Abstract

In recent years, global nut, spice, and herb productions have developed rapidly, and consumption has also increased. During the same period, a massive outbreak of food pathogens was linked to nuts, spices, herbs, and their products, leading to a major change in the way those products are processed. Cold plasma is a new technology used in food processing, which can improve the safety and extend shelf-life of product. A variety of active substances generated by cold plasma can act on microorganisms at ambient temperature and even on complex geometric shapes and heat-sensitive materials without leaving any chemical residues. The chapter introduces the application of various plasma discharge modes (plasma jets, dielectric barrier discharges, and microwave-driven discharges) on surface decontamination of nuts, spices, and herbs. In addition, a brief overview of the effect on their surface color, antioxidation activities, and other qualities with cold plasma treatment. We believe that cold plasma has a wide application prospect in extending the shelf-life and maintaining the quality of these dried foods.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

12.1 Introduction

Over the past century, the number of pathogenic fungi infecting plants, animals, and people has increased. Fungal diseases of crops have a significant effect on food security and have predictable economic consequences (Fisher et al. 2012, 2016). Fungus can grow on various foods, such as grains, meat, milk, fruits, vegetables, nuts, and the products of these merchandise, which causing food spoilage, such as the production of toxins, discoloration, odors, spoilage, and the accumulation of pathogenic and allergenic proliferators (Filtenborg et al. 1996; Taniwaki et al. 2009). For thousands of years, low water content or dried foods and products have been an important part of human diet. These foods are low in moisture, such as nuts, spices and grains, or nuts, herbs, and fruits that have been dried and processed. Food-borne pathogens may contaminate dried products, especially herbs and spices, which are usually highly contaminated with live bacteria (Schweiggert et al. 2007). Sources of contamination are usually associated with the pre-harvest environment and may be transferred through post-harvest treatment or in an open environment. In addition, poor processing practices may also cause recontamination problems. Dry products are often mistakenly considered microbially safe because low moisture content inhibits microbial growth (Gurtler et al. 2014). Nevertheless, microorganisms, such as spores or certain types of Salmonella, which are resistant to dry stress can remain active and reproduce if rehydrated or mixed with a high-moisture product. In recent decades, pathogen contamination of nuts and nut products has been a food safety issue that people have repeatedly paid attention to (Danyluk et al. 2007; Isaacs et al. 2005). For example, in the United States, from 2001 to 2016, there were about 82 cases of nuts and nut products due to contamination by pathogens of recalls in the amount of 148,000 tons (Frelka and Harris 2014). On the one hand, food-borne diseases and poisonings have increased as a result of the incorporation of contaminated herbs and spices into different foods (Buckenhuskes and Rendlen 2004). On the other hand, using spoiled herbs and spices could greatly shorten the shelf-life of food. Most fungal infections, once they occur, are difficult to remove, mainly because microbial resistance of low water activity food is stronger than that of high-water activity food (Fine and Gervais 2005).

At present, thermal or chemical treatment, such as fumigation, radiation, and steam treatment, are commonly used for decontamination of dried products (Schweiggert et al. 2007). Ethylene oxide fumigation and γ irradiation are the more effective methods. However, by-products from the use of ethylene oxide, which is banned by EU law, may cause cancer (Tateo and Bononi 2006). Radiation can only be administered in an approved facility and must be used in appropriate dose to ensure safety and harmlessness. While these methods can reduce fungal contamination, most of them require complex equipment and expensive chemicals, which can have an unacceptable impact on the taste, aroma, and texture of the dried products. What’s more, they may cause health hazards and have very little customer recognition.

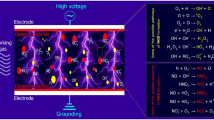

Because of these shortcomings, together with consumer demand for high-quality foods, it is necessary to use new non-thermal technology to replace traditional processes to sterilize dry products. Plasma processing has been widely used in a variety of production processes and has been proposed as an emerging technology in the food industry. Cold plasma (CP) technology has many advantages, such as low cost, eco-friendliness, convenient applicability, and adverse effects on microorganisms. It is a promising purification technology for food and food products. Therefore, the technology can be used as an effective decontamination method for nuts surface to improve microbial safety during post-harvest or storage. This chapter will discuss the application of cold plasma technology to the decontamination of microorganisms or mycotoxins on nuts, herbs, and spices, and the effect of cold plasma treatment on the quality of these dried products.

12.2 Application of Cold Plasma in Nuts

In previous chapter, the mechanism of sterilization of microorganisms by cold plasma was introduced in detail, and the different plasma discharge modes and working gases used to inactivate microorganisms and the results were reviewed. In this chapter, the application of plasma sterilization technology on nuts is discussed (details on bacteria, fungi, spores, and toxins). Table 12.1 showed a comprehensive review of the researches on the sterilization of nut products by cold plasma. The following examples are given to illustrate the microorganisms, surface color, and changes in the quality of nut foods after different types of plasma treatment to show the application prospects of this technology.

12.2.1 Inactivation of Microorganisms and Fungal Toxins in Nuts

12.2.1.1 Bacteria

Cold plasma is a new technology for inactivating bacteria on the surface of nuts. At present, the most studied nuts are almonds and peanuts. Deng et al. (2007) reported that almonds were soaked and inoculated with Escherichia coli (E. coli) and treated with non-thermal plasma (NTP). The data suggested that the number of microorganisms decreased by 5.0 logs for 30 s. The sterilization effect of NTP on E. coli inoculated on the surface of almonds increased with the increase in treatment voltage and frequency, and the sensitivity of E. coli to NTP was higher in the logarithmic phase than in the stable and declining phases. Similarly, Niemira (2012) inoculated the surface of almonds with Salmonella and E. coli O157:H7. The almonds with plasma jet (air, N2) treatment significantly reduced the number of Salmonella and E. coli O157:H7. The air plasma inactivation of the Salmonella on the almonds was more effective than the N2 treatment. Hertwig et al. (2017) investigated the bactericidal effect of CP on Salmonella Enteritidis PT 30 from the surface of unpeeled almond. Air, O2, N2, CO2, and 90% CO2 + 10% Ar were applied as working gases. The results showed that air reduction was more than 5.0 logs, O2 decreased by 4.8 logs, and N2 decreased by 2.0 logs after 15 min treatment. Some researchers reported that treating pistachios with plasma produced by pure oxygen- and pure argon- for 1 min reduced the number of E. coli on the surface of pistachios by 4 logs (Pignata et al. 2014).

12.2.1.2 Fungi and Fungal Toxins

Food safety has always been a crucial issue for consumers and the food industry as microbial contamination has a significant impact on the social and economic burden of health care (Yun et al. 2010).

Nuts or other foods are susceptible to contamination by toxic fungi, and the presence of aflatoxins is inevitable (Arrus et al. 2005). Cold plasma has broad application prospect in detoxification of mycotoxin. Aflatoxins (AFs) are found in various foods such as nuts, grains, and spices (Prelle et al. 2014). Some researchers investigated antifungal effects of low-pressure low-temperature plasma (LPCP) on Aspergillus parasitic in hazelnuts, peanuts, and pistachios. The results showed that air gas plasma treatment for 10 min caused 2 log10 reductions of Aspergillus parasitic, while SF6 plasma had a better effect, reducing the fungal population by about 5 log10 CFU/g in the same time. In testing the efficacy of plasma treatment against aflatoxins, the total aflatoxins were reduced by 50% after 20 min air gas plasma treatment, while total aflatoxins were reduced by only 20% with SF6 plasma treated (Basaran et al. 2008). Pignata et al. (2014) demonstrated plasma treatment of Aspergillus brasiliensis inoculated on pistachios. The surface Aspergillus brasiliensis of pistachio treated with pure oxygen or argon plasma for 30 min decreased by 3–5 log10 CFU/g, while the Aspergillus brasiliensis treated with a mixture of argon and oxygen (10:1 v/v) plasma for only 15 s decreased by 4–5 log10 CFU/g. The data suggested that the plasma generated by Ar/O2 was more efficient than that produced by O2 and Ar. It can be seen that different plasma devices (different gases, process parameters) have different bactericidal effects on the microorganisms on the surface of pistachios.

Hazelnuts can be contaminated with Aspergillus fungi to generate AFs. A. parasiticus can produce four major AFs: B1 (AFB1), B2 (AFB2), G1 (AFG1) and G2 (AFG2), while A. flavus can only produce AFB1 and AFB2 (Wogan 1966). Siciliano et al. (2016) optimized the operating parameters of detoxification of aflatoxins in shelled hazelnuts by atmospheric cold plasma. The content of total aflatoxin and AFB1 on hazelnuts decreased by more than 70% under plasma treatment of 1000 W and 12 min. The sensitivity of aflatoxins B1 and G1 to plasma was higher than that of aflatoxins B2 and G2, respectively, while aflatoxin B1 was higher than that of aflatoxin G1. Therefore, CP may be an effective method to reduce the amount of toxin on the surface of food due to its effectiveness and help to maintain the sensory properties of food. Likewise, Dasan et al. (2016) designed the atmospheric pressure fluidized bed plasma (APFBP) disinfection and decontamination system and studied the effectiveness of different plasma parameters about the decontamination of Aspergillus flavus and Aspergillus parasite of hazelnuts. The results confirmed that Aspergillus flavus was significantly decreased by 4.50 log CFU/g, and the Aspergillus parasite was significantly decreased by 4.19 log CFU/g after treatment with air plasma at 100% V-25 kHz. The decontamination effect of plasma on A. flavus and A. parasiticus was positively correlated with the treatment voltage and frequency. The same authors explored the effect of the reactor diameter and plasma gas of the APFBP system on the inactivation efficiency of spores produced by A. flavus and A. parasiticus inoculated on the surface of hazelnuts based on previous research (Dasan et al. 2017). The results confirmed that the decontamination effect of plasma on the spores decreased with an increase in the diameter of the fluidized bed reactor. At the end of a 30-day storage period, the population of A. flavus and A. parasiticus in the untreated group was increased by 115% and 76%, respectively, while the treated sample group was decreased by 5% and 10%, respectively. This means that the damage of spores by plasma processing was not temporary and the harmful effects on spore structure could not be repaired during storage.

Sen et al. (2019) studied the decontamination effect of atmospheric pressure plasma (AP) and low-pressure plasma (LP) on hazelnuts inoculated with A. flavus and A. parasiticus. After LP plasma treatment (100 W and 30 min), the A. parasiticus and A. flavus decreased by 5.6 as well as 4.7 log CFU/g, respectively. Meanwhile, under AP-air plasma treatment with air flow of 3000 L/h, 655 W for five times, A. parasiticus and A. flavus decreased 5.5 and 5.4 log CFU/g, respectively. Although the same plasma system was used by Dasan et al. (2016), they did not use a rotating drum and rotating nozzle. The advantage of this was that AP plasma systems could use different power frequency parameters, plus a rotating drum and nozzles, which helps to achieve a uniform and better plasma processing of samples. The growth of A. parasiticus and A. flavus inoculated on groundnuts decreased by 97.9% and 99.3%, respectively, when treated by cold plasma (60 W, 24 min) (Devi et al. 2017). The main parameters of the plasma, such as power, frequency, working gases, and voltage related to the reactor, directly affected the internal parameters of the plasma and were unique in each plasma system (Lerouge et al. 2001). Mošovská et al. (2019) observed the effect of gas diffusion coplanar barrier discharge (DCSBD) cold plasma (Fig. 12.1) about the passivation of A. flavus inoculated on unpeeled hazelnuts using working gases. In a mixed air of oxygen and water vapor, A. flavus decreased by 4.0 log CFU/g and was below the test line (1.0 log CFU/g). A. flavus was reduced by 2.56 log CFU/g treated by synthetic air plasma without water vapor, ambient air inactivation of 2.95 log CFU/g, N2 inactivation of 1.69 log CFU/g. The deactivation of A. flavus by O2 and aqueous vapor plasma was more effective than other gases.

Experimental device for optical measurement of DCSBD plasma generated in different working gases. Arrows indicate the direction of gas flow. (Mošovská et al. 2019). (This figure is reprinted with permission from Elsevier)

In addition, Amini and Ghoranneviss (2016a) found that four types of walnuts, Mazandaran, Toyeserkan, Taleghan, and Shahmirzad, were completely decontaminated from A. flavus inoculated on the surface cold plasma jet processing. Nevertheless, A. flavus count decreased with varieties of walnuts. With the extension of refrigeration time, the content of A. flavus in the control increased and reached 7.1 log CFU/g, while A. flavus in treatment group was negligible after 30 days of storage. CP processing significantly extended the shelf-life of walnuts. Cold plasma has effective bactericidal ability and can be applied as an alternative method for food decontamination.

These studies evaluated that the bactericidal effect of plasma increase with an increase in voltage and frequency. Notably, the contamination of the product surface could be easily removed using cold plasma.

12.2.2 Effect on the Quality of Nuts

The color of the product is a key factor that determines the quality of goods. Some researchers have analyzed the color changes in almonds after CP processing. There was no significant difference in quality properties (odor, appearance, texture, and whole harvest) between nuts (hazelnuts, peanuts, pistachios) treated with CP and untreated samples (Basaran et al. 2008). Hertwig et al. (2017) observed the effect of air, O2, N2, CO2, and 90% CO2 + 10% Ar gas plasma treatment about the color of almonds (Fig. 12.2). When air and N2 were applied as the working gas plasma treatment, the L* and b* values were reduced, and this resulted in darker unpeeled almonds. Significant changes in color occurred when the nuts were treated with only N2 or air. For O2, CO2, and 90% CO2 + 10% Ar, the color of the almond remained stable.

Effect of cold plasma treatment with different working gases on surface color of unpeeled almonds. (a) Air, (b) N2, (c) O2, (d) CO2, and (e) 90% CO2 + 10% Ar. Different letters over the bars indicate a significant difference (p < 0.05) among treatment time (Hertwig et al. 2017). (This figure is reprinted with permission from Elsevier)

Moreover, some experts also reported that total phenol content and antioxidant activity of walnuts for 11 min were not affected by plasma jet treatment, instead both increased with storage time (Amini and Ghoranneviss 2016a). Cashews are classified as allergic food and can cause allergic reactions (Mendes et al. 2016). Some authors found the effect of CP treatment on the composition and sensitization of cashew nut. The cashew nuts were treated with CP, using glow discharge. The data showed that CP processing has little influence on the composition of cashew nut, with almost no effect on the sensitization of cashew nuts. However, the contents of oil and anacardic acids in cashew nuts treated by plasma were increased (Alves et al. 2019). Besides, there were reports that plasma technology has been successfully adopted to reduce the antigenicity of peanut allergens (Venkataratnam et al. 2019).

12.3 Application of Cold Plasma in Spices and Herbs

12.3.1 Microbial Decontamination of Spices and Herbs

Black pepper is a spice applied all over the world and has an important flavor enhancing effect. Black pepper is traditionally harvested manually and then dried naturally, the process that can easily become contaminated with bacteria. Therefore, spices sold in retail stores might contain various of microorganisms (Garcia et al. 2001).

Kim et al. (2017a, b) investigated the effects of microwave CP treatment on A. brasiliensis inoculated on onion powder. It is observed that CP treatment after vacuum drying has a stronger inhibitory effect on A. brasiliensis than hot air drying. Sun et al. (2014) showed that Salmonella inoculated on black pepper treated by atmospheric plasma (APP) for 60–80 s significantly reduced the population of Salmonella by about 4.5–5.0 log CFU/g. Nevertheless, Hertwig et al. (2015a) adopted plasma jet and microwave-driven remote plasma to treat black pepper without inoculation and inoculated with Bacillus subtilis and Salmonella, respectively. The S. enterica, B. subtilis, and B. atrophaeus treated by remote plasma decreased by 4.1, 2.4, and 2.8 log CFU/g, respectively, while plasma jet processing did not produce the same deactivation effect. The manner in which cold plasma interacted with microorganisms was quite complicated and depended on the composition of gas, the mode of plasma discharge, and microorganisms, such as the type of bacteria (Gram-positive or negative) or fungus. Therefore, it was not easy to compare the sterilization results of different plasmas. Furthermore, Hertwig et al. (2015b) applied same remote plasma device to process yeast and mold on black pepper seeds, crushed oregano, as well as paprika powder. The total colonies of pepper seeds and paprika powder treated with remote plasma were decreased by more than 3.0 log CFU/g. Whereas, the total colonies of the oregano only decreased by 1.8 log CFU/g. Mosovska et al. (2018) researched that the inhibition of CP on Bacillus subtilis, E. coli, Salmonella Enteritidis, as well as Bacillus subtilis inoculated on black peppercorn. CP treatment with 300 s caused B. subtilis to decrease by about 5.0 log CFU/g. E. coli and Salmonella Enteritidis were treated and reduced by approximately 7.0 log CFU/g below the detected level (1.0 log CFU/g). In addition, some researchers reported that the microwave CP can inhibit the growth of A. flavus very well in red pepper powder. A. flavus was decreased by 2.5 ± 0.3 log CFU/g after CP treatment with N2 at 900 W for 20 min (Kim et al. 2014). According to Kim et al. (2017a, b), the inactivation effect of microwave-combined cold plasma treatment was significant at higher microwave power. Compared with far-infrared drying, vacuum-dried red pepper treated with CP can reduce spore more effectively. This might be attribute to the fact that vacuum drying gives the red pepper a more even and smooth. Similarly, Choi et al. (2018) reported that the inactivation of E. coli O157:H7 and Staphylococcus aureus inoculated in red pepper powder by radio frequency heat treatment (RF-TT) and dielectric barrier discharge plasma (DBD-PT) (Fig. 12.3). The data exhibited that the number of microorganisms decreased proportionally with the increases in the treatment period. After the combination of RF-TT and DBD-PT treatment, the microbial count was lower than the detection limit (1 log CFU/g).

Schematic diagrams of (a) RF the thermal and (b) indirect DBD-plasma processing systems (Choi et al. 2018). (This figure is reprinted with permission from Elsevier)

Although the growth of mold in tea is rare, tea can be used as a typical dry herb. According to Amini and Ghoranneviss (2016b), the decontamination ability of plasma jet on mold or yeast in black and green tea depended on the treatment time and initial microorganism count. It was found that when the initial population was 3.30 and 3.0 log CFU/g, respectively, the mold and yeast were completely inactivated after 7 min of treatment.

12.3.2 Effect on the Color of Spices and Herbs

Redness is the main parameter that determines the quality of red pepper products. Capsaicin is a main carotenoid, the primary pigment that gives red peppers their red color (Lee et al. 2004). The surface color of the black pepper seeds did not change significantly after using plasma jet and microwave-driven remote plasma treatment (Hertwig et al. 2015b). After plasma treatment, the b* value of oregano was slightly lower that could be due to the destruction of chlorophyll. The a* value of red pepper powder decreased with plasma treated, this indicated that the red color disappeared. As L* as well as b* value increased, the color of red pepper powder became lighter and yellower (Hertwig et al. 2015b). On the contrary, the L*, a*, and b* value of red pepper powder was not notably shifted by low-temperature plasma and microwave low-temperature plasma processing (Kim et al. 2014, 2017a, b; Won et al. 2017). Also, it was reported that onion powder treated by microwave integrated low-temperature plasma treatment did not significantly affect the color of onion powder and quercetin concentration during storage as compared with the control group (Kim et al. 2017a, b). The interpretation of this result may be that different plasma devices and different gas parameters led to different effects on the color of the material surface.

12.3.3 Effect on the Antioxidation Activity of Spices and Herbs

Kim et al. (2017a, b) employed CP to onion powder and demonstrated that the scavenging activity of DPPH-free radicals was higher than that of untreated onion powder without detrimental effects on its physicochemical and flavor characteristics. In addition, Zhang et al. (2018) reported that the antioxidant activity of red pepper powder was positively correlated with CP treatment time. This might be because CP processing could destroy the structure of the material by corroding the sample, thereby promoting the release of antioxidants such as the release of ascorbic acid and phenolic compounds during pretreatment and dehydration (Won et al. 2017).

Kashfi et al. (2020) explored the effect of radio frequency low-pressure low-temperature plasma (LPCP) on the antioxidant activity, total phenol content, and color of Mentha piperita. Under the optimum conditions (50 W, 20 min) for the removal of E. coli, the content of antioxidant activity of the samples was significantly improved, but LPCP also caused some darkening of the color of samples. Few studies have explored the effect of LPCP on phenolic compound. In the study of Harborne and Williams (2000), several species of plants have been found to resist UV radiation generated by CP processing. This might be because UV radiation caused the upper epidermal cells of leaves to produce phenolic substances. Hosseini et al. (2018) studied that the darkening of color of saffron treated by CP could be due to decreased activity of polyphenol oxidase or damage of cell wall.

12.3.4 Effect on the Other Quality Parameters of Spices and Herb

Some researchers also reported the effect of CP treatment on other qualities of herbs or spices. For example, scanning electron microscopy (SEM) and Fourier transform infrared spectroscopy (FTIR) exhibited that the morphology of the surface as well as chemical bonds interior of the black pepper after cold plasma treatment were not significantly changed (Mosovska et al. 2018). The water activity (aw) value of red pepper powder treated by microwave CP at 650 and 826 W reduced with an increase in processing time. The reduced aw value improved the microbial stability of powder products (Kim et al. 2014). Similarly, after intermittent radiofrequency CP processing, the water content and water activity of red pepper powder were significantly reduced compared with the control group (Choi et al. 2018).

Zhang et al. (2018) studied the effect of CP treatment time about the hot air-drying kinetics of and the qualities of red pepper. The data showed that the CP increased the drying speed, and 30 s treatment time achieved the best effect. Microstructure observations indicated the presence of micropores, which explained how plasma treatment improves drying kinetics.

Saffron is the main component of the saffron color. The saffron aroma comes from its vapor-volatile essential oil. Monoterpene aldehyde is the primary source of its distinctive odor, among the volatile oil components of saffron. The major flavor components of saffron are safranal and isophorone derivatives (Zarghami and Heinz 1971). Amini et al. (2017) studied the effect of CP on crocin esters and volatile oils in saffron crocus. When the working gases were Ar, Ar/5% O2, and Ar/10% O2, the contents of crocin esters and saffranal decreased, while the contents of isophorone and 4-ketoisophorone were increased after the treatment.

12.4 Conclusion

Consumer demand for safe and high-quality food requires the development of new technologies with access to the market by the research community and industry. In general, the application of cold plasma in herbs and spices was successful in terms of the inactivation of molds, without affecting the quality of herbs and spices. This is crucial information to attract the industry, and further research is needed in this area. Cold plasma is an emerging non-thermal technology, which has high potential application prospects in mild purification of dry products. There is an urgent need to introduce new technologies to consumers because consumer pays attention to the safety and quality of products already, still cares about the technology that produces processing to apply. Based on theoretical research, it may be possible to bring the success of these promising surface decontamination technologies to the market in the near future.

References

Alves EG, Silva LMA, Oiram F et al (2019) Cold plasma processing effect on cashew nuts composition and allergenicity. Food Res Int 125:108621

Amini M, Ghoranneviss M (2016a) Effects of cold plasma treatment on antioxidants activity, phenolic contents and shelf life of fresh and dried walnut (Juglans regia L.) cultivars during storage. LWT 73:178–184

Amini M, Ghoranneviss M (2016b) Black and green tea decontamination by cold plasma. Res J Microbiol 11(1):42–46

Amini M, Ghoranneviss M, Abdijadid S (2017) Effect of cold plasma on crocin esters and volatile compounds of saffron. Food Chem 235(235):290–293

Arrus K, Blank G, Abramson D et al (2005) Aflatoxin production by Aspergillus flavus in Brazil nuts. J Stored Products Res 41(5):513–527

Basaran P, Basaran N, Oksuz L (2008) Elimination of Aspergillus parasiticus from nut surface with low pressure cold plasma (LPCP) treatment. Food Microbiol 25(4):626–632

Buckenhuskes HJ, Rendlen M (2004) Hygienic problems of phytogenic raw materials for food production with special emphasis to herbs and spices. Food Sci Biotechnol 13:262–268

Choi EJ, Yang HS, Park HW et al (2018) Inactivation of Escherichia coli O157:H7 and Staphylococcus aureus in red pepper powder using a combination of radio frequency thermal and indirect dielectric barrier discharge plasma non-thermal treatments. LWT 93:477–484

Danyluk MD, Jones TM, Abd SJ et al (2007) Prevalence and amounts of Salmonella found on raw California almonds. J Food Protect 70(4):820–827

Dasan BG, Mutlu M, Boyaci IH (2016) Decontamination of Aspergillus flavus and Aspergillus parasiticus spores on hazelnuts via atmospheric pressure fluidized bed plasma reactor. Int J Food Microbiol 216:50–59

Dasan BG, Boyaci IH, Mutlu M (2017) Nonthermal plasma treatment of Aspergillus spp. spores on hazelnuts in an atmospheric pressure fluidized bed plasma system: impact of process parameters and surveillance of the residual viability of spores. J Food Eng 196:139–149

Deng S, Ruan R, Mok CK et al (2007) Inactivation of Escherichia coli on almonds using nonthermal plasma. J Food Sci 72(2):62–66

Devi Y, Thirumdas R, Sarangapani C et al (2017) Influence of cold plasma on fungal growth and aflatoxins production on groundnuts. Food Control 77:187–191

Filtenborg O, Frisvad JC, Thrane U (1996) Moulds in food spoilage. Int J Food Microbiol 33(1):85–102

Fine F, Gervais P (2005) Thermal destruction of dried vegetative yeast cells and dried bacterial spores in a convective hot air flow: strong influence of initial water activity. Environ Microbiol 7(1):40–46

Fisher MC, Henk DA, Briggs CJ et al (2012) Emerging fungal threats to animal, plant and ecosystem health. Nature 484(7393):186–194

Fisher MC, Gow NA, Gurr SJ (2016) Tackling emerging fungal threats to animal health, food security and ecosystem resilience. Biol Sci 371(1709):1–6

Frelka JC, Harris LJ (2014) Nuts and nut pastes. The microbiological safety of low water activity foods and spices. Springer, New York, pp 213–244

Garcia S, Iracheta F, Galvan F et al (2001) Microbiological survey of retail herbs and spices from Mexican markets. J Food Prot 64(1):99–103

Gurtler JB, Doyle MP, Kornacki JL (2014) The microbiological safety of low water activity foods and spices. Springer, New York

Harborne JB, Williams CA (2000) Advances in flavonoid research since 1992. Phytochemistry 55(6):481–504

Hertwig C, Reineke K, Ehlbeck J et al (2015a) Impact of remote plasma treatment on natural microbial load and quality parameters of selected herbs and spices. J Food Eng 167:12–17

Hertwig C, Reineke K, Ehlbeck J et al (2015b) Decontamination of whole black pepper using different cold atmospheric pressure plasma applications. Food Control 55:221–229

Hertwig C, Leslie A, Meneses N et al (2017) Inactivation of Salmonella enteritidis PT30 on the surface of unpeeled almonds by cold plasma. Innov Food Sci Emerg Technol 44:242–248

Hosseini SI, Farrokhi N, Shokri K et al (2018) Cold low pressure O2 plasma treatment of Crocus sativus: an efficient way to eliminate toxicogenic fungi with minor effect on molecular and cellular properties of saffron. Food Chem 257:310–315

Isaacs S, Aramini J, Ciebin B et al (2005) An international outbreak of salmonellosis associated with raw almonds contaminated with a rare phage type of Salmonella Enteritidis. J Food Prot 68(1):191–198

Kashfi AS, Ramezan Y, Khani MR (2020) Simultaneous study of the antioxidant activity, microbial decontamination and color of dried peppermint (Mentha piperita L.) using low pressure cold plasma. LWT 123:109121

Kim JE, Lee DU, Min SC (2014) Microbial decontamination of red pepper powder by cold plasma. Food Microbiol 38:128–136

Kim JE, Choi H, Lee D et al (2017a) Effects of processing parameters on the inactivation of Bacillus cereus spores on red pepper (Capsicum annum L.) flakes by microwave-combined cold plasma treatment. Int J Food Microbiol 263:61–66

Kim JE, Oh YJ, Won MY et al (2017b) Microbial decontamination of onion powder using microwave-powered cold plasma treatments. Food Microbiol 62:112–123

Lee JH, Sung TH, Lee KT et al (2004) Effect of gamma-irradiation on color, pungency, and volatiles of Korean red pepper powder. J Food Sci 69(8):585–592

Lerouge S, Wertheimer MR, Yahia LH (2001) Plasma sterilization: a review of parameters, mechanisms, and limitations. Plasmas Polym 6(3):175–188

Mendes C, Costa J, Vicente A et al (2016) Cashew nut allergy: clinical relevance and allergen characterization. Clin Rev Allergy Immunol 57:1–22

Mosovska S, Medvecka V, Halaszova N et al (2018) Cold atmospheric pressure ambient air plasma inhibition of pathogenic bacteria on the surface of black pepper. Food Res Int 106:862–869

Mošovská S, Medvecká V, Gregová M et al (2019) Plasma inactivation of Aspergillus flavus on hazelnut surface in a diffuse barrier discharge using different working gases. Food Control 104:256–261

Niemira BA (2012) Cold plasma reduction of Salmonella and Escherichia coli O157:H7 on almonds using ambient pressure gases. J Food Sci 77(3):171–175

Pignata C, D’Angelo D, Basso D et al (2014) Low-temperature, low-pressure gas plasma application on Aspergillus brasiliensis, Escherichia coli and pistachios. J Appl Microbiol 116(5):1137–1148

Prelle A, Spadaro D, Garibaldi A et al (2014) Co-occurrence of aflatoxins and ochratoxin A in spices commercialized in Italy. Food Control 39:192–197

Schweiggert U, Carle R, Schieber A (2007) Conventional and alternative processes for spice production - a review. Trends Food Sci Technol 18(5):260–268

Sen Y, Onal-Ulusoy B, Mutlu M (2019) Aspergillus decontamination in hazelnuts: evaluation of atmospheric and low-pressure plasma technology. Innov Food Sci Emerg Technol 54:235–242

Siciliano I, Spadaro D, Prelle A et al (2016) Use of cold atmospheric plasma to detoxify hazelnuts from aflatoxins. Toxins 8(125):1–10

Sun S, Anderson NM, Keller S (2014) Atmospheric pressure plasma treatment of black peppercorns inoculated with Salmonella and held under controlled storage. J Food Sci 79(12):1–6

Taniwaki MH, Hocking AD, Pitt JI et al (2009) Growth and mycotoxin production by food spoilage fungi under high carbon dioxide and low oxygen atmospheres. Int J Food Microbiol 132(3):100–108

Tateo F, Bononi M (2006) Determination of ethylene chlorohydrin as marker of spices fumigation with ethylene oxide. J Food Compos Anal 19(1):83–87

Venkataratnam H, Sarangapani C, Cahill O et al (2019) Effect of cold plasma treatment on the antigenicity of peanut allergen Ara h 1. Innov Food Sci Emerg Technol 52:368–375

Wogan GN (1966) Chemical nature and biological effects of the aflatoxins. Bacteriol Rev 30(2):460–470

Won MY, Lee SJ, Min SC (2017) Mandarin preservation by microwave-powered cold plasma treatment. Innov Food Sci Emerg Technol 39:25–32

Yun H, Kim B, Jung S et al (2010) Inactivation of Listeria monocytogenes inoculated on disposable plastic tray, aluminum foil, and paper cup by atmospheric pressure plasma. Food Control 21(8):1182–1186

Zarghami NS, Heinz DE (1971) Monoterpene aldehydes and isophorone-related compounds of saffron. Phytochemistry 10(11):2755–2761

Zhang XL, Zhong CS, Mujumdar AS et al (2018) Cold plasma pretreatment enhances drying kinetics and quality attributes of chili pepper (Capsicum annuum L.). J Food Eng 241:51–57

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Zhejiang University Press

About this chapter

Cite this chapter

Yan, W. (2022). Application of Cold Plasma in Nuts, Spices, and Herbs. In: Ding, T., Cullen, P., Yan, W. (eds) Applications of Cold Plasma in Food Safety. Springer, Singapore. https://doi.org/10.1007/978-981-16-1827-7_12

Download citation

DOI: https://doi.org/10.1007/978-981-16-1827-7_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1826-0

Online ISBN: 978-981-16-1827-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)