Abstract

Consumers’ demands for fresh fruits and vegetables have been increased over the last decades due to the pursuit of a healthy lifestyle. However, fresh produces are susceptible to microbial contamination, consequently shortening the shelf-life, which poses a challenge to the food industry. Cold plasma with abundant reactive species is considered as a promising decontamination technology against microorganisms. In this chapter, various factors (e.g., processing parameters, microbial characteristics, food properties) affecting the microbial inactivation efficacy of cold plasma were systematically summarized. Additionally, the effects of cold plasma on the quality attributes of fresh produce were provided in detail. The application of cold plasma for the inhibition of endogenous enzymatic activities in fruits and vegetables was also introduced. Furthermore, the existing challenges for the application of cold plasma on the fresh produce preservation were also discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

7.1 Introduction

Fruits and vegetables, as the major source of nutrients, vitamins, and fiber, have become an indispensable part of the total dietary structure of human beings. It is found that adequate daily intake of fresh fruits and vegetables could decrease the risks of cardiovascular diseases (Oyebode et al. 2014) and cancers (Boffetta et al. 2010). Microbial contamination and spoilage are the major concern in fresh fruits and vegetables. In China, the vegetable output is increased at a rate of 1.7% each year and it has reached more than 90 million tons in 2019. However, the proportion of vegetables rotting caused by microbial contamination was as high as 12%, leading to significant economic losses and risks in food safety (Lung et al. 2015; Mari et al. 2016). Additionally, the poor hygiene could also result in cross-contamination (Fernandes et al. 2019). The European Food Safety Authority issued guidance that identified five major risk factors in the contamination of berries: (i) environmental factors (climatic and proximity to animal farming); (ii) contact of the animal with berry fields; (iii) use of contaminated manure or compost during production; (iv) contaminated water used for irrigation, application of agricultural chemicals (e.g., fungicides), or washing; and (v) contamination and cross-contamination among equipment, food handlers, and harvesters (Patange et al. 2019).

Chemical sanitizers, especially chlorine-based products, have been widely used for the microbial decontamination of fresh fruits and vegetables. However, the potential risks in the formation of harmful chlorinated organic compounds cause concerns about human health and environment. Thermal treatment is very effective in microbial inactivation, but it could compromise the nutrients and qualities of food. To overcome these issues, novel technologies have been developed to control microbial contamination without affecting phytochemicals and sensory properties (Bilek and Turantaş 2013; de São José et al. 2014; Lung et al. 2015), including irradiation (Kong et al. 2014), UV light (Liu et al. 2015), high hydrostatic pressure (Sarvikivi et al. 2012), ultrasound (Aday et al. 2013), and more recently cold plasma (Mir et al. 2019). Cold plasma has been successfully applied for the microbial decontamination of fresh produce (Sarangapani et al. 2018). The bactericidal efficacy of cold plasma is influenced by various factors, including voltage, frequency, gas type, and exposure time (Misra et al. 2016). This chapter aims to provide a comprehensive understanding of the application of cold plasma for the preservation of fruits and vegetables, including the factors affecting microbial inactivation efficacy, the effect on food quality, and the future challenges.

7.2 Inactivation Efficacy of Microorganisms on the Surface of Fruits and Vegetables

As commonly known, cold plasma is an active ionized medium sustained by a constant energy supply under ambient pressure and room temperature. Cold plasma treatment is suitable for heat-sensitive and/or vulnerable objects, such as organic materials, fresh produce, liquids, and living biological tissue (Stoffels et al. 2008). The main active components in plasma are as follows:

-

1.

Charged particles (electrons and positive and negative ions).

-

2.

Free radicals (dissociated molecules).

-

3.

Stable conversion products (e.g., ozone).

-

4.

Excited (metastable) atoms and molecules.

-

5.

Energetic photons (e.g., UV).

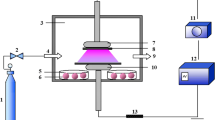

7.2.1 DBD Plasma

As shown in Fig. 7.1a dielectric barrier discharge (DBD) is produced from a large-space uniform discharge with a glow discharge under the atmospheric pressure and wide frequency ranging from 50 Hz to 1 MHz (Bovi et al. 2019). DBD has been used for the surface decontamination of fresh produce in a closed space or fluidized bed. The factors affecting the inactivation efficacy include the type of food produce, inherent surface characteristics, microbial characteristics, attachment strength, exposure time, discharge powers, gas flow rate, electrode shape, and the diffusion capacity of various plasma species. Generally, longer exposure time and higher applied voltage or power result in higher antimicrobial capacity of cold plasma (Ziuzina et al. 2014; Zitong et al. 2020). Regarding microbial characteristics, Ziuzina et al. (2015) found that an in-package DBD treatment for 30 s could achieve 7 log reduction of planktonic Salmonella Typhimurium, L. monocytogenes, and E. coli in lettuce broth, while 300 s exposure was required to reduce biofilm populations by 5 log CFU/ml. Pasquali et al. (2016) made use of DBD plasma system with a dominant frequency of 12.5 kHz and found that E. coli O157:H7 inoculated on radicchio leaves was significantly reduced after 15 min cold plasma treatment (1.35 log MPN/cm2), while it took longer exposure time (30 min) to achieve a significant reduction of L. monocytogenes counts (2.2 log CFU/cm2). Therefore, the affecting factors should be carefully optimized to achieve efficient inactivation by DBD (Pasquali et al. 2016; Timmons et al. 2018; Ziuzina et al. 2014; Zhou et al. 2019).

7.2.2 Plasma Jet

Plasma jet is capable of producing cold plasma in an open space rather than in interstitial space (Matsusaka 2019). High intensity of reactive species generated from the plasma jets react with microorganisms, as shown in Fig. 7.1b. Ziuzina et al. (2014) found that plasma jet treatment for 10, 60, and 120 s resulted in the reduction of Salmonella, E. coli, and L. monocytogenes populations on the tomatoes to undetectable levels from initial populations of 3.1, 6.3, and 6.7 log CFU/sample, respectively. It is found that Cladosporium fulvum, a common pathogen on tomatoes could be significantly inactivated by an atmospheric pressure plasma jet (APPJ) (Lu et al. 2014). APPJ treatment resulted in a 40% reduction of Pectobacterium carotovorum subsp. carotovorum (Pcc) compared to untreated samples (Go et al. 2020). Perni et al. (2008) found that the inactivation ability of plasma jet was different for various bacterial strains. It was reported that P. agglomerans and G. liquefaciens on both mango and melon were reduced below the detection limit (corresponding to 3 log values) after only 2.5 s plasma jet exposure, whereas E. coli and S. cerevisiae required over 5 s to reach the same level of inactivation. Additionally, the surface characteristic of treated fruits is also an important factor affecting the microbial inactivation efficacy of plasma jet (Bhide et al. 2017; Fernandez et al. 2013). Fernandez et al. (2013) demonstrated that a 2-min APPJ treatment resulted in a 2.71 log reduction of S. Typhimurium on membrane filters whereas a 15-min treatment was necessary to achieve 2.72, 1.76, and 0.94 log reductions on lettuce, strawberry, and potato, respectively. Scanning electron microscopy revealed that the topographical features of lettuce, strawberry, and potato protected S. Typhimurium cells from the attack by the active plasma species.

7.3 Effects of Cold Plasma on the Quality Attributes of Fruits and Vegetables

Food quality is the important factor affecting consumers’ choices, such as color, texture, shape, and size. Thus, the effect of cold plasma on the quality of fruits and vegetables should be carefully evaluated (Tournas and Katsoudas 2005).

7.3.1 Color and Texture Characteristics of Fruits and Vegetables Influenced by Plasma Treatment

So far, a lot of studies have evaluated the changes in color and texture characteristics of fruits and vegetables (Lacombe et al. 2015; Min et al. 2018; Misra et al. 2014a, b). Lacombe et al. (2015) found that APPJ treatments for over 60 s could result in significant reductions in the firmness as well as the color characteristics of blueberries. Comparing with APPJ, DBD resulted in no significant changes in color of blueberries (Sarangapani et al. 2017). Similarly, Misra et al. (2014a) applied an air DBD plasma for the in-package decontamination of strawberries and found no significant impact on the color and firmness. DBD plasma has lower working temperature, which could further avoid the thermal damages on the qualities of fruits. It was reported that the DBD plasma resulted in efficient inactivation of Salmonella in grape tomatoes without changes in color or texture (Min et al. 2018). A microwave-driven air plasma torch was used for the indirect treatment of whole pieces of fruits and vegetables in a remote exposure chamber for up to 10 min. The results indicated that the color of tomatoes and carrots and the chlorophyll of cucumbers were severely affected, whereas the elasticity remained almost unaffected in all produce (Baier et al. 2015).

7.3.2 The Effect of Plasma Treatments on the Nutrients of Fruits and Vegetables

Fruits and vegetables are considered as the major source of dietary nutrients. The effect of plasma treatments on the nutritious properties of fruits and vegetables has also been evaluated by researchers (Misra et al. 2015; Rana et al. 2020; Sarangapani et al. 2017). Misra et al. (2015) found that DBD treatment caused minor degradation of ascorbic acid and anthocyanin in strawberries. In addition, DBD plasma treatments were also found to decrease the ascorbic acid levels of whole strawberries and blueberries (Misra et al. 2014a, b; Sarangapani et al. 2017). However, it is demonstrated that DBD plasma treatment could increase the concentrations of sugar, vitamin C, and total anthocyanin of blueberry by 1.5-fold, 2.2-fold, and 79.3%, respectively compared with those in the control groups (Dong and Yang 2019). The total phenol and flavonoid contents were found to be enhanced significantly in DBD-treated blueberries (Sarangapani et al. 2017), and the concentrations of chlorogenic acid, hyprin, phloretin, vanillin, gallic acid, 4-hydroxybenzaldehyde, and rutin were also enhanced in plasma-treated blueberries during 5-day in-package storage compared with the control ones (Rana et al. 2020).

7.3.3 The Effect of Plasma Treatments on the Quality Characteristics of Fruits and Vegetable Juices

Recently, cold plasma has been reported for the preservation of fresh juices, which can maintain the nutritional and sensory attributes. Silveira et al. (2019) used cold plasma to treat whey beverages and the results indicated that plasma treatment contributed to enhanced pH values and lower viscosity of the whey beverages. Garofulić et al. (2015) applied an atmospheric pressure plasma to treat sour cherry Marasca juice, and it was found that the concentrations of anthocyanins and phenolic acids were enhanced compared to thermal pasteurized and untreated juice. Herceg et al. (2016) evaluated the effect of plasma on the phenolic content of pomegranate juice. Pasteurization at 80 °C for 2 min and argon plasma treatment resulted in an increase in the total phenolic content of pomegranate juice by 29.55% and 33.03%, respectively. The increase in anthocyanins and phenolic compounds is attributed to the rupture of the cell walls. Cold plasma was also found to pose a positive effect on the bioactive compounds of fruit juices. Kovačević et al. (2016) evaluated the effect of an argon plasma jet on the anthocyanins of pomegranate juice and the results indicated an increase in anthocyanin content from 21% to 35%. Fernandes et al. (2019) reported that APPJ exposure enhanced the concentrations of hydroxycinnamic acids, and resulted in a 23% loss of anthocyanins in Chokeberry juice. It is found that cold plasma with a high voltage resulted in a decrease in total phenols, total flavonoids, DPPH free radical scavenging, and antioxidant capacity of grape juice as the thermal pasteurization did (Pankaj et al. 2017). de Castro et al. (2020) reported that corona discharge plasma technology promoted the concentration of ascorbic acid and monomeric anthocyanins in the juice, while the activity of peroxidase and polyphenol oxidase were reduced after treatment.

7.3.4 The Effect of Plasma Treatments on the Quality Characteristics of Fresh-Cut Fruits and Vegetables

Microbial contamination could lead to compromise in color and flavor, aging, softening, and deterioration of fresh-cut fruits and vegetables (Olaimat and Holley 2012). Cold plasma can be an alternative to thermal blanching for the enzyme inactivation and microbial decontamination (Fig. 7.2a) (Huang et al. 2017). A direct current, atmospheric-pressure air cold plasma microjet was applied to treat the slice surface of cucumbers, carrots, and pears. And the water content, color parameters, and vitamin C content were found to be minimally affected by plasma treatment (Wang et al. 2012). Using a DBD plasma reactor operating with air resulted in insignificant changes in the antioxidant activity of radicchio leaves (Pasquali et al. 2016). Similarly, Ramazzina et al. (2015) evaluated the effect of DBD plasma treatment on the quality of fresh-cut kiwifruit. It is found that plasma treatment caused a slight loss of pigments, but brought in better quality retention during storage. No significant changes in antioxidants content and antioxidant activity were observed between the treated samples and control ones. Recent studies found that microwave plasma treatment increased the total phenolic content and antioxidant activity of the peel of mandarins (Won et al. 2017). A combination of green tea extract and atmospheric RF plasma jet was used for the decontamination of the fresh-cut dragon fruits, resulting in higher levels of total phenolic content, proteins, and fiber (Matan et al. 2015).

7.3.5 The Effect of Plasma Treatments on the Enzymatic Inactivity of Fruits and Vegetables

The endogenous enzymes could contribute to the enzymatic browning of fruits and vegetables. Some studies found the potential application of cold plasma for enzymatic inactivation to inhibit the browning process (Bußler et al. 2017; Han et al. 2019; Tappi et al. 2016) (Fig. 7.2b). Han et al. (2019) used an APPJ to treat Horseradish Peroxidase (HRP) and found that the residual activity of HRP was decreased to around 17% with the structure destruction and microstructure deformation. Bußler et al. (2017) employed a microwave plasma torch for the efficient inactivation of PPO and POD activities of fresh-cut apples and potatoes. They reported that the PPO activity was reduced by about 62% and 77% in fresh-cut apple and potato tissue, respectively, after 10 min treatment. Similarly, the POD activity was reduced by about 65% and 89% in fresh-cut apples and potatoes, respectively, after 10 min plasma treatment. Tappi et al. (2014) applied DBD plasma to treat fresh-cut apples for 10, 20, and 30 min and found that the PPO residual activity was reduced linearly as the treatment time increased (up to about 42%). Similarly, Tappi et al. (2016) reported a decrease in the activity of PME and POD in plasma-treated fresh-cut melon.

7.4 Challenges of Cold Plasma in the Fresh Preservation Area

Cold plasma has been proven to exhibit a high inactivation efficacy of microorganisms on the surfaces of fresh produces and also to activate partial endogenous enzymes. However, more studies are required to investigate the changes in quality characteristics of plasma-treated produce. The plasma sources, gas compositions, inactivation kinetics, and species interaction between plasma and targets are distinct in various studies, which has been identified as a challenge for researchers, users, and manufacturers. Therefore, the standardization of cold plasma treatment for food processing applications is required in future.

7.4.1 Scale-up for the Industrial Applications of Food Processing

Up to now, cold plasma has been successfully applied in the preservation of fruits and vegetables (Table 7.1). However, most of studies are still in the lab scale. In addition, plasma-activated water (PAW) or in combination with modified atmospheric packaging (MAP) under storage conditions could contribute to the commercial and industrial application (Table 7.1) (Thirumdas et al. 2018).

7.4.2 Market Acceptance from Consumers

With the development of food information traceability technology, the circulation process of fresh food in the whole industry chain will be monitored (Zoroja et al. 2017). For successful adoption and acceptance of a novel processing technology, it is essential to understand the needs of consumers and their recognition of the new technologies. So far, limited data has been available on the large-scale consumers’ sensory evaluation of plasma-treated food, such as color, texture, odor, and surface oxidation.

7.5 Conclusions

Cold plasma is an emerging technology for the preservation of fruits and vegetables, which has attracted much attention from producers, researchers, and consumers in recent years. Cold plasma treatment could efficiently inactivate microorganisms while maintaining nutrition and quality attributes of fresh produces. There are various factors affecting the antimicrobial efficacy of cold plasma, such as exposure time, gas type and flow rate, microbial strains, the surface characteristics of treated fruits or vegetables, and so on, which should be carefully evaluated to achieve efficient microbial removal. Additionally, it is found that cold plasma could preserve fresh-cutting slices and fresh-squeezed juices through the inactivation of endogenous enzymatic activities. Further research works are required to explore the effect of cold plasma on the food quality characteristic, the large-scale equipment as well as the consumers’ acceptance of plasma-treated food.

References

Aday MS, Temizkan R, Büyükcan MB et al (2013) An innovative technique for extending shelf life of strawberry: ultrasound. LWT-Food Sci Technol 52(2):93–101

Agun L, Ahmad N, Redzuan N et al (2020) Sterilization of oyster mushroom crop residue substrate by using cold plasma technology. Mater Today Proc 39:903–906

Baier M, Ehlbeck J, Knorr D et al (2015) Impact of plasma processed air (PPA) on quality parameters of fresh produce. Postharvest Biol Technol 100:120–126

Bhide S, Salvi D, Schaffner DW et al (2017) Effect of surface roughness in model and fresh fruit systems on microbial inactivation efficacy of cold atmospheric pressure plasma. J Food Prot 80(8):1337–1346

Bilek SE, Turantaş F (2013) Decontamination efficiency of high power ultrasound in the fruit and vegetable industry, a review. Int J Food Microbiol 166(1):155–162

Boffetta P, Couto E, Wichmann J et al (2010) Fruit and vegetable intake and overall cancer risk in the European prospective investigation into Cancer and nutrition (EPIC). J Natl Cancer Inst 102(8):529–537

Bovi GG, Frohling A, Pathak N et al (2019) Safety control of whole berries by cold atmospheric pressure plasma processing: a review. J Food Prot 82(7):1233–1243

Bußler S, Ehlbeck J, Schlüter OK (2017) Pre-drying treatment of plant related tissues using plasma processed air: impact on enzyme activity and quality attributes of cut apple and potato. Innov Food Sci Emerg Technol 40:78–86

Cui H, Ma C, Lin L (2016) Synergetic antibacterial efficacy of cold nitrogen plasma and clove oil against Escherichia coli O157: H7 biofilms on lettuce. Food Control 66:8–16

de Castro DRG, Mar JM, da Silva LS et al (2020) Dielectric barrier atmospheric cold plasma applied on camu-camu juice processing: effect of the excitation frequency. Food Res Int 131:109044

de São José JFB, de Andrade NJ, Ramos AM et al (2014) Decontamination by ultrasound application in fresh fruits and vegetables. Food Control 45:36–50

Dong XY, Yang YL (2019) A novel approach to enhance blueberry quality during storage using cold plasma at atmospheric air pressure. Food Bioprocess Technol 12(8):1409–1421

Fernandes FA, Santos VO, Rodrigues S (2019) Effects of glow plasma technology on some bioactive compounds of acerola juice. Food Res Int 115:16–22

Fernandez A, Noriega E, Thompson A (2013) Inactivation of Salmonella enterica serovar Typhimurium on fresh produce by cold atmospheric gas plasma technology. Food Microbiol 33(1):24–29

Fulcheri L, Fabry F, Takali S, Rohani V (2015) Three-phase AC arc plasma systems: a review. Plasma Chem Plasma Process 35(4):565–585

Garofulić IE, Jambrak AR, Milošević S et al (2015) The effect of gas phase plasma treatment on the anthocyanin and phenolic acid content of sour cherry Marasca (Prunus cerasus var. Marasca) juice. LWT Food Sci Technol 62(1):894–900

Go SM, Kim HS, Park MR et al (2020) Antibacterial effect of non-thermal atmospheric plasma against soft rot bacteria on paprika. LWT Food Sci Technol 117:108600

Han YX, Cheng JH, Sun DW (2019) Changes in activity, structure and morphology of horseradish peroxidase induced by cold plasma. Food Chem 301:125240

Herceg Z, Kovačević DB, Kljusurić JG et al (2016) Gas phase plasma impact on phenolic compounds in pomegranate juice. Food Chem 190:665–672

Hertwig C, Leslie A, Meneses N et al (2017) Inactivation of Salmonella Enteritidis PT30 on the surface of unpeeled almonds by cold plasma. Innov Food Sci Emerg Technol 44:242–248

Huang YM, Hsieh SY, Hsu CL (2017) Application of non-thermal atmospheric plasma for blanching on sliced apple and Banana. Taiwanese J Agric Chem Food Sci 55(5):270–291

Khan MSI, Lee EJ, Hong SI et al (2017) Feed gas effect on plasma inactivation mechanism of Salmonella typhimurium in onion and quality assessment of the treated sample. Sci Rep 7(1):1–11

Kong Q, Wu A, Qi W et al (2014) Effects of electron-beam irradiation on blueberries inoculated with Escherichia coli and their nutritional quality and shelf life. Postharvest Biol Technol 95:28–35

Kovačević DB, Kljusurić JG, Putnik P et al (2016) Stability of polyphenols in chokeberry juice treated with gas phase plasma. Food Chem 212:323–331

Lacombe A, Niemira BA, Gurtler JB et al (2015) Atmospheric cold plasma inactivation of aerobic microorganisms on blueberries and effects on quality attributes. Food Microbiol 46:479–484

Lacombe A, Niemira BA, Gurtler JB et al (2017) Nonthermal inactivation of norovirus surrogates on blueberries using atmospheric cold plasma. Food Microbiol 63:1–5

Lafarga T, Colás-Medà P, Abadías M et al (2019) Strategies to reduce microbial risk and improve quality of fresh and processed strawberries: a review. Innov Food Sci Emerg Technol 52:197–212

Liu C, Li X, Chen H (2015) Application of water-assisted ultraviolet light processing on the inactivation of murine norovirus on blueberries. Int J Food Microbiol 214:18–23

Lu Q, Liu D, Song Y et al (2014) Inactivation of the tomato pathogen Cladosporium fulvum by an atmospheric-pressure cold plasma jet. Plasma Process Polym 11(11):1028–1036

Lung HM, Cheng YC, Chang YH et al (2015) Microbial decontamination of food by electron beam irradiation. Trends Food Sci Technol 44(1):66–78

Mari M, Bautista-Baños S, Sivakumar D (2016) Decay control in the postharvest system: role of microbial and plant volatile organic compounds. Postharvest Biol Technol 122:70–81

Matan N, Puangjinda K, Phothisuwan S et al (2015) Combined antibacterial activity of green tea extract with atmospheric radio-frequency plasma against pathogens on fresh-cut dragon fruit. Food Control 50:291–296

Matsusaka S (2019) Control of particle charge by atmospheric pressure plasma jet (APPJ): a review. Adv Powder Technol 30(12):2851–2858

Min SC, Roh SH, Niemira BA et al (2018) In-package atmospheric cold plasma treatment of bulk grape tomatoes for microbiological safety and preservation. Food Res Int 108:378–386

Mir SA, Siddiqui MW, Dar BN et al (2019) Promising applications of cold plasma for microbial safety, chemical decontamination and quality enhancement in fruits. J Appl Microbiol 14541:1–12

Misra NN, Moiseev T, Patil S et al (2014a) Cold plasma in modified atmospheres for post-harvest treatment of strawberries. Food Bioprocess Technol 7(10):3045–3054

Misra NN, Patil S, Moiseev T et al (2014b) In-package atmospheric pressure cold plasma treatment of strawberries. J Food Eng 125:131–138

Misra NN, Pankaj SK, Frias JM et al (2015) The effects of nonthermal plasma on chemical quality of strawberries. Postharvest Biol Technol 110:197–202

Misra NN, Pankaj SK, Segat A, Ishikawa K (2016) Cold plasma interactions with enzymes in foods and model systems. Trends Food Sci Technol 55:39–47

Olaimat AN, Holley RA (2012) Factors influencing the microbial safety of fresh produce: a review. Food Microbiol 32(1):1–19

Oyebode O, Gordon-Dseagu V, Walker A et al (2014) Fruit and vegetable consumption and all-cause, cancer and CVD mortality: analysis of health survey for England data. J Epidemiol Community Health 68(9):856–862

Pankaj SK, Wan Z, Colonna W et al (2017) Effect of high voltage atmospheric cold plasma on white grape juice quality. J Sci Food Agric 97(12):4016–4021

Pasquali F, Stratakos AC, Koidis A et al (2016) Atmospheric cold plasma process for vegetable leaf decontamination: a feasibility study on radicchio (red chicory, Cichorium intybus L.). Food Control 60:552–559

Patange A, Boehm D, Ziuzina D et al (2019) High voltage atmospheric cold air plasma control of bacterial biofilms on fresh produce. Int J Food Microbiol 293:137–145

Perni S, Liu DW, Shama G et al (2008) Cold atmospheric plasma decontamination of the pericarps of fruit. J Food Prot 71(2):302–308

Ramazzina I, Berardinelli A, Rizzi F et al (2015) Effect of cold plasma treatment on physico-chemical parameters and antioxidant activity of minimally processed kiwifruit. Postharvest Biol Technol 107:55–65

Rana S, Mehta D, Bansal V et al (2020) Atmospheric cold plasma (ACP) treatment improved in-package shelf-life of strawberry fruit. J Food Sci Technol Mys 57(1):102–112

Sarangapani C, O'Toole G, Cullen PJ et al (2017) Atmospheric cold plasma dissipation efficiency of agrochemicals on blueberries. Innov Food Sci Emerg Technol 44:235–241

Sarangapani C, Patang A, Bourke P et al (2018) Recent advances in the application of cold plasma technology in foods. Annu Rev Food Sci Technol 9:609–629

Sarvikivi E, Roivainen M, Maunula L et al (2012) Multiple norovirus outbreaks linked to imported frozen raspberries. Epidemiol Infect 140(2):260–267

Silveira MR, Coutinho NM, Rocha RS et al (2019) Guava flavored whey-beverage processed by cold plasma: physical characteristics, thermal behavior and microstructure. Food Res Int 119:564–570

Stoffels E, Sakiyama Y, Graves DB (2008) Cold atmospheric plasma: charged species and their interactions with cells and tissues. IEEE Trans Plasma Sci 36(4):1441–1457

Tappi S, Berardinelli A, Ragni L et al (2014) Atmospheric gas plasma treatment of fresh-cut apples. Innov. Food Sci Emerg Technol 21:114–122

Tappi S, Gozzi G, Vannini L et al (2016) Cold plasma treatment for fresh-cut melon stabilization. Innov. Food Sci Emerg Technol 33:225–233

Thirumdas R, Kothakota A, Annapure U et al (2018) Plasma activated water (PAW): chemistry, physico-chemical properties, applications in food and agriculture. Trends Food Sci Technol 77:21–31

Timmons C, Pai K, Jacob J et al (2018) Inactivation of Salmonella enterica, Shiga toxin-producing Escherichia coli, and Listeria monocytogenes by a novel surface discharge cold plasma design. Food Control 84:455–462

Tournas VH, Katsoudas E (2005) Mould and yeast flora in fresh berries, grapes and citrus fruits. Int J Food Microbiol 105(1):11–17

Vardar C, Ilhan K, Karabulut OA (2012) The application of various disinfectants by fogging for decreasing postharvest diseases of strawberry. Postharvest Biol Technol 66:30–34

Wang RX, Nian WF, Wu HY et al (2012) Atmospheric-pressure cold plasma treatment of contaminated fresh fruit and vegetable slices: inactivation and physiochemical properties evaluation. Eur Phys J D 66(10):276

Won MY, Lee SJ, Min SC (2017) Mandarin preservation by microwave-powered cold plasma treatment. Innov Food Sci Emerg Technol 39:25–32

Zhou D, Wang Z, Tu S et al (2019) Effects of cold plasma, UV-C or aqueous ozone treatment on Botrytis cinerea and their potential application in preserving blueberry. J Appl Microbiol 127(1):175–185

Zitong ZHAO, Xiangyou WANG, Tingjun MA, Yunjin SUN (2020) Optimization of plasma-processed air (PPA) inactivation of Escherichia coli in button mushrooms for extending the shelf life by response surface methodology. Plasma Sci Technol 22(6):065501

Ziuzina D, Patil S, Cullen PJ et al (2014) Atmospheric cold plasma inactivation of Escherichia coli, Salmonella enterica serovar Typhimurium and Listeria monocytogenes inoculated on fresh produce. Food Microbiol 42:109–116

Ziuzina D, Han L, Cullen PJ, Bourke P (2015) Cold plasma inactivation of internalised bacteria and biofilms for Salmonella enterica serovar Typhimurium, Listeria monocytogenes and Escherichia coli. Int J Food Microbiol 210:53–61

Zoroja J, Omejec D, Pejić Bach M (2017) Integrated model of traceability: tracking information for food safety. Poslovna izvrsnost 11(1):139–153

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Zhejiang University Press

About this chapter

Cite this chapter

Sun, Y., Wang, C. (2022). Application of Cold Plasma in Fruits and Vegetables. In: Ding, T., Cullen, P., Yan, W. (eds) Applications of Cold Plasma in Food Safety. Springer, Singapore. https://doi.org/10.1007/978-981-16-1827-7_7

Download citation

DOI: https://doi.org/10.1007/978-981-16-1827-7_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1826-0

Online ISBN: 978-981-16-1827-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)