Abstract

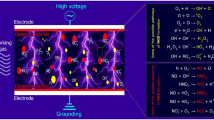

The non-thermal nature of cold plasma processing has brought it to the spotlight in recent times as an alternative food processing technology, especially for foods sensitive to heat. Simply defined as the generation of short-lived reactive species by the application of electricity to gas, non-thermal plasma has become an important food processing technology. Figure 7.1 shows a schematic presentation of atmospheric cold plasma processing of food products. Depending on the plasma technique used (i.e. corona discharge, dielectric barrier discharge, gliding arch, plasma jets, and radio frequency discharges), different reactive species are produced, usually from vibrationally and electronically excited nitrogen and oxygen. The type of reactive species produced largely depends on the type of gas used. The gases mostly used are but not limited to oxygen, nitrogen, argon, hydrogen, air and their mixtures. These reactive species react with surfaces, they come into contact with resulting in modifications. The effects of cold plasma on the various food components such as proteins, starch, lipids, and phenolics have been previously reported. One of the main applications of cold plasma in food processing is for the sterilization of food products. Other applications such as food quality improvement, packaging applications, surface modifications, and the degradation of toxins in foods have been reported. In this chapter, the advantages and challenges of using cold plasma on the quality of fruits, vegetables, meat and dairy products are highlighted. The discussion is focused on the effects of cold plasma on the nutritional, textural and sensory properties of fruits and vegetables, meat and dairy products.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

7.1 Introduction

The non-thermal nature of cold plasma processing has brought it to the spotlight in recent times as an alternative food processing technology, especially for foods sensitive to heat. Simply defined as the generation of short-lived reactive species by the application of electricity to gas, non-thermal plasma has become an important food processing technology. Figure 7.1 shows a schematic presentation of atmospheric cold plasma processing of food products. Depending on the plasma technique used (i.e. corona discharge, dielectric barrier discharge, gliding arch, plasma jets, and radio frequency discharges (Scholtz, Pazlarova, Souskova, Khun, & Julak, 2015)), different reactive species are produced, usually from vibrationally and electronically excited nitrogen and oxygen. The type of reactive species produced largely depends on the type of gas used. The gases mostly used are but not limited to oxygen, nitrogen, argon, hydrogen, air and their mixtures. These reactive species react with surfaces, they come into contact with resulting in modifications. The effects of cold plasma on the various food components such as proteins (Bahrami et al., 2016; Dong, Gao, Xu, & Chen, 2017; Misra et al., 2015; Takai et al., 2014; Yasuda, Miura, Kurita, Takashima, & Mizuno, 2010), starch (Bastos, Santos, & Simao, 2014; Kim & Min, 2017; Thirumdas, Trimukhe, Deshmukh, & Annapure, 2017), lipids (Bahrami et al., 2016; Sarangapani, Ryan Keogh, Dunne, Bourke, & Cullen, 2017), and phenolics (Amini & Ghoranneviss, 2016; Grzegorzewski, Ehlbeck, Schlüter, Kroh, & Rohn, 2011) have been previously reported. One of the main applications of cold plasma in food processing is for the sterilization of food products (Los, Ziuzina, Boehm, Cullen, & Bourke, 2017; Misra & Jo, 2017; Selcuk, Oksuz, & Basaran, 2008). Other applications such as food quality improvement, packaging applications, surface modifications, and the degradation of toxins in foods have been reported (Akocak, 2016; Han et al., 2016; Shi, Cooper, Stroshine, Ileleji, & Keener, 2017). In this chapter, the advantages and challenges of using cold plasma on the quality of fruits, vegetables, meat and dairy products are highlighted. The discussion is focused on the effects of cold plasma on the nutritional, textural and sensory properties of fruits and vegetables, meat and dairy products.

7.2 Advantageous and Challenges of Using Cold Plasma on Food Quality

7.2.1 Nutritional Properties

7.2.1.1 Fruits and Vegetables

The reactive species produced by cold plasma may affect the bioactive compounds in fruits and vegetables leading to changes in their nutritional composition and functional properties. Previous studies have reported that the application of this technology might affect the stability of some nutrients. For instance, Bursać Kovačević et al. (2016) investigated the effect of cold plasma on the stability of anthocyanins in pomegranate juice. In this study, the application of different treatment times, juice volume and gas flow were evaluated. The authors observed an increase in anthocyanin content after treating the juice with cold plasma. The increase in anthocyanin contents in the juice was attributed to the disruption of the fruit cell walls. The application of this technology not only increased the anthocyanins’ content in the juice but also improved the stability.

Elez Garofulić et al. (2015) have reported the degradation of anthocyanins and phenolic compounds treated with cold plasma for longer periods of time. The degradation of anthocyanins and phenolic compounds were observed in the sour cherry Marasca juice samples treated with cold plasma. The extent of degradation positively correlated with an increase in plasma exposure. The degradation of anthocyanins and phenolic compounds, when exposed to plasma for extended periods of time, could be attributed to the reaction of these compounds with the reactive radicals or oxygen spices such as hydroxyl radicals, peroxyl radicals, atomic and singlet oxygen (Brandenburg et al., 2007).

In another study, Grzegorzewski et al. (2011) investigated the effect of cold plasma treatment on the phenolic profile of lamb’s lettuce. The authors observed different degradation rates in various phenolic compounds. All phenolic acids in the fresh lettuce leaves decreased by increasing the plasma exposure. The rate of degradation of phenolic acids, when exposed to plasma, was slower than flavonoids. Luteolin was unaffected by plasma exposure, whereas a significant increase was observed for diosmetin. A significant decrease in the anthocyanin content of blueberries was observed after 90 s atmospheric cold plasma treatment.

A few studies also reported the effect of cold plasma on the ascorbic acid contents of fruits. For instance, Misra et al. (2015) investigated the effect of cold plasma on the chemical quality and ascorbic acid contents of strawberries. In their study, strawberries packaged in polymeric films were exposed to the non-thermal plasma produced from a dielectric barrier discharge. The ascorbic acid content was significantly reduced when the samples were exposed to 80 kV for 1 min. It is interesting to note that the anthocyanin content in the strawberries treated samples was not significantly affected. In another study, the application of cold plasma was reported to affect the degradation of chlorophyll (Ramazzina et al., 2015). A 15% reduction in the chlorophyll content in kiwi fruit was observed after treatment with cold plasma. Chlorophyll degradation by plasma could be mediated by the presence of oxygen produced by cold plasma. In the kiwi fruit, plasma treatment did not affect the ascorbic acid content immediately after plasma treatment, while a significant decrease in the ascorbic acid content observed after storage. Moreover, plasma treatment did not affect the antioxidant content and antioxidant activity of fresh kiwi fruit after cold plasma treatment.

7.2.1.2 Meat Products

Information about the effect of cold plasma on the meat products is very limited. In the meat products, the effects of cold plasma on proteins and lipids is very important. Any changes in the structure of proteins and lipids in meat products directly affect the nutritional and sensorial properties of these products. The free radicals and reactive oxygen species (ROS), including ozone, has the ability to react with fatty acids, oxidizing them to by-products that will affect the nutrient profile of meat products. Plasma has been reported to oxidize lipids by the Criegee mechanism resulting in the production of aldehydes and carboxylic acids in beef (Sarangapani et al., 2017). The extent of lipid oxidation by plasma was reported to be the function of time and applied voltage/energy. Sarangapani et al. (2017) found that the cold plasma treatment of beef significantly decreased the amount of unsaturated fatty acids. This was reported to be due to the cleavage of the double bonds of the unsaturated fatty acids, especially oleic, palmitoleic and linoleic acids by hydroxyl radicals. Oleic acid was reported to be the most susceptible to oxidation by plasma.

In another study, Jayasena et al. (2015) investigated the effect of cold plasma on the quality of pork butt and beef loins. A time-dependent effect of plasma exposure on the extent of lipid oxidation was reported. The lipid oxidation in the pork butt and beef loins was not significantly increased up to a treatment time of 7.5 min. However, a significant increase in the lipid oxidation was observed when the pork butt and beef loins were treated with plasma for 10 min. Kim, Yong, Park, Choe, and Jo (2013) also reported an increase in the lipid oxidation of pork loins treated with plasma produced by a dielectric barrier discharge. Rød, Hansen, Leipold, and Knøchel (2012) observed an increase in the thiobatbituric acid reactive substances (TBARS) of ready-to-eat bresaola treated with cold plasma as a function of plasma power, time and storage.

7.2.1.3 Dairy Products

The effect of plasma on fresh milk was studied by Korachi et al. (2015). In this study, two tungsten electrodes with a 9 kV AC power supply were used. No changes in the fatty acid concentration of the fresh milk compared to the plasma-treated one were observed. After 3 min of plasma treatment, a decrease in the content of unsaturated fatty acids was reported and further decreasing was observed by extending the treatment time. Moreover, slight reductions in stearic acid content were observed after 20 min of plasma treatment. In another study, Korachi et al. (2015) observed an increase in the short-chain length fatty acids of milk after plasma treatment and vice versa for long chain fatty acids. Application of cold plasma up to 20 min did not significantly affect on the fatty acid composition of raw milk. After treating sliced cheddar cheese with flexible thin layer dielectric barrier plasma discharge, Yong et al. (2015), observed a significant increase in TBARS values when the sliced cheddar cheese was exposed to the plasma for 5- and 10-min. The values of 0.132 and 0.183 mg malondialdehyde/kg was reported for untreated and plasma-treated cheddar cheese, respectively.

7.2.2 Textural Properties

7.2.2.1 Fruits and Vegetables

The textural properties of fruits and vegetables are important determinants of their acceptability. Mainly affected by polymeric materials such as pectin and cellulose, in addition to interactions with other components, fruit and vegetable texture can be affected by chemicals, enzymes, storage, and heat. Up to now, only a few studies have reported the effect of cold plasma treatment on the textural properties of fruits and vegetables. Ramazzina et al. (2015) have reported that the cold plasma treatment of kiwi fruit slices did not significantly affect the hardness and the energy needed to rupture the fruit. The penetration tests for the kiwi fruit slices were done at two different points of the pericarp using the texture analyzer.

7.2.2.2 Meat Products

Exposure of meat products to cold plasma does not seem to significantly affect the textural profile. For instance, Jayasena et al. (2015) did not observe any changes in the cohesiveness and springiness of pork butts and beef loins after plasma treatment. Similarly, the hardness, chewiness, and gumminess of the samples did not change, though these parameters have responded more to plasma exposure than springiness and cohesiveness. Kim et al. (2013) also reported that the texture of the pork loins did not significantly change after plasma treatment generated from a flexible thin layer dielectric barrier discharges. More studies are needed to accurately confirm the effects of plasma on the texture of meat products.

7.2.2.3 Dairy Products

There is very little information available on the textural effects of cold plasma on the dairy products. Most of the reports on the use of cold plasma on dairy products have been focused on the decontamination. Thus, more studies need to be conducted to evaluate the effect of cold plasma treatment on the textural properties of dairy products and its feasibility to modify these products.

7.2.3 Sensorial Properties

7.2.3.1 Fruits and Vegetables

Niemira and Sites (2008) did not observe any discoloration, blistering, pitting, unpleasant aroma or any sensory damage after treating golden delicious apples with cold plasma up to 2 min and 40 L/min using a gliding arc cold plasma system. This was reported to be due to the short exposure time of the apples to the plasma discharge. Misra et al. (2014) also found that the color of plasma-treated strawberries was not significantly affected when treated with atmospheric cold plasma. Though reductions were observed in the L, a∗ and b∗ values of the plasma-treated strawberries versus the untreated samples, the difference was not statistically different. In another study, Shi et al. (2011) observed that the turbidity and pH of freshly squeezed orange juice treated with low-temperature plasma were not significantly affected. Vleugels et al. (2005) measured the effects of atmospheric cold plasma on the color of cold peppers. Red green and yellow peppers were cut into 1-cm portions and exposed to cold plasma up to 20 min. After measuring the extent of discoloration of the samples with a reflectance spectrophotometer, they reported no significant changes in the color of the peppers. Their chroma-hue plots suggested a larger color difference in the green peppers than the other samples.

7.2.3.2 Meat Products

Application of cold plasma has reported affecting the color of meat products. The effect of cold plasma on the color of meat products seems to be related to the time and energy of exposure. Jayasena et al. (2015) reported significant changes in the color parameters (L a∗ and b∗) of pork butts and beef loins after treatment with cold plasma using flexible thin layer dielectric barrier discharge system. The effect of cold plasma on the color was depended on the type of meat product, energy and time of exposure. While the b∗-values of the plasma-treated pork butt was not significantly different from the untreated sample, the b∗-value of the plasma-treated beef loin was significantly higher than the untreated sample. It was also observed that prolonged exposure times led to a decrease in the redness of the pork and an increase in greenness. This decrease in redness of the meat samples could negatively affect the consumer acceptance of plasma-treated meat products, as consumers generally use meat surface color as an indicator of freshness. The increase in the greenness of the meat samples may be due to the reaction of myoglobin with hydrogen peroxide forming choleglobin. A similar observation was made by Fröhling, Baier, Ehlbeck, Knorr, and Schlüter (2012) when fresh pork was treated with cold plasma. The higher b∗-values observed when fresh meat products were treated with cold plasma might be due to the oxidation of deoxymyoglobin or myoglobin, which leads to the formation of metmyoglobin (Jayasena et al., 2015; Mancini & Hunt, 2005). Several studies have reported that the plasma treated fresh pork loins were significantly darker than the non-treated samples (Cheng et al., 2010; Kim et al., 2011; 2013). They reported no difference in the redness and greenness of the meat samples. A reduction in the lightness of the pork loin was attributed to the drying of the surface of the sample due to moisture loss. Ulbin-Figlewicz, Brychcy, and Jarmoluk (2015) and Dirks et al. (2012) did not observe any changes in the color of chicken breast samples treated with cold plasma. The chicken breast samples were treated with plasma up to 3 min. Kim et al. (2013) did not find any significant difference in the consumer acceptability of plasma treated fresh pork sample compared to control. However, Jayasena et al. (2015) reported a negative effect of plasma treatment on the cooked pork butt and beef loins taste. The color, overall acceptability, appearance, and off-odor were not significantly affected. This unacceptable taste perception was observed when cooked pork butts and beef loins were treated for at least 10 min. The negative sensory properties of the cold plasma treated samples could be due to the oxidation of lipids. Lee et al. (2012) reported that the plasma treatment negatively influenced the flavor, taste and overall acceptability of cooked egg yolk but not the egg whites.

7.2.3.3 Dairy Products

Several studies have reported the application of cold plasma treatment on the sensorial properties of dairy products. For instance, Gurol, Ekinci, Aslan, and Korachi (2012) and Kim et al. (2015) did not observe any significant changes in the L and b∗- values of commercial whole milk treated with plasma. Even though they observed a decrease in the a∗-values of the samples, the decreases were not significant. Cheddar cheese treated with cold plasma resulted in a decrease in the lightness and redness of the samples but was unaffected with respect to the sensory appearance, color, and total color difference. Cold plasma treatment of milk was reported to enhance the lipid oxidation leading to the generation of off-flavors as observed in cheddar cheese (Lee et al., 2012). Yong et al. (2015) reported significant negative effects on the flavor and overall acceptability of sliced cheddar cheese when exposed to the flexible thin-layer dielectric barrier plasma discharge. The off-flavors in the cheese slices could be due to the oxidation of the high fats available in the product, resulting in the production of a variety of lipid oxidation products.

7.3 Conclusions

The effect of cold plasma on the nutritional, texture and sensory characteristics of food products depends on the time and energy of exposure. In the case of fruits and vegetables, cold plasma has significant effects on their bioactive components, especially on the vitamins and anthocyanins. Lipids and proteins are the main nutritional components affected by cold plasma in meat products. The plasma effects on lipids in meat and dairy products lead to the development of off-flavors, affecting the acceptability of these products. The texture was not affected when plasma was applied to fruits, vegetables, and dairy products. It is important to mention that very limited information currently exists in the use of cold plasma for the modification of the nutritional, texture and sensory characteristics of food and hence these conclusions may change in the near future when more information becomes available.

References

Akocak, P. B. (2016). Current progress in advanced research into fungal and mycotoxin inactivation by cold plasma sterilization. In H. Shintani & A. Sakudo (Eds.), Gas plasma sterilization in microbiology: Theory, applications, pitfalls and new perspectives (pp. 59–74). Norfolk, UK: Caister Academic Press.

Amini, M., & Ghoranneviss, M. (2016). Effects of cold plasma treatment on antioxidants activity, phenolic contents and shelf life of fresh and dried walnut (Juglans regia L.) cultivars during storage. LWT, 73, 178–184.

Bahrami, N., Bayliss, D., Chope, G., Penson, S., Perehinec, T., & Fisk, I. D. (2016). Cold plasma: A new technology to modify wheat flour functionality. Food Chemistry, 202, 247–253.

Bastos, D. C., dos Santos, A. E. F., & Simao, R. A. (2014). Acetylene coating on cornstarch plastics produced by cold plasma technology. Starch, 66(3–4), 267–273.

Brandenburg, R., Ehlbeck, J., Stieber, M., Woedtke, T. v., Zeymer, J., Schlüter, O., & Weltmann, K.-D. (2007). Antimicrobial treatment of heat sensitive materials by means of atmospheric pressure Rf-driven plasma jet. Contributions to Plasma Physics, 47(1-2), 72–79.

Bursać Kovačević, D., Putnik, P., Dragović-Uzelac, V., Pedisić, S., Režek Jambrak, A., & Herceg, Z. (2016). Effects of cold atmospheric gas phase plasma on anthocyanins and color in pomegranate juice. Food Chemistry, 190, 317–323.

Cheng, S. Y., Yuen, C. W. M., Kan, C. W., Cheuk, K. K. L., Daoud, W. A., Lam, P. L., & Tsoi, W. Y. I. (2010). Influence of atmospheric pressure plasma treatment on various fibrous materials: Performance properties and surface adhesion analysis. Vacuum, 84(12), 1466–1470.

Dirks, B. P., Dobrynin, D., Fridman, G., Mukhin, Y., Fridman, A., & Quinlan, J. J. (2012). Treatment of raw poultry with nonthermal dielectric barrier discharge plasma to reduce Campylobacter jejuni and Salmonella enterica. Journal of Food Protection, 75(1), 22–28.

Dong, S., Gao, A., Xu, H., & Chen, Y. (2017). Effects of dielectric barrier discharges (DBD) cold plasma treatment on physicochemical and structural properties of zein powders. Food and Bioprocess Technology, 10(3), 434–444.

Elez Garofulić, I., Režek Jambrak, A., Milošević, S., Dragović-Uzelac, V., Zorić, Z., & Herceg, Z. (2015). The effect of gas phase plasma treatment on the anthocyanin and phenolic acid content of sour cherry Marasca (Prunus cerasus var. Marasca) juice. LWT – Food Science and Technology, 62(1, Part 2), 894–900.

Fröhling, A., Baier, M., Ehlbeck, J., Knorr, D., & Schlüter, O. (2012). Atmospheric pressure plasma treatment of Listeria innocua and Escherichia coli at polysaccharide surfaces: Inactivation kinetics and flow cytometric characterization. Innovative Food Science & Emerging Technologies, 13, 142–150.

Grzegorzewski, F., Ehlbeck, J., Schlüter, O., Kroh, L. W., & Rohn, S. (2011). Treating lamb’s lettuce with a cold plasma – Influence of atmospheric pressure Ar plasma immanent species on the phenolic profile of Valerianella locusta. LWT – Food Science and Technology, 44(10), 2285–2289.

Gurol, C., Ekinci, F. Y., Aslan, N., & Korachi, M. (2012). Low temperature plasma for decontamination of E. coli in milk. International Journal of Food Microbiology, 157(1), 1–5. https://doi.org/10.1016/j.ijfoodmicro.2012.02.016

Han, L., Boehm, D., Amias, E., Milosavljević, V., Cullen, P. J., & Bourke, P. (2016). Atmospheric cold plasma interactions with modified atmosphere packaging inducer gases for safe food preservation. Innovative Food Science & Emerging Technologies, 38, 384–392.

Jayasena, D. D., Kim, H. J., Yong, H. I., Park, S., Kim, K., Choe, W., & Jo, C. (2015). Flexible thin-layer dielectric barrier discharge plasma treatment of pork butt and beef loin: Effects on pathogen inactivation and meat-quality attributes. Food Microbiology, 46, 51–57.

Kim, B., Yun, H., Jung, S., Jung, Y., Jung, H., Choe, W., & Jo, C. (2011). Effect of atmospheric pressure plasma on inactivation of pathogens inoculated onto bacon using two different gas compositions. Food Microbiology, 28(1), 9–13.

Kim, H.-J., Yong, H. I., Park, S., Choe, W., & Jo, C. (2013). Effects of dielectric barrier discharge plasma on pathogen inactivation and the physicochemical and sensory characteristics of pork loin. Current Applied Physics, 13(7), 1420–1425.

Kim, H.-J., Yong, H. I., Park, S., Kim, K., Choe, W., & Jo, C. (2015). Microbial safety and quality attributes of milk following treatment with atmospheric pressure encapsulated dielectric barrier discharge plasma. Food Control, 47, 451–456.

Kim, H.-S., & Min, S. C. (2017). Effects of microwave-discharged cold plasma on synthesis and characteristics of citrate derivatives of corn starch granules. Food Science and Biotechnology, 26(3), 697–706.

Korachi, M., Ozen, F., Aslan, N., Vannini, L., Guerzoni, M. E., Gottardi, D., & Ekinci, F. Y. (2015). Biochemical changes to milk following treatment by a novel, cold atmospheric plasma system. International Dairy Journal, 42, 64–69.

Lee, H.-J., Jung, S., Jung, H.-S., Park, S.-H., Choe, W.-H., Ham, J.-S., & Jo, C. (2012). Evaluation of a dielectric barrier discharge plasma system for inactivating pathogens on cheese slices. Journal of Animal Science and Technology, 54(3), 191–198.

Los, A., Ziuzina, D., Boehm, D., Cullen, P. J., & Bourke, P. (2017). The potential of atmospheric air cold plasma for control of bacterial contaminants relevant to cereal grain production. Innovative Food Science & Emerging Technologies, 44, 36–45.

Mancini, R. A., & Hunt, M. C. (2005). Current research in meat color. Meat Science, 71(1), 100–121.

Misra, N. N., & Jo, C. (2017). Applications of cold plasma technology for microbiological safety in meat industry. Trends in Food Science & Technology, 64, 74–86.

Misra, N. N., Kaur, S., Tiwari, B. K., Kaur, A., Singh, N., & Cullen, P. J. (2015). Atmospheric pressure cold plasma (ACP) treatment of wheat flour. Food Hydrocolloids, 44, 115–121.

Misra, N. N., Patil, S., Moiseev, T., Bourke, P., Mosnier, J. P., Keener, K. M., & Cullen, P. J. (2014). In-package atmospheric pressure cold plasma treatment of strawberries. Journal of Food Engineering, 125, 131–138.

Niemira, B. A., & Sites, J. (2008). Cold plasma inactivates Salmonella Stanley and Escherichia coli O157: H7 inoculated on golden delicious apples. Journal of Food Protection, 71(7), 1357–1365.

Ramazzina, I., Berardinelli, A., Rizzi, F., Tappi, S., Ragni, L., Sacchetti, G., & Rocculi, P. (2015). Effect of cold plasma treatment on physico-chemical parameters and antioxidant activity of minimally processed kiwifruit. Postharvest Biology and Technology, 107, 55–65.

Rød, S. K., Hansen, F., Leipold, F., & Knøchel, S. (2012). Cold atmospheric pressure plasma treatment of ready-to-eat meat: Inactivation of Listeria innocua and changes in product quality. Food Microbiology, 30(1), 233–238.

Sarangapani, C., Ryan Keogh, D., Dunne, J., Bourke, P., & Cullen, P. J. (2017). Characterisation of cold plasma treated beef and dairy lipids using spectroscopic and chromatographic methods. Food Chemistry, 235, 324–333.

Scholtz, V., Pazlarova, J., Souskova, H., Khun, J., & Julak, J. (2015). Nonthermal plasma — A tool for decontamination and disinfection. Biotechnology Advances, 33(6, Part 2), 1108–1119.

Selcuk, M., Oksuz, L., & Basaran, P. (2008). Decontamination of grains and legumes infected with Aspergillus spp. and Penicillum spp. by cold plasma treatment. Bioresource Technology, 99(11), 5104–5109.

Shi, H., Cooper, B., Stroshine, R. L., Ileleji, K. E., & Keener, K. M. (2017). Structures of degradation products and degradation pathways of aflatoxin B-1 by high-voltage atmospheric cold plasma (HVACP) treatment. Journal of Agricultural and Food Chemistry, 65(30), 6222–6230.

Shi, X., Zhang, G., Wu, X., Li, Y., Ma, Y., & Shao, X. (2011). Effect of low-temperature plasma on microorganism inactivation and quality of freshly squeezed orange juice. IEEE Transactions on Plasma Science, 39(7), 1591–1597.

Takai, E., Kitamura, T., Kuwabara, J., Ikawa, S., Yoshizawa, S., Shiraki, K., … Kitano, K. (2014). Chemical modification of amino acids by atmospheric-pressure cold plasma in aqueous solution. Journal of Physics D: Applied Physics, 47(28), 285403.

Thirumdas, R., Trimukhe, A., Deshmukh, R. R., & Annapure, U. S. (2017). Functional and rheological properties of cold plasma treated rice starch. Carbohydrate Polymers, 157, 1723–1731.

Ulbin-Figlewicz, N., Brychcy, E., & Jarmoluk, A. (2015). Effect of low-pressure cold plasma on surface microflora of meat and quality attributes. Journal of Food Science and Technology, 52(2), 1228–1232.

Vleugels, M., Shama, G., Deng, X. T., Greenacre, E., Brocklehurst, T., & Kong, M. G. (2005). Atmospheric plasma inactivation of biofilm-forming bacteria for food safety control. IEEE Transactions on Plasma Science, 33(2), 824–828.

Yasuda, H., Miura, T., Kurita, H., Takashima, K., & Mizuno, A. (2010). Biological evaluation of DNA damage in bacteriophages inactivated by atmospheric pressure cold plasma. Plasma Processes and Polymers, 7(3–4), 301–308.

Yong, H. I., Kim, H.-J., Park, S., Kim, K., Choe, W., Yoo, S. J., & Jo, C. (2015). Pathogen inactivation and quality changes in sliced cheddar cheese treated using flexible thin-layer dielectric barrier discharge plasma. Food Research International, 69, 57–63.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Annor, G.A. (2019). Cold Plasma Effects on the Nutritional, Textural and Sensory Characteristics of Fruits and Vegetables, Meat, and Dairy Products. In: Roohinejad, S., Koubaa, M., Greiner, R., Mallikarjunan, K. (eds) Effect of Emerging Processing Methods on the Food Quality. Springer, Cham. https://doi.org/10.1007/978-3-030-18191-8_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-18191-8_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-18190-1

Online ISBN: 978-3-030-18191-8

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)