Abstract

Growing environmental issues, social concerns, enforced regulations and intense competition have motivated electronic companies to inculcate Reverse Logistics (RL) practices in action for sustainable Reverse Supply Chain (RSC). Due to lack of expertise and the heavy costs associated with the setting up of reverse logistics system, RL practices are widely embraced by most companies through Third Party Reverse Logistics Providers (3PRLPs). Due to the dependency of companies on 3PRLPs, the evaluation and selection of 3PRLP is a matter of strategic concern and requires critical decision-making. The main challenge in this regard that the companies face is to identify the appropriate criteria for assessing the performance of 3PRLP under a sustainable environment. In this sense, the main intent of the current study is to provide a systematic framework for an electronics company to (i) identify the most relevant 3PRLP performance evaluation criteria under three sustainability dimensions namely, economic, environmental and social, (ii) extract the most influential list of sustainable criteria and (iii) determine the weights of importance of the influential criteria. In order to attain this objective, a decision-making model is proposed in which firstly, the economic, environmental and social criteria are derived from an extensive literature survey. Secondly, Delphi technique is used to shortlist the most influential criteria. Thirdly, the Best Worst Method (BWM) is used to determine the importance of the shortlisted criteria. The result analysis shows that environmental sustainability is the primary focus of the companies for the implementation of RL, contrary to the assumption that economic performance is always the major motivation. ‘Quality’, ‘RL Practices’ and ‘Health and Safety’ are accorded the highest ranking under economic, environmental and social dimensions, respectively. The proposed model can assist electronic companies in determining the most important criteria for sustainable 3PRLP selection for outsourcing RL activities.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

17.1 Introduction

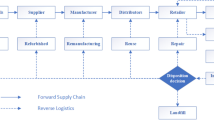

The process of Reverse Logistics (RL) involves activities aimed at the appropriate backward flow of products which are considered as reached their end-of use/end-of-life stage by the consumers [40]. Rogers and Tibben-Lembke [83] defines RL as, ‘the trend of design, schedule, planning, controlling and warehousing and also information for returned products in reverse flow of classical supply chain in order to recover value and get the competitive advantage’. Figure 17.1 provides a schematic view of the forward and reverse flow of goods and the activities involved in a generic Supply Chain (SC). RL has gained immense attention in the past two decades as a result of the environmental sensitization of consumers and governments. For businesses, RL proves to be a key strategy in managing a sustainable SC [32]. Companies are inclined towards RL nowadays due to decrease in availability of raw materials and consequently rise in their prices [46]. The specific activities of RL such as repair, remanufacture, refurbish help gain monetary benefits in terms of reselling of refurbished products while recycling, disassemble and proper disposal help in reducing the ill effects of the dumping of unused products [103]. Moreover, the backward channel provides opportunities of jobs to various marginalized workers, specifically in developing nations such as India, Bangladesh and Taiwan. Hence, all the three dimensions of sustainability are covered naturally under the umbrella of RL activities [48, 101].

Most logistics systems fail to manage the concurrent flows as they have different necessities and are managed under different constraints [27]. The forward flow is customer demand driven, while the reverse flow is driven by the quantity of products returned. Each RL process requires a different considered focus, hence companies need to plan and design RL network which is an uphill task [34]. Additionally in RL the amount of returned products is uncertain, the backward flow is untimely and the condition of the products is unknown, which adds further complexity in scheduling and planning the RL activities [89]. Organizations, particularly, in India, although are legally bound to implement RL but do not have a suitable structure in place. There are many hindering factors such as lack of knowledge, lack of government support, lack of awareness amongst consumers and other financial and organizational constraints [75]. Consequently, most organizations prefer outsourcing the complex task of managing RL activities to reduce the cost of implementation, for streamlining the recovery and redistribution process and for focusing on their core competencies [2, 28].

Outsourcing of RL activities has its own challenges and choosing a reliable and sustainable Third Party Reverse Logistics Provider (3PRLP) is a daunting task. The associated financial as well as operational impact along with the long-term effect of the partnership needs to be recognized [102]. Accordingly, the organization may choose to outsource all or some of its RL activities. Consequently, 3PRLP selection process sometimes involves choosing a single 3PRLP and other times choosing multiple 3PRLPs. Moreover, the outsourcing may be done under partial or full collaboration with 3PRLPs [24]. The strategic decision of choosing the 3PRLP, the activities to be outsourced and the nature of the partnership must be based on a critical analysis of the operational, financial, sustainable capabilities of the reverse logistics provider by the Reverse Supply Chain (RSC) managers.

Within the context of 3PRLP evaluation and selection process, identification of appropriate criteria of evaluation is of prime importance as they echo the organization’s requirements and expectations from the partnership with the 3PRLP. In addition to the traditional criteria such as cost, quality, flexibility and responsiveness, assessing the capabilities of 3PRLPs with regard to environmental and social concerns has become imperative for organizations focusing on managing sustainable SC practices [11, 15, 31]. Clearly, unlike the evaluation criteria for forward logistics provider, which is more economically driven, the evaluation criteria of 3PRLP must include environmental and social performance indicators. Hence, 3PRLP evaluation process requires a more detailed list of attributes and criteria, most of which may be difficult to quantify and involves a more difficult process of data collection [39]. Moreover, the filtration of the criteria to extract the most significant ones and the sorting of the criteria in the order of their weights of importance are essential parts of the 3PRLP selection process. Selection of criteria ideally should be company specific, case specific and industry specific as they impact the decision selection of 3PRLPs. Moreover, the process of selection of performance criteria for 3PRLP evaluation with sustainable perspective is dominated by the presence of conflicting opinions of different stakeholders of the SC of the organization, which adds to the complexity in the decision-making environment. Multiple-criteria decision-making (MCDM) techniques promise to be very effective in this regard for simultaneously evaluating various criteria based on sustainability dimensions in group decision-making environment [63].

Although there has been ample research on the need for outsourcing to 3PRLPs for achieving a sustainable RSC and the type of criteria to be considered for evaluation of 3PRLPs, however, most of these studies are theoretical in nature. Very few studies have developed mathematical models for the identification and selection of criteria in a systemized manner. This study focuses on identification and selection of key performance criteria for the evaluation of 3PRLPs based on all three dimensions of sustainability, by developing a decision-making model for an electronic company based in India. The company XYZ is looking for a partnership venture with a suitable 3PRLP with the aim of achieving a sustainable RSC. In the first stage, an exhaustive list of criteria based on economic, environmental and social dimensions is prepared through an extensive literature survey. The criteria are identified specifically for the evaluation of 3PRLPs who are providing services in the electronics industry. In order to extract the most relevant criteria as per the company’s requirements, Delphi technique is employed to gather opinions of the Decision Makers (DMs) through a structured questionnaire and semi-structured interviews. The data analysis of the information gathered through the Delphi technique helps in the first level of filtration of the criteria. In the second stage, Best Worst Method (BWM) technique is employed to rank the importance of economic, environmental and social dimensions and also to rank the criteria under the three dimensions of sustainability as per the decision-making team.

The remainder of this chapter is organized as follows: Sect. 17.2 provides literature review on the need for outsourcing in RL and the importance of sustainability related factors for evaluation and selection of 3PRLP. Section 17.3 explains the proposed methodology developed for the identification, evaluation and selection of criteria with regard to all the three dimensions of sustainability. The application of the proposed methodology is presented in Sect. 17.4. Section 17.5 provides the result discussion of the study. Section 17.6 concludes the paper and includes suggestions for future research scope.

17.2 Literature Review

The focus of the study is on the analysis of key sustainable criteria for the evaluation of third-party logistics provider in RL. The literature review presented in this section discusses the work done by researchers over the years in that direction. The literature review section is divided into three sections: Sect. 17.2.1 discusses the need for outsourcing in RL in SC; Sect. 17.2.2 demonstrates the plethora of work with regard to identification, evaluation and selection of sustainable performance criteria for provider selection in RL; Sect. 17.2.3 highlights the research gap and provides the significant contribution of the present study.

17.2.1 Outsourcing in Reverse Logistics

Forward logistics in SC refers to all activities with regard to the flow of product and information from the suppliers to the customers for satisfying customer’s needs and meeting their expectations [16]. Contrary to this, RL refers to all activities of SC aimed at managing the reverse flow of returned product from the consumption point to the origin point for the purpose of capturing value and proper disposal [83]. However, it does not imply that RL is just reversing the forward logistics [31, 64]. RL faces many complexities and its effective implementation requires suitable RL network configuration to carry the broad range of activities such as collection, sorting, inspection, disassembly, remanufacture, recycling and disposal [35]. Due to the lack of knowledge and infrastructure, most firms prefer to outsource RL activities to specialized 3PRLP for advantages such as reduced costs, advanced technology and better performance [4]. However, the problem of third party provider selection faces greater complexity for outsourcing activities related to RL in comparison to traditional forward logistics because of the major difference in their scope of work and expertise [41]. Even the most successful third-party logistics providers are not able to manage the reverse flow of products efficiently and effectively [27]. 3PRLPs must be specialized in handling the value-added activities for the reverse flow of returned products [2]. They must be well equipped to carry these activities following proper environmental guidelines [8]. Therefore, dependency of the firms on 3PRLPs is huge in terms of achievement of sustainable business practices [19]. Due to these differentiators with regard to the objective of outsourcing, 3PRLPs play a strategic role in aiding firms to attain sustainable competitive advantage, government support and customer satisfaction [40]. Hence, suitable 3PRLP selection for outsourcing in RL is a crucial decision for RSC managers and has emerged as an important research area [102].

17.2.2 Sustainable Performance Criteria for Provider Selection in Reverse Logistics

The decision of provider selection, while considering complete or partial outsourcing of the RL activities, needs the development of a comprehensive conceptual framework based on various performance metrics [1, 26]. The framework is broadly influenced by the set of criteria and the evaluation approach [105]. Identification of an appropriate set of performance criteria is a critical stage of the decision-making process, as it significantly impacts the evaluation rankings of the alternatives [13]. Hence, 3PRLP selection problem must be characterized by exhaustive research on the selection of performance criteria of evaluation of 3PRLPs. In the literature, traditional economic criteria such as cost of services, financial position, asset ownership are considered essential criteria by most authors [6, 77, 87]. Further, process-based criteria such as resource capacity, network capacity, skilled manpower, service capability, flexibility and quality of service have always been considered important for evaluation of 3PRLPs [50, 95]. Moreover, 3PRLPs offering complete RL services must be equipped with advanced equipment, specialized infrastructure and secure IT and tracking system [2]. Most organizations seek to implement RL for pursuing sustainability goals as RL activities majorly cover all sustainability dimensions [59, 74, 96, 100]. Hence, sustainability performance metrics of 3PRLPs are extremely important for a effective RSC [3, 19]. A review of research on 3PRLP evaluation and selection demonstrates that evaluation criteria based on all three dimensions of sustainability—economic, environmental and social—are dominant in the recent literature [12, 15, 31]. However, there is a lack of studies focusing on the critical analysis of 3PRLP evaluation criteria and development of mathematical models for selection of criteria with regard to industry specific requirements.

17.2.3 Research Contribution

The literature analysis presented above demonstrates that sustainability related factors are essential for the evaluation of 3PRLPs. However, none of the studies have discussed all the performance evaluation criteria in a systematic way. It is evident from the above discussion that most of the studies with regard to developing 3PRLP evaluation criteria are based on the triple bottom approach. The motivation of researchers is more on developing models for the evaluation of 3PRLPs while less emphasis is laid on the systematic identification and selection of the key criteria. Moreover, most of the studies focusing on the need for developing the criteria for evaluation of 3PRLP are based on theoretical findings and lack development of analytic models. This gap is considered in the study. Most importantly, organizations need to consider the criteria which match their requirements [73]. In this direction, this chapter aims to develop a 3PRLP selection model for an Indian electronics company for the selection of key evaluation criteria identified from the plethora of criteria in the literature and practice. The novelty of the study is to provide a systematic framework for an electronics company to achieve the following objectives:

-

1.

To identify a broad set of 3PRLP sustainable performance evaluation criteria through an extensive literature survey.

-

2.

To prioritize the key sustainable criteria based on deliberations amongst the team of experts from an electronics company using Delphi technique which is very effective in managerial decision-making.

-

3.

To determine the rank of importance of the key criteria under each sustainability dimension using BWM, an efficient MCDM technique.

17.3 Methodology used for Selection and Evaluation of Criteria

The selection process of 3PRLP ideally must involve a thorough evaluation of the performance of 3PRLPs based on key criteria based on all three sustainability dimensions. Hence, the focus of the study is to develop a systematic model which can provide guidance to the case company in (i) identifying the most relevant 3PRLP performance evaluation criteria under three sustainability dimensions namely, economic, environmental and social, (ii) extracting the most influential list of sustainable criteria and (iii) determining the weights of importance of the influential criteria. In order to attain this objective, a decision-making model is proposed, in which, firstly, the economic, environmental and social criteria are derived from an extensive literature survey. Secondly, Delphi technique is used to shortlist the most influential criteria. Thirdly, in accordance with the above evaluated results, BWM is used to determine the importance of the shortlisted criteria. The steps of the proposed methodology are described in the following sections:

17.3.1 Identification of Criteria

For the purpose of evaluation of 3PRLP, identification of relevant criteria is carried out with the aid of an extensive research analysis of studies on 3PRLP evaluation. On the basis of the broad literature review, a total of thirteen economic criteria and eleven environmental and eleven social criteria are identified. The relevant criteria have been briefly described in Tables 17.1, 17.2 and 17.3.

17.3.2 Delphi Technique for Identification of Key Sustainable Criteria for 3PRLP Evaluation

The Delphi technique is used with consideration to varying outlooks of DMs in evaluating the importance of each criterion under the three dimensions considered in this study namely, economic, environmental and social. The decision-making team included 7 members of the company each with a minimum experience of six years. They were designated as Manager Supply Chain Operations, Manager Business Operations, Manager Human Resources, Senior Manager Information and Security, General Manager CSR and Sustainability, Chief Financial Officer.

The Delphi technique can be elaborated in the following steps [60]:

- Step 1: :

-

The principal step is to identify the possible criteria for each of the three dimensions through a broad literature review. For our evaluation, we have thirteen criteria for the economic dimension, and eleven criteria each for environmental and social dimensions, respectively.

- Step 2: :

-

Post the identification of the criteria, the DMs scrutinize each and every criterion based on the sustainability impact they put on outsourcing the logistics. The dependency amongst the identified criteria is also checked.

- Step 3: :

-

Post analysis, the criteria are ranked on basis of their importance which is assessed through a developed questionnaire with the panel of experts. The DMs rank the criteria on the following scale: ‘very poor’-1, ‘poor’-2, ‘medium’-3, ‘good’-4 and ‘very good’-5.

- Step 4: :

-

The specified ranks are then collected and the mean of the ranks for each criteria is calculated. Further, normalization is done to obtain the final ranking.

- Step 5: :

-

The top six out of thirteen economic criteria, five out of eleven environmental criteria and four out of eleven social criteria are selected as per the DMs opinion.

17.3.3 Best Worst Method for Ranking of Key Sustainable Criteria for 3PRLP Evaluation

The BWM technique was developed by Rezaei, 2015 and has since been applied to numerous multi-criteria-based modelling problems [42, 84, 97]. The major advantages of using BWM over other multi-criteria-based evaluation techniques are: (i) the number of pairwise comparisons is less resulting in less time, cost and effort; (ii) it results in better consistency of the judgement matrix.

Consider the set of ‘k’ criteria \(\{C_1,C_2,\ldots ,C_k\}\) and the set of ‘m’ DMs \(\{DM_1,DM_2,\ldots ,DM_m\}\). The BWM technique to find the weights of importance of the ‘k’ criteria is briefly described below [81]:

- Step 1: :

-

Each DM is asked to select his/her best (most desirable) and the worst (least desirable) criteria.

Let \(C_B^i\) be the best criteria and \(C_W^i\) be the worst criteria of the ith DM \((i=1,2,\ldots ,m)\).

- Step 2: :

-

For each DM, the preference of the best criteria over the other criteria is calculated.

A numerical scale of 1–9 is used in this study, where a value of ‘1’ represents equal preference and a value of ‘9’ represents the extreme preference of the best criteria over the other criteria. This results in the Best-to-Others (BO) vector given by

$$\begin{aligned} \{ a_{B1}^i,a_{B2}^i,\ldots ,a_{Bk}^i\} \end{aligned}$$Where, \(a_{Bj}^i\) indicates the preference of the best criteria over jth criteria.

Also, \(a_{Bj}^i \geqslant 1 \quad \forall j=1,2,\ldots ,k\) and \(a_{BB}^i=1\).

- Step 3: :

-

For each DM, the preference of each criterion with the worst criteria is calculated. This results in the Others-to-Worst (OW) vector given by

$$ \{ a_{1W}^i,a_{2W}^i,\ldots ,a_{kW}^i\} $$Where, \(a_{jW}^i\) indicates the preference of the jth criteria over the worst criteria. Also, \(a_{jW}^i \geqslant 1 \quad \forall j=1,2,\ldots ,k\) and \(a_{WW}^i=1\).

- Step 4: :

-

Calculate the optimal weights \((v_1^i,v_2^i,\ldots ,v_k^i)\) of the criteria as per the judgement of ith DM. The objective is to ascertain the optimal weights of the criteria in order to minimize the maximum of the absolute differences \(|v_B^i-a_{Bj}^i v_j^i |\) and \(|v_j^i-a_{jW}^i v_W^i |\) for \(j=1,2,\ldots ,k\).

- Step 5: :

-

Formulate the min-max model as follows [82]:

\(\min \max \limits _{j}\{|v_B^i-a_{Bj}^i v_j^i |,|v_j^i-a_{jW}^i v_W^i |\}\)

Subject to

\(\sum \limits _{j=1}^{k} v_j^i =1\)

\(v_j^i \geqslant 0 \quad \forall j=1,2,\ldots ,k\)

- Step 6: :

-

Using \(\alpha ^i\) to denote the maximum absolute difference, formulate the following equivalent linear model for calculating weights of criteria as per the ith DM [82]:

\(\min \alpha ^i\)

Subject to

\(|v_B^i-a_{Bj}^i v_j^i | \leqslant \alpha ^i \quad \forall j=1,2,\ldots ,k\)

\(|v_j^i-a_{jW}^i v_W^i | \leqslant \alpha ^i \quad \forall j=1,2,\ldots ,k\)

\(\sum \limits _{j=1}^k v_j^i =1\)

\(v_j^i \geqslant 0 \quad \forall j=1,2,\ldots ,k\)

\(\alpha ^i\) can be considered as an indicator of the consistency of the comparisons. Its value close to zero shows a high level of consistency. The reliability of the model also relies on the value of \(\alpha ^i\). The greater the value, the less reliable the comparisons are [65].

- Step 7: :

-

Solve the linear model of BWM to get the optimal weights.

Let the optimal solution of model formulated in Step 6 be given by \(({v_1^i}^*,{v_2^i}^*,\ldots ,{v_k^i}^*)\) and the optimal objective value be \({\alpha ^i}^*\).

- Step 8: :

-

Calculate the final weights \({w_1,w_2,\ldots ,w_k}\) of criteria by taking average of the optimal weights obtained for each DM as follows:

$$ w_j=\frac{\sum \limits _{i=1}^{m}{v_j^i}^*}{m} \quad \forall j=1,2,\ldots ,k $$

17.4 Application of the Proposed Methodology

17.4.1 Identification of Key Criteria Using Delphi Technique

The objective of using the Delphi technique is to select the most important criteria according to the DMs from a list of thirteen criteria in economic dimension and eleven in environmental and social dimensions respectively. The criteria must be shortlisted on the basis of their importance in evaluating the capabilities of 3PRLPs in sustainably managing the RL operations. The Delphi technique aids in identifying the critical criteria, the inter-dependency amongst the criteria and the irrelevant criteria as per the DMs opinions and end goals. Henceforth, the key sustainable criteria are extracted as shown in Fig. 17.2.

This has resulted in finalization of six key economic criteria: (1) Financial Performance (FNP) refers to the financial capability of the 3PRLP in providing the RL services at minimum cost and its mutual commitment towards achieving liquidity and profitability for organization; (2) Resource Capacity (RCP) which refers to the capacity of the 3PRLP to invest in RL operations, facility development and other infrastructure development; (3) Quality (QL) corresponds to the quality of the service provided by the 3PRLP and the quality of the final remanufactured product, recovered parts and material; (4) Assets Management (ASSM) refers to management of the facilities and vehicles, transportation activities, manpower engaged by the 3PRLP; (5) Technology Innovation (TI) incorporates the ability of the 3PRLP to invest in technical development in order to fulfil the RL service level, provide information security system for a better communication between the facilities and advanced components and equipment for better working conditions; (6) Optimization Capabilities (OPC) refers to the technique level and the range of services provided by the 3PRLP. It also includes the inventory management, space utilization, demand forecasting and equipment handling skills of 3PRLP.

The evaluation of eleven environmental criteria using Delphi technique resulted in clustering the criteria and identifying five key criteria with the aim towards selecting 3PRLP who will be able to carry RL activities with reduced environmental degradation. The five combined environmental criteria are (1) RL Practices (RLP) which includes developing efficient logistics system by 3PRLP for carrying all RL activities such as collection, sorting, recycling, remanufacture and redistribution with emphasis on maximizing value creation and minimizing the deterioration of the environment. RLP also includes the capability of disposal of wastes in order to protect the environment; (2) Green Level (GRL) of 3PRLP is measured in terms of the green practices adopted by the 3PRLP such as green packaging using biodegradable materials and training of employees is an unavoidable practice for the safety of the environment. It also involves green design of 3PRLP’s facilities to factor in short-term as well as long-term impact on the environment; (3) Environmental Management System (EMS) refers to the commitment and alignment of 3PRLP towards the environmental objectives of the organization. Its compliance towards the environmental protection laws and environmental policies. Its efforts towards reduction of carbon footprint in every stage of the RSC; (4) Pollution Prevention and Control (PP&C) relates to measures adopted and efforts made by 3PRLPs for reduction, elimination, or prevention of pollutant emissions; (5) Resource Consumption (RCN) refers to the ability of 3PRLP to reduce the consumption of resources such as energy, raw material and water.

Eleven social criteria are evaluated and combined in the following four key criteria: (1) Human Resource Policies (HRP) which is to check compliance of 3PRLP with various ILO laws related to employee welfare and transparency towards labour equity. Compliance and transparency with regards to employment laws is very important as most RL activities in India are still conducted in an unorganized manner involving women and children to work in hazardous conditions; (2) Stakeholder Empowerment (STE) refers to the contribution of 3PRLP towards educating and empowering its stakeholders. It also refers to the ability of the 3PRLP to respond effectively towards company’s and customer requirements; (3) Employment Practices (EMP) refers to how effectively 3PRLP has managed to build relationship with staff. Additionally, it also includes the attitude of 3PRLP towards employment compensation, flexible working arrangements and career development; (4) Health and Safety (H&S) refers to the policies adopted by 3PRLP to ensure the safety of the employees, provide security, and maintaining an environment friendly workplace for the health of the employees.

17.4.2 Evaluation of Key Sustainable Criteria Using Best Worst Method

Next, the BWM technique is utilized to prioritize the key performance criteria under the triple bottom line approach and reduce the existence of inconsistency of DMs. Four BWM models are formulated—Model 1 is for finding the rank of importance of the three sustainability dimensions viz. economic, environmental and social. Table 17.4 below provides the weights of each dimension obtained from solving model 1 on the basis of preferences given by DM 1. It can be seen from Table 17.4 the value of \(\alpha ^1\) for model 1 is 0.045, which is closer to zero. Hence, the evaluation of DM1 is consistent.

Similarly, evaluation of weights of the other six DMs are determined and the final average weights of the three sustainability dimensions are calculated. The result is shown graphically in Fig. 17.3. It can be seen that the environmental dimension gains the highest average weight with the economic dimension following at second number and the social dimension achieves the third rank.

BWM technique is also used for evaluating the criteria under the three sustainability dimensions as illustrated in Fig. 17.2. The results of the three BWM models are presented in Tables 17.5, 17.6 and 17.7. Table 17.5 represents the weights of the top six shortlisted economic criteria obtained from solving model 2 on the basis of preferences given by DM 1. The value of \(\alpha ^1\) for model 2, in this case, is 0.094, which means the comparison of criteria for DM1 is consistent.

Similarly, evaluation of weights of the other six DMs are determined and the final average weights of the criteria under economic dimension are calculated. The result is shown graphically in Fig. 17.4. The top six amongst the thirteen criteria in the descending order of their average weights are; ‘Quality’ (QL) (0.375), ‘Financial Performance’ (FNP) (0.234), ‘Resource Capacity’ (RCP) (0.156), ‘Technology Innovation’ (TI) (0.094), ‘Optimization Capabilities’ (OPC) (0.094) and ‘Assets Management’ (ASSM) (0.047).

Table 17.6 represents the weights of the top five shortlisted environmental criteria obtained from model 3 on the basis of preferences given by DM 1. The value of \(\alpha ^1\) for model 3 is obtained as 0.095, which shows the comparison is consistent for DM1.

Similarly, evaluation of weights of the other six DMs are determined and the final average weights of the criteria under environmental dimension are calculated. The result is shown graphically in Fig. 17.5. The top five criteria in descending order of their average weights are: ‘RL Practices’ (RLP) (0.437), ‘Environmental Management System’ (EMS) (0.266), ‘Green Level’ (GRL) (0.133), ‘Pollution Prevention and Control’ (PP&C) (0.106), ‘Resource Consumption’ (RCN) (0.057).

Table 17.7 represents the weights of the top four shortlisted social criteria obtained from model 4 on the basis of preferences given by DM 1. The value of \(\alpha ^1\) for model 4 is 0.044, the consistency ratio is very close to zero, hence the result is reliable.

Similarly, evaluation of weights of the other six DMs are determined and the final average weights of the criteria under social dimension are calculated. The result is shown graphically in Fig. 17.6. In today’s era, an organization needs to have respect for policies with regard to employee health and safety, workplace safety, security and safety procedural compliance. Hence, it must also give emphasis on the same aspects while evaluation of 3PRLP. The criteria in the descending order of their average weights are; ‘Health and Safety’ (H&S) (0.485), ‘Employment Practices’ (EMP) (0.265), ‘Human Resource Policies’ (HRP) (0.176), ‘Stakeholder Empowerment’ (STE) (0.074).

17.5 Result Discussion

The sustainability criteria shortlisted using Delphi technique are evaluated under each dimension using BWM. Next, the weights of importance of the three dimensions of sustainability are derived using BWM. The results of the four BWM models have been presented in Tables 17.4, 17.5, 17.6 and 17.7. Table 17.4 provides the weights of each dimension obtained from solving model 1. It can be seen that the environmental dimension gains the highest weight with the economic dimension following at second number and the social dimension achieves the third rank. The environmental dimension being ranked first is reflective of the DMs opinion that the primary objective of the organization in choosing to outsource to 3PRLP is to manage the returned flow of products and associated activities in an environmentally safe manner. The second rank of economic dimension shows that financial performance and RL associated costs hold importance for bringing profit to the organization. The social dimension is ranked third, which implies that workplace safety and employment practices although important for the company, are not given more importance than environmental and economic aspects.

Table 17.5 shows the top six amongst the thirteen economic criteria. ‘QL’ plays an important role in outsourcing to 3PRLP as the quality of the recycled material, refurbished product and quality service are important for creating value for customers and which is the idea behind RL. Also, it can be seen from Table 17.4 that the environmental dimension ranks first which shows that for the company, the focus is on ‘RLP’ for the environmental gains in terms of quality recovery of products and materials. Further, in outsourcing logistics, an important concern for the organization is that 3PRLP is mutually committed towards its business needs. In this context, ‘FNP’ has hence been ranked second, which refers to the ability of the 3PRLP to gain economic benefits from RSC performance for the organization. Next, ‘RCP’ which ranks third measures the capability of 3PRLP to invest in RL network operations and specialized infrastructure. The criteria ‘TI’ and ‘OPC’ hold the same level of importance. Both criteria have relevance in measuring the ability of 3PRLP to invest in strong technical development and efficiently manage RSC processes.

Table 17.6 represents the weights of the top five shortlisted environmental criteria obtained from model 3. Due to increase in environmental pollution, stakeholders demand for reduction of carbon footprint in every stage of the RSC. This justifies the obtained rankings of the criteria based on judgments of the DMs. ‘RLP’ is the highest ranked criteria under the environmental dimension. In RL, sustainability is of utmost importance and for that 3PRLP must focus on execution of all ‘RLP’ efficiently and enhancement of safe recycling and disposal capability. Ranked second is ‘EMS’, as the company is strict about compliance towards environmental policies. Hence, it wants to associate with 3PRLP who actively monitors the environmental level of their ‘RLP’ and adheres to all the environmental protection laws and environmental policies. ‘GRL’ is ranked third, which measures the capability of 3PRLP to focus on the green design of facilities to factor in short-term as well as long-term impact on the environment, in order to enhance the environmental performance of the RSC network.

Table 17.7 represents the weights of the top four shortlisted social criteria obtained from model 4. The criteria ‘H&S’ has received the first rank, which shows that the company is concerned towards not only maintaining safety standards for their organization, but also expect the same from the 3PRLP. Ranked second is ‘EMP’, which means the 3PRLP must have the ability to contribute towards career development of their employees while also providing opportunities to the local people for the development of regional sustainability. Ranked third is ‘HRP’ as compliance with various ILO laws relating to employee welfare is needed in RL. It is essential as many unorganized sectors use unscientific methods to recycle and recover full value from the returned products.

A comparative ranking of weights of the three dimensions of sustainability for 3PRLP evaluation and within each dimension the importance of criteria as per the DMs has been shown graphically in Fig. 17.7. It gives a clear picture to the RSC managers regarding how much emphasis must be laid on the criteria for the evaluation of 3PRLP for achieving sustainability.

17.6 Conclusion

Concerning the result analysis, the conclusion of the study is presented. The identification of key performance criteria for 3PRLPs is complex. This research has attempted an integrated MCDM model, which combines Delphi and BWM techniques to evaluate and select the appropriate key performance criteria for the selection of sustainable 3PRLPs. The proposed model is applied in the electronic industry to check the applicability and validity of the model. From the list of sustainable criteria derived from a broad literature review, few are shortlisted and weighted in order to acquire the main aspects for the assessment of sustainable performance of 3PRLPs. Delphi technique has been applied for the first level of screening of the criteria which is based on the results of various levels of questionnaires sent to a panel of experts and choosing the most prominent criteria of economic, environmental and social dimensions according to the DMs. The criteria have been shortlisted on the basis of their importance in evaluating the sustainable performance of 3PRLPs. Post the Delphi technique, the inter-dependent key criteria have been clubbed together to acquire a smaller number of criteria to ease the complexity of the decision-making. Next, the methodology involves the BWM technique to prioritize the key performance criteria under the triple bottom line approach. Four BWM models have been formulated. First model is for finding the rank of importance of the three sustainability dimensions viz. economic, environmental and social. Next, three BWM models are utilized to find the rank of importance of all criteria under each sustainability dimension. The result of model 1 shows that the environmental dimension has achieved the highest preference since the motivation behind RL is to achieve reduce the negative impact of the SC activities, and hence environmental sustainability is the foremost responsibility of the 3PRLPs. The importance of environmental dimension justifies the DMs outlook on the criteria selection. As per the result derived from model 2, QL and FNP have been the topmost key performance criteria under the economic dimension. QL is of great importance as the quality of service and product is of high significance for a customer, whereas FNP refers to the economic benefits for the company from the RL operations. Value for customers and economic benefits have been the idea behind RL. The result of model 3 yields RLP and EMS as the top two criteria under environmental dimension. This ascertains that reduction of carbon footprint and compliance towards environmental policies in RSC are the major goals towards sustainability. Lastly, model 4 solved for social dimension yields H&S and EMP as the top two social criteria. It is justifiable as safety and opportunity for employees is a major consideration for the organization and hence expect the same from 3PRLP. The obtained results validate that the integrated decision-making model proposed in the study successfully addresses the sustainable performance criteria selection problem. The final list of criteria derived in the study along with their rank of importance, sustainable 3PRLP selection problem can prove to be very useful in sustainable 3PRLP selection problem. There are a few limitations of the study. The criteria identified in the study broadly covers all the sustainable aspects of the evaluation of 3PRLPs. However, the study is limited to electronic industries. Further, the criteria selection is based on the opinions of the DMs of a specific industry which can vary when applied to other case studies. However, it has a lot of scope for modification by researchers and practitioners with regard to the change in the decision-making environment. This study can also be expanded by incorporating the risk dimension, as risk is an important factor to be taken under control while performing the RL. Risk factors like financial risk, operational risk and organizational risk can be considered while selecting the 3PRLPs.

References

Agrawal, S., Singh, R.K., Murtaza, Q.: A literature review and perspectives in reverse logistics. Resour. Conserv. Recycl. 97, 76–92 (2015)

Agrawal, S., Singh, R.K., Murtaza, Q.: Outsourcing decisions in reverse logistics: sustainable balanced scorecard and graph theoretic approach. Resour. Conserv. Recycl. 108, 41–53 (2016)

Agrawal, S., Singh, R.K., Murtaza, Q.: Reverse supply chain issues in Indian electronics industry: a case study. J. Remanuf. 8(3), 115–129 (2018)

Aguezzoul, A.: Third-party logistics selection problem: a literature review on criteria and methods. Omega 49, 69–78 (2014)

Aktas, E., Agaran, B., Ulengin, F., Onsel, S.: The use of outsourcing logistics activities: the case of turkey. Transp. Res. Part C: Emerg. Technol. 19(5), 833–852 (2011)

Ali, S.M., Arafin, A., Moktadir, M.A., Rahman, T., Zahan, N.: Barriers to reverse logistics in the computer supply chain using interpretive structural model. Global J. Flex. Syst. Manag. 19(1), 53–68 (2018)

Andersson, D., Norrman, A.: Procurement of logistics services - a minutes work or a multi-year project? Eur. J. Purch. Supply Manag. 8(1), 3–14 (2002)

Anttonen, M., Halme, M., Houtbeckers, E., Nurkka, J.: The other side of sustainable innovation: is there a demand for innovative services? J. Clean. Prod. 45, 89–103 (2013)

Awasthi, A., Chauhan, S.S., Goyal, S.K.: A fuzzy multicriteria approach for evaluating environmental performance of suppliers. Int. J. Prod. Econ. 126(2), 370–378 (2010)

Bai, C., Sarkis, J.: Integrating sustainability into supplier selection with grey system and rough set methodologies. Int. J. Prod. Econ. 124(1), 252–264 (2010)

Bai, C., Sarkis, J.: Flexibility in reverse logistics: a framework and evaluation approach. J. Clean. Prod. 47, 306–318 (2013)

Bai, C., Sarkis, J.: Integrating and extending data and decision tools for sustainable third-party reverse logistics provider selection. Comput. Oper. Res. 110, 188–207 (2019)

Bouzon, M., Govindan, K., Rodriguez, C.M.T., Campos, L.M.: Identification and analysis of reverse logistics barriers using fuzzy Delphi method and AHP. Resour. Conserv. Recycl. 108, 182–197 (2016)

Boyson, S., Corsi, T., Dresner, M., Rabinovich, E.: Managing effective third party logistics relationships: what does it take? J. Bus. Logist. 20(1), 73 (1999)

Centobelli, P., Cerchione, R., Esposito, E.: Environmental sustainability in the service industry of transportation and logistics service providers: systematic literature review and research directions. Transp. Res. Part D: Transport Environ. 53, 454–470 (2017)

Chopra, S., Meindl, P., Kalra, D.V.: Supply Chain Management: Strategy, Planning, and Operation, vol. 232. Pearson, Boston (2013)

Choy, K.L., Chow, H.K., Tan, K.H., Chan, C.K., Mok, E.C., Wang, Q.: Leveraging the supply chain flexibility of third party logistics - hybrid knowledge-based system approach. Expert Syst. Appl. 35(4), 1998–2016 (2008)

Cochran, J.K., Ramanujam, B.: Carrier-mode logistics optimization of inbound supply chains for electronics manufacturing. Int. J. Prod. Econ. 103(2), 826–840 (2006)

Colicchia, C., Marchet, G., Melacini, M., Perotti, S.: Building environmental sustainability: empirical evidence from logistics service providers. J. Clean. Prod. 59, 197–209 (2013)

da Silveira Guimarães, J.L., Salomon, V.A.P.: ANP applied to the evaluation of performance indicators of reverse logistics in footwear industry. Procedia Comput. Sci. 55, 139–148 (2015)

Deng, W.J., Giesy, J.P., So, C.S., Zheng, H.L.: End-of-life (EoL) mobile phone management in Hong Kong households. J. Environ. Manag. 200, 22–28 (2017)

Dou, Y., Sarkis, J.: A joint location and outsourcing sustainability analysis for a strategic offshoring decision. Int. J. Prod. Res. 48(2), 567–592 (2010)

Efendigil, T., Önüt, S., Kongar, E.: A holistic approach for selecting a third-party reverse logistics provider in the presence of vagueness. Comput. Ind. Eng. 54(2), 269–287 (2008)

Fawcett, S.E., Fawcett, A.M., Watson, B.J., Magnan, G.M.: Peeking inside the black box: toward an understanding of supply chain collaboration dynamics. J. Supply Chain Manag. 48(1), 44–72 (2012)

Gauthier, C.: Measuring corporate social and environmental performance: the extended life-cycle assessment. J. Bus. Ethics 59(1–2), 199–206 (2005)

Geethan, K.A.V., Jose, S., Chandar, C.S.: Methodology for performance evaluation of reverse supply chain. Int. J. Eng. Technol. 3(3), 213–224 (2011)

Genchev, S.E., Richey, R.G., Gabler, C.B.: Evaluating reverse logistics programs: a suggested process formalization. Int. J. Logist. Manag. (2011)

Giri, B.C., Sarker, B.R.: Improving performance by coordinating a supply chain with third party logistics outsourcing under production disruption. Comput. Ind. Eng. 103, 168–177 (2017)

Goebel, P., Reuter, C., Pibernik, R., Sichtmann, C.: The influence of ethical culture on supplier selection in the context of sustainable sourcing. Int. J. Prod. Econ. 140(1), 7–17 (2012)

Göl, H., Çatay, B.: Third-party logistics provider selection: insights from a Turkish automotive company. Supply Chain Manag.: Int. J. (2007)

Govindan, K., Cheng, T.C.E.: Sustainable supply chain management. Comput. Oper. Res. 54(C), 177–179 (2015)

Govindan, K., Soleimani, H.: A review of reverse logistics and closed-loop supply chains: a journal of cleaner production focus. J. Clean. Prod. 142, 371–384 (2017)

Govindan, K., Pokharel, S., Sasikumar, P.: A hybrid approach using ISM and fuzzy TOPSIS for the selection of reverse logistics provider. Resour. Conserv. Recycl. 54, 28–36 (2009)

Govindan, K., Palaniappan, M., Zhu, Q., Kannan, D.: Analysis of third party reverse logistics provider using interpretive structural modeling. Int. J. Prod. Econ. 140(1), 204–211 (2012)

Govindan, K., Sarkis, J., Palaniappan, M.: An analytic network process-based multicriteria decision making model for a reverse supply chain. Int. J. Adv. Manuf. Technol. 68(1–4), 863–880 (2013)

Govindan, K., Khodaverdi, R., Jafarian, A.: A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. J. Clean. Prod. 47, 345–354 (2013)

Govindan, K., Khodaverdi, R., Vafadarnikjoo, A.: A grey DEMATEL approach to develop third-party logistics provider selection criteria. Ind. Manag. Data Syst. (2016)

Govindan, K., Kadziński, M., Sivakumar, R.: Application of a novel PROMETHEE-based method for construction of a group compromise ranking to prioritization of green suppliers in food supply chain. Omega 71, 129–145 (2017)

Govindan, K., Agarwal, V., Darbari, J.D., Jha, P.C.: An integrated decision making model for the selection of sustainable forward and reverse logistic providers. Ann. Oper. Res. 273(1–2), 607–650 (2019)

Govindan, K., Kadziński, M., Ehling, R., Miebs, G.: Selection of a sustainable third-party reverse logistics provider based on the robustness analysis of an outranking graph kernel conducted with ELECTRE I and SMAA. Omega 85, 1–15 (2019)

Guarnieri, P., Sobreiro, V.A., Nagano, M.S., Serrano, A.L.M.: The challenge of selecting and evaluating third-party reverse logistics providers in a multicriteria perspective: a Brazilian case. J. Clean. Prod. 96, 209–219 (2015)

Gupta, H., Barua, M.K.: Supplier selection among SMEs on the basis of their green innovation ability using BWM and fuzzy TOPSIS. J. Clean. Prod. 152, 242–258 (2017)

Hasan, M.: Sustainable supply chain management practices and operational performance (2013)

Hong, J., Chin, A.T., Liu, B.: Logistics outsourcing by manufacturers in China: a survey of the industry. Transp. J. 17–25 (2004)

Hwang, B.N., Shen, Y.C.: Decision making for third party logistics supplier selection in semiconductor manufacturing industry: a nonadditive fuzzy integral approach. Math. Probl. Eng. (2015)

John, S.T., Sridharan, R., Kumar, P.R.: Reverse logistics network design: a case of mobile phones and digital cameras. Int. J. Adv. Manuf. Technol. 94(1–4), 615–631 (2018)

Kafa, N., Hani, Y., El Mhamedi, A.: A fuzzy multi criteria approach for evaluating sustainability performance of third-party reverse logistics providers. In: IFIP International Conference on Advances in Production Management Systems, pp. 270–277. Springer, Berlin (2014)

Kannan, D.: Role of multiple stakeholders and the critical success factor theory for the sustainable supplier selection process. Int. J. Prod. Econ. 195, 391–418 (2018)

Kannan, G., Haq, A.N.: Analysis of interactions of criteria and sub-criteria for the selection of supplier in the built-in-order supply chain environment. Int. J. Prod. Res. 45(17), 3831–3852 (2007)

Kannan, G., Murugesan, P., Senthil, P., Noorul Haq, A.: Multicriteria group decision making for the third party reverse logistics service provider in the supply chain model using fuzzy TOPSIS for transportation services. Int. J. Serv. Technol. Manag. 11(2), 162–181 (2009)

Keshavarz Ghorabaee, M., Amiri, M., Kazimieras Zavadskas, E., Antuchevičienė, J.: Assessment of third-party logistics providers using a CRITIC–WASPAS approach with interval type-2 fuzzy sets. Transport 32(1), 66–78 (2017)

Klassen, R.D., Whybark, D.C.: The impact of environmental technologies on manufacturing performance. Acad. Manag. J. 42(6), 599–615 (1999)

Knemeyer, A.M., Ponzurick, T.G., Logar, C.M.: A qualitative examination of factors affecting reverse logistics systems for end-of-life computers. Int. J. Phys. Distrib. Logist. Manag. (2002)

Labuschagne, C., Brent, A.C., Van Erck, R.P.: Assessing the sustainability performances of industries. J. Clean. Prod. 13(4), 373–385 (2005)

Lai, K.H., Wu, S.J., Wong, C.W.: Did reverse logistics practices hit the triple bottom line of Chinese manufacturers? Int. J. Prod. Econ. 146(1), 106–117 (2013)

Lambert, S., Riopel, D., Abdul-Kader, W.: A reverse logistics decisions conceptual framework. Comput. Ind. Eng. 61(3), 561–581 (2011)

Lao, S.I., Choy, K.L., Ho, G.T.S., Tsim, Y.C., Chung, N.S.H.: Determination of the success factors in supply chain networks: a Hong Kong-based manufacturer’s perspective. Meas. Bus. Excell. (2011)

Li, F., Li, L., Jin, C., Wang, R., Wang, H., Yang, L.: A 3PL supplier selection model based on fuzzy sets. Comput. Oper. Res. 39(8), 1879–1884 (2012)

Li, J., Wang, Z., Jiang, B.: Managing economic and social profit of cooperative models in three-echelon reverse supply chain for waste electrical and electronic equipment. Front. Environ. Sci. Eng. 11(5), 12 (2017)

Linstone, H.A., Turoff, M. (eds.): The Delphi Method, pp. 3–12. Addison-Wesley, Reading (1975)

Liou, J.J., Tamošaitienė, J., Zavadskas, E.K., Tzeng, G.H.: New hybrid COPRAS-G MADM model for improving and selecting suppliers in green supply chain management. Int. J. Prod. Res. 54(1), 114–134 (2016)

Liu, H.T., Wang, W.K.: An integrated fuzzy approach for provider evaluation and selection in third-party logistics. Expert Syst. Appl. 36(3), 4387–4398 (2009)

Mavi, R.K., Goh, M., Zarbakhshnia, N.: Sustainable third-party reverse logistic provider selection with fuzzy SWARA and fuzzy MOORA in plastic industry. Int. J. Adv. Manuf. Technol. 91(5–8), 2401–2418 (2017)

Meade, L., Sarkis, J., Presley, A.: The theory and practice of reverse logistics. Int. J. Logist. Syst. Manag. 3(1), 56–84 (2007)

Mi, X., Tang, M., Liao, H., Shen, W., Lev, B.: The state-of-the-art survey on integrations and applications of the best worst method in decision making: why, what, what for and what’s next? Omega 87, 205–225 (2019)

Mothilal, S., Gunasekaran, A., Nachiappan, S.P., Jayaram, J.: Key success factors and their performance implications in the Indian third-party logistics (3PL) industry. Int. J. Prod. Res. 50(9), 2407–2422 (2012)

Muller, A., Kolk, A.: CSR performance in emerging markets evidence from Mexico. J. Bus. Ethics 85(2), 325–337 (2009)

Nikolaou, I.E., Evangelinos, K.I.: A framework for evaluating the social responsibility quality of reverse logistics. Quality Management in Reverse Logistics, pp. 53–72. Springer, London (2013)

Nikolaou, I.E., Evangelinos, K.I., Allan, S.: A reverse logistics social responsibility evaluation framework based on the triple bottom line approach. J. Clean. Prod. 56, 173–184 (2013)

Nnorom, I.C., Osibanjo, O.: Toxicity characterization of waste mobile phone plastics. J. Hazard. Mater. 161(1), 183–188 (2009)

Pamučar, D., Stević, Ž., Zavadskas, E.K.: Integration of interval rough AHP and interval rough MABAC methods for evaluating university web pages. Appl. Soft Comput. 67, 141–163 (2018)

Parast, M.M., Adams, S.G.: Corporate social responsibility, benchmarking, and organizational performance in the petroleum industry: a quality management perspective. Int. J. Prod. Econ. 139(2), 447–458 (2012)

Perçin, S.: An integrated fuzzy SWARA and fuzzy AD approach for outsourcing provider selection. J. Manuf. Technol. Manag. (2019)

Prajapati, H., Kant, R., Shankar, R.: Bequeath life to death: state-of-art review on reverse logistics. J. Clean. Prod. 211, 503–520 (2019)

Prakash, C., Barua, M.K.: Integration of AHP-TOPSIS method for prioritizing the solutions of reverse logistics adoption to overcome its barriers under fuzzy environment. J. Manuf. Syst. 37, 599–615 (2015)

Prakash, C., Barua, M.K.: A combined MCDM approach for evaluation and selection of third-party reverse logistics partner for Indian electronics industry. Sustain. Prod. Consum. 7, 66–78 (2016)

Prakash, C., Barua, M.K.: An analysis of integrated robust hybrid model for third-party reverse logistics partner selection under fuzzy environment. Resour. Conserv. Recycl. 108, 63–81 (2016)

Presley, A., Meade, L., Sarkis, J.: A strategic sustainability justification methodology for organizational decisions: a reverse logistics illustration. Int. J. Prod. Res. 45(18–19), 4595–4620 (2007)

Ravi, V., Shankar, R., Tiwari, M.K.: Productivity improvement of a computer hardware supply chain. Int. J. Product. Perform. Manag. (2005)

Razzaque, M.A., Sheng, C.C.: Outsourcing of logistics functions: a literature survey. Int. J. Phys. Distrib. Logist. Manag. (1998)

Rezaei, J.: Best-worst multi-criteria decision-making method. Omega 53, 49–57 (2015)

Rezaei, J.: Best-worst multi-criteria decision-making method: some properties and a linear model. Omega 64, 126–130 (2016)

Rogers, D.S., Tibben-Lembke, R.S.: Going backwards: reverse logistics trends and practices. The University of Nevada, Reno. Center for Logistics Management, Reverse Logistics Council (1998)

Salimi, N., Rezaei, J.: Evaluating firms’ R&D performance using best worst method. Eval. Program Plan. 66, 147–155 (2018)

Sarkis, J., Talluri, S.: A model for strategic supplier selection. J. Supply Chain Manag. 38(4), 18–28 (2002)

Sarkis, J., Helms, M.M., Hervani, A.A.: Reverse logistics and social sustainability. Corp. Soc. Responsib. Environ. Manag. 17(6), 337–354 (2010)

Sasikumar, P., Haq, A.N.: Analysing interactions among battery recycling barriers in the reverse supply chain. Enterprise Networks and Logistics for Agile Manufacturing, pp. 249–269. Springer, London (2010)

Sasikumar, P., Haq, A.N.: Integration of closed loop distribution supply chain network and 3PRLP selection for the case of battery recycling. Int. J. Prod. Res. 49(11), 3363–3385 (2011)

Serrato, M.A., Ryan, S.M., Gaytán, J.: A Markov decision model to evaluate outsourcing in reverse logistics. Int. J. Prod. Res. 45(18–19), 4289–4315 (2007)

Sharma, S.K., Kumar, V.: Optimal selection of third-party logistics service providers using quality function deployment and Taguchi loss function. Benchmarking: Int. J. (2015)

Singh, R., Shankar, R., Kumar, P., Singh, R.K.: A fuzzy AHP and TOPSIS methodology to evaluate 3PL in a supply chain. J. Model. Manag. (2012)

Stock, G.N., Greis, N.P., Kasarda, J.D.: Logistics, strategy and structure. Int. J. Oper. Prod. Manag. (1998)

Tan, A.W.K., Yu, W.S., Arun, K.: Improving the performance of a computer company in supporting its reverse logistics operations in the Asia-Pacific region. Int. J. Phys. Distrib. Logist. Manag. (2003)

Tate, K.: The elements of a successful logistics partnership. Int. J. Phys. Distrib. Logist. Manag. (1996)

Tavana, M., Zareinejad, M., Santos-Arteaga, F.J., Kaviani, M.A.: A conceptual analytic network model for evaluating and selecting third-party reverse logistics providers. Int. J. Adv. Manuf. Technol. 86(5–8), 1705–1721 (2016)

Turki, S., Sauvey, C., Rezg, N.: Modelling and optimization of a manufacturing/remanufacturing system with storage facility under carbon cap and trade policy. J. Clean. Prod. 193, 441–458 (2018)

van de Kaa, G., Kamp, L., Rezaei, J.: Selection of biomass thermochemical conversion technology in the Netherlands: a best worst method approach. J. Clean. Prod. 166, 32–39 (2017)

Wu, C., Barnes, D.: An integrated model for green partner selection and supply chain construction. J. Clean. Prod. 112, 2114–2132 (2016)

Yayla, A.Y., Oztekin, A., Gumus, A.T., Gunasekaran, A.: A hybrid data analytic methodology for 3PL transportation provider evaluation using fuzzy multi-criteria decision making. Int. J. Prod. Res. 53(20), 6097–6113 (2015)

Yu, H., Solvang, W.D.: Incorporating flexible capacity in the planning of a multi-product multi-echelon sustainable reverse logistics network under uncertainty. J. Clean. Prod. 198, 285–303 (2018)

Zarbakhshnia, N., Jaghdani, T.J.: Sustainable supplier evaluation and selection with a novel two-stage DEA model in the presence of uncontrollable inputs and undesirable outputs: a plastic case study. Int. J. Adv. Manuf. Technol. 97(5–8), 2933–2945 (2018)

Zarbakhshnia, N., Soleimani, H., Ghaderi, H.: Sustainable third-party reverse logistics provider evaluation and selection using fuzzy SWARA and developed fuzzy COPRAS in the presence of risk criteria. Appl. Soft Comput. 65, 307–319 (2018)

Zarbakhshnia, N., Soleimani, H., Goh, M., Razavi, S.S.: A novel multi-objective model for green forward and reverse logistics network design. J. Clean. Prod. 208, 1304–1316 (2019)

Zarbakhshnia, N., Wu, Y., Govindan, K., Soleimani, H.: A novel hybrid multiple attribute decision-making approach for outsourcing sustainable reverse logistics. J. Clean. Prod. 242, 118461 (2020)

Zhang, R., Zhang, H., Liu, B.: Selection of reverse-logistics servicer for electronic products with fuzzy comprehensive evaluation method. Grey Syst.: Theory Appl. (2012)

Acknowledgements

We would like to show our gratitude to the anonymous reviewers for their valuable comments and suggestions to improve the chapter.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Darbari, J.D., Sharma, S., Pinto, M.C.B. (2021). Identification and Analysis of Key Sustainable Criteria for Third Party Reverse Logistics Provider Selection Using the Best Worst Method. In: Laha, V., Maréchal, P., Mishra, S.K. (eds) Optimization, Variational Analysis and Applications. IFSOVAA 2020. Springer Proceedings in Mathematics & Statistics, vol 355. Springer, Singapore. https://doi.org/10.1007/978-981-16-1819-2_17

Download citation

DOI: https://doi.org/10.1007/978-981-16-1819-2_17

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1818-5

Online ISBN: 978-981-16-1819-2

eBook Packages: Mathematics and StatisticsMathematics and Statistics (R0)