was designed. Its dimensions were chosen in such a way that it can completely fit in the empty space of the preceding collimator.

4.6.4 Dhruva Reactor Imaging Beamline

The Dhruva reactor is indigenously made India’s largest nuclear research reactor that is located in BARC, Mumbai as shown in Fig. 4.47. It is a 100 MW vertical tank-type thermal reactor that uses natural metallic uranium as fuel and heavy water as moderator and coolant. The reactor went critical on August 8, 1985. The building of Dhruva marked a turning point in India’s indigenous nuclear technology development and use. Inside the reactor, many beamlines exist to satisfy the demands of a diverse multidisciplinary user group. It has been in extensive use for condensed matter research, material irradiation, fuel testing, neutron activation analysis, neutron radiography and production of radioisotopes for application in the fields of medicine, agriculture and industry.

Scientists from BARC, other units of the Department of Atomic Energy (DAE), universities, and national labs collaborate on joint projects at Dhruva, which has been recognized as a National Facility for Neutron Beam Research to meet the requirements of the Indian scientific community. Many of the collaborations are supported by the University Grants Commission—DAE Consortium for Scientific Research (UGC-DAE-CSR), the Board of Research in Nuclear Sciences (BRNS) and other agencies.

A state of art neutron radiography beamline was commissioned at one of the radial beam port as shown in Fig. 4.48. This beamline is operational since 2016 [78]. The collimator has been designed using dual aluminium cone shaped housing filled with mixture of sand-B4C powder for absorbing scattered neutrons and lead rings at different positions to absorb gamma radiation. A sapphire crystal as neutron filter followed by a bismuth crystal for gamma filtering has been used at the input of the collimator. Sand-B4C powder, cadmium sheets, lead rings and Boral has been used as filler materials in the annular housing. The collimator has been designed in such a way that radiography-tomography or phase contrast imaging studies can be performed on the same beamline. Shielding hutch and a motorized shielding door of the beamline have been made using borated polythene and lead blocks. The beamline has been utilized for non-destructive evaluation of fuel pin, ceramic to metal joints, locomotive parts. It is also utilized for advanced studies like hydrogen diffusion in Ziraclloy, water retention in plants, lead melting.

Technical Specifications

-

Vertical tank type, 100 MW research reactor

-

Natural metallic Uranium

-

Maximum thermal neutron flux of ~1.8 × 1014 n-cm−2 s−1

-

Radial beam line alignment

-

Thermal neutron energy spectrum

-

Maximal beam intensity at sample position [n-cm−2 s−1] ~4 × 107

-

Filter Options—Bi, Sapphire

-

L/D collimation ratio ~160

-

Cadmium ratio ~250

-

Effective Beam size at sample position ~120 mm diameter

-

Detectors—Scintillator-based CCD camera system, Image plate

-

Imaging Options—Radiography, tomography, phase contrast imaging.

4.7 Radioisotope-Based Neutron Imaging Facilities

Radioisotope-based neutron sources (Am–Be, Pu–Be, Sb–Be, etc.) can be used for neutron imaging with suitable moderator and collimator geometry. In this context, Fantidis et al. [79] had reported design consideration of neutron radiography system using Sb–Be neutron source. Authors had reported thermal neutron flux for different L/D, with and without Bismuth filter along with 1.85 × 1013 Bq 124Sb source. Sinha et al. [80] had also reported neutron radiography using Pu–Be neutron source of strength 2 × 107 n/s along with image intensifier and CCD camera. Sinha et al. had reported the thermal neutron flux of 70 n-cm−2 s−1 with L/D of 10 using thermalizing assembly of HDPe. However, the lower thermal flux with isotopic neutron source compared to reactor and spallation neutrons is the major issue for having good image quality.

4.8 Accelerator-Based Neutron Imaging Facilities

The accelerator-based neutron sources as discussed in Chap. 2 are used for neutron imaging, advanced research and commercial applications. The different accelerator-based neutron imaging facilities are discussed in the following sections.

4.8.1 Fusion Reaction-Based Neutron Imaging Facilities

Rapid advancement in the development of high energy and high current accelerators for high neutron yield production has increased their scope for neutron imaging. D-T, p-Be and D-Be are most common reactions used in these accelerators. List of few thermal and fast neutron imaging reported facilities are given in Tables 4.1 and 4.2 respectively [81,82,83,84].

4.8.2 Photo-Neutron Based Neutron Imaging Facilities