Abstract

MXenes, represented by Mn+1XnTx, are an emerging class of two-dimensional (2D) nitrides, carbides and carbonitrides (X) of transition elements (M) containing terminations of free surface-active groups (T). These are derived by selective etching out ‘A’ from their corresponding MAX phases. MXene, like their other 2D material counterparts, has exceptional electrical, electrochemical, mechanical and structural properties which make them a formidable candidate for electrode materials in energy storage systems like rechargeable lithium-ion batteries, supercapacitors and microsupercapacitors. They have excellent metal-ion storage capacity due to large interlayer space, low ion diffusion barrier, metal-like conductivity, high thermal stability and hydrophilic surface. Also, increased electrochemical performance has been observed when MXenes are used in conjuncture with graphene and carbon nanotubes (CNT) or dopants like silver, silicon, etc., as heterostructures or hybrid composites of 2D materials synthesized via innovative mix of processes. Thus, MXenes have been successfully identified and demonstrated as future sustainable energy material for energy storage application in the upcoming battery technology revolution.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The themes of sustainability, carbon neutrality and energy efficiency have spearheaded the increased focus on developing new and advanced renewable sources of energy production and conversion to lay the foundations for next-generation electrochemical and capacitive energy storage devices, an obvious shift from fossil fuel-based systems.

Batteries, a part and parcel of our daily lives, have infused life into both small and big electronics right from microcomputers to electric vehicles and are the predominant energy storage devices. Lithium-ion batteries (LIBs), common household names now because of their easy usability and portability, provide very high energy and power density. There has been a surge in research activities to further enhance performance, efficiency and life cycle of LIBs and other metal-ion batteries by studying and experimenting newer ways of electrode material design, their charge storage mechanisms and manufacturing techniques which could also help bring down the cost of energy production and storage (Mao et al., 2018). Similarly, extensive adaptation of portable electronic and microelectronic systems has hard pressed the need to develop better supercapacitors and microsupercapacitors. Constrained by size, these are expected to provide higher energy density, higher temperature tolerance, and quick charge and discharge capability with extended life cycles (Fan et al., 2018).

There is one common thread that connects all these seemingly daunting tasks and is at the heart of battery technology. And that is our ability to design and integrate highly compatible materials with exceptional mix of electronic, electrochemical, mechanical and functional properties as electrode material.

In this regard, two-dimensional (2D) materials have revealed tremendous potential by far. Single layer atom thick, they exhibit quite remarkable mechanical, electrical, electronic and chemical properties owing to which they have been able to make deep headways in the fields of semiconductors, electrodes, photovoltaics, water purification, etc. One prominent material among them is graphene, which also holds the distinction of being the first discovered 2D material in 2004, which has come to singlehandedly dominate electronic industry and garnered major research interest.

The year 2011 saw the world being introduced to a new class of 2D materials in the form of MXenes when the first in the family, a non-oxide, layered Ti3C2 ceramic was synthesized from its three-dimensional bulk crystalline Ti3AlC2 phase by a chemical process known as exfoliation that included selective etching at room temperature and was soon followed by discovery and synthesis of more than a dozen other MXenes structures, an endeavour driven by worldwide skyrocketing demand of high performance energy storage materials for new generation metal-ion batteries and supercapacitors. What impressed researchers about these materials was their interesting mechanical, thermal and electrochemical properties that manifested metal-like electrical and thermal conductivity, ceramic like strength, stiffness and heat resistance together with higher volumetric capacitance and unique structural characteristics which facilitated both effective charge storage and transport (Naguib et al., 2011) (Ghidiu et al., 2014).

2 MXene: A Novel 2D Material

MXenes are novel entrants in the world of two-dimensional materials and are essentially the layered carbides, carbonitrides and very recently nitrides of early transition metals. These are denoted by Mn+1Xn (n = 1, 2, 3) where ‘M’ represents an early transition metal (like Sc, Ti, Zr, V, Nb, Cr, Mo) and ‘X’ represents a carbon or a nitrogen. The ‘ene’ in MXene draws inspiration from graphene due to its sheet-like structure. They may have more than one ‘M’ in them which may be arranged as either solid solutions or ordered phases.

Alternatively, in the representation of functionalized MXenes Mn+1XnTx, the additional denotation ‘T’ refers to free active group (like –H, –F, = O and –OH) surface terminations which are leftovers from the aqueous etchants (HF, H2O, HCl) used during selective etching of element ‘A’ from their parent MAX phase. These terminations add hydrophilic nature to the MXenes and strongly influence their electrochemical and dielectric properties. Also, MXene with certain specific terminations can be achieved via controlled chemical treatment, intercalation and delamination, thermal annealing and exfoliation methods.

The MAX phases are themselves a group of layered structures given as MnAXn+1 (n = 1–3) where ‘A’ may be one of Al, P, Si, Ga, S, As, Ge, In, Sn, etc. The MAX phase consists of alternate stacked MX layer and ‘A’ layer. Selective etching removes the A element, while keeping the MX arrangement unchanged as A element is bonded relatively weaker and is more reactive as compared to very strong M–X bond (Luo, 2018).

Structure wise, MXenes have hexagonal symmetry, a property derived from parent MAX phase lattice structure. MXenes can be prepared in three different forms. One with single M element such as Ti2C and Mo2C, other existing as a solid solution of one or more M elements arranged randomly such as (Ti, V)2C2 and (Cr, V)3C2 and finally as double-ordered M elements where either a single M element layer or two layers of a single M element are arranged in between layers of a second M element such as Mo2TiC2 and Mo2Ti2C3. All of these MXenes can be thus represented as M2X, M3X2 and M4X3, derived from their corresponding MAX phases M2AX, M3AX2 and M4AX3 (Khazaei et al., 2017). Figure 1 shows the structure of these MAX phases and their related MXenes.

The first MXene, titanium carbide Ti3C2Tx, the most widely studied MXene, was synthesized, or rather discovered in 2011. The MAX phase Ti3AlC2 powders were mixed with 50 wt. % hydrofluoric acid (HF) solution for 2 h at room temperature.

The following suspension solution was washed with deionized water multiple times, and the powdered precipitate was allowed to settle via centrifuge action.

The above two equations show the formation of MXenes with surface groups, namely OH and F. This process, termed as selective etching process, has been since applied to other precursor MAX phases with the help of other acids as well such as hydrochloric acid (HCl) and lithium fluoride salt (LiF) to synthesize various different MXenes. Upon sonication treatment, MXenes can be delaminated to produce single flake suspensions. Before delamination, MXenes are essentially multilayered structures (Tang et al., 2018). Figure 2 explicitly explains the aforementioned process.

Reproduced with permission from ref. Naguib et al. (2011). Copyright 2012, American Chemical Society

Schematic for the preparation route of MXenes from the MAX phases.

This method was further extended to synthesize other MXenes such as Ti2C, Ta4C3, (Ti0.5, Nb0.5)2C, Ti3CN, (V0.5, Cr0.5)3C2, Ti2C3, and Cr2TiC2. Alternatively, NH4HF2 and mixture of LiF and HCl were also reported to be used as etchants to prepare some MXenes. With time, various endeavours were carried out to produce different MXenes by using different etchants and etching techniques. Needless to say that etching parameters like etching time, etchant concentration, particle size of the MAX phase and temperature during the chemical reactions play crucial parts in the conversion of given MAX phase into MXene. Mo2C, one of the early transition metal carbides, is the first MXene synthesized from Mo2Ga2C phase rather than its MAX phases. Also, Zr3C2 MXene was prepared from Zr3Al3C5, also not its MAX phase. As of now, over 70 different types of MXenes have been identified and prepared including Ti3C2, Ti2C, V2C, Cr3C2, Fe2C, Nb4C3, Nb2C, Mo1.33C, Mo2C, Hf3C2, V2C, Cr2C, Ta2C, Cr2N, Ti4N3, etc. Many more have been predicted to exist, waiting to be discovered (Zhu et al., 2017).

3 MXene: Properties

MXenes, comparatively the newer entrants into the family of 2D materials, have posed several interesting questions to scientists across disciplines by providing interesting mix of properties. They are both chemically and mechanically stable due to their ceramic nature. Structurally, they are found in both mono-layer and multilayer forms with very large interlayer spacing, even greater than that found in graphite and this thickness of layers can be controlled. This open space between the layers is capable of ion intercalation which means the ions of a range of sizes can be inserted into this space which is very important for the material to be used as cathode in energy conversion applications. Thus, as the layered structure is partially delaminated, not only does it allow ion intercalation but also electric double layer (EDL) formation contributing to charge storage in capacitors. Hydrogen bonding and van der Waals attraction mainly contribute to the interaction between layers of MXenes. The presence of functional groups as terminations provides abundant opportunities for creating desired surface properties and helps control their electrochemical, thermoelectric and dielectric properties. Surface terminations render the otherwise metallic MXenes into semiconductors such as Sc2CF2, Sc2CO2 and Ti2CO2. Moreover, the transition elements (M) in MXenes are very active. Also, a range of transition metals can be used to make the same where each can be tailored for specific applications (Tang et al., 2018; Zhu et al., 2017).

With regards to their mechanical property, it has been estimated by direct functional theory that the in-plane elastic constants of some of these MXenes exceed 500 GPa, which is even more than that of commonly used structural steel which has stiffness value of 400 GPa (Kurtoglu et al., 2012). The electrode material application requires that the MXenes possess very good structural, mechanical, electrochemical, ion movement and electronic transport properties. Their electronic properties are derived from the ‘M’ atoms. All the non-functionalized MXenes display metallic nature, and surface functionalized ones generally display semiconducting nature. Density functional theory (DFT) optimized calculations have shown that Sc-based MXenes such as Sc2CF2, Sc2C(OH)2 and Sc2CH2 nanotubes and Mo2CTx films to have semiconductor-like properties. High conductivity of Ti-based MXenes such as Ti3C2Tx was attributed to the Ti vacancy defects. This high conductivity characteristic has put them up for potential application as transparent conductors, electrochemical biosensors, magnetic materials, superconductors, absorbents for heavy metals and flexible electronic devices in addition to their usage in energy storage devices. MXenes have already been experimentally incorporated for potential applications such as rechargeable metal-ion batteries, supercapacitors, field effect transistors, electromagnetic interference shielding, hydrogen storage, sensing, catalysts, composites and biomedical devices among many others. The experimental results have been extremely promising and motivating (Khazaei et al., 2017).

4 MXene for Energy Storage Applications

Aided by modern industrial trends and progressive national policies, as the world transitions from fossil fuel-based energy generation to that derived from renewable sources like wind, sun etc., the need for energy storage devices like electrochemical batteries and supercapacitors is projected to soar higher by the day. They find wide range of applications from portable electronic devices, electric mobility systems to large electric grid systems. Lithium-ion batteries are the most popular form of electrochemical energy storage (EES) systems but they face plethora of challenges as well. These batteries have their own set of safety and cost concerns. They are also marred by very long charging time. It is believed that battery electrode materials have achieved their operational limitations and newer and better devices working on other metal ions like sodium, potassium, magnesium, calcium, etc., are the need of the hour due to their wider and easier availability together with multivalent character. These newer systems also call for improved electrolyte and electrode material development and selection for optimum efficiency (Er et al., 2014).

Of many hurdles facing the growth of LIBs and supercapacitors, two are of extreme significance:

-

1.

It is quite tough to obtain high energy and power density at the same time for these devices.

-

2.

There is an obvious resource crunch with supply chain issues leading to their higher prices (Sun et al., 2018).

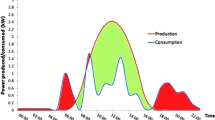

Also, the challenge to utilize and store all of the energy produced at larger scales has propelled the scientists to incorporate high performance materials into these devices for optimum efficiency. Working-wise, both rechargeable batteries and supercapacitors have altogether different pros and cons. Batteries produce very high energy densities in expense of poor power densities. Supercapacitors, on other hand, have superior power densities and fast charge–discharge rate but very low energy densities. Thus, researchers have made immense endeavours to develop electrodes capable of giving a mix of longer life cycle, high energy density and high power density outputs (Xiong et al., 2018). MXenes have been able to help achieve exactly these characteristics. Following are some of the research outputs that establish MXene and MXene-based hybrid structures as the next-generation high-efficient electrode materials for novel batteries and supercapacitors.

4.1 MXenes for Metal-Ion Batteries

Lithium-ion batteries have come to dominate the world of commercial metal-ion-based batteries. They form the backbone of modern-day portable electronic gadgets and are poised for growth in electric vehicles and standalone power storage units. Due to intermittent nature of energy generation of the new renewable energy systems like wind turbines and solar photovoltaics, it becomes increasingly necessary to have a totally reliable storage facility to compensate them in an environmentally sustainable manner devoid of carbon footprints and therein lies the applicability of these rechargeable battery systems.

Of late, they have reached operational ceiling due to lower power density output due to graphite electrodes which is used because of its easy cyclability and low cost. Thus, it was of paramount importance that novel electrode materials be explored for greater electrochemical performance. Also, due to relative scarcity of lithium metal, it is also wise to look for other possible metal based alternatives like battery technologies based on ions of sodium (Na), magnesium (Mg), potassium (K), aluminium (Al) and calcium (Ca). MXenes have come to show their high metal-ion absorption capacity with minimum ion diffusion barrier which arises owing to their high electronic conductivities, greater interlayer spacing and availability of highly active transition metals. Ti3C2Tx MXene, the most widely studied MXene in the whole of MXene world, has shown immense promise (Meng et al., 2018a).

Following results discuss the various efforts being put into the development of highly efficient MXene-based rechargeable battery electrodes.

Wang et al. investigated the current collecting capacity of free-standing Ti3C2Tx film to replace the conventionally used Al- and Cu-based anode and cathode materials in rechargeable Li-based batteries. For the purpose of the experiment, anode made of multilayer Ti3C2Tx and cathode of LiFePO4 was used. The MXene film, in comparison with Cu metal, offered reduction in weight of the battery by about three times. The cyclic voltammograms showed improved Li-ion insertion and extraction in LiFePO4 structure. The high flexibility of the electrode also positioned itself for its applications in flexible electronics (Wang).

Lu et al. studied the effect of reduction in fluorine (−F) surface terminations on the energy storage efficiency of Ti3C2 MXene for anode material in lithium-ion batteries. These terminations in large amount significantly brought down Li-ion storage capacity by providing higher diffusion barrier. Thus, hydrogen annealing was employed to remove excess –F terminations, and the resulting MXene was used as anode in Li-ion battery, it displayed improved volumetric specific capacity of about 123.7 mAh/cm3 and quite high cycling stability after 100 cycles (Lu et al., 2018).

Du et al. fabricated Ti2CX2/graphene hybrid flexible electrode for applications in electrochemically efficient lithium-ion batteries and used first principle method to study its behaviour. It was found that graphene helps avoid restacking of delaminated MXene layers in turn raising its electrical conductivity. The Li-ion mobility was greatly increased which is important for quick ion transport, with high adsorption of Li ions as well. Also, the improved structural stability characterized better structural stiffness (Du et al., 2019).

Zheng et al. employed a microwave irradiation method to uniformly grow carbon nanotubes (CNTs) in situ over Ti3C2, Ti2C and V2C MXenes to form a hybrid composite structure for potential applications in anode material in Li-ion batteries. The CNT/Ti3C2 system showed high reversible capacities of 430 and 175 mAhg−1 at current densities of 1 Ag−1 and 10 Ag−1, respectively, which is much better than the values for pristine Ti3C2. This proved their great potential in energy conversion applications (Zheng et al., 2018).

Kong et al. prepared a nanocomposite mixture of Silicon and Ti3C2 MXene with a 1:5 weight ratio via simple ultrasonic mixing to replace traditional Si-based anode in Li-ion batteries. The electrochemical measurements clearly showed the rise in reversible capacity of the composite with 188 mAhg−1 at 0.2 Ag−1 at the end of 150 cycles as compared to 17 mAhg−1 of pure Si. This phenomenon was because of Si-filled interlayer of the Ti3C2 MXene (Kong et al., 2018).

Zhao et al. developed an altogether new hybrid composite with MXene/MXene combination of transition metal carbide (Ti3C2Tx) and transition metal oxides (Co3O4 and NiCo2O4). These were used as anodes in Li ion battery and their electrochemical performance was studied. The Ti3C2Tx/NiCo2O4 electrode fabricated by spray coating showed particularly high rate capacitance of about 1330 mAh/g. Generally speaking, all MXenes composites had improved discharge–charge cycle performance and impressive rate capabilities over standalone parent MXenes (Zhao et al., 2016).

Ali et al. developed two-dimensional nanocomposite heterostructures of iron oxide (Fe2O3) and Ti3C2Tx MXene for anode material in Li-ion batteries. Composites of varying ratios, i.e. Ti3C2Tx/25 wt. % Fe2O3 and Ti3C2Tx/50 wt. % Fe2O3, were prepared via ball milling, hydrothermal process and wet sonication process; and effect of all these processes was studied. Hydrothermal and wet sonication processes resulted in high oxidation of MXene surface, whereas ball milling produced low surface oxidation and high specific surface area. It was seen that nanocomposite with 50 wt. % Fe2O3 prepared via ball milling presented the highest specific energy capacity of about 270 mAhg–1 and charge–discharge performance reached 100 mAh/g. Thus, this result showed good promise for their utility in energy storage applications (Ali et al., 2018).

Wang et al. synthesized layered Li4Ti5O12/Ti3C2Tx MXene composite via in situ method. It provided exemplary Li-ion storage capability and rapid ionic diffusion by reducing the travel path of ions and electrons. Moreover, it manifested high discharge capacity with 116 mAhg−1 at a rate of 10 Ag−1 and high cyclic stability after 500 cycles at 178 mAhg−1 (Wang, 2018).

Halim et al. investigated the electrochemical properties of delaminated molybdenum carbide (Mo2CTx) MXene prepared from its MAX phase Mo2Ga2C by selectively etching out gallium followed by delamination and intercalation with tetrabutylammonium hydroxide (TBAOH) in water, as shown in Fig. 3. The MXene showed semiconductor-like characteristics. It also showed very high capacitance retention upon 10,000 cycles at 10 A/g when tests were carried out on thick Mo2CTx film for supercapacitor application. When 8% carbon nanotubes were added into these MXene films to test Li-ion storage capability, over 1000 cycles, it displayed very good cycle performance with reversible capacity of 250 mAh/g (Halim et al., 2016).

Reproduced with permission from ref. Gao, et al. (2020) Copyright 2020, American Chemical Society

Schematic of synthesis and delamination process of Mo2CTx.

Lv et al. have studied the application of delaminated Ti3C2Tx MXene in Na-ion batteries. Intercalation and delamination were achieved by ultrasonic treatment in alcohol and dimethyl sulfoxide (DMSO), and a well-developed layered structure was obtained. It was confirmed that delamination led to layer space increase. A relatively higher sodium storage capability was observed in the charge–discharge process while Na-ion insertion into interlayer space concluded the very high rate performance. Cycle performance also confirmed the high stability of the structure of electrodes (Lv et al., 2018).

Meng et al. designed an S-functionalized Ti3C2 MXene and investigated the Na-ion storage capacity of Ti3C2, Ti3C2O2 and Ti3C2S2 MXenes to study the changes in storage capabilities with changes in the surface terminations. It was found that Ti3C2S2 shows substantially reduced ion diffusion barrier, fast discharge/charge rate and higher Na specific capacity compared to Ti3C2O2 mono-layer and thus has an upper hand in terms of electrical conductivity for more efficient electrode material. This was due to large non-positive Na adsorption energies for individual Ti3C2S2 layers (Meng, 2018a, 2018b).

Xie et al. developed porous Ti3C2Tx MXene electrode via sulphur loading and removal method and analysed its performance for Na-ion storage for practical applications in large-scale Na-ion batteries. It was observed that the ultrathin MXene nanosheets and its open framework due to porous nature facilitated Na-ion storage on its surface. Its volumetric efficiency (216 mAhcm−3) was greater than that of non-porous Ti3C2Tx film (64 mAhcm−3) at a current density of 100 mAg−1. Thermal annealing helped raise its columbic efficiency to 99% from 96.5% for multilayered Ti3C2Tx. The rate performance achieved was judged to be the best by far of all previous investigations (Xie et al., 2018).

Tao et al. employed a combination of facile hydrothermal and annealing methods to synthesize CoNiO2 nanoparticles chemically bonded to Ti3C2Tx forming a multilayer composite structure. It showed excellent rate capability, electrical conductivity and electrochemical performance which was attributed to the fact that nano size of CoNiO2 helps increase the number of electrochemically active sites and reduces distance for sodium-ion diffusion during discharge–charge cycles (Tao et al., 2018).

Xu et al. synthesized layered composite made of a few nanosheets of MoS2 on highly conductive Ti3C2Tx MXene substrate by one step hydrothermal process for applications in magnesium metal batteries. When used as cathode material, composite showed an increased capacity with 165 mAh/g at 50 mA/g and rate performance was found to be 93 mAh/g at 200 mA/g. It was also evident that Mg-ion charge storage had significantly increased (Xu et al., 2018).

Zhao et al. studied the magnesium-ion storage capacity of porous Ti3C2Tx anode films in magnesium-ion storage batteries in Mg-ion-containing electrolyte condition. The cathode performed extremely well in the context of rate performance and cycle consistency. The specific capacitance stood at 210, 140 and 55 mAhg−1 at 0.5, 1, and 5 C, making them promising candidates for Mg-ion batteries (Zhao et al., 2019).

Liu et al. demonstrated growth of nickel sulphide (Ni3S2) nanofibres on nickel foam by hydrothermal process for the development of binder-less electrode for higher efficiency Na-ion battery. These interconnected nanofibres were able to reduce the diffusion paths of Na ions, thus enhancing the conductivity, specific capacitance, capacity retention and discharge–charge cycle stability. They have proved their suitability to be used as anode material with cathode made of activated carbon due to generation of high energy and power density (Liu et al., 2019).

Mashtalir et al. picked Nb2CTx MXene, delaminated it using iso-propylamine and later produced carbon nanotube/MXene composite thin film electrodes and tested it for its lithium storage ability. The CNT/Nb2CTx anode exhibited specific capacity of greater than 400 mAh/g at 0.5 C and very high volumetric capacitance of about 325 F/cm3 (Mashtalir et al., 2015).

Zhu et al. synthesized Ti3CN nanosheets from the MAX phase Ti3AlCN for potential application in Na-ion batteries. Its properties were compared with those of Ti3AlC2 and Ti3C2 nanosheets prepared from the same MAX phase. The electrochemical tests indicated that Na-ion battery based on nanosheets of Ti3CN had higher specific capacity (507 mAhg−1) as compared to that based on Ti3C2. Its columbic efficiency reached almost 100% at the end of seven cycles and remained 100% at specific capacity of 139 mAhg−1 after 50 cycles while operating at current density of 20 mAg−1. For a test condition of 500 mAg−1, the discharge capacity fared at 98.9 mAhg−1 for the electrode made of nanosheets of Ti3CN, a 1.65 times rise over the value of 59.7 mAhg−1 for Ti3C2 electrode. This was a clear representation of its superior electrochemical efficiency for its use in sodium-ion batteries (Zhu et al., 2018a). Figure 4 shows scanning electron microscopy (SEM) images for Ti3CN nanosheets at different magnifications.

Reproduced with permission from ref. Zhu et al. 2018a. Copyright 2018, American Chemical Society

a SEM images of Ti3CN nanosheets, b High magnification SEM images of Ti3CN nanosheets.

Meng et al. performed DFT method to quantify the adsorption of Na ions on MXenes of zirconium carbide family, i.e. Zr2C, Zr3C2, Zr2CO2, and Zr3C2O2. Zr2C and Zr3C2, displayed magnetic nature while Zr2CO2 was semiconductor. All of these MXenes displayed metallic behaviour after Na adsorption which is reflective of the rapid electron movement within the electrode in sodium-ion batteries which in turn enhanced the rate capability of the MXene. The combined properties of Zr2CO2/Zr3C2O2 MXenes like low diffusion barrier, high electrical conductivity, high theoretical values of sodium-ion storage capacity greatly consolidated the confidence that it would make a promising electrode material for Na-ion battery (Meng, 2018).

Du et al. brought about a new method of preparing sulphur cathode in the lithium–sulphur (Li–S) batteries wherein hollow nanospheres of TiO2 with sulphur additions were embedded into the interlayers of Ti2C MXene to form a composite cathode. It effectively improved the cathode’s cycle performance. With initial discharge specific capacity of 1408.6 mAhg−1 at 78.4 wt. % sulphur, after 200 cycles, it was maintained at an impressive 464.0 mAhg−1. This was mainly attributed to high conductivity and enhanced volumetric expansion of Ti2C (Du et al., 2019).

Demiroglu et al. investigated the electrochemical behaviour of hybrid heterostructures of Sc2C(OH)2/graphene, Ti2CO2/graphene and V2CO2/graphene and studied the diffusion and adsorption of alkaline sodium, potassium and calcium atoms. The latter two systems showed better metal-ion intercalation and thermal stability. The energy barriers were reduced by half and rate capacities increased as compared to those of only MXene-based structures. These heterostructures systems were thus found suitable for certain low and high voltage applications (Demiroglu et al., 2019).

Yang et al. prepared a flexible composite cathode material made of carbon nanofibres with MoS2 MXene via electrospinning followed by annealing method for applications in rechargeable aluminium metal-ion batteries. The composite electrode displayed very good aluminium storage capabilities together with excellent discharge–charge capacity with 293 mAhg−1 at current density of 100 mAg−1 which was retained up to 126.6 mAhg−1 at the end of 200 cycles (Yang et al., 2019). Table 1 summarizes the electrochemical performance of various MXene-based systems for applications in metal-ion batteries.

4.2 MXenes for Supercapacitors

Supercapacitors are capacitors with quite high capacitance lying between those of rechargeable batteries and electrolytic batteries. They have faster charge delivery rate and longer charge–discharge cycle than a typical rechargeable battery. They are famed for their temperature tolerance and the ability to be integrally assembled in tandem with solar cells and batteries.

Broadly speaking, there can be two kinds of supercapacitors, both with different processes of charge storage and transfer. Some supercapacitors do not undergo phase change during operation and instead employ redox reactions, intercalations and electrosorption which are quite fast thus providing greater energy densities. These are called pseudocapacitors and are quite different from electrical double layer capacitors (EDLCs), which primarily operate by forming electrical double layer at the interface of the electrode and electrolyte solution. The more the specific surface area of this interface, the more is its capacitance. EDLCs mainly employ electrodes made from carbon or its derivatives like activated carbon and graphite. Regarding pseudocapacitors, traditional materials like MnO2, MoO3, Nb2O5, RuO2, etc., do provide high capacitance, but they lack behind owing to their low electrical conductivity. On this front, MXenes have shown tremendous improvement. Their unique structure and electronic properties make them highly suitable for supercapacitor applications. The interlayer provides large space for unhindered and fast electron movement, and in-depth researches have shown that these materials both on their own and with combination of other heteroatoms have achieved very high volumetric capacitance, structural stability, flexibility and rate performance due to lower ion diffusion barrier and ultrahigh ion storage and delivery (Lukatskaya et al., 2017). Some of these results have been discussed ahead.

Zhang et al. used alkalinizing and annealing to strike out excess surface group terminations from the self-assembled layers of Ti3C2Tx MXene film to form the supercapacitor electrode. Upon electrochemical tests, it was evident that the electrode film showed very high volumetric capacitance having value of 1805 Fcm−3 at current density of 1 Ag−1 and capacitance containment of 98% after 8000 cycles. This was contributed mainly by improvement in number of active sites in the MXene (Zhang et al., 2018).

Li et al. prepared Ti3C2Tx MXene film electrode decorated with silver (Ag) nanoparticles aqueous dispersion method. The hybrid material displayed high areal capacitance of 332.2 mF cm−2, good rate performance and cycle stability with 87% after 10,000 cycles (Li et al., 2018).

Yu et al. devised a unique fabrication process, as shown in Fig. 5, which involved encapsulating activated carbon in between Ti3C2Tx MXene layers via sonication and vacuum filtration followed by peeling off and drying the filtered layers. The MXene layers not only act as flexible backbone but also as binders. The resulting electrode displays very high capacitance of 126 F/g with improved rate performance of 57.9% at 100 A/g. These properties are ideal for its application in flexible supercapacitors (Yu, 2018).

Hu et al. prepared binder-free thick film electrode with pseudocapacitive delaminated Ti3C2Tx MXene which were then laser cut to fabricate on-chip microsupercapacitors (MSC) which exhibited areal capacitance of about 71.16 mFcm−2 which was a staggering seven times more than the currently used carbon-based on-chip MSCs which measure around 0.1–10 mFcm−2 and even greater than previously studied on-chip MSCs pertaining to similar MXene (4.2–61.0 mFcm−2), thus making its case formidable for microelectronics applications (Hu et al., 2018).

Chang et al. tried to overcome the stiffness of nano-scale MXene sheets for their application in stretchable and bendable supercapacitors by coming up with alternative electrode design in which certain Ti3C2Tx MXene nanocoatings with programmable crumpling and folding were developed. These were then loaded and unloaded at elevated temperatures to embed memory-based deformation characteristics. When these were employed as supercapacitor electrodes, they demonstrated high mechanical stability, high volumetric capacitance and a 27 times increase in areal capacitance when compared to flat MXene electrode. This was in addition to increase in stretchability of 80% in 1D and 225% in 2D (Chang et al., 2018).

Yu et al. assembled lithium-ion capacitor (LIC) with carbon nanotubes (CNTs) filled Ti3C2Tx MXene film as anode and activated carbon-made cathode. This composite film displayed excellent reversible capacity (489 mAhg−1), cycle stability and performance. The capacity retention of the electrode stood at 83% after 5000 cycles together with high energy density of 67 Whkg−1, proving its effectiveness as anode in LICs (Yu et al., 2018a, 2018b).

Zou et al. prepared a composite material for cathodes in supercapacitors by electrostatically assembling α-Fe2O3 and Ti3C2Tx MXene at room temperature. The resulting composite displayed a range of working potential of 1.2 V with a high specific capacitance of 405.4 and 197.6 Fg−1 at current densities of 2 and 20 Ag−1, respectively. Even more significant was its capacitance retention capacity of 97.7% at the end of 2000 cycles which definitely shows immense promise for supercapacitor cathode material (Zou et al., 2018).

Zhu et al. synthesized symmetric Ti2CTx−Ti2CTx supercapacitor which presented considerable cyclic performance with great power and energy densities. Also, 100% capacitance was retained after 3000 cycles at 20 A/g current density (Zhu et al., 2018b).

Yang et al. reported excellent results from composite electrode made by electrophoretic deposition of carbon nanotubes (CNTs) filled Ti3C2 MXene film over graphite paper. The specific capacitance of the electrode was improved by over 1.5 times and 2.6 times with respect to those of pure Ti3C2 MXene and CNTs. After 10,000 cycles, the electrode film retained an impressive 100% capacitance. Thus, it helped prove the effectiveness of electrophoretic deposition method of cathode preparation for supercapacitors (Yang et al., 2018).

Yue et al. developed a three-dimensional aerogel structure by ice-template method for microsupercapacitor having Ti3C2Tx and reduced graphene oxide as its components. The electrode was covered on its outside with polyurethane which provided excellent self-healing property to the material which was evident from the fact that the device possessed very high capacitance retention of about 81.7% at the end of fifth healing. At the end of 15,000 cycles, 91% charge retention was observed with very high specific capacitance of 34.6 mFcm−2 (Yue et al., 2018).

Wen et al. prepared novel Ti3C2Tx MXene-based electrodes which were doped with heteroatoms of nitrogen. The electrode showed significantly high capacitances of 192 F/g and 82 F/g in the electrolytic solutions of 1 M H2SO4 and 1 M MgSO4, respectively, which were much higher in comparison with undoped MXene which stood at 34 F/g and 52 F/g, respectively (Wen et al., 2017).

Peng et al. investigated the electrochemical performance of an MXene-based solid-state microsupercapacitors where larger and smaller flakes of Mxene Ti3C2Tx were made to act as current collector and active material, respectively. The device so fabricated manifested very high areal capacitance peaking at 27.3 mFcm−2 and capacitance of 356.8 Fcm−2 with retention of capacitance after 10,000 cycles of 100% (Peng et al., 2016).

Jiang et al. fabricated MnO2 and Ti3C2Tx MXene-based hybrid composite electrode which showed tremendous increase in conductivity, specific capacitance, cycle and structural stability. The transfer of electron and diffusion of ions were facilitated by the chemical reaction occurring between the nanoneedles of MnO2 and layers of Ti3C2Tx. The energy density peaked very high coupled with amazing 100% retention of capacitance upon 1000 cycles at 0.2 mAcm−2 (Jiang et al., 2018).

Shan et al. investigated the electrochemical characteristics of vanadium carbide (V2C) for supercapacitor application in aqueous condition. The MXene was prepared by HF etching and delaminated using tetramethylammonium hydroxide (TMAOH) base. Measurements were taken in different electrolyte solutions, namely H2SO4, MgSO4 and KOH to garner data on the dependence of its performance on electrolyte medium. The maximum specific capacitance obtained were 487, 184 and 225 F/g in 1 M H2SO4, 1 M KOH, and 1 M MgSO4, respectively. That these values were much greater than what had been previously reported gave strong boost to their candidature for supercapacitor electrode application (Shan et al., 2018).

Dall’Agnese et al. sought manufacturing of a Li-ion capacitor based on vanadium carbide (V2C) Mxene which produced capacitance of about 100 F/g at 0.2 mVs−1. When assembled as a cell with carbon-based cathode and MXene anode, a cell voltage of 3.5 V was obtained (Dall’Agnese et al., 2015). Table 2 summarizes the electrochemical performance of various MXene-based systems for applications in supercapacitors.

5 Conclusion

There is a new buzz in the scientific community about a novel two-dimensional material called Mxene, which after graphene, has attracted many a minds due to its unique mechanical, electrical and primarily electrochemical properties, thus predicting its widespread utility in next-generation highly efficient electrochemical devices for energy storage and delivery which are the need of the hour due to our increasing dependence on small-scale portable electronic devices, medium-scale utility in electric vehicles and large-scale standalone or grid-connected power storage units. Mxene and Mxene-based hybrid structures are being tested for potential electrode materials in both rechargeable battery systems and supercapacitors under variety of aqueous electrolytic solutions on parameters such as power density, energy density, life cycle, charge–discharge cycles, structural stability, volumetric capacitance, areal capacitance, flexibility and deformability, rate performance, ion diffusion barrier, electron mobility, electrical and thermal conductivities. New and improved techniques of etching and post-etching treatments like sonication, annealing, etc., have been developed for optimum intercalation and exfoliation, desired interlayer spacing, removal of excess surface terminations, designed inclusion of dopants and thin and flexible Mxene-based composite films.

As the saying goes, the best way to prepare for the future is to envision and create it. The era of sustainable and carbon neutral energy generation and storage is upon us already, and it requires development of new age materials with unprecedented performance, efficiency and versatility. It demands focussed and coordinated research efforts and planned product development, so that the technology reaches wide spread application at affordable costs to public and at no cost to the nature. And that future is ours to make and is up for grabs!

References

Ali, A., Hantanasirisakul, K., Abdala, A., Urbankowski, P., Zhao, M.-Q., Anasori, B., Gogotsy, Y., Aissa, B., & Mahmoud, K. A. (2018). Effect of synthesis on performance of MXene/Iron oxide anode material for Lithium-Ion batteries. Langmuir.

Chang, T.-H., Zhang, T., Yang, H., Li, K., Tian, Y., Lee, J. Y., & Chen, P.-Y. (2018). Controlled crumpling of two-dimensional titanium carbide (MXene) for highly stretchable, bendable, efficient supercapacitors. ACS Nano.

Dall’Agnese, Y., Taberna, P.-L., Gogotsi, Y., & Simon, P. (2015). Two-dimensional vanadium carbide (MXene) as positive electrode for sodium-ion capacitors. The Journal of Physical Chemistry Letters, 6(12), 2305–2309.

Demiroglu, I., Peeters, F. M., Gulseren, O., Cakir, D., & Sevik, C. (2019). Alkali metal intercalation in MXene/graphene heterostructures, a new platform for ion battery applications. The Journal of Physical Chemistry Letters.

Du, C., Wu, J., Yang, P., Li, S., Xu, J., & Song, K. (2019). Embedding S@TiO2 nanospheres into MXene layers as high rate cyclability cathodes for lithium-sulphur batteries. Electrochimica Acta, 295, 1067–1074.

Er, D., Li, J., Naguib, M., Gogotsi, Y., & Shenoy, V. B. (2014). Ti3C2 MXene as a high capacity electrode material for metal (Li, Na, K, Ca) ion batteries. ACS Applied Materials & Interfaces, 6(14), 11173–11179.

Fan, Z., Wang, Y., Xie, Z., Xu, X., Yuan, Y., Cheng, Z., & Liu, Y. (2018). A nanoporous MXene film enables flexible supercapacitors with high energy storage. Nanoscale, 10(20), 9642–9652.

Gao, L., Li, C., Huang, W., Mei, S., Lin, H., Ou, Q., Zhang, Y., Guo, J., Zhang, F., Xu, S., & Zhang, H. (2020). MXene/polymer membranes: Synthesis, properties, and emerging applications. Chemistry of Materials 32(5), 1703–1747.

Ghidiu, M., Lukatskaya, M. R., Zhao, M.-Q., Gogotsi, Y., & Barsoum, M. W. (2014). Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance. Nature, 516, 78–81.

Halim, J., Kota, S., Lukatskaya, M. R., Naguib, M., Zhao, M.-Q., Moon, E. J., Pitock, J., Nanda, J., May, S. J., Gogotsi, Y., & Barsoum, M. W. (2016). Synthesis and characterization of 2D molybdenum carbide (MXene). Advanced Functional Materials, 26(18), 3118–3127.

Hu, H., Bai, Z., Niu, B., Wu, M., & Hua, T. (2018). Binder-free bonding of modularized MXene thin films into thick film electrodes for on-chip micro-supercapacitors with enhanced areal performance metrics. Journal of Materials Chemistry A, 6(30), 14876–14884.

Iqbal, A., Kwon, J., Kim, M. K., & Koo, C. M. (2021). MXenes for electromagnetic interference shielding: Experimental and theoretical perspectives. Materials Today Advances, 9, 100–124.

Jiang, H., Wang, Z., Yang, Q., Hanif, M., Wang, Z., Dong, L., & Dong, M. (2018). A novel MnO2/Ti3C2Tx MXene nanocomposite as high performance electrode materials for flexible supercapacitors. Electrochimica Acta.

Khazaei, M., Ranjbar, A., Arai, M., Sasaki, T., & Yunoki, S. (2017). Electronic properties and applications of MXenes: A theoretical review. Journal of Material Chemistry C, 5, 2488–2503.

Kong, F., He, X., Liu, Q., Qi, X., Sun, D., Zheng, Y., Wang, R., & Bai, Y. (2018). Enhanced reversible Li-ion storage in Si@Ti3C2 MXene nanocomposite. Electrochemistry Communications, 97, 16–21.

Kurtoglu, M., Naguib, M., Gogotsi, Y., & Barsoum, M. W. (2012). First principles study of two-dimensional early transition metal carbides. MRS Communications, 2(04), 133–137.

Li, L., Zhang, N., Zhang, M., Wu, L., Zhang, X., & Zhang, Z. (2018). Ag-Nanoparticle-decorated 2D titanium carbide (MXene) with superior electrochemical performance for supercapacitors. ACS Sustainable Chemistry & Engineering, 6(6), 7442–7450.

Liu, M. C., Li, J., Yang, Q.-Q., Xu, Y., Kong, L.-B., Bai, R.-J., Liu, W., Niu, W., & Chueh, Y.-L. (2019). Hierarchically Interconnected Ni3S2 nanofibers as binder-free electrodes for high-performance sodium-ion energy storage devices. ACS Applied Nano Materials.

Lu, M., Li, H., Han, W., Chen, J., Shi, W., Wang, J., Meng, X.-M., Qi, J., Li, H., Zhang, W., & Zheng, W. (2018). 2D titanium carbide (MXene) electrodes with lower-F surface for high performance lithium-ion batteries. Journal of Energy Chemistry.

Lukatskaya, M. R., Kota, S., Lin, Z., Zhao, M.-Q., Shpigel, N., Levi, M. D., Halim, J., Taberna, P.-L., Barsoum, M. W., Simon, P., & Gogotsi, Y. (2017). Ultra-high-rate pseudocapacitive energy storage in two-dimensional transition metal carbides. Nature Energy, 2(8), 17105.

Luo, K., Zha, X.-H., Zhou, Y., Guo, Z., Lin, C.-T., Huang, Q., Zhou, S., Zhang, R., & Du, S. (2018). First-principles study on the electrical and thermal properties of the semiconducting Sc3(CN)F2 MXene. RSC Advances, 8(40), 22452–22459.

Lv, G., Wang, J., Shi, Z., & Fan, L. (2018). Intercalation and delamination of two-dimensional MXene (Ti3C2Tx) and application in sodium-ion batteries. Materials Letters, 219, 45–50.

Mao, J., Zhou, T., Zheng, Y., Gao, H., Liu, H., & Guo, Z. (2018). Two-dimensional nanostructures for sodium-ion battery anodes. Journal of Materials Chemistry A, 6(8), 3284–3303.

Mashtalir, O., Lukatskaya, M. R., Zhao, M.-Q., Barsoum, M. W., & Gogotsi, Y. (2015). Amine-assisted delamination of Nb2C MXene for Li-Ion energy storage devices. Advanced Materials, 27(23), 3501–3506.

Meng, Q., Ma, J., Zhang, Y., Li, Z., Hu, A., Kai, J.-J., & Fan, J. (2018a). Theoretical investigation of zirconium carbide MXenes as prospective high capacity anode materials for Na-ion batteries. Journal of Materials Chemistry A, 6(28), 13652–13660.

Meng, Q., Ma, J., Zhang, Y., Li, Z., Zhi, C., Hu, A., & Fan, J. (2018b). The S-functionalized Ti3C2 Mxene as a high capacity electrode material for Na-ion batteries: a DFT study. Nanoscale, 10(7), 3385–3392.

Naguib, M., Kurtoglu, M., Presser, V., Lu, J., Niu, J., Heon, M., Hultman, L., Gogotsi, Y., & Barsoum, M. W. (2011). Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Advanced Materials, 23(37), 4248–4253.

Naguib, M., Mochalin, V. N., Barsoum, M. W., & Gogotsi, Y. (2013). 25th Anniversary article: MXenes: a new family of two-dimensional materials. Advanced Materials, 26(7), 992–1005.

Peng, Y.-Y., Akuzum, B., Kurra, N., Zhao, M.-Q., Alhabeb, M., Anasori, B., Kumbur, E. C., Alshareef, H. N., Ger, M.-D., & Gogotsi, Y. (2016). All-MXene (2D titanium carbide) solid-state microsupercapacitors for on-chip energy storage. Energy & Environmental Science, 9(9), 2847–2854.

Shan, Q., Mu, X., Alhabeb, M., Shuck, C. E., Pang, D., Zhao, X., Chu, X.-F., Wei, Y., Du, F., Chen, G., Gogotsi, Y., Gao, Y., & Dall’Agnese, Y. (2018). Two-dimensional vanadium carbide (V2C) MXene as electrode for supercapacitors with aqueous electrolytes. Electrochemistry Communications.

Sun, S., Liao, C., Hafez, A. M., Zhu, H., & Wu, S. (2018). Two-dimensional MXenes for energy storage. Chemical Engineering Journal, 338, 27–45.

Tang, H., Hu, Q., Zheng, M., Chi, Y., Qin, X., Pang, H., & Xu, Q. (2018). Mxene–2D layered electrode materials for energy storage. Progress in Natural Science: Materials International, 28(2), 133–147.

Tao, M., Zhang, Y., Zhan, R., Guo, B., Xu, Q., & Xu, M. (2018). A chemically bonded CoNiO2 nanoparticles/MXene composite as anode for sodium-ion batteries. Materials Letters, 230, 173–176.

Wang, C.-H., Kurra, N., Alhabeb, M., Chang, J.-K., Alshareef, H. N., & Gogotsi, Y. (2018a). Titanium carbide (MXene) as a current collector for Lithium-Ion batteries. ACS Omega, 3(10), 12489–12494.

Wang, J., Dong, S., Li, H., Chen, Z., Jiang, S., Wu, L., & Zhang, X. (2018b). Facile synthesis of layered Li4Ti5O12-Ti3C2Tx (MXene) composite for high-performance lithium ion battery. Journal of Electroanalytical Chemistry, 810, 27–33.

Wen, Y., Rufford, T. E., Chen, X., Li, N., Lyu, M., Dai, L., & Wang, L. (2017). Nitrogen-doped Ti3C2Tx MXene electrodes for high-performance supercapacitors. Nano Energy, 38, 368–376.

Xie, X., Kretschmer, K., Anasori, B., Sun, B., Wang, G., & Gogotsi, Y. (2018). Porous Ti3C2Tx MXene for ultrahigh-rate sodium-ion storage with long cycle life. ACS Applied Nano Materials, 1(2), 505–511.

Xiong, D., Li, X., Bai, Z., & Lu, S. (2018). Recent advances in layered Ti3C2Tx MXene for electrochemical energy storage. Small (weinheim an Der Bergstrasse, Germany), 14(17), 1703419.

Xu, M., Bai, N., Li, H.-X., Hu, C., Qi, J., & Yan, X.-B. (2018). Synthesis of MXene-supported layered MoS2 with enhanced electrochemical performance for Mg batteries. Chinese Chemical Letters, 29(8), 1313–1316.

Yang, L., Zheng, W., Zhang, P., Chen, J., Tian, W. B., Zhang, Y. M., & Sun, Z. M. (2018). MXene/CNTs films prepared by electrophoretic deposition for supercapacitor electrodes. Journal of Electroanalytical Chemistry.

Yang, W., Lu, H., Cao, Y., Xu, B., Deng, Y., & Cai, W. (2019). A Flexible Free-standing MoS2/Carbon Nanofibers Composite Cathode for Rechargeable Aluminum-Ion Batteries. ACS Sustainable Chemistry & Engineering.

Yue, Y., Liu, N., Ma, Y., Wang, S., Liu, W., Luo, C., Zhang, H., Cheng, F., Rao, J., Hu, X., Su, J., & Gao, Y. (2018). Highly self-healable 3d microsupercapacitor with MXene–graphene composite aerogel. ACS Nano, 12(5), 4224–4232.

Yu, L., Hu, L., Anasori, B., Liu, Y.-T., Zhu, Q., Zhang, P., Gogotsi, Y., & Xu, B. (2018a). MXene-bonded activated carbon as a flexible electrode for high-performance supercapacitors. ACS Energy Letters, 3(7), 1597–1603.

Yu, P., Cao, G., Yi, S., Zhang, X., Li, C., Sun, X., Wang, K., & Ma, Y. (2018b). Binder-free 2D titanium carbide (MXene)/carbon nanotube composites for high-performance lithium-ion capacitors. Nanoscale, 10(13), 5906–5913.

Zhang, X., Liu, Y., Dong, S., Yang, J., & Liu, X. (2018). Surface modified MXene film as flexible electrode with ultrahigh volumetric capacitance. Electrochimica Acta, 294, 233–239.

Zhao, M.-Q., Ren, C. E., Alhabeb, M., Anasori, B., Barsoum, M. W., Gogotsi, Y. (2019). Magnesium-ion storage capability of MXenes. ACS Applied Energy Materials.

Zhao, M.-Q., Torelli, M., Ren, C. E., Ghidiu, M., Ling, Z., Anasori, B., Barsoum, M.-W., & Gogotsi, Y. (2016). 2D titanium carbide and transition metal oxides hybrid electrodes for Li-ion storage. Nano Energy, 30, 603–613.

Zheng, W., Zhang, P., Chen, J., Tian, W. B., Zhang, Y. M., & Sun, Z. M. (2018). In situ synthesis of CNTs@Ti3C2 hybrid structures by microwave irradiation for high-performance anodes in lithium ion batteries. Journal of Materials Chemistry A, 6(8), 3543–3551.

Zhu, J., Ha, E., Zhao, G., Zhou, Y., Huang, D., Yue, G., Hu, L., Sun, N., Wang, Y., Lee, L. Y. S., Xu, C., Wong, K., Astruc, D., & Zhao, P. (2017). Recent advance in MXenes: A promising 2D material for catalysis, sensor and chemical adsorption. Coordination Chemistry Reviews, 352, 306–327.

Zhu, J., Wang, M., Lyu, M., Jiao, Y., Du, A., Luo, B., Gentle, I., R., & Wang, L. (2018a). Two-dimensional titanium carbonitride MXene for high-performance sodium-ion batteries. ACS Applied Nano Materials.

Zhu, K., Jin, Y., Du, F., Gao, S., Gao, Z., Meng, X., Chen, G., Wei, Y., & Gao, Y. (2018b). Synthesis of Ti2CTx MXene as electrode materials for symmetric supercapacitor with capable volumetric capacitance. Journal of Energy Chemistry.

Zou, R., Quan, H., Pan, M., Zhou, S., Chen, D., & Luo, X. (2018). Self-assembled Mxene (Ti3C2Tx)/α-Fe2O3 nanocomposite as negative electrode material for supercapacitors. Electrochimica Acta.

Acknowledgements

This book chapter was financially supported by Empowerment and Equity Opportunities for Excellence in Science (EEQ/2018/000873), Science & Engineering Research Board (SERB), Department of Science and Technology, Government of India and Ministry of Human Resource and Development (MHRD), Government of India.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Mishra, M., Behura, S.K., Beidaghi, M., Verma, K., Singh, S. (2021). MXene: A Non-oxide Next-Generation Energy Storage Materials for Batteries and Supercapacitors. In: Singh, S., Verma, K., Prakash, C. (eds) Advanced Applications of 2D Nanostructures. Materials Horizons: From Nature to Nanomaterials. Springer, Singapore. https://doi.org/10.1007/978-981-16-3322-5_6

Download citation

DOI: https://doi.org/10.1007/978-981-16-3322-5_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-3321-8

Online ISBN: 978-981-16-3322-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)