Abstract

In this chapter, the authors focus on the impact of artificial intelligence (AI) and associated technological changes on work and jobs in Australia’s utility sector. The chapter comprises extensive commentary on the collective effects of AI incorporating machine learning, big data, blockchain, and other technological advances. The aim is to attempt to predict vocational areas in this industry sector that may diminish, noting that it is a demanding task amidst a plethora of differing views. The analysis mainly focuses on disruptive technology in a relatively broad context that is intended to complement knowledge contributed within other chapters that focus on different industry sectors.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

Introduction

This chapter focuses on the impact of artificial intelligence on the utility sector in relation to employment. The utility sector provides basic amenities, such as water, sewage services, electricity, natural gas, and renewable energy. In this chapter, an industry overview is outlined, along with prominent new technologies that impact on productivity and the workforce as well as relevant challenges and opportunities. The chapter ends by outlining the key issues identified in the research.

Industry Overview

The energy industry overlaps with the utility industry in terms of the overall responsibility for the production and distribution of energy, water, and gas throughout Australia. The utility industry sector comprises companies participating in the exploration and development of coal, uranium, oil and gas and renewable energy assets (Australian Stock Exchange 2013).

Australia has rich natural resources and possesses extensive energy assets (Australian Stock Exchange 2013; Australian Renewable Energy Agency 2018). Australia is also the world’s largest coal exporter and a major supplier of LNG (Liquefied Natural Gas) and Uranium to world markets, in particular Asia. Companies in the utility sector are generally involved in water, electricity, and gas distribution, generation, and infrastructure. The utility industry is charged with responsibility for the infrastructure used to provide public services, sewerage systems, power line distribution, stormwater drains, and more. The utility sector, including energy, has major employers among its ranks in all states creating approximately 155,000 jobs for electrical engineers, civil engineers, chemical engineers, and many other professionals (Nichols n.d.).

Many other occupations feature in this sector and as illustrated in Table 12.1, the jobs included range from professions to trades, semi-skilled and unskilled jobs. These will be outlined with estimations on the level that AI is expected to impact on jobs and the future of employment in this sector. In 2013 Bloomberg estimated the market capital worth of the top 100 stocks in the energy and utilities field to be worth a sizeable AUD $130.5 billion (Australian Stock Exchange 2013).

In the next decade, it is anticipated by (Nichols n.d.) that this industry sector will alter significantly (Lauterbach and Bonime-Blanc 2018). The research points to three main challenges. These include: (i) growing demand for renewable energy sources, (ii) a mounting need to invest in Australia’s energy infrastructure, and (iii) the pressure to adapt to revised policies and public expectations, as private and public organisations meet environmental changes and challenges aided by artificial intelligence which is having a considerable impact on the utility sector (Lauterbach and Bonime-Blanc 2018).

Employment Impact

Industry 4.0 (I4.0) technologies, including automation and artificial intelligence (AI), may cause some labour-intensive jobs to become obsolete (Skilton and Hovsepian 2018; Susskind 2020; World Economic Forum 2020). However, at the same time, the transformation process brings in new business opportunities to the market, which creates new jobs (Furness 2019). Most of the tools and equipment in the utility sector are designed to be operated and maintained by the workforce and most likely, technological developments will continuously augment the workforce. Vocational fields under threat of abolition due to automation in all industries involve repetitive and routine work (Frey and Osborne 2017; Manpower Group 2018; O’Neill 2017; Susskind 2020; World Economic Forum 2016). As pointed out previously many people work in semi-skilled and unskilled positions work in the utility industry sector (Job Outlook 2020). To further substantiate the notion that many routine/repetitive jobs are at risk, (Manyika et al. 2017) cite copious largescale studies which claim such occupations were at risk. They contend that in all industries, including the utility sector, there will be change that is propelled by emerging technologies in the 4th industrial revolution (4IR) that will eliminate activities that involve routine vocational tasks – including physical work and many other jobs – that reduce the need to employ people (Manyika et al. 2017). Currently, however, humans are good at handling complex problems and, with interpretations of sensory perception, while machines are better with repetitive tasks that require high precision and speed (Susskind 2020).

Apart from processes that involve physical machines, automation can also bring transformations to paper-based and management workflows that exist in all businesses (Susskind 2020; Manyika et al. 2017). Filing robots can undertake and data entry tasks at high speed and with a low error rate (Susskind 2020; Manyika et al. 2017). With an effectively designed AI algorithm, relatively fairer judgements can be made in some day-to-day decision-making processes. Businesses can also reduce their expenditure on recruiting and training management personnel (Dignan 2020).

The utility industry, which was considered a slow mover in technology adoption, needs to increase its competitive edge by undertaking digital transformation while facing new challenges – including competition from new sources driven by technology and by changes in consumer demand (ABI Research 2019). In some countries the utility industry has been upgrading its infrastructure by conducting digital transformation (ABI Research 2019) with projects costing US$14 billion being spent on modernising the infrastructure of the utility industry in the United States. In addition, an estimated 55% of the total expense on security measures will be spent on securing smart infrastructure to tackle the rising cybersecurity risk (ABI Research 2019).

New technologies such as the Internet of Things (IoT) and big data enable new perspectives on renewable energy, storage, and distributed energy resources (DERs). In 2015, more than 250 million IoT devices were installed in utilities, globally (APEC 2015). IoT spending in 2019 is expected to be US$726 billion, and it is anticipated that US$1 trillion will be exceeded in 2022 (IDC 2019). Moreover, big data plays a vital role in making use of unstructured data to enhance competitive advantage and the efficiencies of the utility industry. It is expected that 65% of power, gas, and water companies will deploy edge computing to optimise their assets in the United States (Villali 2018).

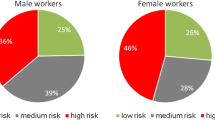

Table 12.1 indicates the proportion of jobs in the utility sector that are susceptible to automation. Numerous occupations in the utility sector are listed using job forecasting by (Byrds et al. 2017; Job Outlook 2020) for a balanced perspective. Table 12.1 indicates that low skill occupations will require considerably fewer staff given the impact of artificial intelligence on these occupations.

The increasing adaptation of high-speed machines and intelligent controllers in workplaces indicates a major disruption to the vocational job market. Specifically, data (see Byrds et al. 2017) suggests that lower skilled jobs (truck drivers, recycling and rubbish collectors, “other” stationary plant operators), and chemical, gas, petroleum and power plant operators are all in vocational fields destined to experience significant susceptibility to automation. However, jobs which require medium to very high skill levels are also not immune to disruption. In the utility sector, electrical distribution trades workers possess medium skills, but the susceptibility to automation is ranked at 36% which suggests that one person in three in the occupations in this category may lose their jobs. Environmental scientists, despite having high-level skills, are also likely to be susceptible to automation which indicates many job losses as AI encroaches on the professions in this category (see Table 12.1–46%).

Key Technologies

Energy

Electricity generation companies are upgrading their infrastructure by adopting new technologies such as the industrial internet of things (IIoT), machine learning, and Cloud computing on asset monitoring (Rebolini et al. 2017), smart metering (Gordon 2019; T&D World Staff 2019), predictive maintenance, and the operations of distributed energy resources (DERs) (Darrell 2019). The implicit risk in adopting the new technologies in developed countries has raised awareness in various arenas as the changes in demand could affect the self-sustainability of the existing utility networks, thus influencing the reliability standards in the industry (Sotter 2019).

The cost of electricity transmission can be significantly reduced with the help of AI (T&D World 2020). Solutions adopting IIoT and machine learning can collect behavioural information concerning asset depreciation and maintenance and support preventive maintenance programs. IIoT can be employed in utilities such as electricity-generating coal plants where, with the aid of sensor networks and AI, a new control operating platform can be developed to increase the efficiency of the plant. Also, operational faults and maintenance issues can be predicted in advance.

IIoT devices have outperformed their counterparts in monitoring applications. Compared to traditional sensing devices, IIoT devices are low-cost and easily installed. These devices can be widely deployed to legacy machines or equipment that was not previously monitored. Also, IIoT devices can communicate through the internet, which helps to establish a sensor network within a short timeframe (West 2018).

Drones enable the utility sector to extend their sensing capabilities at a relatively low cost significantly. Overhead transmission cables (Nichols 2019) and other utility assets can now be inspected via drones rapidly and regularly, which allows service providers to perform predictive maintenance and avoid nationwide outages. However, drones and other autonomous vehicles operating in the working environment can be a hazard to other human workers within proximity. Those issues can be handled with smart sensors and motion capture technologies (Vicon 2019). With the help of machine learning, drones can estimate motions of moving subjects in the environment and avoid them.

To reduce capital expenses, utilities are likely to cooperate with third-party companies to establish, upgrade, and maintain a communication network (Grijpink et al. 2018). Instead of developing a new communication infrastructure, Dakota Valley Electric Cooperative, an electric company in North Dakota, USA, cooperated with a national cell phone service provider to establish a sensor network with 9300 smart meters over a short timeframe. Such partnerships help the company in saving millions of dollars (Verizon 2017).

In an ordinary power generation system, energy is generated from various power sources, including coal, hydro, and nuclear power plants. These sources can fulfil most of the energy demand throughout the day. The key drawback is that they involve large overheads in cranking them up after a complete shutdown (Ganganath et al. 2017), so they are normally left in continuous operating modes. To cope with the demands during peak hours, peaker plants, such as gas turbines, which can operate almost instantly but less efficiently, are used to top up the supply. However, the introduction of renewable energy sources has imposed new challenges to the system as they introduce fluctuations to energy supply, such as through wind turbines and solar panels. Extra energy storage and sensing units are needed for storing and releasing energy dynamically depending on the needs. In most existing power grids, sensing devices have been installed at major branches and leaf nodes to continuously collect system parameters at the hundred-millisecond time resolution (Faheem et al. 2018).

With the development of DERs, buyers and sellers will begin to merge in the electricity market. Buildings, including residential, can generate and store electricity resulting in excess energy being generated which can be released to the market. Electric vehicles (EVs) can also function as mobile DERs, and buyers can thus introduce dynamic factors that add to the grid. Still, in the process, since the generation is uneven, it can jeopardise its stability (Furukawa 2019). With the emergence of distributed power generation units like rooftop solar panels, power retailers need a mechanism to pay households who contributed power to the grid but, more importantly, the system has to regulate the quality of the power by monitoring and to compensate all the fluctuations introduced by different power sources and loads continuously (Hinson 2019). IIoT-based platforms (Connected Technology Solutions 2019) allow users to optimise their energy usage and reduce their carbon footprint.

To eliminate the impact introduced by the increasing number of DERs to the grid, explicitly monitoring and controlling the power flow at every node in the grid can be achieved with IIoT devices and Cloud computing (Vidhyalakshmi and Kumar 2016). Not only new tools on the Cloud are available, but new business opportunities are also created at the same time (Amazon Web Services 2017). To maintain their competitive edge and self-sustainability, electric companies must adapt to the changing electricity market. Nonetheless, rising issues such as cybersecurity, service availability and data ownership must also be tackled.

Water, Oil, and Gas

By employing sensor networks to the aging water infrastructure, water scarcity and loss can be dealt with efficiently. For example, corroding pipes can be inspected by using sensors, and leaks can be traced. Smart technologies provide a track record to not only the utility companies but also the consumers about their water usage. For example, Sydney Water has applied IIoT technologies on upgrading its service by deploying low-cost sensors to gather data and conduct further data analytics (Prackwieser et al. 2019). Service faults can be detected beforehand, which help to establish better maintenance plans. It is reported that water interruptions to over 100,000 properties were avoided, and water interruptions were detected in advance for over 50,000 customers within 1 year. To support developing countries to employ water-monitoring equipment, a smart low-cost device was created (IEEE IoT Tech Expo 2019). Also, this low-cost device diverts water storage during drier phases by enabling better planning for the drainage systems (Fell et al. 2019).

Recent advancements in IIoT technologies provide new ways to conduct asset integrity management (AIM) promptly and continuously in the oil and gas industry (Maguire 2019a). The integrated system allows business operators to schedule an inspection and perform preventive maintenance in a cost-effective manner, which can ultimately reduce their cost due to downtimes and possibly enhance productivity. Integrating IIoT systems with AIM allows data to be aggregated with minimum human interventions and thus reduces data-entry errors and potential security risks (Maguire 2019b).

AI technologies have been used in the oil and gas sector for classifying types of rock while drilling to improve efficiency (Pallanich 2019). Digital twin models have been developed to indicate the status of machines and the condition of the environment in real-time, which enables continuous optimisation. Autonomous robots, including unmanned aerial vehicles (UAVs) and unmanned underwater vehicles (UUVs), will be digitally coordinated with surveillance systems to perform asset integrity management (AIM), which allows the human workforce to be “redistributed” to tasks that are too costly to be automated (Lu et al. 2019).

The adoption of AI not only allow businesses in the oil and gas sector to perform maintenance tasks predictively and avoid downtimes it also enables predictive maintenance and introduces new business opportunities for selling lubricants and other oil by-products (Michu 2020). Consumable suppliers can help other companies to monitor the health condition of their machines, proactively provide maintenance suggestions, and arrange the delivery of the right amount of consumables in time.

The oil and gas sectors are reluctant to store their data off-site. However, while having on-site data can have advantages such as higher security and having a more rapid data access rate, the cost to own and maintain a state-of-the-art business and IT system for more than 1023 bytes of data annually is high (Sharma 2019). The elastic storage and computational power offered by modern Cloud and I4.0 systems make it attractive for the industry to consider data storage and processing off-premises, as partnering with a Cloud service provider allows access to industrial-graded security measures at a low cost (Michu 2020). It also opens new opportunities as the data is accessible throughout an organisation, which enables the synchronisation among departments and the whole value chain (Michu 2020).

Challenges and Opportunities

In this section, eight fundamental challenges in the utility sector are identified that are linked with developments in new technologies.

Lack of Talent and Appropriate Training

Like many tech giants, utility companies are aware of the importance and the power of their data. However, as indicated in Vigliarolo (2020), very few of them analyse and make effective use of the data. Many employees are not aware of how to use the data to assist their decision making in their daily tasks, which means most of the efforts in data collection are being wasted. Training is required to help employees to realise what data they need and to equip them with the skillsets and tools for working with data.

Even though many job titles may become obsolete as they could be replaced with AI-based and I4.0 systems, many new job positions are likely to emerge as intelligent information systems where regular updates and fine-tuning are needed to keep up with their dynamic production environment (Dawson et al. 2019). In time these newly created positions will be absorbed in the technological advances stemming from the enduring or continually recurring changes induced by AI (Susskind 2020). Programmers are needed to monitor the correctness of AI-algorithms in terms of accuracy and fairness and to ensure the consistency of the autonomous decision-making process under different intrinsic and extrinsic influences. For applications where discretion and exceptions apply, expert-systems should only be used to assist human decision-makers. Auditors with engineering backgrounds are required to regularly assess the intentional and non-intentional impacts imposed by intelligent algorithms. Professional consultants will also be needed to regularly review algorithms and system architectures to ensure they comply with Australian and International laws and regulations. Strong demand in data scientists/analysts is expected as they are essential for ensuring attributes in data have been handled by AI-based information systems in an unbiased manner and to help prevent potential privacy breaches. To enhance the transparency of Utility 4.0 systems, technical writers are necessary to convert sophisticated algorithms into layman readable documentations. To prepare the workforce for the upcoming challenges, experienced trainers are critical to the development of training programs for AI developers and users, on ethical AI practices and standards. The lack of training personnel and resources could slow the growth of Utility 4.0 technology adoption in the utility sector.

Cyber-Physical Attacks

Utility networks comprise tremendous numbers of sub-systems, which are geographically distributed within and across nations. Fully integrating them with Utility 4.0 technologies can improve their overall utilisation, while at the same time make them more vulnerable and fragile to supply and demand fluctuations (Zhang et al. 2017). Interconnecting utility infrastructure using communication networks also exposes the system to software glitches and cyber-attacks (Faheem et al. 2018). With utility networks connected online, cyber-physical attacks have become a potential challenge. The Department of Energy in the US have been steering the development of roadmaps in deploying countermeasures into their energy delivery systems (Energy Sector Control Systems Working Group 2011). A cyber-physical attack often begins with gaining access to network-level parameters. From there, the weakness of a utility network can be spotted, and attackers will initiate attacks to bring a set of nodes offline which could trigger a system-level failure with minimum effort. In SRIVASTAVA et al. (2018), network science techniques have been developed to assess and quantify the vulnerability of a utility network. The outcomes allow early detection and blocking of cyber-physical attacks.

Security

Security and privacy issues related to Utility 4.0 are significant concerns of service providers and end-users. Smart meters and Cloud clusters need to authenticate each other’s identities before exchanging customers’ usage information. Password-based authentications have demonstrated many shortcomings in IIoT and other applications that comprise massive volumes of connected entities with limited capabilities (World Economic Forum 2020). Alternatives, including password-less authentications, can address both the security and scalability issues at a lower cost. The effort and time saved from managing passwords can bring better user experience and help companies generate new revenue (World Economic Forum 2020).

I4.0 or IIoT devices require regular software updates to fix programming bugs and tackle new security exploitations. Unlike consumer electronics, which commonly have an average of 5-year of technical support from their release dates (Perlow 2020), industrial devices are expected to operate for 10+ years and with a very high expectation on their reliabilities under harsh operating environments. Apart from relying on the support commitments from the II4.0 solution providers over the lifetime of the products, a more sustainable approach for utility companies is to have their in-house application developers work on open-source platforms, which introduces a strong demand for programmers and security experts.

Artificial Intelligence, Privacy, and Ethics

While AI is good at revealing hidden correlations in data, it is worth noting that we are still years or even decades from Artificial General Intelligence, which refers to AI that can be applied to an arbitrary context without special training or fine-tuning. Most of the AI implementations that are operating in the field today are adopting the “human-in-the-loop approach” (Gopalakrishna et al. 2017). In this process, the crucial role of a human operator is to safeguard the decision-making process by resolving biases, ethical issues, and vague interpretations in AI training processes (Gopalakrishna et al. 2017). A typical example is panic buying behaviour in the recent pandemic outbreak. The sudden surge in demands for masks and hygiene products due to freak events can cause an AI system to act irrationally as it has no or inadequate contextual information (Heaven 2020). Training processes in ordinary AI implementations often require access to massive volumes of data collected from assets including sensors and cameras. For understanding and predicting the behaviours of a target group, personal data can be involved which is likely to lead to privacy and ethical issues (Heaven 2020). The major obstacles are often the difficulty in seeking consensus from the subjects due to poor communication and lack of trust between the parties (Wilson 2019).

Social Responsibility

Apart from focusing on the economic benefits that Utility 4.0 technologies can bring to the industry, the rising public concerns on the impact of these technologies on the environment and social sustainability have stressed the expectation for the industry to develop scientific ways to quantify their impact. One possible solution is to adopt the assessment method proposed in (Bai et al. 2020) which involves a nonlinear mapping between performance parameters and evaluation metrics which measure the corresponding influences on the United Nations Sustainable Development Goals. The same approach can be applied to Utility 4.0 solutions.

Electric Vehicles and Distributed Energy Resources

The rapid adoption of EVs and DERs have imposed stress and fluctuations on energy networks. EVs’ owners, who are likely to perform charging in the evening, are likely to trigger power surges in the network, especially at times of the year when the demands for air conditioning and heating are also high. DERs, which primarily comprise solar panels, on the other hand, will inject extra power into the system during the daytime. Such a mismatch induces the demand for energy storage units and pricing policies to steer the behaviours of the end-users. (Patil and Kalkhambkar 2019) showed that, by coordinating the charging schedules of EVs via an information system, the charging cost of each EV could be minimised and help to flatten the power peaks in the network. The same can be applied with regard to coordinating gas-powered water boilers and wet electric appliances within the same water distribution network. Moreover, in the study conducted by the National Renewable Energy Laboratory of the United States (Ardani et al. 2018), it has been shown that instabilities in a power grid can be mitigated by coordinating DERs in the area via an information system.

An Open Utility Market

Blockchain is the enabling technology behind many popular cryptocurrencies, including Bitcoin (Nakamoto 2014) and Ethereum (Wood 2015). The abstract ideas of blockchain and its first application, Bitcoin, were introduced in Nakamoto’s white paper in 2014 (Nakamoto 2014). Blockchain is a distributed database with an irreversible nature whereby new data can only be appended to the end of the chain. As each block contains a hashed version of its previous block, modifying the data in a single block requires the modification of all the blocks built on top of the underpinning blocks. The chain is replicated and stored on multiple nodes on the blockchain network, which makes the database immune to a single-point-of-failure and virtually impossible to shut down. Transactions among individuals are broadcast and verified by blockchain nodes on the network in a fully distributed manner such that a central regulatory authority is not necessary. Cryptocurrencies and utility systems share similarities, including many data exchanges among individuals (Christidis and Devetsikiotis 2016). By integrating utility networks with blockchains, machine-to-machine (M2M) communications can be executed freely and securely without the need for a centralised system (Pureswaran and Brody 2015). The deployment and maintenance costs of a Utility 4.0 network can, therefore, be vastly reduced. With the tamper-proof nature of blockchains, less computational resources are required to secure the transactions. Dong et al. (Dong et al. 2018) discussed the application of blockchain technologies in future utility systems. As Utility 4.0 systems will be primarily based on Industrial IoT devices and Cloud systems, blockchain serves as a secure platform for data storage and verification. Smart contracts can be issued and executed autonomously among utility companies, individual DER operators, and end-users, which allow a more open utility market.

Marching Into the Post-pandemic era

The Coronavirus outbreak crisis in 2020 has triggered utility industries to reassess their day-to-day business practices and reposition their technology adoption strategies to adapt to the post-pandemic era. Maintaining social distancing at the workplace is essential for slowing down the future waves of the contagious virus before a vaccine becomes widely available. On the bright side, by incorporating the workforce into the digital-twin model, Utility 4.0 technologies can help the utility sector to remain competitive and agile in such a difficult time (Javaid et al. 2020). In this section, three cases of Utility 4.0 technologies are outlined which can tackle issues in the sector during a pandemic.

Redesign Workflows to Minimise Human Contacts

Workflows and the layouts of the workplace need to be redesigned to minimise human-to-human contacts in day-to-day businesses. Virtual reality (VR) technologies can be used to quickly evaluate workflows and structures to identify the underlying biohazards. Hundreds and thousands of designs and their combinations can speedily be realised in the virtual space at low cost. Once a design has been chosen, VR can then be used for training the workforce to adapt to the new setup (Ulmer et al. 2019). The utilisation of VR technologies in the training process allows human instructors to provide supervision remotely to reduce physical contacts further.

Maintenance tasks that required technical support personnel to work face-to-face with operators on-site in the past can now be accomplished with the support team assessing the situation remotely using Augmented Reality (AR) technologies. Live video streams captured by operators on site allow the remote support team to conduct accurate situational assessments. The support team can then provide suggestions and instructions to the operators by interactively annotating in the augmented space. The AR technology allows a single supportive team to manage multiple sites.

Contact Tracing

The workforce in the utility sector, particularly for those involved in routine maintenance tasks, are often required to work in confined spaces such as maintenance holes, which imposes challenges in enforcing social distancing rules. Nevertheless, due to poor ventilation, social distancing needs to be carried out both spatially and temporally. That is space should not be used by other personnel within a fixed duration of time, which would be determined by the size of the space and the ventilation condition.

In mid-July 2020, the World Health Organization (WHO) changed its guidance on the airborne transmission of COVID-19 to “cannot be ruled out”. While maintaining social distancing and personal hygiene remain the commonly adopted approaches in slowing down the pandemic, for places where social distancing cannot be maintained, wearing surgical masks, and keeping the space well ventilated are recommended. By integrating sensing and monitoring systems into the Utility 4.0 systems, utility companies can have real-time information on their workforce, which allows them to make dynamic plans in minimising the possibility of airborne transmissions. By integrating video technologies and machine learning algorithms, existing surveillance systems can be used to detect if the staff have worn the appropriate safety gear before entering a workspace (Kamoona et al. 2019).

Besides, airflow meters and revolution sensors can be installed in air ducts and fans, respectively to continuously monitor ventilation conditions. To ensure the sustainability of the system, the airflow of a room should be regulated proportionally to its number of occupants. Kurihara et al. (2016) have demonstrated a cost-effective way of monitoring and regulating in-door pressure. Their design utilises a single low-cost aeration fan to act as both a sensor and an actuator. When the indoor-outdoor air pressure difference has exceeded a certain threshold, the fan will act like a windmill and start spinning. Such an action will cause the fan to generate electricity which triggers the fan circuitry to turn on and keep the air pressure difference within a desirable range. Controlling air pressure in confined workspaces is crucial in containing highly contagious respiratory droplets.

Shifting Utility Demand under COVID-19

As more people are required to work or study from home due to the pandemic, demands have been shifted from commercial districts toward residential districts. This makes load shifting even more critical as residential districts often, by design, have comparatively lower energy reserve margins. Ali et al. (2019) have performed a simulation study on the effect of load shifting in Australia’s residential areas. According to their research, Australia’s energy demands can be accomplished with its renewable energy sources by shifting the utilisation window of electric water boilers in residential areas by as little as an hour. With Utility 4.0 systems, utility prices will be adjusted dynamically. Smart appliances will intelligently pick the right time to turn on to reduce the overall cost and ultimately yield a more stable system (Elham and Shahram 2017).

Conclusion

Existing challenges in the industry, together with new challenges due to the adoption of modern i4.0 concepts and technologies in their day-to-day businesses, have been discussed. Their corresponding solutions proposed in the literature in recent years have been reviewed. From there, several fundamental research gaps and business opportunities have been identified. Several emerging demands in the utility sector due to the outbreak of COVID-19 have also been identified and practical solutions have been introduced. It is argued that Utility 4.0 technologies are not disrupting but instead are transforming the job market in the utility sector. While vocational jobs could become obsolete with the further adoption of intelligent systems, the complexity of these new systems has generated new job opportunities for establishing, maintaining, and futureproofing them. In general, the utility sector is highly applicable for digitalisation as it involves extensive physical assets that continuously generate valuable data. However, apart from direct data usage in production control in the upstream, such as power plants and oil refineries, and in fault detections in the midstream, which covers the transmission and distribution networks, there is a lack of any business case to involve the massive volume of end-users. Opening the proprietary utility networks to the public can bring economic benefits, while at the same time introduce new technical issues such as security and system integrity. Advanced sensing technologies and intelligent control mechanisms in Utility 4.0 systems can facilitate coordination among users with heterogenous equipment and needs. AI can be used under human supervision to process big data collected from utility assets and support better decision making. However, privacy and ethical issues must be appropriately addressed whenever personal data is involved. Utility 4.0 technologies can shape a utility company to become more lean and agile, which is essential for it to maintain its competitiveness for the post-pandemic era and what is likely to be a very challenging future.

References

ABI Research. (2019). Warning: Undetected unauthorized activity in critical systems is the number 1 cybersecurity risk to utilities. Retrieved from https://www.abiresearch.com/press/warning-undetected-unauthorized-activity-critical-systems-number-1-cybersecurity-risk-utilities

Ali, S. M. H., Lenzen, M., & Tyedmers, E. (2019). Optimizing 100%-renewable grids through shifting residential water-heater load. International Journal of Energy Research, 43(4), 1479–1493.

Amazon Web Services. (2017). Pacific gas & electric company case study. Retrieved from https://aws.amazon.com/solutions/case-studies/pacific-gas-electric

APEC. (2015). Internet of Things (IoT) development for the promotion of information economy. Retrieved from https://www.apec.org/Publications/2015/12/Internet-of-Things-IoT-Development-for-the-Promotion-of-Information-Economy

Ardani, K., O’Shaughnessy, E., & Schwabe, P. (2018). Coordinating distributed energy resources for grid services: A case study of pacific gas and electric, National Renewable Energy Laboratory.

Australian Renewable Energy Agency. (2018). Australian energy resource assessment. Retrieved from https://arena.gov.au/assets/2018/08/australian-energy-resource-assessment.pdf

Australian Stock Exchange. (2013). Energy & utilities sector profile. Retrieved from https://www.asx.com.au/documents/professionals/ASX_Energy_and_Utilities.pdf

Bai, C., Dallasega, P., Orzes, G., & Sarkis, J. (2020). Industry 4.0 technologies assessment: A sustainability perspective. International Journal of Production Economics, 229, 1–15. https://doi.org/10.1016/j.ijpe.2020.107776.

Byrds, J., Spraggon, B., O’Neill, M., & Liddy, M. (2017). Could a robot do your job?, Australian Broadcasting Commission News Sydney. Retrieved from https://www.abc.net.au/news/2017-08-08/could-a-robot-do-your-job-artificial-intelligence/8782174?nw=0

Christidis, K., & Devetsikiotis, M. (2016). Blockchains and smart contracts for the internet of things. IEEE Access, 4, 2292–2303.

Connected Technology Solutions. (2019). EDF Energy deploys PTC’s ThingWorx for innovative energy management solution. Retrieved from http://connectedtechnologysolutions.co.uk/remote-monitoring-capabilities-to-increase-value-to-customers-whilst-reducing-carbon-footprint

Darrell, P. (2019). Innovative Microgrid Will Power Finnish Distribution Center, POWER. Retrieved from https://www.powermag.com/innovative-microgrid-will-power-finnish-distribution-center

Dawson, D., Schleiger, E., Horton, J., McLaughlin, J., Robinson, C., Quezada, G., Scowcroft, J., & Hajkowicz, S. (2019). Artificial intelligence: Australia’s ethics framework. Data61 CSIRO, Australia.

Dignan, L. (2020). Your manager, or 69% of what that person does, will be automated, says Gartner, ZD Net. Retrieved from https://www.zdnet.com/article/your-manager-or-69-of-what-that-person-does-will-be-automated-says-gartner

Dong, Z., Luo, F., & Liang, G. (2018). Blockchain: A secure, decentralized, trusted cyber infrastructure solution for future energy systems. Journal of Modern Power Systems and Clean Energy, 6, 958–967. https://doi.org/10.1007/s40565-018-0418-0.

Elham, S., & Shahram, J. (2017). Cost reduction and peak shaving through domestic load shifting and DERs. Energy, 124, 146–159.

Energy Sector Control Systems Working Group. (2011). Roadmap to achieve energy delivery systems cyber security. US Department of Energy.

Faheem, M., Shah, S. B. H., Butt, R. A., Raza, B., Anwar, M., Ashraf, M. W., Ngadi, M. A., & Gungor, V. C. (2018). Smart grid communication and information technologies in the perspective of industry 4.0: Opportunities and challenges. Computer Science Review, 30, 1–30. https://doi.org/10.1016/j.cosrev.2018.08.001.

Fell, J., Pead, J., & Winter, K. (2019). Low-cost flow sensors: Making smart water monitoring technology affordable. IEEE Consumer Electronics Magazine, 8(1), 72–77.

Frey, C., & Osborne, M. (2017). The future of employment: How susceptible are jobs to computerisation? Technological Forecasting and Social Change, 114(C), 254–280.

Furness, D. (2019). Robots aren’t coming to steal your job. They’re coming to improve it, Digital Trends. Retrieved from https://www.digitaltrends.com/cool-tech/dont-fear-the-robot-automation-threat-overblown

Furukawa, K. (2019). Honda, GM blockchain project to examine how EV owners could earn revenue from smart grids, Nikkei Asian Review. Retrieved from https://asia.nikkei.com/Business/Automobiles/Honda-and-GM-join-in-smart-grid-and-electric-car-research

Ganganath, N., Wang, J. V., Xu, X., Cheng, C.-T., & Tse, C. K. (2017). Agglomerative clustering-based network partitioning for parallel power system restoration. IEEE Transactions on Industrial Informatics, 14(8), 3325–3333.

Gopalakrishna, A. K., Ozcelebi, T., Lukkien, J. J., & Liotta, A. (2017). Relevance in cyber-physical systems with humans in the loop. Concurrency and Computation, 29(3), 1–18.

Gordon, P. (2019). Swedish telco to connect 900,000 IoT-enabled smart meters. Smart Energy International. Retrieved from https://www.smart-energy.com/industry-sectors/smart-meters/swedish-telco-to-connect-900000-iot-enabled-smart-meters

Grijpink, F., Ménard, A., Sigurdsson, H., & Vucevic, N. (2018). The road to 5G: The inevitable growth of infrastructure cost. Mckinsey & Company. Retrieved from https://www.mckinsey.com/industries/telecommunications/our-insights/the-road-to-5g-the-inevitable-growth-of-infrastructure-cost

Heaven, W.D. (2020). Our weird behavior during the pandemic is messing with AI models. MIT Technology Review. Retrieved from https://www.technologyreview.com/2020/05/11/1001563/covid-pandemic-broken-ai-machine-learning-amazon-retail-fraud-humans-in-the-loop

Hinson, S. (2019). Microgrid in a box: A plug-and-play microgrid will make rooftop solar grid-friendly. IEEE Spectrum, 56(12), 28–33.

IDC. (2019). Worldwide internet of things spending guide. Retrieved from https://www.idc.com/getdoc.jsp?containerId=IDC_P29475

IEEE IoT Tech Expo. (2019). Using IoT to improve water quality in developing countries. Retrieved from https://innovate.ieee.org/innovation-spotlight/low-cost-water-iot

Javaid, M., Haleem, A., Vaishya, R., Bahl, S., Suman, R., & Vaish, A. (2020). Industry 4.0 technologies and their applications in fighting COVID-19 pandemic. Diabetes & Metabolic Syndrome, 14(4), 419–422. https://doi.org/10.1016/j.dsx.2020.04.032.

Job Outlook. (2020). Explore careers, national skills commission, Australian Government Canberra. Retrieved from https://joboutlook.gov.au/careers/explore-careers?keywords=&industry=4&skilllevel=0

Kamoona, A. M., Gostar, A. K., Tennakoon, R., Bab-Hadiashar, A., Accadia, D., Thorpe, J., & Hoseinnezhad, R. (2019). Random finite set-based anomaly detection for safety monitoring in construction sites. IEEE Access, 7, 105710–105720.

Kurihara, Y., Kaburagi, T., & Watanabe, K. (2016). Room ventilation control by a self-sensing fan. IEEE Sensors Journal, 16(7), 2094–2099.

Lauterbach, A., & Bonime-Blanc, A. (2018). The artificial intelligence imperative: A practical roadmap for business, ABC-CLIO.

Lu, H., Guo, L., Azimi, M., & Huang, K. (2019). Oil and gas 4.0 era: A systematic review and outlook. Computers in Industry, 111, 68–90. https://doi.org/10.1016/j.compind.2019.06.007.

Maguire, D. (2019a). How to secure oil & gas assets in the age of the IIoT. Engineer Live. Retrieved from https://www.engineerlive.com/content/how-secure-oil-gas-assets-age-iiot

Maguire, D. (2019b). How to secure oil & gas assets in the age of the IIoT- part two. Engineer Live. Retrieved from https://www.engineerlive.com/content/how-secure-oil-gas-assets-age-iiot-part-two

ManpowerGroup. (2018). Skills Revolution 2.0.: Robots need not apply: Human solutions for the skills revolution. Retrieved from https://www.manpowergroup.com/wps/wcm/connect/59db87a7-16c6-490d-ae70-1bd7a322c240/Robots_Need_Not_Apply.pdf?MOD=AJPERES

Manyika, J., Chui, M., Miremadi, M., Bughin, J., George, K., Willmott, P., & Dewhurst, M. (2017). A future that works: Automation, employment, and productivity. New Jersey: McKinsey Global Institute, MGI McKinsey & Company. Retrieved from https://www.mckinsey.com/~/media/mckinsey/featured%20insights/Digital%20Disruption/Harnessing%20automation%20for%20a%20future%20that%20works/MGI-A-future-that-works-Executive-summary.ashx.

Michu, S. (2020). Shell lubricants digitises its customers services to meet industry 4.0, Express Computer. Retrieved from https://www.expresscomputer.in/artificial-intelligence-ai/shell-lubricants-digitises-its-customers-services-to-meet-industry-4-0/38147

Nakamoto, S. (2014). Bitcoin: A peer-to-peer electronic cash system. Retrieved from https://bitcoin.org/bitcoin.pdf

Nichols, G. (2019). Drones that weave through workers in factories. ZD Net. Retrieved from https://www.zdnet.com/article/drones-that-weave-through-workers-in-factories/#ftag=RSSbaffb68

Nichols, P. (n.d.). Energy and utilities in Australia: an overview. Gradate Careers Association Melbourne. Retrieved from https://gradaustralia.com.au/career-planning/energy-and-utilities-in-australia-an-overview

O’Neill, M. (2017). Explainer: What is artificial intelligence?. Australian Broadcasting Commission Sydney. Retrieved from http://www.abc.net.au/news/2017-08-07/explainer-what-is-artificial-intelligence/8771632

Pallanich, J. (2019). ADNOC Embraces Digital to Reduce Offshore Personnel. OE Digital. Retrieved from https://www.oedigital.com/news/470082-adnoc-embraces-digital-to-reduce-offshore-personnel

Patil, H., & Kalkhambkar, V. N. (2019). Charging cost minimisation by centralised controlled charging of electric vehicles. International Transactions on Electrical Energy Systems, 30(12226). https://doi.org/10.1002/2050-7038.12226.

Perlow, J. (2020). How IoT betrays us: Today, Sonos speakers. Tomorrow, Alexa and electric cars?. ZD Net. Retrieved from https://www.zdnet.com/article/sonos-abandoning-its-legacy-customers-is-precisely-what-is-wrong-with-iot

Prackwieser, C., Cash, D., & Wassell, M. (2019). IoT as a digital enabler of a hyper-connected water utility. Water e-Journal, 4(3), 1–10. Retrieved from http://ozwater.org/Watersource/wp-content/uploads/2019/09/001-Prackwieser-Christoph_v1.pdf.

Pureswaran, V. & Brody, P. (2015). Device democracy: Saving the future of the internet of things. IBM Institute for Business Value. Retrieved from http://www-935.ibm.com/services/us/gbs/thoughtleadership/internetofthings

Rebolini, M., Valant, A., & Pepe, F. M. (2017). Terna’s approach for on-line monitoring system Intelligent management of Assets in a large scale infrastructures. Paper presented at AEIT International Annual Conference (AEIT), Cagliari, Italy, (pp. 1–6).

Sharma, G. (2019). Oil, gas industry is embracing its ‘Big Data Tsunami’. Rigzone. Retrieved from https://www.rigzone.com/news/oil_gas_industry_is_embracing_its_big_data_tsunami-22-jul-2019-159366-article/?all=HG2

Skilton, M., & Hovsepian, F. (2018). The 4th industrial revolution: Responding to the impact of artificial intelligence on business (1st ed.). Springer International Publishing.

Sotter, E. (2019). Energy 4.0, revolution or fad. Electric Energy Online. Retrieved from https://electricenergyonline.com/energy/magazine/1233/article/Energy-4-0-Revolution-or-Fad-.htm

Srivastava, A. K., Ernster, T. A., Liu, R., & Krishnan, V. G. (2018). Graph-theoretic algorithms for cyber-physical vulnerability analysis of power grid with incomplete information. Journal of Modern Power Systems and Clean Energy, 6, 887–899. https://doi.org/10.1007/s40565-018-0448-7.

Susskind, D. (2020). A world without work: Technology, automation and how we should respond. Henry Holt and Company.

T&D World. (2020). Transmission system operator uses AI to reduce costs. Retrieved from https://www.tdworld.com/test-and-measurement/article/21119870/transmission-system-operator-uses-artificial-intelligence-to-reduce-costs

T&D World Staff. (2019). Ameren Missouri to Deploy 1.4 million advanced meters. IoT World Today. Retrieved from https://www.iotworldtoday.com/2019/04/30/ameren-missouri-to-deploy-1-4-million-advanced-meters

Ulmer, J., Braun, S., Lai, C. Y., Cheng, C.- T., & Wollert, J. (2019). Generic integration of VR and AR in product lifecycles based on CAD models. Paper presented at the 23rd World Multi-Conference on Systemics, Cybernetics and Informatics (WMSCI 2019), Orlando, Florida, USA, pp. 109–114.

Verizon. (2017). Dakota valley electric cooperative combines traditional service values with a modern grid. Retrieved from https://16966c0d02ae8ddc176e-a393fe9355878ef10df79e27f1add196.ssl.cf5.rackcdn.com/files/case_studies/10808573_Dakota_Valley_Written_CS_f1a_sb.pdf

Vicon. (2019). Helping robots and humans work hand-in-hand. Retrieved from https://www.vicon.com/resources/case-studies/tu-dortmund-helping-robots-and-humans-work-hand-in-hand

Vidhyalakshmi, R., & Kumar, V. (2016). Determinants of cloud computing adoption by SMEs. International Journal of Business Information Systems, 22(3), 375–395.

Vigliarolo, B. (2020). Businesses understand the value of big data, but employees aren’t being trained to use it. TechRepublic. Retrieved from https://www.techrepublic.com/article/businesses-understand-the-value-of-big-data-but-employees-arent-being-trained-to-use-it

Villali, J. (2018). Top 10 worldwide utilities 2019 predictions. IDC. Retrieved from https://www.idc-community.com/2018/11/28/top-10-worldwide-utilities-2019-predictions

West, A. (2018). Duke energy leverages IIoT for predictive maintenance applications. IHS Markit Technology. Retrieved from https://www.insight.tech/industry/duke-energy-leverages-iiot-for-predictive-maintenance-applications

Wilson, R. (2019). In advance of a priority service register data-sharing programme being rolled out nationwide by April 2020, what have United Utilities and Electricity North West learnt from piloting the scheme. Utility Week. Retrieved from https://static.utilityweek.co.uk/app/uploads/2019/10/03164133/fleX-Oct-Dec-2019.pdf

Wood, G. (2015). Ethereum: A secure decentralised generalised transaction ledger EIP-150 revision. Ethereum & Ethcore. Retrieved from http://gavwood.com/Paper.pdf

World Economic Forum. (2016). The future of jobs: employment, skills and workforce strategy for the fourth industrial revolution. WEF Geneva.

World Economic Forum. (2020). Passwordless authentication the next breakthrough in secure digital transformation. World Economic Forum in collaboration with the FIDO Alliance. Retrieved from http://www3.weforum.org/docs/WEF_Passwordless_Authentication.pdf

Zhang, X., Liu, D., Zhan, C., & Tse, C. K. (2017). Effects of cyber coupling on cascading failures in power systems. IEEE Journal on Emerging and Selected Topics in Circuits and Systems, 7(2), 228–238.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Cheng, CT., Ganganath, N., Lee, TK., Fok, KY. (2021). Utilities. In: Nankervis, A., Connell, J., Montague, A., Burgess, J. (eds) The Fourth Industrial Revolution. Springer, Singapore. https://doi.org/10.1007/978-981-16-1614-3_12

Download citation

DOI: https://doi.org/10.1007/978-981-16-1614-3_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1613-6

Online ISBN: 978-981-16-1614-3

eBook Packages: Business and ManagementBusiness and Management (R0)