Abstract

The development of two-dimensional (2D) high-performance electrode materials is the key to new advances in the fields of energy storage and conversion. As a novel family of 2D layered materials, MXenes possess distinct structural, electronic and chemical properties that enable vast application potential in many fields, including batteries, supercapacitor and catalysis. However, MXene layers are easily formed by stacking together, which significantly reduces the specific surface area, hinders the transmission of ions, and restricts other functional materials on the surface, thereby reducing performance. In addition, due to the inherent defects of a single electrode material, electrodes or catalysts made of single-phase MXene may not meet specific practical application requirements. MXenes nanocomposites materials based on enhanced electrochemical performance through nano-engineering technology and surface modification for morphological control are highly sought after to solve these challenges. This review aims to present recent advances in these emerging MXene nanocomposites for energy storage and conversion applications such as batteries, supercapacitors and catalytic reactions. We also introduced some of the challenges and opportunities in this rapidly developing field.

Graphic abstract

摘要

二维 (2D) 高性能电极材料的开发是能源存储和转换领域取得新进展的关键。作为一种新型的二维层状材料, MXenes 具有独特的结构、电子和化学特性, 在许多领域具有巨大的应用潜力, 包括电池、超级电容器和催化。然而, MXene层很容易通过堆叠在一起形成, 这显着降低了比表面积, 阻碍了离子的传输, 并限制了表面上的其他功能材料, 从而降低了性能。此外, 由于单一电极材料的固有缺陷, 单相MXene制成的电极或催化剂可能无法满足特定的实际应用要求。 MXenes 纳米复合材料通过纳米工程技术增强电化学性能和形态控制的表面改性而备受追捧, 以解决这些挑战。本综述旨在介绍这些新兴的 MXene 纳米复合材料在用于能量存储和转换应用 (如电池、超级电容器和催化反应) 方面的最新进展, 以及这个快速发展领域的一些挑战和机遇。

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

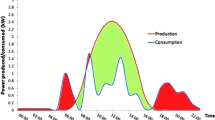

The ability to produce, store and use fuel for energy production shapes human society [1]. With the rapid growth of the human population, the energy demand is increasing, so is the environmental pollution problem, which requires us to develop environmentally friendly and renewable solutions to replace fossil fuels [2]. Recent advances in electrochemical energy conversion (EES) and storage technologies such as batteries [3,4,5], supercapacitors [6,7,8,9,10], and catalysis [11,12,13,14,15,16] promise alternative sources for a sustainable environment [17,18,19]. Although significant achievements have been made in energy storage devices, some fundamental challenges remain. For example, it is difficult for these devices to achieve high power density and high energy density at the same time [20]. Meanwhile, rechargeable energy storage is limited and comes at high costs. Therefore, it is particularly urgent and important to develop new high-performance energy storage materials to increase device performance [21,22,23,24,25,26].

Since the discovery of graphene in 2004, two-dimensional (2D) layered materials have received more attention due to their unique physical and chemical properties [27,28,29,30,31]. Owing to the good electrical conductivity, high intrinsic mobility, and excellent mechanical stability of 2D nanomaterials [32], they are widely used in biology, medicine, environmental protection [33, 34], catalysis [35,36,37,38], sensors [39, 40], energy storage, and conversion [41,42,43,44,45,46]. Since then, many new 2D nanomaterials have been successfully prepared, such as phosphorene [47, 48], hexagonal boron nitrides [49,50,51], silicene [52, 53], transition metal dichalcogenides [54], germanane [55], and metal oxides [56, 57]. Recently, a vast family of 2D transition metal carbides and nitrides called MXenes have emerged that have shown various excellent performances [58,59,60]. MXenes have attracted more researchers in the field of EES due to their unique surface hydrophilicity, high conductivity, rich surface redox chemistry and superior mechanical properties. Generally, MXene is etched from the MAX phase composed of layered ternary carbides whose molecular formula are Mn+1AXn, where M is an early transition metal (e.g., Nb, V, Ti, Ta, Zr, or Mo), A is an element from groups (Cd, Al, Si, P, S, Ga, Ge, As, In, Sn, Tl, Pb, S), and X is carbon and nitrogen. Therefore, the general formula of MXenes is Mn+1XnTx (n = 1–4), T represents the surface end groups that come from the etching process. M-X atomic layers are mainly connected by ionic and covalent bonds in the MAX phase, while metallic bonds connect M-A layer [61]. In general, the covalent bonds are greater than the ionic bonds, and the ionic bonds are greater than the metal bonds; thus, the M-A binding force connected by the metal bond is relatively weak, which provides favorable conditions for etching the A layer from the MAX phase (Fig. 1) [62].

Reproduced with permission from Ref. [62]. Copyright 2017, Royal Society of Chemistry. Reproduced with permission from Ref. [63]. Copyright 2018, Wiley–VCH

MAX and MXene genomes: with combinations of 12 transition metals (orange), 12 group A elements (blue), and 2 X elements (green), close to 100 MAX phases that have either M2AX, M3AX2, or M4AX3 structures that have been reported to date. Moreover, transition metals in M layer can form a solid solution and/or double-M ordered phases, leading to numerous complex multi-elemental phases. By selective etching of A layer from MAX phases, close to 30 MXenes have been experimentally synthesized (marked in green) and many more are theoretically predicted. The asterisks indicate MXenes with ordered divacancies.

So far, among all discovered MXene, Ti3AlC2 is the most widely studied [63,64,65]. The key to obtaining Ti3C2 material is to precisely etch the Al atomic layer in Ti3AlC2 taking advantage of the etchant's high selectivity. The etchant widely used to prepare Ti3C2 is usually hydrofluoric acid (HF) [66]. After the Al atomic layer etched accurately, the ion or solvent water continues to react with the surface of the layered material to form the surface functional group –OH, –F, or –O, which is denoted as Ti3C2Tx, where the functional group –F, –OH, or –O is represented as Tx. Because these surface functional groups –OH, –F, or –O are hydrophilic, they can easily form hydrogen bonds with water to form a stable colloidal solution. By controlling the synthesis conditions, the surface functional groups can be adjusted. However, this method of first etching and then stripping into a single layer or several layers does not lead to high yields. This is because during the peeling process, the exposed metal sites on the surface are easily oxidized in the air, and the electrical conductivity of the Ti3C2Tx material is reduced. Other etchants such as NH4F/NH4HF2, HF/LiCl, KCl/HF salt solution, LiF, and HCl were tried to solve the above problems, improving the efficiency and safety of the experiment [67,68,69,70,71,72,73]. The cation is in a free state during the etching process, and the inserted water molecules and cations in the MX layer can enlarge the spacing of the Ti3C2Tx material. Mild shaking can be used to obtain single-layer or multi-layer Ti3C2Tx. To improve MXenes materials' performance, the surface terminating functional groups or intercalation ions are sometimes adjusted to achieve changes in the energy band and the interlayer spacing. Besides, methods commonly used to prepare MXenes include fluoride salt, chlorine, and other high-temperature corrosion and chemical vapor deposition [74,75,76,77,78,79]. However, it is necessary to strictly control the time, temperature, atmosphere and other conditions. Since the Al layer in the Ti3C2Tx material is removed by etching, its electrical conductivity is reduced. Like other 2D materials, the layers are stacked together because of the interaction between the electrode layers, the structure becomes very compact, and the specific surface area is also greatly reduced [80, 81]. This will reduce the number of active surface sites [82, 83], block the transmission of electromagnetic waves and ions [84], and also prevent it from loading other functional materials, resulting in poor performance [85]. Owing to the shortcomings of single electrode materials, the electrodes or catalysts made from them have poor performance [86, 87]. Accordingly, researchers have tried to incorporate other materials into the MXene layer, and develop composite materials with high electrochemical properties through morphological control through nano-engineering and surface modification technologies [88,89,90,91,92,93,94,95].

This review aims to introduce the latest development of emerging MXene-based nanocomposites material in energy storage and conversion applications. Some applications of MXene nanocomposites in batteries, supercapacitors and catalytic reactions are presented. The main challenges and prospects of MXene nanocomposite materials in the future energy conversion and storage are also put forward. The structure of this review is shown in Fig. 2 [96,97,98,99,100,101,102,103].

2 Batteries

Traditional non-renewable energy resources (such as oil and coal) on the earth are gradually depleting; meanwhile, the large-scale exploitation and use of conventional energy have caused severe environmental pollution [104,105,106]. Therefore, vigorous research efforts have been devoted to developing sustainable and clean energy resources such as solar energy, tidal energy, wind energy, and high-efficiency batteries to reduce the consumption and dependence on traditional energy sources [107, 108]. Among them, rechargeable batteries have attracted heated attention due to their long cycle life, short charging time, and mobility. To further improve the performance, the preparation of new electrode materials becomes particularly important [109].

2.1 Li-ion batteries

Li-ion batteries are widely used in various portable electronic devices due to their long cycle life, high energy density and environmental friendliness. It is urgent to improve the current LIB's energy density and rate capability [58, 110,111,112,113,114,115,116]. MXenes have been studied to meet this challenge due to their adjustable surface functional groups, inherent high metal conductivity, embedding ability, and excellent mechanical stability [117,118,119,120,121].

Silicon and silicon-based anodes have attracted widespread attention due to their abundant reserves and large specific capacity. However, due to the inherent poor conductivity, the inevitable volume expansion during the lithium insertion process, and the irreversible formation of Li silicate and Li2O in the first cycle, the cycle life, initial coulombic efficiency (CE) and the rate performance of the silicon-based anode are poor. Very recently, Meng et al. [122] reported a new method for preparing Ti3C2Tx scrolls by cold quenching in liquid nitrogen. High-capacity silicon nanoparticles were added during the preparation process to generate Ti3C2Tx/Si composite scrolls in situ. The addition of 10% silicon nanoparticles greatly improves the capacity, rate capability and cycle stability of Ti3C2Tx scrolls. Wei et al. [123] prepared SiO/wrinkled MXene composites through a simple and scalable electrostatic self-assembly method. Under the action of folds MXene, it can be more tightly coupled with SiO particles to avoid electrical isolation of active materials due to volume expansion, and it can also improve the inherent low conductivity of SiO, so that the SiO/wrinkled MXene composite material exhibits excellent electrochemical performance.

Mu and colleagues [125] designed and synthesized SiO2/MXene microspheres for the first time by combining spray drying with the Stöber method (Fig. 3a). First, HF acid was used to selectively etch the Al layer in the MAX phase to prepare laminated MXenes (Ti3C2Tx). Then, SiO2 nanoparticles produced by the hydrolysis of TEOS were grown on the MXene sheet. Owing to the binding effect between the MXene matrix and the SiO2 nanoparticles, the SiO2 nanoparticles can be firmly anchored on the MXene sheet. Finally, SiO2/MXene microspheres were prepared by the spray-drying method. The inside of the microsphere is a stacked MXene-SiO2-MXene laminate structure, and a flexible MXene film wraps the outside of the microsphere [124, 125]. Through bonding, SiO2 nanoparticles are firmly fixed on the microspheres composed of laminated MXene. And this structure has synergistic effects: (1) the sandwich MXene matrix inhibits the agglomeration of SiO2 nanoparticles, while the embedded SiO2 nanoparticles can prevent the re-stacking of MXene flakes; (2) multilayer MXene with a three-dimensional (3D) network has high metallic conductivity, which can promote the transfer of electrons and facilitate the diffusion of lithium-ions; (3) because the tough MXene film covers the surface of the microspheres, the specific surface area and the occurrence of side reactions are significantly reduced, and the CE is improved; (4) because of the bonding between the MXene matrix and the SiO2 nanoparticles, the entire microsphere structure is more stable; (5) SiO2 will have large volume changes during the cycle, and the flexible MXene matrix can effectively alleviate the strain caused by it; (6) SiO2 nanoparticles with size of about 30 nm can shorten the lithium ions' path length, effectively avoiding lithium-ions from breaking. Therefore, the microsphere SiO2/MXene hybrid material exhibits excellent electrochemical performance as the anode in LIBs. For example, at 100 mA·g−1, it has a high reversible capacity of 838 mAh·g−1, which has high reversible capacity and excellent cycle stability. At 200 mA·g−1, the capacity retention rate is 97% in 100 cycles. The capacity retention rate in 200 cycles at 1 A·g−1 reaches 93%. Significantly, when the mass load is 2.58 mg·cm−2, the area capacity of the SiO2/MXene anode is as high as 2.16 mAh·cm−2 [46].

Reproduced with permission from Ref. [125]. Copyright 2019, Wiley–VCH. b Illustration of sandwich-like Si/d-Ti3C2 hybrids as an electrode of LIBs: electrochemical response of spray-coated Ti3C2Tx/NiCo2O4 films (m(NiCo2O4)/m(Ti3C2Tx) = 1) vs. Li/Li+. Reproduced with permission from Ref. [128]. Copyright 2017, Elsevier. c Schematic illustration of various methods used for SnO2 deposition on Ti3C2 MXene sheets, including hydrothermal synthesis, sputtering, and ALD, where an atomistic view of exfoliated MXene sheets is shown on left, stack of exfoliated MXene sheets is in middle, and MXene hybrid electrodes after SnO2 deposition are on right. Reproduced with permission from Ref. [126]. Copyright 2019, Elsevier. d CVs at 0.1 mV·s−1; e cycling performance of activated sample at 1.0C; f rate performance. Reproduced with permission from Ref. [137]. Copyright 2016, Elsevier

a Schematic diagram for synthesis process of SiO2/MXene microspheres.

There are relatively few researches on applying Si/MXene hybrid materials as LIBs anodes. Zhu et al. [126] prepared a porous, sandwich-like Si/d-Ti3C2 hybrid in a synthetic approach, as shown in Fig. 3b. This hybrid material has high electrochemical cycle stability; even after 200 cycles, the reversible capacity of Si/d-Ti3C2 can reach more than 1130 mAh·g−1. First of all, d-Ti3C2 can effectively alleviate the volume expansion during the lithiation process; secondly, it can also increase the electrical contact between the electrode frame and the silicon nanoparticles.

It is known that there are surface functional groups on the surface of MXene nanosheets, such as –O, –OH or –F [42, 111]. These surface functional groups provide hydrophilicity, which is beneficial for contacting aqueous electrolytes but may be harmful to contact non-aqueous electrolytes. The adsorption and insertion of metal ions are controlled by chemical properties and surface structure to achieve the best working potential window and storage capacity. Therefore, to improve its electrochemical performance in organic electrolytes, decoration of MXene surface through chemical treatment can be used. For example, based on density functional theory calculations, researchers predicted that the theoretical capacity of exposed Ti3C2 to embed Li is 320 mAh·g−1, and it can be doubled when a double layer of Li atoms is formed between MXene sheets [58, 127]. However, functional groups such as –OH or –F on the surface of MXene limits the capacity of Li-ions. Therefore, the lithium-ion storage capacity of Ti3C2F2 is only 130 mAh·g−1, and the lithium-ion storage capacity of Ti3C2(OH)2 is 67 mAh·g−1 [43].

Subsequently, Ahmed et al. [128,129,130] used a hydrothermal synthesis method to deposit SnO2 on the peeled MXene sheets and then used sputtering or atomic layer deposition (ALD) deposition to grow MXene film on the copper foil substrate. Figure 3c shows a schematic diagram of three different synthesis processes and their effects on MXene sheets. The hydrothermal synthesis method allows SnO2 particles to form on the twisted MXene flakes under high pressure, high temperature and water environment, so that MXene is modified. The MXene sheet is covered with the SnO2 thin film deposited by sputtering, mainly on the accessible outer surface, while MXene retains its morphology and structure due to the non-conformity of the sputtering process. The emergence of the ALD process allows the conformal SnO2 film to cover the surface of MXene completely. The research showed that during the cycling of lithium-ion batteries (LIBs), MXene could be prepared by ALD to make it stably loaded with SnO2 anode [131, 132]. Simultaneously, because the oxidants commonly used in ALD will cause harmful oxidation of MXene at high temperatures, the surface functional groups of MXene can protect it from this oxidation, which acts as good protection for MXene. The designed SnO2/MXene electrode provides high capacity because SnO2 has a conversion reaction. The MXene sheet provides a conductive network to adapt to the significant volume changes of SnO2 during battery charging-discharging. Under the same conditions, if a thin HfO2 passivation layer is deposited on the surface of SnO2, the performance of the SnO2/MXene electrode will be further improved, and the stable specific capacity of the electrode is 843 mAh·g−1. The presence of the HfO2 layer will slow down the reaction between SnO2 and the electrolyte, and the crystal structure of SnO2 will not change during the cycle [128].

Because of the electrostatic interaction between metal cations and Ti3C2 MXene, Zhang et al. [133] successfully synthesized ultra-thin, curved, wrinkled and larger interlayer spacing NiCo-LDH nanosheets on the surface of Ti3C2 MXene. NiCo-LDH is tightly anchored on the surface of Ti3C2 MXene, which greatly enhances the durability of the structure. The unique microstructure of NiCo-LDH exposes more active sites, which is conducive to the diffusion of lithium ions inside the active material. In the process of lithium-ion insertion, the layered NiCo-LDH/Ti3C2 MXene can greatly reduce the volume expansion.

It is an attractive idea to develop high-performance, multifunctional materials for applications in energy conversion and storage, catalysis, etc., through a well-designed approach with complementary properties of nanomaterials. For example, researches used alternating filtration, spraying, and in-situ wet chemical synthesis to hybridize Ti3C2Tx and transition metal oxides (TMOs), such as NiCo2O4 and Co3O4. By successfully combing the metal conductivity of Ti3C2Tx with the high capacity of TMOs, excellent electrochemical performance was obtained on an anode of LIBs [134,135,136,137]. The thus-obtained MXene/TMO composite membrane electrode has a high reversible capacity exceeding 1200 mAh·g−1. The excellent rate performance and long-term stability exhibited by all films are unexpected. In particular, the reversible capacity of the coated Ti3C2Tx/NiCo2O4 composite film electrode at 0.1, 5 and 10 °C are 1330, 650 and 350 mAh·g−1, respectively, and there is no capacity degradation after hundreds of cycles (Fig. 3d–f) [128].

2.2 Sodium-ion batteries

Owing to the lithium sources and uneven distribution of lithium, researchers have begun to pay attention to the development of new low-cost non-lithium rechargeable batteries. Sodium is another alkali metal whose physical and chemical properties are similar to lithium. Moreover, its low cost, wide distribution, and rich resources have made it an excellent EES candidate. Therefore, sodium-ion batteries have the potential to become the next generation of energy storage batteries [99, 128, 138,139,140,141].

MXene materials have great application prospects in sodium-ion batteries because of their excellent properties. This application's main challenge is the limited ion accessibility between the multilayer MXene layers, resulting in poor cycle life and low capacity [142, 143]. To overcome this, researchers have tried to apply a method that has been successfully used to increase the interlayer spacing of clays: pillaring (that is, inserting a second species between layers) in MXenes. Recently, Maughan et al. [144] successfully inserted silicon-based pillars between Ti3C2 layers through a new amine-assisted columnization method. Figure 4a is a schematic diagram of the synthesis process of columnar MXene. Ghidiu et al. [145] used HCl and fluoride salts to etch the MAX phase and washed the synthesized Ti3C2 with hydrochloric acid to remove impurities to obtain Ti3C2-OH. To insert Si (Ti3C2-OH-Si) between Ti3C2 layers, Ti3C2-OH was mixed with DDA and TEOS and calcined at 300, 400, or 500 °C under argon. The interlayer spacing can be controlled by changing the calcination temperature and selecting amines, and the maximum interlayer spacing reported by MXene could reach 3.2 nm. The Pillaring method can also increase the surface area; as shown by the Brunauer Emmett Teller (BET) result, the surface area reached 235 m2·g−1, 60 times the original surface area. This is also the highest reported surface area of MXenes obtained using the intercalation method. Simultaneously, the surface chemistry can be optimized for the pillaring process according to the intercalation mechanism. Researchers tested the porous MXene in sodium-ion battery applications. It has more excellent capacity, better stability and rate performance, and maintains a 98.5% capacity between the 50th and 100th cycles. This shows that the pillar support technology is of great help in applying MXenes materials in sodium-ion batteries through improving MXenes nanocomposites' performance and contributing to the future application of MXene nanocomposites.

a Schematic diagram illustrating pillaring process of MXenes; b schematic diagram showing formation process of 3D PANI/Ti3C2Tx network by self-assembly method. Reproduced with permission from Ref. [145, 145] Copyright 2020, American Chemical Society. c Illustration of route for synthesis of Na2Ti3O7@C, electrochemical measurements of Na2Ti3O7@C composite in sodium-ion batteries; d CV curves at a scan rate of 0.1 mV·s−1; e–f rate performance and corresponding charge/discharge curves. Reproduced with permission from Ref. [151]. Copyright 2019, Elsevier

The functional groups on the surface of MXene are negatively charged and can anchor sodium ions, resulting in slow ion diffusion kinetics. To overcome this, Chen et al. [146] and Wang et al. [147] designed a positively charged conductive polyaniline (PANI) and Ti3C2Tx to self-assemble into a 3D PANI/Ti3C2Tx network. The preparation process (Fig. 4b) is mainly through self-assembly, and the conductive polymer PANI is used to construct a layered porous 3D PANI/Ti3C2Tx network. First, the Ti3AlC2 suspension was obtained using a LiF-HCl aqueous solution. The polymerization was conducted by slowly adding 1 mol·L−1 aqueous HCl solution containing a certain amount of aniline monomer to the Ti3C2Tx suspension under ice bath conditions. In this process, the aniline monomer may first be adsorbed to Ti3C2Tx through electrostatic interaction as the zeta potential and hydrogen bond prove that their charges are opposite. Subsequently, the aniline monomer polymerizes along the surface and bridges adjacent Ti3C2Tx nanosheets, and finally forms a 3D PANI/Ti3C2Tx network.

The introduced polymers (polyaniline) induce the assembly of Ti3C2Tx nanosheets and increase the interlayer spacing of Ti3C2Tx nanosheets due to the intercalation effect. Studies have proved that the 3D network of Ti3C2Tx with PANI has good sodium storage performance compared with other Ti3C2Tx components. The reasons are summarized as follows: (1) unique 3D network structure and expanded interlayer spacing for the Na-ion, which can improve the kinetics. (2) there is a covalent Ti-N bond at the interface between Ti3C2Tx and PANI, which significantly enhances the durability of the structure; (3) the PANI/Ti3C2Tx nanosheet surface is positively charged, which substantially accelerates the transfer of Na+; (4) PANI/Ti3C2Tx has high conductivity, and the charge transfer resistance has been greatly reduced, which helps fast electron transfer. Because of the above reasons, PANI/Ti3C2Tx has a high specific capacity, which is better than those of PANI (14.8 mAh·g−1), Ti3C2Tx (89.2 mAh·g−1) and HCl/Ti3C2Tx (123 mAh·g−1), at 100 mA·g−1. It has a high specific capacity of 254 mAh·g−1 at 100 mA·g−1, and it also has excellent high-rate cycle life (> 10,000 times). PANI/Ti3C2Tx exhibits excellent performance even when operating under severe temperature range from + 50 to − 30 °C.

Multilayer Ti3C2Tx material has a relatively low specific capacity, which limits its practical application [148, 149]. Tao et al. [150] and Zhong et al. [151] recently prepared a pompons-like composite material Na2Ti3O7@C through MXene derivatives and applied it as anode electrode material for sodium ions. Figure 4c is a schematic diagram of the synthesis process of Na2Ti3O7@C. First, Ti3C2Tx can be obtained by selective etching of Ti3AlC2, because the functional groups (–OH, –O, –F) on Ti3C2Tx have an opposite adsorption effect on Na-ions in the solution, followed by mixing the product with a certain amount of hydrogen peroxide and sodium hydroxide. Then through the hydrothermal reaction, the staggered Na2Ti3O7 nanoribbons can be generated in situ. Then it is dispersed in the Tris buffer solution, and at the same time, dopamine hydrochloride is quickly added to the suspension to form a dopamine-coated Na2Ti3O7 precursor. To obtain the final product Na2Ti3O7@C, the precursor needs to be gently annealed. Therefore, a simple hydrothermal method and an economically feasible and measurable annealing process were used to prepare Na2Ti3O7 nanobelts. The surface of the Na2Ti3O7 nanobelt is evenly coated with carbon. In this way, by synthesizing cross-linked nanobelts with open porosity and proper interlayer spacing Na2Ti3O7@C, the structural stability and slow sodium ion reaction kinetics can be greatly improved. Simultaneously, the surface is covered with a uniform carbon coating, which can effectively improve the conductivity, promote electron transport, and maintain the structure's integrity during cycling. When Na2Ti3O7@C is used as the negative electrode material of sodium-ion batteries, it has excellent electrochemical performance. Its reversible capacity is as high as 173 mAh·g−1 at 200 mA·g−1; its cycle life can be up to 200, with each cycle attenuation being only 0.026%. In the first cathode process, two broad peaks around 0.45 and 0.80 V form, corresponding to the decomposition of the electrolyte and the formation of a solid-phase electrolyte interface layer. Na2Ti3O7@C has high conductivity and fast reaction kinetics, and its reversible capacities are 115, 123, 131, 146, 165, 177, and 195mAh·g−1. When the current density is restored to 0.05 mA·g−1, Na2Ti3O7@C can still output a reversible capacity of 183 mAh·g−1 in the subsequent cycles. At the same time, its curves almost overlap with good reproducibility, showing that the electrochemical properties of Na2Ti3O7@C are highly reversible (Fig. 4d–f) [137].

2.3 Lithium-sulfur batteries (LSBs)

LSBs are deemed a promising development direction of the next-generation high-energy rechargeable lithium batteries because of their high theoretical energy density and low cost. However, LSBs have inherent disadvantages, such as low specific capacity, low energy efficiency, and rapid capacity decay. These problems are mainly caused by the inevitable shuttle effect of lithium polysulfides (LiPSs) intermediates, the large volume change of the sulfur electrode during the cycle, and the poor conductivity of sulfur [152,153,154,155,156].

The strong adsorption of transition metal disulfides and metal oxides on polar materials or the physical constraints of LiPSs in nanostructured carbon composites, have attracted more and more attention from researchers. However, even if it has chemical adsorption and physical constraints, their effect on improving battery performance is limited [157]. For example, Jiao et al. [158] immobilized polysulfide by anchoring uniformly dispersed TiO2 on the MXene nanosheet as a capture center. The heterostructure of TiO2-Mxene has a large surface area, high efficiency in capturing polysulfide, high electrocatalytic activity and conductivity advantage. This catalyst can effectively improve cycle stability and sulfur utilization in lithium-sulfur batteries. Alhabeb et al. [159] and Huang et al. [160] synthesized TiS2 nanosheets confined by N, S co-doped porous carbon (TiS2@NSC) by coating polydopamine (PDA) on Ti3C2Tx (Fig. 5a). Inspired by the adhesion of proteins, some researchers have used PDA for the surface functionalization and modification of materials, which can easily adsorb a kind of dopamine (DA) through self-polymerization on various substrates. Introducing PDA to the surface of MXene can protect Ti3C2Tx nanosheets from re-stacking and oxidation. Also, PDA-derived carbon will limit TiS2 during the vulcanization process, and its product is TiS2@NSC. When the main sulfur body uses TiS2@NSC, the corresponding sulfur cathode (S/TiS2@NSC, 70 wt% sulfur, 2.5 mg·S·cm−2) can reach 920 mAh·g−1 in 120 cycles at 0.2C. After 200 cycles at 1.0C discharge capacity, the specific capacity can reach 695 mAh·g−1, the electrolyte (µl)/sulfur (mg) ratio (E/S) is 6. Simultaneously, as a stand-alone electrode, by integrating TiS2@NSC with cotton carbon fiber (CF), after 100 cycles under the condition of an E/S of 8 at 0.1C, a high area capacity is maintained.

Reproduced with permission from Ref. [160]. Copyright 2019, WILEY–VCH. b Schematic illustration of Ti3C2@CF preparation and as a multifunctional cathode material to ameliorate performance of Li–S batteries. Reproduced with permission from Ref. [161]. Copyright 2020, Royal Society of Chemistry. c Schematic illustration of fabrication of KB/S@Ti3C2Tx composite. Reproduced with permission from Ref. [164]. Copyright 2020, Springer. d CVs of SA-Zn-MXene, MXene, and Al foil from −1.0 to 1.0 V at 3 mV·s−1, revealing efficient catalytic effect of SA-Zn-MXene. Reproduced with permission from Ref. [153]. Copyright 2020, WILEY–VCH

a Schematic illustration of synthesis of sandwich-like, single-layer TiS2 nanosheets confined within PDA derived N, S codoped porous carbon (TiS2@NSC), and its application in LSBs as a bifunctional sulfur host for trapping LiPSs and catalytically accelerating conversion of LiPSs.

Gan et al. [161] recently wrapped the separated 2D ultra-thin Ti3C2 nanosheets with 3D CF to prepare Ti3C2@CF sulfur matrix material, which can significantly increase their surface area. The synthetic route is shown in Fig. 5b. Because the material is a high-density uniform thin layer, it can well load sulfur on its surface, without causing any loss of electrode conductivity. There is a strong bond between Ti3C2 nanosheets and lithium polysulfide, which can effectively inhibit shuttle. The flexible Ti3C2 coating can also dramatically improve CF's ductility, which has an excellent ability to withstand the deformation and stress caused by volume expansion, thereby avoiding cathode powdering. The LSBs thus obtained has impressive cycle stability, and its capacity decay rate is negligible (at 0.5 °C, the capacity of the first 200 cycles is 0.06%). After 1000 cycles at 1 °C, the cycle capacity is still enormous (626.0 mAh·g−1).

To obtain high-performance LSBs, the improvement of high-sulfur surface-loaded LSBs has aroused the attention of many researchers [162]. In order to better suppress the shuttle effect in lithium-sulfur batteries, Li et al. [163] reported the preparation of a functional separator, which was modified by loading Ti3C2Tx nanosheet coatings of different masses on the separator to effectively block and capture soluble lipopolysaccharide intermediates. In lithium-sulfur batteries, rapid lithium-ion transmission is achieved. Recently, Zhang et al. [164] used electrostatic self-assembly methods to analyze the separator's intermediate layer and sulfur host (Fig. 5c). A Ketjen black/sulfur (KB/S)@Ti3C2Tx with interwoven structure was synthesized, in which MXene nanosheets can chemically/physically adsorb soluble polysulfides, the KB carbon core is beneficial for the improvement of electrical conductivity. This interlaced structure is beneficial to the structural integrity during the volume expansion/contraction of the sulfur electrode. However, KB@Ti3C2Tx is applied as an intermediate layer on the diaphragm (about 3 μm), which further prevents the possible escape of polysulfides from the cathode. In order to make the interlayer not lose the weight energy density/volume, only the intermediate layer can have the slightest weight ratio and thickness, which delays the activation of dissolved polysulfides and improves the overall utilization of sulfur. Combining the effective KB@Ti3C2Tx modified diaphragm and KB/S@Ti3C2Tx cathode makes it possible to obtain a stable Li–S battery with a high sulfur surface load in a relatively poor electrolyte.

Subsequently, Zhang et al. [153] injected a monoatomic zinc layer into MXene to synthesize single-atom zinc implanted MXene (SA-Zn-MXene). This layer has a superior affinity for polysulfides and thus can significantly reduce the rate-limiting step and greatly reduce the conversion energy barrier of Li2S2 and Li2S. At the same time, the redox rate of polysulfides is also increased.

As shown in Fig. 5d, the CV curve of SA-Zn-MXene has four peaks at − 0.58, 0.06, 0.63, and − 0.07 V. The first dominant peak at − 0.58 V is due to the reduction of Li2S6 to Li2S2/Li2S on the working electrode. Simultaneously, there are two peaks at 0.06 and 0.63 V, mainly due to the reduction and oxidation between the S on the working electrode and Li2S6. The peak at − 0.07 V can be attributed to the oxidation of Li2S2/Li2S to Li2S6 on the same electrode. The four peaks in CV curve of SA-Zn-MXene have higher current densities than MXene (for instance, the current density of SA-Zn-MXene is 6 times higher than that of MXene at the peak of 0.63 V), implying that the monoatomic zinc MXene can greatly improve the kinetics of these redox reactions. The constant potential nucleation analysis at 2.05 V further proved this catalytic effect.

In addition, the SA-Zn-MXene layer can help promote the nucleation of Li2S2/Li2S on the surface of the SA-Zn-MXene layer exposed in a large area. Such unique characteristics endow SA-Zn-MXene with a high-rate capability of up to 6.0C and a reversible capacity (≈1136 mAh·g−1). Some researchers have applied SA-Zn-MXene to make MXene sulfur cathode, which has a high-rate capacity (640 mAh·g−1 at 6.0C), high area capacity (5.3 mAh·cm−2) and good circulation stability. The capacity retention rate after 200 cycles at 4.0C still reaches 80% [164].

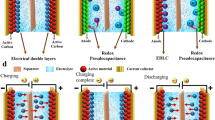

3 Supercapacitor

With the continuous growth of human society's demand for clean energy, the development of new energy storage equipment is crucial [165]. As a major kind of energy storage device, supercapacitors attracted heated attention due to their unique electrochemical properties such as superior rate performance, high power density, long cycle life, and excellent safety [44, 166,167,168,169,170,171]. Supercapacitors are generally classified into pseudo-capacitors and electric double-layer capacitors (EDLCs) based on their energy storage mechanism. First of all, in a pseudo-capacitor, the charge is stored by Faraday oxidation–reduction reaction. Secondly, EDLCs realize electrostatic charge storage by separating ions in the Helmholtz double layer on the electrode surface [144, 172,173,174]. When the number of active materials of EDLCs is limited, the energy density will be relatively low, which limits its application in real life. In contrast, pseudo-capacitors can provide higher energy density, however, the cycle of life is shorter [175,176,177].

3.1 Electric double-layer capacitor

An electric double-layer capacitor is a new type of energy storage element between batteries and traditional capacitors. It has high energy density and power density, fast charging speed, long cycle life, and no pollution to the environment. It is widely used in practical applications. MXene has great application prospects in batteries, supercapacitors, electrocatalysts and photocatalysts, and has attracted many researchers' attention. MXene electrode shows a high capacitance in an aqueous solution. Still, in a non-aqueous solution, it will show an even higher capacitance and a wider voltage window, which can further increase the energy density [178,179,180,181,182]. However, the universal inherent shortcomings of 2D nanomaterials will limit the future development and practical application.

Therefore, to design and synthesize 2D-2D heterostructures, Wang et al. [183] designed a 2D ordered mesoporous carbon (OMC) thin layer in the interlayer space of MXene (Fig. 6a). Using MAX to synthesize the most commonly used 2D layered MXene (Ti3C2Tx), pre-synthesized low molecular weight phenolic resin and amphiphilic triblock copolymer F127 (PEO-PPO-PEO) were added to the Ti3C2Tx dispersion in ethanol. Afterward, the mixed solution was in a vacuum oven to evaporate ethanol because the well-dissolved small phenolic resin molecules and F127 unimer can easily penetrate the middle layer of Ti3C2Tx, and F127 unimers and resol molecules can be embedded in the middle layer of Ti3C2Tx. With the gradual evaporation of ethanol, F127 unimers will be induced to assemble into micelles (the core is a hydrophobic PPO block). The shell is a PEO block with –OH end groups and a hydrophilic PEO block, because the sol molecules and hydrogen bonds exist mutually. The function makes the assembly of micelle@resol more and more compact, allowing the 2D ordered micelle@resol layer to exist between the Ti3C2Tx nanosheets, resulting in Ti3C2Tx-micelle@resol composite material. To finally form a 2D-2D heterostructure (abbreviated as Ti3C2Tx-OMC), the Ti3C2Tx-micelle@resol composite material is heat-treated in an inert atmosphere to convert micelle@resol into an OMC layer. MXene-derived carbon (MDC) composed of microporous carbon nanosheets can be obtained by etching the metal on the MXene substrate, and the Ti in Ti3C2Tx-OMC is entirely removed by chlorination to get pure carbon. The highly interconnected nanopore network between the MXene layers provides a path for ion diffusion and accelerates the electron transfer between the MXene layers. Moreover, the embedded 2D OMC prevents the re-stacking of the nanosheets.

Reproduced with permission from Ref. [183]. Copyright 2017, Nature. b Schematic illustrations demonstrating (i) interdigitated and (ii) sandwich configurations of asymmetric MSCs, where interdigitated architecture (i) allows for facile in-plane diffusion of ions between electrodes while (ii) sandwich architecture impedes ion transport pathways between layers of the electrode materials; c CVcurves of asymmetric MSC at different scan rates (2–5000 mV·s−1) in a 2-electrode configuration; d CV curves of MSC and individual electrodes recorded at 2 mV·s−1 in a 3-electrode configuration; e Ragone plots of asymmetric interdigitated MSC (black, top right), asymmetric sandwich MSC (red, bottom right), and all-MXene symmetric interdigitated MSC (blue, middle left) with scan rates ranging between 2 and 5000 mV·s−1. Reproduced with permission from Ref. [184]. Copyright 2017, WILEY–VCH. f Schematic illustration of surface modification of PCL electro-spun fibers and schematic illustrations of ion diffusion in a Ti3C2Tx film and a (MWCNT/Ti3C2Tx)2-PCL film. Reproduced with permission from Ref. [185]. Copyright 2018, Royal Society of Chemistry

a Schematic illustration of synthetic route: preparation of (i) MXene/F127 unimer/resol mixture, (ii) MXene-F127 micelles@resol composite, (iii) MXene-OMC composite and (iv) MDC-OMC composite.

The micro-manufacturing process of micro-supercapacitors (MSC) is relatively cumbersome, usually involves precision lithography protocols and multi-step processing. Recently, Couly et al. [184] designed and manufactured an asymmetric micro supercapacitor based on MXene, which has flexibility, no collector, and no binder. Since the device configuration and electrode structure are very important to improve the selected electrode material's electrochemical performance, they designed two device configurations, namely, sandwich (cofacial) and interdigital (coplanar) layouts of reduced graphene oxide (rGO) and Ti3C2Tx 2D layers, as shown in Fig. 6b. However, the difference between the two layouts is that the MXene and rGO layers face each other in the sandwich configuration. In contrast, the interdigital configuration is located on the same plane. The designed device structure uses customized masks and scalable spraying technology to fabricate interdigital shapes on flexible and transparent substrates. The electrode material is composed of rGO and titanium carbide Ti3C2Tx. Because they are both 2D layered materials, the ion diffusion rate in the interdigital electrode structure will increase significantly. In the two-electrode configuration, they tested the electrochemical performance of MSC with Ti3C2Tx-MXene as the positive electrode and rGO as the negative electrode. The CV curves of the asymmetric MSC are shown in Fig. 6c. A voltage window of 1 V and a rectangular CV shape can be observed, indicating good capacitive behavior. To distinguish the different properties of the two electrodes, a silver wire pseudo-reference was used to insert the gel electrolyte to allow the two to contact. As shown in Fig. 6d, when the symmetrical Ti3C2Tx interdigital MSC was tested, the maximum voltage window could be 0.6 V, which illustrates the previous symmetrical configuration's narrow voltage window. It is possible to increase the total potential window to 1 V if reduced rGO was used as the positive electrode. Because of the extended voltage window, the asymmetric interdigital mesenchymal MSC will show better energy density than the symmetrical interdigital mesenchymal MSC under similar power density (Fig. 6e). The asymmetric micro supercapacitor based on MXene has an energy density of 8.6 mWh·cm−3 and a power density of 0.2 W·cm−3. It works under a voltage window with 1 V. After 10,000 cycles, it still maintains 97% of the initial value capacitance. The symmetrical devices are slightly better than asymmetrical devices at high scan rates. This may be due to that the conductivity of MXene is higher than that of rGO, which gives the full MXene symmetric device a higher rate capability, even if it exhibits a high degree of flexibility during mechanical bending.

Zhou et al. [185] developed a simple layered assembly process, mainly by spraying multi-walled carbon nanotubes (MWCNTs) and Ti3C2Tx on the electrospun polycaprolactone (PCL) nanofiber network to form the template electrode. The MWCNTs and Ti3C2Tx nanosheets were uniformly deposited on the PCL fiber substrate, and the obtained independent composite film was applied to the supercapacitor electrode. From the morphology of the annealed (MWCNT/Ti3C2Tx)2-PCL hollow fiber, it can be seen that the MWCNTs in the multilayer composite film are helpful for the separation of Ti3C2Tx layers. The electrolyte pathway created by combining these interlayer spacing types partially overcomes the reassembly problem of Ti3C2Tx nanosheets. It can increase the electrolyte ion diffusion rate during the charge and discharge process and accelerate the diffusion of electrolyte ions to the electrode's inner area, as shown in Fig. 6f. The results show that the composite fiber electrode's capacitance retention rate is higher than that of the vacuum-filtered Ti3C2Tx film at a high scan rate. When the composite film's scan rate is increased from 10 mV·s−1 to 100 V·s−1, the capacitance retention rate is 14%–16% of the initial capacitance. The standard vacuum-filtered Ti3C2Tx thin-film electrode has a capacitance retention rate of only 1%. The easy-to-contact morphology, hierarchical structure and high porosity of these Ti3C2Tx/fiber composite membrane electrodes, as well as the inherent high capacitance of MXenes, greatly enhance their overall charge storage and high-rate performance. Besides, the composite electrode has better capacitance retention than other nanostructured electrodes. The use of 2D Ti3C2Tx nanosheets, the synergistic effect of hierarchical nanostructures constructed by layer-by-layer (LbL) assembly, and the high accessible surface area of electrospun nanofiber scaffolds greatly improve the accessibility and diffusion of electrolyte ions in active materials. This composite membrane provides nanofiber-supported electrodes with equivalent capacitance and high flexibility, and they also maintain high conductivity and structural integrity even when they are bent or folded 100 times.

3.2 Pseudo-capacitor

Compared with battery materials for electric double-layer capacitors, pseudo-capacitor materials have a higher specific capacity and high-rate characteristics, which has prompted more and more researchers to pay attention to the research of pseudo-capacitor materials and related energy storage systems. In recent years, nanomaterials have been widely used in the field of energy storage. Among the 2D materials, MXene has attracted substantial attention in the field of EES due to its unique surface hydrophilicity, high conductivity, rich surface redox chemistry and superior mechanical properties [186,187,188,189,190,191]. The size of the carriers is a key challenge for MXene nanocomposites using multivalent water electrolytes. This requires further modification of MXene electrodes to better carry out reversible electrochemical reactions and store charges. Some researchers have found that pre-insertion of foreign species in the spacing of the MXene electrode is of great help in improving the accessibility of carriers into the electrode. So far, many nano-material interlayers, including nano-tin nanoparticles, nano-carbon and surfactants, have been inserted into the pillars of multilayer MXene electrodes [192,193,194,195,196,197,198]. For example, Tian et al. [199] reported that one-dimensional (1D) cellulose nanofibers are used as functional additives to assemble MXenes. CNF has a high aspect ratio and its special interaction with MXene enables nanocomposites to have high mechanical strength without sacrificing electrochemical performance.

Conversion magnetite has attracted more and more people's attention because of its non-toxic, abundant reserves and large lithium storage capacity. However, whether it is a nanocomposite of 2D materials or original magnetite, they cannot simultaneously prevent re-stacking, crushing, and poor structural uniformity due to the lack of interfacial interaction between the layers. Recently, Wang et al. [200] synthesized and prepared 3D layered Fe3O4/C@MXene composites with interconnected and mesoporous/macroporous conductive networks. Figure 7a shows the synthesis process of hollow Fe3O4/C microspheres wrapped in several layers of MXenes (Fe3O4/C@MXene). MXenes after ultrasonic peeling, because of their abundant surface functional groups with inherent negative charges (i.e., hydroxyl, oxygen and fluorine functional groups), can promote dispersion in the aqueous solution. Because MXene has higher intrinsic conductivity and milder synthesis conditions (such as free of concentrated acids and strong oxidants), MXene can better replace solution-treated rGO. In addition, the Fe3O4 surface layer can react delicately with H+ in the dilute inorganic acid to produce positively charged Fe(II, III) OH2+. Therefore, under the condition of pH≈2, the zeta potential is opposite, with a difference of 78.1 mV, which induces Fe3O4/PEG and MXene to form Fe3O4/PEG@MXene with a 3D layered open structure through electrostatic self-assembly at room temperature, and the potential of zeta is partially offset. Sequential annealing in argon can obtain Fe3O4/C@MXene through the constitutive electrostatic self-assembly strategy. This strategy forms an effective ion diffusion channel and an effective electron/charge transfer network by alternately arranging electroactive Fe3O4/C micro-spacer layers and multilayer MXene. In addition, the integration of flexible 2D MXene-coated hollow Fe3O4/C microspheres provides additional buffer space and constraints for the pulverization and aggregation of Fe3O4/C during continuous cycles. After long-term cycling, the undegraded specific capacity of 907 mAh·g−1 remains at 0.5 A·g−1, which has good cycling stability. When used as the anode of a 4.0 V lithium-ion capacitor, a high energy density of 130 Wh·kg−1 can be obtained, with a maximum power density of 25,000 W·kg−1.

a Thypical synthetic procedures of electrostatically self-assembled Fe3O4/C@MXene nanocomposites. Reproduced with permission from Ref. [200] Copyright 2020, American Chemical Society. b Schematic diagram of synthetic process of NiCoAl-LDH/V4C3Tx composite; c scheme illustration of synthesis route of Ti3C2/CuS composites; d Ragone plots of average power density vs. energy density; e cycling stability at a current density of 2 A·g−1 over 5000 cycles. Reproduced with permission from Refs. [201, 201]. Copyright 2019, Royal Society of Chemistry

In recent years, layered double hydroxides (LDHs) as a typical "pseudo-capacitance" electrode material have attracted researchers' attention, since LDHs exhibit typical battery-type behavior where a pair of important Faraday redox peaks are observed in the CV curve. They have a large potential separation, so they are considered battery-type materials. However, LDHs usually undergo irreversible phase changes during charging and discharging, which reduces their electrical conductivity and has poor rate capability. To improve its electrochemical performance, LDHs can be mixed with conductive materials. Recently, Niu et al. [201] reported the face-to-face electrostatic orderly self-assembly of monolayer MXene and edge-enriched CoAl-LDH nanosheets on the molecular scale to prepare MXene/CoAl-LDH heterostructures. Thanks to the unique structure and strong interfacial interaction between MXene and CoAl-LDH, the electrical conductivity, the accessible surface area of electrolyte ions and the number of exposed electroactive sites have increased dramatically, which can exhibit excellent electrochemical performance. Wang et al. [198] have successfully synthesized NiCoAl-LDH/V4C3Tx heterostructures and 3D interconnected porous networks by hydrothermal methods. The microstructure of the porous network is shown in Fig. 7b. First, by etching V4AlC3 powder with HF, V4C3 MXene can be obtained. Because there are functional groups such as –OH, –O, and –F on the surface of MXene, they can be firmly fixed on the V4C3 MXene nanosheets, which is of great help to the nucleation of NiCoAl-LDH nanosheets. Then, the V4C3 MXene sheet and C6H8O7 were dispersed in a solution containing Al3+, Ni2+, Co2+, and urea to synthesize a 3D interconnected porous NiCoAl-LDH/V4C3Tx composite material. In 1 mol·L−1 KOH, when the current density is 1 A·g−1, the specific capacitance is 627 C·g−1. Even at a high current density of 20 A·g−1, the specific capacitance is 300 C·g−1, resulting in NiCoAl-LDH/V4C3Tx heterojunction with good rate performance. Besides, the maximum energy density of a hybrid supercapacitor composed of NiCoAl-LDH/V4C3Tx as the battery electrode and activated carbon (AC) as the capacitor electrode in 1 mol·L−1 KOH is 71.7 Wh·kg−1. Even with a power density of 20,000 W·kg−1 and a discharge time of 8.1 s, the energy density can still be maintained at 45 Wh·kg−1, which shows that the NiCoAl-LDH/V4C3Tx//AC hybrid device has ultra-high-speed energy storage ability.

CuS has been used as an electrode material for supercapacitors because it has a higher theoretical capacity and chemical stability. For example, the combination of CuS nanomaterials and other 2D conductive nanostructure materials will increase the surface area, facilitate the transmission of electrons, and reduce the diffusion resistance of ions in the electrode, resulting in higher capacity. Considering the excellent chemical stability of CuS and the good electrical conductivity of Ti3C2 sheets, the development of Ti3C2/CuS composite materials as electrode materials for alkaline hybrid capacitors is of great significance to the research of electrode materials. Pan et al. [202] reported composite preparation between Cu nanoparticles and 2D Ti3C2, and studied their electrochemical performance. The Ti3C2 flakes and CuS nanoparticles were combined by the hydrothermal method. Figure 7c illustrates the preparation steps of Ti3C2/CuS composite material. Because the surface of Ti3C2 is negatively charged, positively charged Cu2+ are adsorbed between the layers and on the surface of Ti3C2, and CuS is decorated on the Ti3C2 sheet to form a Ti3C2/CuS composite material. The Ti3C2/CuS composite electrode in the standard three-electrode system exhibits better electrochemical performance than the Ti3C2 electrode and has a strong redox reaction. When the current density is 1 A·g−1, the optimal specific capacity of Ti3C2/CuS composite electrode is as high as 169.5 C·g−1, which is about five times that of Ti3C2. The increase in the composite electrode's specific capacity is due to the synergistic effect of the excellent electrical conductivity of Ti3C2 and the excellent electrochemical reaction activity of CuS. Figure 7d shows the Ragone diagram of TC-9//Ti3C2 ASC, which further illustrates the overall electrochemical characteristics of ASC. It can be seen that when the power density of TC-9//Ti3C2 is 750.2 W·kg−1, the highest energy density is 15.4 Wh·kg−1. TC-9//Ti3C2 ASC has high cycle stability at a current density of 2 A·g−1, as shown in Fig. 7e, even after 5000 cycles, it still maintains 82.4% of the initial specific capacitance.

Conductive polymers have many advantages, such as good conductivity, high specific capacitance, and low cost, but they are usually prone to volume expansion and contraction during charging and discharging. Combining MXene with conductive polymers is a practical approach to obtain performance greater than each of these two. Increasing the energy of electrochemical capacitors while maintaining high power, long-term cycle stability, and safety is challenging. Ogihara et al. [203] introduced a new type of asymmetric capacitor that used an intercalated metal–organic framework (iMOF) composed of dilithium 2,6-naphthalenedicarboxylate as the negative electrode. Figure 8a shows the preparation process of the self-assembled electrode. The carboxylic acid units on the surface of 2,6-Naph (COOLi)2 make it hydrophilic. In contrast, the surface of conductive nano-carbon is hydrophobic, facilitating the self-assembly of these two through hydrophilic-hydrophobic interactions. Compared with Li/Li+, it shows a flat platform near 0.8 V, suitable for high voltage with high safety. A very thick iMOF electrode was self-assembled from conductive nano-carbon, active material, and the amphiphilic polymer was also synthesized to show higher volumetric energy density. The electrode has an efficient pathway for the transport of Li+ and electrons. Therefore, it shows a significant area capacity exceeding 2.5 mAh·cm−2. The asymmetric capacitor using iMOF negative electrode and activated carbon (AC) positive electrode has a high capacity (60Wh·L−1) with good power and cycle stability.

Reproduced with permission from Ref. [203]. Copyright 2016, Royal Society of Chemistry. b Schematic illustration of preparation of CTAB−Sn (IV)@ Ti3C2 by HF etching, CTAB prepillaring, and Sn4+ pillaring methods; c typical charge−discharge curves of CTAB−Sn (IV)@Ti3C2//AC LIC at different current densities; d long-term cycling performance of LIC at 2 A·g−1, charge−discharge curves at 2 A·g−1. Reproduced with permission from Ref. [204]. Copyright 2016, American Chemical Society

a Schematic illustration of preparation of a porous 2,6-Naph (COOLi)2 electrode from a slurry of active material and conductive nanocarbon with amphiphilic polymer.

To further increase the overall energy density of MXene-based LICs, how to reasonably increase and utilize the interlayer space of MXene is particularly important. Pillar-supported interlayer clay (PILCs) has attracted more attention due to its application in catalysis and separation. While maintaining the distance between the clay layers, the stabilizing pillars can also increase the layers' distance. Therefore, Luo et al. [204] tried to prepare CTAB-Sn@Ti3C2 from the liquid-phase cetyltrimethylammonium bromide (CTAB), Sn4+, and Ti3C2 MXene using the pillaring method (Fig. 8b). The interlayer spacing of Ti3C2 can be controlled according to the intercalation agent's size (cationic surfactant). The maximum interlayer spacing can increases 177% compared to the original spacing, reaching 2.708 nm. The higher power density was obtained based on the weight and column effect of CTAB-Sn@Ti3C2, while the assembled LIC still has a higher energy density. When the CTAB-Sn@Ti3C2 anode is coupled with commercial AC cathode, the power density and energy density of LIC are higher than those of traditional MXene materials. Owing to the different energy storage mechanisms of the anode and cathode, the rectangular CV of CTAB-Sne@Ti3C2//AC LIC is different from the ideal rectangular CV. When the scan rate increases, the shape of the CV remains unchanged. The charge and discharge curves are shown in Fig. 8c. These curves present almost oblique straight lines. For CTAB-Sn@Ti3C2//AC LIC at current densities of 0.2, 0.5, 1, 2, 5 A·g−1, the specific capacitance values are 51, 42, 34, 33, 25 F·g−1. The CTAB-Sn@Ti3C2//AC LIC also exhibits good cycle performance. Under the condition of 2 A·g−1 after 4000 cycles, the capacity retention rate is 71.1% (Fig. 8d), and the coulombic efficiency during cycling is close to 100%.

4 Catalysts

Unlike short-term energy storage strategies (such as batteries and supercapacitors), catalytic conversion of simple molecules into value-added chemicals is a longer-term solution to the world energy crisis. In the past few years, significant advances in low-cost calculations and density functional theory have made it possible to design materials from basic physical equations. The shift to a theoretically guided material design paradigm is expected to enhance the discovery and development process of catalysts by providing proper guidance to screen feasible MXene catalysts faster than experimental methods [205, 206].

4.1 Photocatalysts

Because of the abundant exposed metal sites and excellent electrical conductivity of MXenes, they can effectively transfer/separate photo-induced carriers and provide many active surface sites in catalytic reactions. Therefore, they show great promise as co-catalysts in photocatalysis. In addition, MXenes has unique photothermal conversion characteristics, which can significantly improve the activity of the catalyst and increase the reaction rate. More importantly, the unique 2D structure of MXene with abundant surface groups helps build 2D/2D heterojunctions based on MXene and 2D semiconductors. A firm interface contact can be established between the photocatalyst and the promoter. This kind of 2D/2D heterojunction with close contact, due to its strong physical properties and electronic coupling, can significantly help the separation and transfer of light-induced carriers at the heterojunction interface and can effectively improve the photocatalytic performance of nanosheets, although the aggregation of nanoplatelets may result in a smaller surface area. Compared with 0D/2D and 1D/2D composite materials, 2D/2D compact heterojunctions have a larger contact surface, ensuring better structural stability [207,208,209,210].

Recently, Cao et al. [211] successfully synthesized 2D/2D heterojunction of ultra-thin Ti3C2/Bi2WO nanosheets by growing Bi2WO6 ultra-thin nanosheets in situ on the surface of Ti3C2 ultra-thin nanosheets. The synthesis process is shown in Fig. 9a. First, Ti3AlC2 was etched into an accordion-shaped structure using HF. Then, ultra-thin Ti3C2 nanosheets were prepared using the dimethyl sulfoxide (DMSO) intercalation-assisted ultrasonic peeling method, after which they were put in the Bi(NO3)3 aqueous solution. Because Ti3C2 nanosheets have abundant negative potential end groups (–O or –OH), they have a strong adsorption effect on Bi3+ cations. Then, the Na2WO6-CTAB mixed solution was added to the above suspension and subjected to hydrothermal treatment. The electrostatic attraction between Ti3C2 and Bi3+ cations can ensure that Bi2WO6 grows in situ on the surface of Ti3C2, resulting in intimate contact between Ti3C2 and Bi2WO6. The resultant Ti3C2/Bi2WO6 has a polyatomic layered hybrid structure and has significant photocatalytic CO2 reduction performance. The total output of CH4 and CH3OH is much greater than the that of the original Bi2WO6 ultra-thin nanosheets because the Ti3C2/Bi2WO6 2D/2D heterojunction has a relatively short charge transport distance and a large interface contact area, which promotes the effective transfer of electrons from the photocatalyst (Bi2WO6) to the cocatalyst (Ti3C2). In addition, the improvement of the pore structure and specific surface area of the 2D/2D heterostructure ultra-thin nanosheets significantly enhanced its CO2 adsorption capacity, thereby further promoting the photocatalytic reaction.

a Schematic illustration of synthetic process of 2D/2D heterojunction of ultrathin Ti3C2/Bi2WO6 nanosheets. Reproduced with permission from Ref. [211]. Copyright 2018, Wiley–VCH. b Schematic illustration of synthesis of ultrathin TCQD anchored TiO2/C3N4 core–shell nanosheets; c flowchart for preparation of binary CdS-MX heterostructures; d illustration of the proposed reaction mechanism for photocatalytic H2 evolution integrated with ethanol conversion over CdS-MX composites under visible light irradiation in ethanol containing 30 mmol·L−1 H2SO4. Reproduced with permission from Refs. [212, 212]. Copyright 2020, Elsevier

The guar-based polymer carbon nitride (CNs) with a special 2D layered structure has been applied in photocatalysis because it is chemically and thermally stable, and its electronic properties and optics are chemically and thermally stable. C3N4 has a negative reduction potential (1.2 eV) and a narrow band gap (2.8 eV). It is integrated with TiO2 to design and synthesize an s-type heterojunction photocatalyst, a promising candidate material. Recent research has focused on synthesizing TiO2/C3N4 composite materials, with greatly improved photocatalytic activity. He et al. [212] synthesized a core–shell structured TiO2/C3N4 composite material. The surface of C3N4 was modified with telomere Ti3C2 quantum dots (TCQD) to effectively reduce CO2 to hydrocarbon fuel. The interface assembly of TCQD on TiO2/C3N4 core–shell nanosheets is shown in Fig. 9b. By using the amphiphilic Pluronic triblock copolymer F127 as the bridging agent and glycerol as the specific structure-directing agent, 2D TiO2 nanosheets with single-layer mesopores were synthesized by hydrothermal-induced solvent-constrained single micelle self-assembly. 2D TiO2 nanosheets are crystallized by calcining the nanosheets. Based on a given pretreatment, the precursor is urea. Through calcination, an ultra-thin C3N4 shell layer is deposited on the surface of TiO2 to ensure that the mesoporous nanosheets can capture and anchor urea molecules. Water-soluble TCQD can be obtained by a simple two-step method. First, Ti3AlC2 can selectively etch the Al layer by HF to synthesize layered Ti3C2. Then, the functionalized TCQD ending in –OH, –NH, –O, –F is passivated by the ammonia solution in the ultrasonic and surface heating method under a protective nitrogen atmosphere. During the hydrothermal treatment of amino groups, the nucleophilic substitution reaction between ammonia and epoxy groups produces secondary and primary amines. With the help of mechanical force, the well-defined TCQD is produced by the rupture of the surrounding oxygen bonds and the direct binding of the amine group to the Ti3C2 side at the same time. Using the enriched termination state of TCQD, TCQD was assembled on the surface of C3N4 through ultrasonic assistance, electrostatic action and long-term stirring, resulting in T-CN-TC composite material. The zero-distance contact between the ultra-thin core–shell nanosheets and the strong coupling between C3N4 and TCQD are obtained through this mechanism, which provides an effective transmission channel for carriers. It is worth noting that the s-configuration heterojunction between TiO2 and C3N4 helps maintain photogenerated carriers' redox capability. The existence of TCQD accelerates the spatial migration of electrons on C3N4 and becomes a channel and acceptor for electron transfer. The results show that the synergy between the heterojunction and TCQD greatly enhances the photocatalytic CO2 reduction activity. The co-degradation rate is 4.39 μmol·g−1·h−1, which is three times higher than that generated by C3N4-TiO2 alone [212].

The comprehensive and selective conversion of bioethanol into fine chemicals and hydrogen (H2) using solar photocatalysis is a promising approach to cope with the current energy and environmental crises, which has attracted more and more attention. Recently, Li et al. [213] reported the gentle synthesis of CdS-Ti3C2Tx binary heterostructures (CdS-MXene) combining 1D CdS nanowires (NWs) and 2D MXene structures. An improved solvothermal method was used to prepare CdS NWs, and Ti3AlC2 was etched with HCl/LiF to remove the Al layer in it to prepare Ti3C2Tx nanosheets. Figure 9c is a flow chart for electrostatic assembly of 1D CdS NW and 2D Ti3C2Tx NSs. Bioethanol is selectively converted into 1,1-diethoxyethane (DEE) by a photocatalytic coupled redox reaction under acidic conditions. The results show that the close interface contact between the semiconducting 1D CdS NWs and the conductive 2D MXene, and the synergistic effect of matching energy level arrangement, the separation and migration of carriers have been greatly improved. Also, the photocatalytic mechanism of converting ethanol to DEE and the precipitation of H2 by the dual-functional photocatalytic system on the CdS-MXene composite material is shown in Fig. 9d. Under visible light irradiation (λ > 420 nm), CdS NW is excited by light to generate carriers. Subsequently, due to the close contact between CdS and MXene in the CdS-MXene complex and the matching of the energy level, the photogenerated electrons tend to migrate from CdS to MXene, thereby leaving photo-induced voids on the valence band (VB) of CdS. Therefore, ethanol is oxidized by the pores in the VB of CdS to generate the free-radical intermediate CH(OH)CH3. These free radical intermediates are further oxidized to AH due to kinetic instability. Then, AH and ethanol are acetalized under acidic conditions to synthesize DEE. At the same time, the protons extracted from ethanol are reduced by photogenerated electrons to generate H2. It is proved that CH(OH)CH3 appears as a critical free-radical intermediate in the photoredox process. Facts have proved that under the premise of sustainable development, a reasonable construction of MXene-semiconductor-based composite materials will greatly promote the realization of photo-redox coupled organic synthesis and the evolution of H2.

4.2 Electrocatalysts

MXenes has also received more and more attention from researchers in the field of electrocatalysis. As a future clean energy conversion technology, electrocatalysis is of great help in improving the future development of the field of catalysis, including hydrogen evolution reaction (HER), nitrogen reduction reaction (NRR), oxygen reduction reaction (ORR), carbon dioxide reduction reaction (CO2RR), oxygen evolution reaction (OER) and methanol oxidation reaction (MOR). Owing to the MXene properties mentioned above, its electrocatalytic performance has become a hot research topic recently. MXenes can be used as both a catalyst and a carrier [102, 103, 214,215,216,217,218,219,220,221].

In many renewable energy storage and conversion technologies, ORR plays a key role. The platinum-based electrocatalyst is currently the most advanced ORR electrocatalyst, but the rare earth abundance is low, the stability is poor, and the price is high. There is an urgent need to develop high-performance precious metal-free ORR electrocatalysts as a substitute for platinum, but this is still a significant challenge for researchers. Therefore, Chen et al. [222] reported a strategy using a metal–organic framework (MOF) to prepare a cobalt-inlaid carbon nanotube/Ti3C2 nanosheet composite (Co-CNT/Ti3C2). The preparation process is shown in Fig. 10a. The Ti3AlC2 MAX phase was etched using HCl and LiF to prepare the Ti3C2 nano-layer. ZIF-67 particles can be grown in situ on the Ti3C2 nanolayer, converted into Co-CNT during the pyrolysis process. However, the Ti3C2 nanolayer can be used as a 2D conductive scaffold for the growth of Co-CNTs, which helps balance carbon graphitization and surface area. Because Co–N/C has abundant active sites, reasonable graphitization and suitable carbon surface area, the optimized Co-CNT/Ti3C2 has comparable ORR activity (half-wave potential of 0.82 V, diffusion limiting current density of 5.55 mA·cm−2), but has better stability than commercial Pt/C (half-wave potential is 0.82 V, diffusion limiting current density is 5.30 mA·cm−2), which facilitates application in renewable storage and conversion technology with unlimited possibilities.

Reproduced with permission from Ref. [220]. Copyright 2019, Royal Society of Chemistry. b Schematic illustration of preparation process of Ti3C2Tx − CoBDC hybrid for OER. Reproduced with permission from Ref. [223]. Copyright 2017, American Chemical Society. c Schematic diagram of MoS2QDs@Ti3C2TxQDs@MWCNTs–2 composite preparation procedure as bifunctional catalyst for ORR and MOR in alkaline solution. Reproduced with permission from Ref. [223]. Copyright 2018, Elsevier. d ORR polarization curve of designed electrocatalyst compared with those of individual components and noble metals; e ORR polarization curves of electrocatalyst at different rotation speeds (from 400 to 2500 r·min−1). Reproduced with permission from Ref. [224]. Copyright 2020, American Chemical Society

a Schematic illustration describing formation process of CoCNT/Ti3C2 composites.

To further improve the electrocatalytic performance, Zhao et al. [223] hybridized Ti3C2Tx (MXene phase) nanosheets with 2D cobalt 1,4-phthalate (CoBDC) in situ through an assisted process of interdiffusion reaction. The preparation process of Ti3C2Tx nanosheets and OER's Ti3C2Tx-MOF hybrid formation are shown in Fig. 10b. The hybrid material was applied to the OER. The hybrid material obtained a current density of 10 mA·cm−2 on a reversible hydrogen electrode with a potential of 1.64 V, and the Tafel slope at 0.1 mol·L−1 KOH was 48.2 mV·dec−1. These results are better than those of standard IrO2-based catalysts and are comparable or even better than the results of the most advanced transition metal-based catalysts previously reported. Although the CoBDC layer provides a large active surface area and a highly porous structure, the Ti3C2Tx nanosheets are conductive and hydrophilic, which can quickly transfer ions and charges on the Ti3C2Tx-CoBDC interface, and accelerate the contact of the catalytically active CoBDC surface with the water-electrolyte. The hybrid nanosheets were further made into the air cathode of a rechargeable zinc-air battery and successfully applied to light-emitting diodes' power supply. Moreover, Wen et al. [224] used a simple in-situ co-precipitation method to directly grow 2D cerium-doped NiFe layered double hydroxide nanosheets on the surface of 2D Ti3C2Tx MXene. Owing to the synergistic effect of cerium doping and MXene coupling, the obtained NiFeCe-LDH/MXene hybrid material presents a hierarchical nanoporous structure, high electrical conductivity and strong interface bonding. Therefore, the hybrid catalyst exhibits excellent catalytic activity for OER. When the current density is 10 mA·cm−2 in an alkaline medium, it provides a low initial overpotential of 197 mV and an overpotential of 260 mV, which are much lower than those of its pure LDH counterpart and IrO2 catalyst.

However, there are few reports on Ti3C2Tx as a dual-function electrocatalyst for ORR and MOR. Some researchers have tried to develop new dual-function electrocatalysts. Because Ti3C2TxQDs and MoS2QDs have good catalytic activity, the ideal choice for preparing new MOR and ORR electrocatalysts is to synthesize the composite material of MoS2QDs and Ti3C2TxQDs with MWCNT embedded in an alkaline solution. Van der Waals force can be used on the surface of MWCNTs to modify the surface of MoS2QD, while Ti3C2Tx quantum dots can be fixed on the surface of COOH-functionalized MWCNTs through electrostatic interaction. Subsequently, Yang et al. [225] synthesized a new type of composite multilayer carbon nanotubes (heat-bonded) decorated with Ti3C2Tx and molybdenum disulfide QDs (MoS2QDs@Ti3C2TxQDs@MWCNTs). Among them, Ti3C2TxQDs and MoS2QDs are prepared, as exhibited in Fig. 10c. The electrochemical results show that MoS2QDs@Ti3C2TxQDs@MWCNTs has good catalytic activity for ORR and MOR, mainly due to the electrochemical activity, good catalytic function and specific surface area of these components. Compared with conventional electrocatalysts, the obtained MoS2QDs@Ti3C2TxQDs@MWCNTs embodies three advantages: low cost, feasible preparation process, and no platinum. The results show that the prepared MoS2QDs@Ti3C2TxQDs@MMWCNTs composite material is rich in functional groups and has good electrochemical activity. In particular, combining the excellent electrochemical performance of MoS2QDs and Ti3C2TxQDs with superior electrocatalytic activity, the synthesized MoS2QDs@Ti3C2TxQDs@MWCNTs composite materials, whether they are ORR in alkaline solution or MOR both show excellent bifunctional electrocatalytic performance. At the same time, MoS2QDs@Ti3C2TxQDs@MMWCNTs catalysts show better ORR activity than other non-Pt catalysts, with high half-potential (E1/2 = 0.75 V) and low Tafel slope (90 mV·dec−1), close to commercial Pt/C (20%) catalyst (Tafel slope of 89 mV·dec–1, E1/2 = 0.80 V). Besides, in alkaline solution, MoS2QDs@Ti3C2TxQDs@MMWCNTs also have good electro-oxidation performance for methanol. Therefore, the maximum oxidation current density of methanol at 2.2 V is 160 A·g−1. The results show that the combination of MoS2 and Ti3C2TxQDs with MWCNT provides the potential for the preparation of ORR and MOR bifunctional electrocatalysts.

Recently, Wu et al. [226] designed and studied a detrimental nitride electrocatalyst in the form of unusual molecular flakes, and metal titanium carbide flakes stabilized the catalyst. The electrocatalytic activity of pure trimetallic nitride without Ti3C2 (in nano form), 20 wt% Pt (referred to as Pt/C) supported on carbon, and pure Ti3C2 after the same annealing treatment were studied. The electrocatalyst designed has a higher positive charge than all other control samples (including Pt/C) when scanning the cathode peak position by CV, indicating good ORR activity. The outline of linear sweep voltammetry (LSV) is shown in Fig. 10d. The electrocatalyst showed a significantly right-shifted onset potential (0.95 V, vs. reversible hydrogen electrode) and halfwave potential (E1/2 = 0.84 V, vs. reversible hydrogen electrode), as well as a substantially higher limiting current density (5.95 mA·cm−2) than Pt/C and the individual nitride. According to reports, Ti3C2 alone has almost no ORR reactivity. As shown in Fig. 10e, to explain the ORR kinetics, one can observe the ORR polarization curves of the catalyst at different speeds of the rotating disk electrode. According to the corresponding Koutecky-Levich diagram calculation, as the rotational speed increases linearly, the current density also increases, and the number of electrons transferred per oxygen is 3.94. The rotating disk electrode's measurement also confirmed that the number of electrons transferred is close to 4. The yield and peroxidation are even lower than 4%. This shows that the catalyst catalyzes the ORR reaction directly in the four-electron path, and in addition to the oxygen decomposition reaction. It is expected to increase the catalytic activity and release an excellent activity for catalytic ORR at half-wave potentials as low as 0.84 V. A flexible fibrous zinc-air battery was fabricated where the gel uses a designed electrocatalyst, and the electrolyte is an air cathode. It exhibits enhanced long-lasting electrochemical performance and a competitive energy density of 627 Wh·kgZn−1. This work has opened up a new way to apply MXene materials in future portable devices and wearable applications. Moreover, FePc and Ti3C2Tx MXene were chosen as model catalysts and supports. Since Ti3C2Tx MXene has surface terminals including hydroxyl and fluorine, when FeN4 parts adhere to the Ti3C2Tx surface by van der Waals forces, they can interact with four-coordinated Fe (II) strongly and weaken the Fe–N bond or hydrogen bond. The coupling of FePc and Ti3C2Tx MXene leads to significant Fe 3d electron delocalization and spin configuration changes. These strong interactions make it easier for FeN4 active sites to absorb the involved reactive species, and achieve a dual enhancement of the inherent ORR activity of FePc catalysts, thereby promoting ORR catalysis [227,228,229].

5 Summary and outlook

The development of advanced electrode materials plays a crucial role in developing high-performance EES and conversion devices. In the past decades, graphene research has prompted people to explore other 2D materials for such applications. One new yet up-and-coming candidate is MXene, which possesses many outstanding properties, including high melting point, hardness, high electrical and thermal conductivity, excellent antioxidant properties, hydrophilic properties, and high surface area. MXenes have presented great promise as electrode materials for energy-related applications.