Abstract

The emergence of the new class of organic–inorganic hybrid perovskite materials has found numerous applications in a plethora of next-generation optoelectronic devices like solar cells, light-emitting diodes, photodetectors, and lasers. Synthetic controls of perovskite materials through composition engineering, solvent chemistry, morphology and surface controlling, surface passivation, and band engineering have made the perovskite solar cells the fasted growing technology in the history of solar cells evolution. The perovskite semiconductors possess a number of unique functionalities like easily tunable band-gap energy, solution processability, form long-range crystals at low temperatures (<150 °C), excellent charge transport properties, and self-resistance toward electronic impurity. However, ionic nature and relaxed structural arrangement of the perovskite crystals makes them vulnerable to degradation by moisture and temperature. The stability of perovskite-based solar cells is one of the major roadblocks for their commercialization, though the power conversion efficiency (25.1%) is comparable to monocrystalline silicon solar cells. In this chapter, we will discuss the recent progress in synthesis strategy, structural stability, optical and electronic properties, and evolution in device engineering of the highly efficient perovskite solar cells. We will also elaborate on the future directions to improve stability of the perovskite solar cells.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

1.1 Global Energy Crisis

Global energy demand rises by 1.3% each year, and the empirical evidence points toward a steady increase in energy consumption until the year 2040 (International Energy Agency 2019). Almost one billion of the global population still do not have access to electricity, highlighting the need for additional energy. Electricity drives the modern civilization, and energy security is paramount to the sustainable development and prosperity of the human civilization. The over-reliance on fossil fuel to meet the growing energy demand has contributed in a major way to aggravate the current energy problem. Rapid consumption of fossil fuel severely depleted the global energy reserves and their combustion destroying our environment by pouring the harmful greenhouse gasses into it. To contain the global average temperature to increase below 2 °C rapid cut in greenhouse gasses has been suggested by multiple scientific and environmental forums.

1.2 Renewable Clean Energy Alternatives

The generation of energy from renewable energy sources with a minimum carbon footprint could be a possible way forward to the present energy crisis. Several renewable energy technologies have been explored over the years, among which most common technologies with large-scale production capabilities are wind, hydro, geothermal, biomass, and solar. These energy resources are intermittent, in terms of geographical positioning and duration of availability of the energy sources during a day; however, they can be complimentary to develop smart electricity grid to meet all the energy needs. For example, wind speed varies during a day, or the hydropower resource may not be available in all the places; similarly, solar light is inaccessible during the night time. A smart combination of renewable energy sources together with storage capacity (batteries, fuel production, and pumped-storage hydro) would meet most of the energy demands of our daily life.

Among all renewable energy sources, solar energy is particularly interesting as it provides an inexhaustible and universal source of energy. Annually earth receives around 1 × 109 TWh of solar energy with a typical intensity of around 1000 W/m2 on the ground. Cumulative global annual energy consumption is merely 0.012% (124,290 TWh) (Morton 2006; https://www.iea.org/reports/world-energy-outlook-2019) of the annual solar irradiance. This is to say that the sun provides the earth with as much energy every hour as human civilization consumes every year. Though solar energy is ubiquitous, the conversion of solar energy to useful electrical energy is not as economical when compared to fossil fuel-based alternatives.

1.3 Solar Cell Technology

A solar cell device absorbs the incident light and converts it to the usable electrical power, known as the photovoltaic effect, discovered by French physicist Edmond Becquerel in 1839. Typically, a semiconductor of appropriate band-gap (EG) is used in solar cells to absorb solar radiation. Photons having energies higher than EG are absorbed by the semiconductor to create excited electrons in the conduction band and vacancy of electrons in the valance band. These negative and positive charge carriers are separated and extracted from the solar cells to achieve electrical power. Carrier selective contacts, on either side of the absorber layer, are used for the preferential collection of electron and hole at the terminal electrodes of a solar cell. Solar radiation is a panchromatic one and extends within the broad energy range of 3.5–0.5 eV. The wide bandwidth of the solar spectrum makes it challenging to harness in the solar cell devices. Semiconductor having a specific band-gap EG is transparent to the photons having energy lower than EG, which is accounted for transmittance loss in solar cells. Similarly, absorption of high energy photons (>EG) excites the valance band electrons to deep inside the conduction band. The high energy photon releases their excess energy quickly (~10−12 s) through the emission of phonon to reach the conduction band minimum. The loss of the excess energy for the high energy photons (>EG) is known as thermalization loss for the solar cell. Additional losses in a solar cell are emission loss due to spontaneous emission of the photoexcited electron from the conduction band to valance band (Hirst and Ekins-Daukes 2011). Those losses are qualified as intrinsic loss, as they cannot be overcome by device and material optimization in the high-performing solar cells. The fundamental efficiency limit for single-junction solar cells is limited to 33.7%, formulated in 1961 by Shockley and Queisser (Shockley and Queisser 1961). The first actual solar cell was developed in 1954 at Bell laboratories using the silicon semiconductor to show the photoconversion efficiency of 6%. Over the last 60 years, research and development have pushed the PCE of silicon solar cells to record 26.7% (Yoshikawa et al. 2017), very close to its theoretical limit of 29% (Andreani et al. 2018). The silicon solar cell technology is already a proven technology with more than 90% accumulated share in the PV market (Andreani et al. 2018).

1.4 The Emergence of Perovskite Solar Cells (PSCs)

In last ten years, the organic–inorganic hybrid perovskite solar cells (PSCs) have emerged as a potential alternative to the existing photovoltaic technologies as their efficiency has improved from 3.8% in 2009 to 25.1% in 2019 as shown in Fig. 1 (Kojima et al. 2009; NREL solar energy chart: https://www.nrel.gov/pv/assets/pdfs/pv-efficiency-chart 2019). The unprecedented growth of the PSCs is associated with the fact that the perovskite materials can be synthesized from low-cost solution processing and can be made crystalline below 200 °C, promising for the cost competitiveness of the disruptive solar cell technology (Green et al. 2014; Zuo et al. 2016). The band-gap of the perovskite semiconductors can be tunable for a range of 2.2–1.2 eV through composition engineering. Hybrid perovskite systems possess the direct band-gap with the strong absorption coefficient (>104 cm−1), which requires only 1-µm-thick perovskite layer to absorb the full solar radiation above their band-gap. Long-range crystallinity of solution-processed perovskite layer contributes significantly to achieve high carrier mobility (1–30 cm2 V−1 S−1) and long carrier lifetime (~100 ns) in their solid films (Johnston and Herz 2016). The carrier diffusion length in PSCs exceeds 10 µm as a result (Tainter et al. 2019), allowing efficient extraction of photogenerated carriers in solar cells. The aforementioned traits make hybrid perovskites unique for the solar cells (Grätzel 2014) as well as other optoelectronic applications, like light-emitting diodes (Tan et al. 2014; Zhang et al. 2017a), lasers (Chen et al. 2016a; Stylianakis et al. 2019), and photodetectors, (Hu et al. 2014a; Wang and Kim 2017).

Despite several advancements, there are concerns over the stability of the perovskite materials (Wang et al. 2019), which hinders their prospect for commercialization. The organic–inorganic hybrid perovskite materials suffer from poor stability when exposed to heat, oxygen, moisture, and even illumination (Lee et al. 2015a; Smecca et al. 2016; Aristidou et al. 2015). The instability of perovskite materials lies with the fact that the perovskite crystals are ionic, and there exits significant empty space within the perovskite unit cells which makes them soft crystals and the volatile nature of the organic component in the perovskite crystal. Significant progress has been made to improve the stability of perovskite semiconductor through compositional engineering to minimize the crystal strain, tuning the unit cell toward cubic structure, and replacement of the volatile component (Wang et al. 2019; Asghar et al. 2017). Development of the two-dimensionally confined perovskite layer, interlinked by long-chain organic molecules has been investigated to reduce the moisture induce degradation of the perovskite layer (Grancini et al. 2017; Tsai et al. 2016). However, the special confinement and insulating ligands have a detrimental effect on charge transport. Nevertheless, it is an interesting approach to improve the stability of perovskite semiconductors.

In this book chapter, a detailed overview of PSCs will be discussed. Progress in synthesis strategies in terms of composition engineering and structure–property correlation to attain the high photovoltaic efficiency will be explained. The evolution of device engineering for the PSCs to attain high photovoltaic efficiency and better stability will be summarized.

2 Intrinsic Properties of Perovskites

2.1 Structural Properties

Metal halide perovskites are known as the common cluster of compounds with general chemical formula of AMX3, where A is organic or inorganic cations (typically MA = CH3NH3+, FA = HC(NH2) +2 , Cs+, K+, Rb+, etc.), M is metal cations (Pb2+, Sn2+, Eu2+, Ge+, etc.), and X is halide anions (Cl−, Br−, I−) (Kojima et al. 2009; NREL solar energy chart: https://www.nrel.gov/pv/assets/pdfs/pv-efficiency-chart 2019; Sum and Mathews 2014). In a perovskite unit cell, A cation is situated at the eight corners of the cube, while M-cation is placed at the body center and six numbers of X anions are located at the face centers. AMX3 belongs to an extended large family of organic–inorganic metal halide perovskites where the [MX6]4− octahedra can grow three-dimensional (3D), two-dimensional (2D), one-dimensional (1D), or zero-dimensional (0D) crystal structures having the same unit cell as shown in Fig. 2. For example, in MAPbI3 each [PbI6]4− octahedra is connected with six neighbors of iodide forming a 3D network while MA+ is located at the void of the network (see Fig. 2a). In other words, the [PbI6]4− octahedras are connected three dimensionally in the crystal structure. For the 2D case (see Fig. 2b), longer organic cations like CH3(CH2)nNH3+ situated at A-site where each [PbI6]4− octahedron is connected with four neighbors iodide anions, forming a 2D network layer that is sandwiched between two CH3(CH2)nNH3+ layers and the chemical formula becomes A2PbI4. It results in multiple quantum well structures from the stacking of these sandwiched layers via van der Waals interaction with the CH3(CH2)nNH3+ layer as the barrier. In 1D case (see Fig. 2c), each octahedra is attached to two opposite corners with neighboring octrahedras and forming parallel infinite chains (e.g., (C10H21NH3)2PbI4). Lastly, for 0D structure (e.g., Cs4PbI6), each [PbI6]4− octrahedra is separated by four Cs+ ions to form an isolated molecule resembles to a quantum dot array (see Fig. 2d).

The lead halide perovskite structure (AMX3), in which A-site cation, plays a very important role for formation of stable perovskite crystal structure (Park and Seok 2019; Correa-Baena et al. 2017). The stability parameter is characterized the Goldschmidt tolerance factor (t),

where rA, rM, and rX are the ionic radii of the A-site cation, metal cation, and halide, anions, respectively. For an example, the ionic radii of I− and Pb2+ ions are 2.03 Å (rX) and 1.33 Å (rM), respectively, as represented in Fig. 3, and the radii of A-site cation is in the range of 2.3–2.8 Å (rA). When the perovskite is formed using Cs+, MA+, or FA+ as the A-site cations, the optical properties of the perovskites change with the cation result in a red-shifting absorbance onset. In other words, band-gap of the perovskite material changes in this order, MA+ (1.55 eV) < Cs+ (1.5 eV) < FA+ (1.45 eV). However, the volume per APbI3 unit changes from 222, 248, and 256 Å3 for Cs+, MA+, and FA+ cations, respectively. Thus, Cs+ and MA+ differ significantly in radial size, but the band-gap changes a little compared to difference between the MA+ and FA+ cations.

Halide substitution. The advantage of these metal halide lead halide perovskites is the capability to tune their optoelectronic properties by substitution the halide ions. For an example, the iodine ions in MAPbI3 perovskite structure can be substituted with both Cl− and Br− anions (Correa-Baena et al. 2017). Same substitution of the ions can be possible for MAPbBr3 and MAPbCl3 perovskite structures. While halide substitution, the band-gap of the perovskites changes 2.97, 2.24, and 1.53 eV for the MAPbCl3, MAPbBr3, and MAPbI3 perovskite, respectively. At room temperature, MAPbCl3 and MAPbBr3 perovskites are found to be in a cubic structure while the phase changes to a tetragonal structure at lower temperatures. Moreover, MAPbI3 crystallizes to tetragonal crystal structure, whereas FAPbI3 crystallizes to hexagonal δ-phase or cubic α-phase at room temperature as shown in Fig. 4.

Organic cation substitution. Similar to halide substitution, organic cations can also be replaced in the perovskites (Correa-Baena et al. 2017). For an example, MA+ cations can be exchanged with slightly bigger sized FA+ cations. The cation exchange in perovskites has very small impact on the optical band-gap or very little change in band-gap observed. DFT computations demonstrate that organic cations do not contribute to the electronic states close to the band edges. However, with cation exchange the crystal lattices changes which results in a slight change in the band-gap.

Organic/inorganic ion mixing. Simultaneous exchange of both organic cations and anions has been done as well. For an example, the performance of MAPbI3 perovskite-based solar cells is not highly efficient (Correa-Baena et al. 2017). On the other hand, FAPbI3 and CsPbI3 perovskite structures (cubic phase) are not stable at room temperature. However, the compositional mixing of MA/FA/Cs/Br/I perovskites has been studied enormously. FAPbI3 perovskite-based photovoltaics appears to give better device performance over MAPbI3, but some MA+ cations in FAPbI3 perovskites stabilizes the perovskite structure. Introducing Br− anions in FAPbI3 perovskites allows to tune the band-gap, enhance structural stability, and improve the device performance. Therefore, it is very important to design principle to mix cations and halides to achieve final perovskite compositions that is advantageous while evading their disadvantages.

2.2 Electronic Structure

Perovskite is known for the common cluster of compounds with general chemical formula. The electronic band structures of organic–inorganic perovskites can be calculated by using a semiempirical technique based on the extended Huckel theory and an ab initio method based on the Hartree–Fock theory (Sum and Mathews 2014). Another approach is using ultraviolet photoelectron spectroscopy and first principles density functional theory (DFT) band calculations at the room temperature. DFT calculations for 3D MAPbI3 perovskite crystals reveal that the valence band maxima contain Pb 6p–I 5p σ antibonding orbital, while the conduction band minima comprise of Pb 6p–I 5s σ antibonding and Pb 6p–I 5p π antibonding orbitals as represented in Fig. 5. Nevertheless, DFT calculations also show that the A-site cation has a very little influence on the band-gap energy, of which is mainly determined by the [PbI4]6− network.

Absorption coefficient. The absorption coefficient of materials is described as the amount of a given color of light is absorbed by the material for a given thickness. Thats means that more light absorbs by a material then its absorption coefficient will be higher. The absorption coefficient is represented by the Greek letter “α”. It has units of cm−1 because it defines the amount of light absorbed per unit thickness of the material. Since the material absorbance varies with the wavelength of the light, so the absorption coefficient is a function of wavelength/color. For an example, the absorption coefficient of MAPbI3 thin films is around 1.5 × 104 cm−1 at 550 nm, that gives the penetration depth is only 0.66 mm for 550 nm light. However, for 700 nm light, the absorption coefficient of MAPbI3 thin films is around 0.5 × 104 cm−1 and corresponding penetration depth is around 2 mm (Park 2015). Higher penetration depths led to more incoming light can be absorbed by the perovskite films, which is essential for high-efficiency PSCs.

Balanced charge transport behaviors. The charge transport properties of MAPbX3 perovskites were reported by Xing et al. (2013) and Stranks et al. (2013). Transient spectroscopic analysis reveals that upon absorbing the light perovskites exhibited balanced electron- and hole-transporting behavior. The calculated electron diffusion length for MAPbI3 thin film is around 130 nm while the hole diffusion length is calculated to 100 nm (Xing et al. 2013). However, by doping Cl− ions in MAPbI3 perovskite, the electron and hole diffusion length enhanced to 1069 nm and 1213 nm, respectively (Stranks et al. 2013). The longer and balanced charge diffusion lengths results in improved solar cells device performance.

3 Perovskite Structure Formation Techniques

3.1 Single Crystals (SCs)

Solution temperature-lowering (STL) method. In this method, the solubility of the lead halide perovskites in acid halide solvents (e.g., HI, HBr, HCl) plays an important role for perovskite crystal growth. The perovskite materials solubility changes significantly with temperature. This mechanism is generally used for perovskite SCs growth. At first perovskite, seed crystals are dipped into an acid halide solvent at certain temperature (see Fig. 6a). Upon lowering the temperature, the saturation of the solute in the solvent takes place and corresponding crystal growth start around the perovskite seed crystals. High-quality MAPbI3 SCs can be grown by this temperature-lowering process. In a glass beaker, MAPbI3 seed crystals are spanned by a stirrer in HI solvent at 65 °C (Dang et al. 2015). By lowering the temperature to 40 °C, saturation of perovskites solute in the HI solvent expedite the crystal formation and finally 10 mm × 10 mm × 8 mm-sized MAPbI3 SCs. These as-synthesized SCs exhibit two natural facets in the directions of (100) and (112) crystal planes. The advantages of this method are that the crystal growths are easily controlled with temperature and high-quality large-size SCs can be obtained.

Inverse temperature crystallization (ITC) method. The ITC crystal growth mechanism is totally opposite to the temperature-lowering method. The perovskite materials whose solubility in a particular solvent are decreasing with increasing the temperature. Several research groups investigated the lead halide perovskites solubility in N, N-dimethylformamide (DMF), dimethylsulfoxide (DMSO), and γ-butyrolactone (GBL). Interestingly, in these solvents the perovskite crystal structure formation was observed with increase of solution temperature. By this ITC method, mm-sized MAPbX3 and FAPbX3 (X = Cl−, Br−, I−) SCs were obtained via using different organic solvents (Saidaminov et al. 2015; Liu et al. 2015a).

Basically, in the solvent mixture organic solvents such as DMF and DMSO are connected with lead halides and form intermediate adducts. The perovskite SCs can be developed by removing the organic solvents at higher temperature (see Fig. 6b). For example, when MAI and PbI2 are mixed in DMF, an intermediate MAPbI3-DMF adduct phase is formed due to a strong interaction of DMF–MA bonding. In a similar way, MAPbI3-DMSO adduct phase is formed due to the interaction of DMSO–PbI2 bonding, when MAI and PbI2 are mixed in DMSO. The MAPbI3 single crystal was obtained by removing the DMF or DMSO solvent via annealing.

Anti-solvent vapor-assisted crystallization (AVC) method. The AVC method is used to grow the perovskite crystals that are highly soluble in a solvent but have very poor solubility in other solvent (Shi et al. 2015). By this method, mm-sized MAPbX3 SCs were obtained by using the anti-solvent dichloromethane (DCM), that is slowly diffused into the solution containing MAX and PbX2 (X = Br−, I−) dissolved in DMF or GBA solvents (see Fig. 6c). This growth method for preparation of the hybrid halide perovskites SCs are highly efficient and applicable. However, it is difficult to develop large-size SCs that is important for large-area optoelectronic device applications.

Slow evaporation method (SEM). This slow evaporation method is a traditional and easy solution-based process for growth of SCs. Liao et al. (2015) have prepared the SCs of hybrid perovskite analogue (benzylammonium)2PbX4 (X = Cl−, Br−). In this process, stoichiometric mixture of benzylammonium chloride and PbCl2 was mixed in concentrated HCl aqueous solution. Bulk (benzylammonium)2PbX4 crystals with the dimensions of 5 mm × 10 mm × 2 mm were obtained via the slow evaporation of DMF solution at 90 °C (see Fig. 6d). The preferred growth of single crystalline planes is extended along the [001] direction. Although this process is highly efficient, sometimes this method is hard to control precisely, that limits the industrial applications.

Droplet-pinned crystallization (DPC) method. Micrometer-sized MAPbI3 single crystalline arrays can be formed using this DPC method (Jiang and Kloc 2013). At first, MAPbI3 precursor solution was drop-casted on PEDOT:PSS-coated indium tin oxide (ITO) glass substrate, on which smaller wafers were placed (see Fig. 6e). Upon annealing, the precursor solvent was evaporated and rectangular-shaped MAPbI3 SCs arrays were formed within some minutes. This method is very useful for growth of micrometer-sized SCs. It also provides a platform to grow single crystalline thin films.

3.2 Thin Films

Perovskites thin films are usually grown using solution process and vapor-phase deposition techniques. Very careful control on several processing parameters, such as the perovskite film thickness, crystallinity, perovskite phase purity, and perovskite film morphology, plays a significant role in achieving high-quality perovskite thin films and corresponding final device performance. The optimized perovskite thin-film processing steps can lead to desired perovskite thin-film thickness, highly crystalline films, uniform morphology, bigger crystal sizes, and less defect states. For solution-processed perovskite thin films, the processing parameters are types of perovskite precursors and solvent mixtures, precursor solubility, spin-coating speed, solvent engineering steps, types of anti-solvents, volume of the anti-solvent, time of anti-solvent injection, post-film thermal annealing temperature and time.

Single-step solution deposition. It is the simplest way to prepare a perovskite thin film via solution-processed spin-coating method. This perovskite thin films formation depends on various components, like substrate on which perovskite film will be deposited, precursors, solvents/mixed solvent and followed by spin-coating parameters. After spin coating, the semiconducting thin film is further annealed for faster crystallization process. The final film crystallinity, thickness, and morphology depend on various processing parameters. Single-step perovskite films formation was first introduced by Im et al. in 2011 (Im et al. 2013). In this process, they prepared a precursor solution by mixing an equimolar MAI and PbI2 powders in γ-butyrolactone (GBL) solvent at 60 °C for 12 h under vigorous stirring. Then the mixed solution was filtered through a 0.45 mm size PVDF filter for final thin-film formation via spin coating (see Fig. 7a). Then they spin-coated the precursor concentrations are in various concentrations of 10.05, 20.13, 30.18, 40.26 to 41.22 wt%. They observed that mesoporous TiO2 films are better than compact films of TiO2 for growth of thick uniform perovskite films. On the top of mesoporous TiO2 film, the precursor solution was dropped and waits for one min to penetrate the solution into a mesoporous TiO2 layer, which was then spin-coated at 2000 rpm for 40 s in an ambient atmosphere. The spin-coated MAPbI3 film was annealed at different temperatures, and tetragonal crystal structure was formed. With increasing the concentration of the perovskite precursor, the film formation abruptly changes. A yellow-colored perovskite film was obtained for 10.05 wt% of precursor concentration, while it transformed to black color when the wt% concentration increased to 40.26 wt%. The color change of perovskite thin films at different precursor concentrations is ascribed due to higher perovskite precursor concentrations led to enhanced precursor interaction upon annealing and corresponding formation of the black perovskite phase. The UV-vis absorption spectra of films prepared from different concentrations of the perovskite precursor showed an increase in light absorption with higher precursor concentrations. It is also observed that up on annealing from temperature 40–100 °C, the perovskite film led to an increase in the absorption intensity, however, beyond 100 °C the absorption intensity decreases.

Selection of mixed solvents to dissolve perovskite precursors is also very important for formation of smooth perovskite surface with uniform crystal domains (Kim et al. 2014a). A mixed precursor solution of DMF and GBL was used to dissolve MAI and PbI2 at 60 °C inside a nitrogen glovebox. The morphology of spin-coated perovskite films hugely differs when the films when spin-coated from different solvents like only DMF, only GBL, and mixed DMF and GBL solvents. The perovskite films formed from GBL solvents show formation of larger crystal grains with poor surface coverage. However, the perovskite films prepared from DMF show an improved morphology but non-uniform crystal dimensions. When the perovskite films developed from mixed solvent of DMF:GBL, the films display a smooth surface morphology with denser packing having uniform crystal dimension of 100 nm. The root-mean-square (RMS) roughness of the perovskite thin film reduces to 6.6 nm (for DMF:GBL) from 24.53 nm (for GBL) and 8.88 nm (for DMF). The crystallization process of perovskites varies from different solvents to solvents due to different evaporation rate of each solvent during spin-coating process. A higher evaporation rate of a solvent could lead to irregular thin-film surface morphology while mixture of different solvents may increase precursor solubility and controls the evaporation rate and resulted in an uniform and compact perovskite film.

Solvent engineering approach. This method is slightly modified compared to conventional single-step solution deposition process where some volume of an anti-solvent is drop-casted on top of perovskite film during spin coating of the perovskite precursor (see Fig. 7b). This solvent engineering process for perovskite preparation was first introduced by Jeon et al. in 2014 (Jeon et al. 2014). Usually, perovskite precursors are dissolved in a mixed solvent of GBL and DMSO. An anti-solvent that does not dissolve the perovskite but is miscible with GBL and DMSO, such as toluene, chlorobenzene, and chloroform, was dropped during the spin coating to facilitate an intermediate complex (MAI–PbI2–DMSO) film and reduces the growth kinetic for perovskite crystallization process. The intermediate phase is confirmed by X-ray diffraction (XRD) and Fourier-transform infrared spectroscopy (FTIR) analysis (Beckmann 2010). This intermediate thin film was finally annealed at 130 °C and fully converted into perovskite phase. The resulted films are very uniform, dense, and smooth over larger active area.

Two-step deposition: Two-step deposition or sequential deposition technique, in which individual precursor layers, is deposited separately and interacts together to develop a final perovskite thin film (Burschka et al. 2013). At first, lead halide films are grown on the substrate via spin coating and later this film is dipped in MAI in IPA solution, leading to formation of MAPbI3 perovskite thin films (see Fig. 7c). The precursor PbI2 dissolved in DMF solvent and the solution was spin-coated on top of a mesoporous TiO2 layer, followed by annealing at 70 °C to form yellow-colored PbI2 film. This film was then dipped in a 5–10 mg/ml MAI precursor in IPA for several seconds of time, followed by rinsing in IPA and annealing at 70 °C. The yellow PbI2 films transformed into black-colored films confirmed the formation of the perovskite phase. The thin-film morphology greatly depends on MAI solvent concentration and dipping time. This procedure is very useful for large-area device fabrication with reproducible high-quality crystalline perovskite film and excellent photovoltaic device performance.

Vacuum processing technique. In vapor deposited technique, the perovskite precursor powders MAI and PbCl2 are placed separately in a thermal boat and simultaneously thermally evaporated on a substrate to form a perovskite film (Liu et al. 2013). Usually, the MAI and PbCl2 precursors were evaporated with a molar ratio of 4:1 in a vacuum of 10−5 mbar and resulted in a dark reddish-brown-colored perovskite (MAPbI3−xClx) film (see Fig. 7d). The resulted perovskite films show a complete, crystalline, uniform coverage, and larger grain size compared to the conventional solution-processed perovskite. This procedure is also very advantageous for large-area device fabrication.

4 Basic Principle of PSCs

Mainly three key parameters play crucial role for device performance of the PSCs. First, the active perovskite material, the material needs to be designated in such a way that it has optimized band-gap and high-phase stability. However, the band-gap of the perovskites can be tuned in the visible to infrared spectral range by mixing/exchanging the halide anions (X = Cl−, Br−, I−) or replacing the cations (MA+, C2H5NH3+, FA+, Cs+, K+, Rb+). Second, the surface morphology of the perovskite thin films, uniform top layer, and large crystals formation is very essential for efficient charge transport and good diode characteristics; this is widely governed by precursor/solvent selections and post-processing conditions. Third, selection of proper charge transporting materials and optimizing the energy levels alignment is between the perovskite and the neighboring transport layers in order to enable effective charge transport throughout the device. In this regards, detailed study on the position of conduction band (CB) minimum and valence band (VB) maximum is required for perovskites and transporting materials.

The basic principle of solar cells is to convert the solar energy into electrical energy. The solar energy originates from the Sun, considered as a blackbody with a light spectrum at the temperature of about 5800 K. As the Sunlight passes through the Earth’s atmosphere, it is attenuated by light scattering and some part is absorbed via chemical interactions with the atmospheric molecules. The atmosphere absorbs certain wavelengths of light and changing the amount of light reaching the Earth’s surface. The water vapor mostly contributes for absorption of Sunlight spectra while molecular nitrogen, oxygen, and carbon dioxide also absorb some parts. The final solar spectrum that reaches to the Earth’s surface varies with the light path length covered through the atmosphere. AM 1.5 spectrum with light intensity of 100 mW cm−2 are standardized as the measuring conditions for characterization of solar cells (see Fig. 8).

4.1 Charge Generation and Transport in Perovskite Materials

For the semiconductor-based photovoltaics, the photons from Sunlight with enough energy can excite the electrons from the valence band to the conduction band across the band-gap and that results in generation of charge carriers. The photogenerated charge carriers can be separated out with proper band alignment of transporting layers such that electrons and holes are moving in opposite directions and store at counter electrodes. This is how solar cells are working under Sunlight. When Sunlight is falling on any absorbing active material, there are two types of loss mechanisms happened that hinder the solar cell efficiency. In a single-junction solar cell, the absorbing material cannot absorb photons having energy less than the band-gap of the active material and the light directly transmit through the material (see Fig. 9a). These low energy photons do not contribute to solar cells device performance. However, the photons having energy higher than the band-gap, absorbed by the active material, and the charge carriers are excited to higher energy states. After a very short time period, these excited charge carries relaxes to band edges of the active material through non-radiative thermalization process (see Fig. 9b). Here the excess energy of the incident photons is losses via this non-radiative process. Finally, the band-gap energy contributes to the device electricity. These two loss mechanisms reduce half of incident solar energy conversion to electrical energy.

Generation of charge carriers. In an ideal semiconductor, the valence and conduction bands are not flat. The band alignment is depending on the k-vector in the phase space that describes the momentum of an electron in the semiconductor. So, the energy of an electron is dependent on its momentum because of the periodic crystal structure of the semiconductor. If the maximum energy of the valence band and the minimum energy of the conduction band matches at the same k-vector in the E–k space, an electron can be excited from the valence band to the conduction band without a change in the momentum. Such a semiconductor is called a direct band-gap material. If the maximum energy of the valence band and the minimum energy of the conduction band does not match at same k-vector, so the electron cannot be excited without changing its momentum, such materials are called an indirect band-gap material. The absorption coefficient of a direct band-gap material is much higher than an indirect band-gap material; thus, the absorbing semiconductor can be much thinner for a direct band-gap semiconductor.

In a semiconductor, electrons can only stay at energy levels below the valence band edge (Ev) and above the conduction band edge (Ec). Between these two energy levels no allowed energy states exist for the electrons. Hence, the band-gap energy difference is, Eg = Ec − Ev. When the Sunlight with incident photons has energy higher than the band-gap of the semi-conducting material, which are absorbed and subsequently excite electrons from an initial energy level Ei to a higher energy level Ef as shown in Fig. 10a. So, the photons with an energy smaller than Eg incident on the ideal semiconductor, it will not be absorbed by the material. If an electron is excited from Ei energy level to Ef energy level, a void is created at Ei energy level and the void acts like a positive charged particle and is so-called a hole. Therefore, the absorption of a photon leads to formation of an electron–hole pair where electron stays at conduction band and hole stays are at valence band.

Separation of the photogenerated charge carriers. The excited electron can stay at the conduction energy level for a very short period of time, which is so-called the lifetime of the electron. The time period is generally in millisecond to microsecond scale. After the lifetime, the electrons will return back to the valence energy level from the conduction energy level and recombine with the holes. The electron–hole recombination energy will be released either as a photon (radiative recombination) or relaxes via lattice vibrations (non-radiative recombination) as shown in Fig. 10b. One can store the energy for further use before the electron–hole recombination process by separating out the electrons and holes via an external circuit and it is so-called solar cells circuit. A solar cell has to be designed such that the electrons and holes can transfer to opposite directions in presence of favorable adjacent energy levels of transporting materials in a very short span of time, i.e., less than the lifetime of the excited electrons. This requirement limits the thickness of the absorber materials.

Collection of the photo-generated charge carriers. Finally, the opposite charge carriers are extracted from the solar cells with electrical contacts and the energy is stored in a battery. Here, the chemical energy of the electron–hole pairs is converted into electrical energy.

4.2 Characterization Processes of PSCs

Power conversion efficiency (PCE). The most important parameter to characterize the solar cells is the PCE, which can be obtained from the current density–voltage (J–V) characterization. As demonstrated in Fig. 11, under illumination and without external bias, a negative current is flowing through the circuit. The current density under these conditions through the solar cells device is called short-circuit current density (Jsc). When a positive bias is applied to the circuit, up to an open-circuit voltage (Voc) a negative current is transporting though the circuit, indicating the power generation by the solar cell. The PCE of a solar cell is defined as the ratio of the maximum power output (Pout) to the incident light power (Pin), and it is represented by the formula,

where the fill factor (FF) can be thought of as the biggest rectangular area (blue area; see Fig. 11) covered under the current voltage curve. It is the quotient of maximum solar power output and the product of Voc and Isc.

External quantum efficiency. Another important parameter to characterize solar cells is the external quantum efficiency (EQE). It is the conversion ratio of the incident photon into electron in a solar cell, which is also known as the incident photon to converted electron (IPCE). The EQE is defined as the ratio of the number of output electrons to the number of incident photons at different wavelengths. EQE of a solar cell is depended on many factors, such as light absorption-co-efficient of the active layer, exciton generation efficiency, exciton dissociation efficiency, and carrier extraction efficiency.

5 Working Principle of PSCs

5.1 Device Architectures

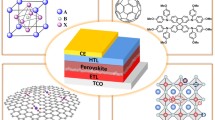

Selection of the transporting materials with proper band alignment is a crucial part. In PSCs, perovskite layer acted as an absorber layer. Depending upon the electron and hole transport toward light entering electrode, PSCs can be classified into two parts n-i-p structure and p-i-n structure. One can easily understand this classification by checking the position of transporting layer [n-i-p: electron-transporting materials (ETMs) layer placed on top of TCO; and p-i-n: hole-transporting materials (HTMs) layer placed on top of TCO]. These two types of solar cells device structures are subclassified into two other parts mainly mesoscopic and planer structure. The mesoscopic structure incorporates a mesoporous layer (in front of light entering window), whereas the planar structure consists of all planar layers of transporting layers. Sometimes PSCs are classified without transporting layers.

Regular n-i-p structure. PSCs are often called as solid-state dye sanitized solar cells (SS-DSSCs). PSCs are modified form of conventional DSSC. Here the light absorption was governed by the solid-state perovskite material in DSSCs, and it was fabricated from dyes. Conventional PSCs structure is n-i-p (see Fig. 12) type, where the n-type metal oxide layer (transporting layer) was deposited on top of the conducting oxide layer. On the top of this n-type transporting layer, intrinsic absorber perovskite layer was grown and finally the p-type transporting layer and top electrode was deposited in succession. The efficiency of the PSCs mostly depends on the proper selection of transporting materials. Mesoscopic layer (like, TiO2) was deposited as a transporting layer in front of the light entering window to enhance the charge collection ability from perovskite layer and as a result the PSCs device performance enhanced.

Inverted p-i-n structure. Inverted p-i-n structure was imported from the organic solar cells. Where the p-type hole-transporting layer (HTL) was deposited on top of the TCO and the n-type electron-transporting layer (ETL) was deposited under the top electrode. Here the holes and electrons are forced to move in two different directions and collected at different electrodes (see Fig. 13). In this device configuration, mesoscopic and planer PSCs were fabricated in the presence of different perovskite compositions.

Electron-transporting layer-free structure. A compact p-type transporting layer was deposited on top of transparent conductive oxide (see Fig. 14a), or on top of perovskite layer (see Fig. 14b) to fabricate electron-transporting layer-free PSCs. On top suitable electrodes are deposited. This type of PSCs is fabricated on planar structure and helps to achieve high PCE by increasing the open-circuit voltage (Voc). Recently, scientists have developed a suitable method for fabricating PSCs without one transporting layer and achieved higher PCE.

The essential requirements of HTM layers in PSCs are due to several advantages such as,

-

(1)

Suitable band matching with perovskite layer helps to attain high Voc values.

-

(2)

Enhancement of the fill factor (FF) by reducing the series resistance governed by the high hole mobility in the device.

-

(3)

The optical loss in the devices can be minimized by proper selection of low optical absorption of the transporting material in the visible region.

5.2 PSCs with Various HTM Layers and Their Device Performance

The thickness of the transporting layer should be maintained at an optimum value to overcome the resistive losses and allowed better crystalline growth of the perovskite. Some of the PSCs device structures are shown in Fig. 15.

Nanoparticles as HTMs

Nanomaterials are a suitable candidate for large-area optoelectronic industry due to their low production costs and ease synthesis helps. Superior optoelectronic properties such as easy processability, low synthesis cost, tunable band-gap, high mobility serve the nanomaterials as an alternative choice as a transporting layer material for PSCs. Tunable optoelectronic properties of nanomaterials help easy band matching with perovskite. As a result, the use of nanomaterials in the PSCs expected to improve the performance the device indeed. In the previous study, on colloidal QDs have been used in DSSC to get a device performance of 7% as an alternative to molecular dyes (Ip et al. 2012). Here, in this section we will discuss the device performance of in PSCs with various hole-transporting nanomaterials, such as Cu2ZnSnS4, WO3, NiO, CuS nanocrystals (NCs) together with CuInS2- and PbS-based QDs.

Cu2ZnSnS4 Nanoparticles (NPs). Earth-abundant Cu2ZnSnS4 (CZTS) NPs display some interesting properties such as high hole mobility (6–30 cm2 V−1 s−1), ideal band-gap (1.5 eV) and permit them to use as a HTL in PSCs (Chen et al. 2013; Zhou et al. 2013; Walsh et al. 2012; Vanalakar et al. 2015). Wu et al. introduced the CZTS NPs as a transporting material due to the band matching with absorber perovskite layer in which the PCE was reached to 13% (Wu et al. 2015a). In this report, the NPs were synthesized with different reaction times of 20, 30, and 40 min to achieve different sizes such as CZTS-20, CZTS-30, and CZTS-40, and optical absorption was verified with mostly used organic HTM spiro-OMeTAD. After analyzing the SEM images, it was revealed that smooth, uniform, and homogeneous perovskite layer was formed on top of CZTS NPs. When compared with the commonly used spiro-OMeTAD HTM layer, it was found that the CZTS layer improved the interfacial contact between the perovskite layer and the top electrode to reduce the non-radiative recombination at the interfaces. The results suggested that the CZTS NPs can be effectively acts as a low-cost HTM layer as its able to transport holes effectively in PSCs (Fig. 16).

WO3 NCs. In 2015, Li et al. had shown the successful use of WO3 NCs as an efficient inorganic HTL in PSCs (Li 2015). Highly transparent WO3 NCs layer (87% transparency) allows the incoming photons to be absorbed by the perovskite layer, high work function, and deep energy levels of WO3 makes them efficient HTM in PSCs. It was also observed that the WO3-based PSCs were more stable compared to the other organic and nanocrystalline HTLs-based solar cells. It was found that the device performance was considerably well with WO3 as HTL and a PCE of 7.68% observed (Table 1).

NiO NCs. In 2014, Zhu et al. had successfully demonstrated the use of NiO NCs as an efficient HTL in PSCs. The NiO layer (30–40 nm thick) was grown by conventional sol–gel method and the corresponding solar cells device exhibited a PCE of 9.11% (Zhu et al. 2014). From the photoluminescence (PL) measurements, it was found that the NiO thin films have superior hole extraction ability from the perovskite layer compared to PEDOT:PSS layer.

CuS NPs. Rao et al. also discovered the use of CuS NPs as a hole-transporting material in an inverted perovskite solar cell (Rao et al. 2016). CuS NPs-based solar cells exhibit some interesting features, such as reproducibility, low charge recombination, effective hole extraction, higher stability, and ability to modify work function of ITO layer, found perfect band matching with the perovskite layer. From the SEM images, it was confirmed that the CuS NPs provide good surface coverage on ITO substrate. AFM studies of root-mean square (RMS) roughness suggest that no pinholes were formed in the CuS layer. From the J–V curves, it was discovered that the solar cell device exhibited PCE value of 16.2% and stability of the device boosted up to 250 h.

Copper indium disulfides (CuInS2) colloidal Quantum Dots (QDs). Less toxic suitable band-gap (1.45 eV) with high extinction coefficient in the visible region of CuInS2 QDs enables them to use as an HTM layer in PSCs. Lv et al. introduced CuInS2 as an HTM in PSCs by replacing organic HTMs (Kolny-Olesaik and Weller 2013). The use of CuInS2 QDs (VB: 5.00–5.05 eV) improves the hole conduction from perovskite layer (VB: −5.43 eV) due to suitable band matching (Pan et al. 2014). The devices were fabricated by depositing colloidal CuInS2 QDs on top of the MAPbI3-coated TiO2 films, during testing under suitable light intensity these cells delivered a PCE of 6.57%. The device performance was improved with a PCE of 8.38%, which was achieved by using modified CuInS2 QDs with ZnS shell layer. The ZnS layer helps to reduce the non-radiative carrier recombination at the interface of TiO2 and HTM layer (Santra et al. 2013).

Lead sulfide (PbS) QDs. Excellent optoelectronic properties of PbS QDs, such as high absorption coefficient, low band-gap, tunable band-gap, large exciton Bohr radius (~18 nm), motivate to implement them as a p-type HTM layer in PSCs (Hodes 2013; Snaith 2013). Solution-processed PbS QDs as an inorganic HTM layer in PSCs was successfully demonstrated and attained a PCE of 7.5% (Hu et al. 2015). By varying the band-gap of PbS QDs, the energy level alignments between the perovskite and PbS QDs can easily be tuned to achieve optimized device performance (Tang et al. 2011). Dai et al. have reached device efficiency nearly 8% with a good device stability by using colloidal PbS QDs as an inorganic HTM layer (Li et al. 2015a). This article investigated the solar cells performance by optimizing the PbS QDs layer thickness. Here two-step spin-coating method provides a higher PCE of 7.8%, whereas one-step method contributed lower PCE 4.73%. Enhanced solar cells device performance was achieved due to the low recombination in two-step processed perovskite thin films. From the SEM images of the two-step processed MAPbI3, thin films deposited on TiO2 layer showed more uniform surface coverage over the one-step process. These results discovered the efficient use of PbS QDs as a low-cost HTM in perovskite/QD hybrid solar cells.

Copper-based HTMs

Copper Iodide (CuI). Inexpensive, stable, wide band-gap, with high conductivity make CuI as a favorable candidate for HTM layer in PSCs. Christians et al., used CuI using the drop casting method and recorded a PCE of 6% (Christians et al. 2014). When compared with the conventional spiro-OMeTED HTM layer, it was found that the electrical conductivity of CuI solar cells was two orders higher and resulted in significant improvement in device performance. The stability test of these solar cell devices was carried out under constant illuminations of 100 mW/cm2 AM 1.5G for a period of 2 h without encapsulation under ambient conditions. It was found that Jsc value remained constant for CuI based solar cells, while there is a decrement of Jsc of 10% from initial value was observed for spiro-OMeTAD-based solar cells. CuI HTM-based PSCs exhibited higher Voc value with lower device efficiency compared to the conventional spiro-OMeTAD HTM-based solar cells (Table 2).

Cuprous oxide (Cu2O) and Copper oxide (CuO). Earth-abundant and easy processable Cu2O and CuO are typically p-type semiconductors, with suitable band alignment matches well with the perovskite (MAPbI3) energy levels. Copper-based oxide materials have shown high hole mobility of 100 cm2 V−1 s−1, which makes them suitable as an HTM material (Shao et al. 2010; Bao et al. 2009). Zuo et al. had successfully introduced the copper-based oxide materials as HTMs in PSCs. They have achieved maximum PCE of 13.35% with Cu2O and 12.16% with CuO considered as inorganic HTMs (Zuo and Ding 2015). Cu2O and CuO thin films showed smooth surface morphology that was analyzed from AFM study. The RMS values were obtained as of 2.81 nm and 3.32 nm, respectively. Highly crystalline MAPbI3 films were observed on Cu2O and CuO thin films compared with PEDOT:PSS films. These oxide transporting layers facilitate the charge transport and as a result increase in the device performance (Dong et al. 2015a). Cu2O solar cells were found more stable compared to PEDOT:PSS-based solar cells. The PCE value of Cu2O HTM-based solar cells reduced from 11.02 to 9.96%, whereas for PEDOT:PSS HTM-based solar cells declined from 10.11 to 6.79%, when the devices were kept for 70 days in the nitrogen filled glove box. In another study, Yu et al. have reported Cu2O HTM-based PSCs with maximum PCE of 11.0% (Yu et al. 2016) (Table 3).

Sun et al. had reported a PCE of 17.1% by using CuOx as an inorganic HTM layer in PSCs and exhibited short-circuited current density of 23.2 mA/cm2, open-circuit voltage of 0.99 V, and fill factor of 0.74 (Sun et al. 2016). The devices were found to be stable for approximately 200 h. The better device performance of CuOx-based PSC devices was achieved due to efficient hole transport from perovskite layer to HTM layer. Low contact resistance of CuOx layer was beneficial for such enhanced device performance. From AFM study, it was discovered that the surface roughness or RMS value of ITO surface was 4.7 nm and the RMS value was decreased to 4.2 nm with addition of CuOx HTM layer on top of ITO surface that improves the overall surface morphology and prevents short-circuited current leakage inside the device. Rao et al., have reported an output power efficiency of 19.0% where MAPbI3−xClx have been used as an absorber layer and CuOx used as a HTM layer (Rao et al. 2016). Doping of Cl offers the better surface morphology compared to undoped perovskites thin film and improved the hole mobility which in turn enhanced the device performance. The SEM morphology of MAPbI3 films revealed that the average perovskite particle size was very small and form several grain boundaries, which trigger the non-radiative trap assisted recombination in turn reduced the overall device performance.

Copper thiocyanate (CuSCN). CuSCN is immensely used as an inorganic HTM layer in PSCs due to their some promising characteristics, such as their high optical transparency, high hole mobility of 0.01–0.1 cm2 V−1 s−1 and good chemical stability (O’Regan et al. 2000; Tsujimoto et al. 2012; Pattanasattayavong et al. 2013a, b). Qin et al. had reported the fabrication of PSCs with copper thiocyanate (CuSCN) used as an HTM and achieved device PCE of 12.4% (Qin et al. 2014a). Ye et al. found in inverted PSCs with CuSCN HTM that exhibited an average PCE of 16.6% which was better compared to other conventional organic HTM layers used in PSCs (Ye et al. 2015). It was found that the device fabricated from perovskite layer deposited on top of a CuSCN via one-step deposition method was much efficient compared to two-step deposition. In one-step deposition process, the perovskites crystallized slowly and resulted in low surface roughness. The high device performance also signifies the smaller interface contact resistance between the perovskite layer and the CuSCN layer (Table 4).

Nickel oxide (NiOx). NiOx is also ambient stable having larger band-gap (5.4 eV), and suitable energy levels match well with energy band to perovskite and make them as a potential candidate for HTM layer in PSCs. Yin et al. observed a higher PCE of 16.47% on a ITO-coated glass substrate compared to those of ITO-PEN (polyethylene naphthalate) substrate solar cells (PCE of 13.43%). Here solution-processed NiOx was used as a HTM layer in the inverted planar heterojunction (Yin et al. 2016). From the J–V curve and EQE spectra, it was exposed that NiOx-based device show low recombination than that of PEDOT:PSS which is commonly used HTM in perovskite solar cell. The use of pristine and copper-doped NiOx as HTMs was represented by Kim et al., publicized the use of pristine and copper-doped NiOx as HTMs for high performing and stable planar PSCs (Kim et al. 2014b). After careful analysis of J–V curves of Cu:NiOx HTM-based PSC showed the maximum PCE of 15.40% compared to pristine NiOx HTM exhibited PCE of 8.94%.

Wei et al. fabricated PSCs using Li–Mg-doped NiO as HTM and Ti(Nb)Ox used as an ETL, showing a highest PCE of 18.3% with a Jsc= 20.4 mA/cm2, Voc = 1.08 V, FF = 0.83 (Chen et al. 2015a). Introduction of Li+ and Mg2+ into the NiO lattice increased the conductivity and avoid the undesirable shift of valence band (Chen et al. 2015a; Alidoust et al. 2014; Huang et al. 2014; Deng et al. 2012). For the stability test, the devices were kept under dark condition for 1000 h and it was found that the efficiency was reduced to its 97% from the initial value. Same experiment was carried out under 1000 h constant illumination condition, and the device PCE value was reduced to 90% from its initial value (Table 5).

Carbon Materials-based HTMs

Advantageous optoelectronic properties of carbon (C) materials, such as carbon nanotubes, graphene, and graphene oxide, as a transporting layer have gained significant attention in the field of organic electronics. It was observed that the carbon material-based solar cells had achieved a maximum PCE of 15.5% with better stability (Aitola et al. 2016). Zheng et al. had reported to achieve a PCE of 12.8% by using graphene sheet doped functionalized thiolated nanographene (TSHBC) as a HTM layer in PSCs and the device improved to an efficiency of 14% (Cao et al. 2015a) (Fig. 17; Table 6).

NiOx/PEDOT:PSS. Use of hybrid PEDOT:PSS/NiOx HTL was reported by Park et al. in an inverted planar device architecture and the device exhibited a PCE of 15.1% (Park et al. 2015). The hybrid PEDOT:PSS/NiOx transporting layer was deposited by spin-coating different concentrations of (0.1, 1.0 and 5.0%) PEDOT:PSS solution on top of NiOx layer. The device fabricated with 1.0% PEDOT:PSS/NiOx as HTL displayed highest PCE of 13.9% compared to other compositions. Device with pure PEDOT:PSS (11.8%) and bare NiOx (12.7%) achieved a lower PCE. From the impedance spectroscopy studies, it was observed that there was a subsequent reduction of internal resistance for PEDOT:PSS/NiOx HTL based PSCs.

Spiro-OMeTAD. Due to several advantageous features of spiro-OMeTAD HTM layer, such as favorable glass transition temperature (Tg = 120 °C), easy solubility, ideal ionization potential, suitable absorption spectrum, and solid-state morphology introduced them the most commonly used organic HTM layer in PSCs which can provide the high output (Huang et al. 2016a). Spiro-OMeTAD was introduced by Bach et al. in 1998 (Bach et al. 1998) in DSSCs to use them as an efficient heterojunction layer formed with dye absorbers achieved a good PCE. Recently, many researchers extensively utilized the spiro-OMeTAD as HTM layer in solid-state DSSCs. Using spiro-OMeTAD, the PSCs boosted the device PCE up to 22%. The devices fabricated with spiro-OMeTAD suffered low stability toward water, light, and heat due to amorphous nature and the chemical structure spiro-OMeTAD. Pristine and various-doped spiro have been used as a HTM layer in PSCs to overcome the low stability of the devices. These various dopants in the spiro-OMeTAD enhance the electrical conductivity, stability of the device. The first doping effect was employed in spiro-OMeTAD by lithium and antimony-based salts Li[(CF3SO2)2N] (Li-TFSI) and achieved the highest PCE of 7.2% (Burschka et al. 2013). Doping of antimony in spiro-OMeTAD resulted in generation of free charge carriers via oxidization. Generated Li+ ions inside the system by the ionic lithium improve the device performance, but due to extreme hygroscopic nature of lithium accelerates the decomposition of perovskite and degrades the device performance quickly. The presence of pinhole channels from the bottom to the top across the organic transporting layer spiro-OMeTAD accelerates the degradation processes, the pinholes are generated from the migration of Li-TFSI film, Hawash et al. (2015). Hua et al. (2016) had successfully demonstrated the use of fluorine-doped spiro-OMeTAD and found enhanced stability of PSCs. Improvement of the device performance was observed when non-hygroscopic materials (tetrafluoro-tetra cyanoquinodimethane [F4-TCNQ])-doped spiro-OMeTAD used instead of pristine spiro-OMeTAD. The energy offset between the perovskite and the spiro-OMeTAD has to be small enough in order to achieve a high Voc (Ou et al. 2017). In 2018, Hawash et al. observed that spiro-OMeTAD with various new additives and dopants excels pristine spiro-OMeTAD both in terms of device performance and stability (Hawash et al. 2018) (Fig. 18; Table 7).

PEDOT:PSS mixed polymer-based HTMs. The HOMO energy level of PEDOT film at −5.0 eV facilities the hole extraction from the perovskite layer due to band matching. In 2014, You et al. (2014) had successfully demonstrated the use of poly (3,4-ethylene dioxythiophene) polystyrene sulfonate polymer (PEDOT:PSS) as an HTM to fabricate high-efficiency PSCs at a low temperature, where PEDOT:PSS and PCBM were used as hole and electron transport layers, respectively. The device exhibited a PCE of 11.5% on glass/ITO substrate, while a 9.2% PCE was achieved in a flexible substrate (polyethylene terephthalate/ITO). The successfully grown of conducting poly (3,4-ethylene dioxythiophene) polystyrene sulfonate polymer (PEDOT:PSS) and applys them as a potential HTM in PSCs was demonstrated by Jiang et al. in 2017, (Jiang et al. 2017). They had deposited PEDOT:PSS layer on top of perovskite and showed an excellent PCE of 17.0%. One of the major drawback of PSCs fabricated by depositing PEDOT:PSS on top of perovskite layer is their limited stability in ambient atmosphere, modified by the inverted structure of PSCs, where perovskite layer was deposited on top of PEDOT: PSS layer. In 2017, Luo et al. (2017a) achieved a PCE of 15.34% by using GO-modified PEDOT:PSS. They had found that the device was less effective with the application of PEDOT:PSS (11.90%) layer in PSCs. It was also found that the devices fabricated with GO-modified PEDOT:PSS were much stable as compared to unmodified one and maintained PCE up to 83.5% of the initial PCE value after aging for 39 days. During the spin coating of the GO solution (ethanol in the GO solution), the hydrophilic PSS material can be partially removed from the surface. Energy levels of various HTMs used in PSCs and the highest achieved efficiency presented in Figs. 16 and 17, respectively.

5.3 PSCs with Various ETM Layers and Their Device Performance

In the PSCs, the conventional compact ETL layer was used due to two different reasons, primarily to extract the photogenerated electrons from perovskite layer, and secondly, working as a hole blocking layer. This also indicates that the compact ETL layer should able to hinder the reverse movement of the electrons from the FTO substrate to the perovskite layer. It is important for the ETL layer to have continuous, uniform, and high transparent and thin structure for the better performance of the solar cells. The MAPbBr3 and MAPbI3-based PSCs efficiency were limited to 3.8% while using TiO2 as an ETM layer. Later scientists have devoted themselves to improve the device performance and achieved an efficiency of more than 15%. Recently, Yang et al. have reported 19.3% efficient PSC using a polyethyleneimine (PEI) thin layer on TiO2 as ETM fabricated in air (Zhou et al. 2014b) (Table 8).

Recently, metal oxides have gained much attention as a suitable ETL layer due to their good stability, high electron mobility, easy processability, and high transparency. Among various metal oxide materials, TiO2, Al2O3, ZnO, SnO2, SrO2, etc., have shown potential in the perovskite cell device performance. TiO2 is widely used in PSCs as an ETL layer. Ultra-thin TiO2 could smooth the surface and keep the uniformity where the mesoscopic TiO2 has better light scattering effect prolonging the incident light path. Park et al. (Lee et al. 2014) studied the effect of the crystal phase and morphology of the TiO2 for the device performance of PSCs. They have reported that the rutile TiO2 film was better than the anatase TiO2 film because of the smooth surface of perovskite capping layer and lower conduction band position of the rutile TiO2 film than that of the perovskite layer. Mali et al. have reported the use of transporting layer made by two TiO2 layers, atom layer deposited (ALD) ultra-thin TiO2 was deposited on top of the surface of one-dimensional TiO2 nanorod arrays (Mali et al. 2015a). The device structure with 4.8 nm ALD passivated TiO2 nanorod achieved the output PCE of 13.45%. In this method, it helped the light absorption and avoided the high-temperature processed TiCl4 treatment. It is conventional that the nanorods, nanotubes, and nanofibers have shown better electron transport ability than nanoparticle films because of their directional charge transport properties. The PCE-based on TiO2 nanorods grown in different method, with water-HCl solution was found to be higher than that with ethanol-HCl solution, which could be attributed to their special orientation, good optical properties, high conductivity, fast charge transfer, and reduced charge recombination (Wu et al. 2015b). TiO2 is not suitable for flexible devices because it needs to be annealed at high temperature to get better crystallite (Table 9).

Al2O3 mesoscopic scaffold was used as an ETL layer and MAPbCl3−xIx as the light absorber in PSCs (Lee et al. 2012). An optimal thick Al2O3 layer was fabricated at low temperature by atomic layer deposition (ALD) method. Introduction of Al2O3 layer effectively blocks the electron recombination between the perovskite and fluorine-doped tin oxide (FTO) layer and enhances the electron transport between the junction (Zhang et al. 2017b). It was observed that the perovskite cells with a 5 nm Al2O3 layer revealed a PCE of 16.2%, which is much higher than the device fabricated without Al2O3 layer (PCE ~ 11.0%) (Table 10).

In an inverted PSCs, ZnO and SnO2 are usually used as an ETL layer because of their excellent electron mobility property. Low-temperature synthesized ZnO layer was used as a transporting layer in PSCs and the device exhibited a PCE value of 15.7% (Liu and Kelly 2014). SnO2 has higher electron mobility and deeper conduction band than TiO2. It was reported that SnO2 shows better environmental stability with beneficial for charge transportation from perovskite layer to electron transport layer. SnO2 layer is generally fabricated at low temperature, and the corresponding solar cells had achieved a PCE of 13%. Such devise showed a good device stability in ambient environment (Song et al. 2015a). A higher device efficiency of 17.2% was achieved by preparing the SnO2 as a transporting layer. This layer was fabricated by spin coating of SnCl2·H2O precursor and annealing at 180 °C in the air (Ke et al. 2015a). A high efficiency of 19.9% was achieved by adopting solution-processed SnO2 that was fabricated at the temperature of 150 °C (Jiang et al. 2016). WO3 transporting layer are also exhibiting a good stability and higher mobility compared to TiO2 layer. It was observed that WO3-based devices are more sensitive to ambient moisture compared to TiO2-based devices. The WO3 ETM layer-based PSCs also degrade faster (Gheno et al. 2017). These devices showed better photovoltaic device performance when TiO2 NPs were covered on WO3 thin-film surface. Amorphous WOx:TiOx composites were fabricated at a relatively low temperature, and they were very effective as a ETL layer in PSCs. The addition of TiOx and WOx could raise the Fermi level and simultaneously suppress the non-radiative charge recombination at the perovskite interfaces (Wang et al. 2016d) (Table 11).

Doping in the metal oxides reduces the surface vacancies and other defects and reduces the charge recombination probability, which could exhibit better device performance due to their better electron mobility and suitable energy levels. The oxygen vacancies on TiO2 surface are not beneficial for charge transport and also detrimental for efficient device performance (Leijtens et al. 2013). A 15% enhancement in short-circuit current density was observed when the device fabricated with Y3+-doped TiO2 layer. TiO2 doped with Y3+ was used to modify the morphology of the perovskite active layer and improved the electron transfer properties (Qin et al. 2014b). Al-doped TiO2 shown enhanced conductivity as the doping might remove the oxygen defects from the TiO2 lattice causes the device stability (Pathak et al. 2014). Mg-doped TiO2 demonstrated better optical properties and better energy level alignment with the perovskite active layer which provided better electron transportation (Wang et al. 2015). Nitrogen-doped ZnO (N:ZnO) nanorods also enhance the electron mobility and corresponding PSC devices exposed higher PCE (Mahmood et al. 2015b) (Table 12).

Fullerenes and their derivatives. Fullerene and its derivatives are commonly used as an ETL layer in inverted PSCs due to their band matching with perovskite layer and better electron transport ability. C60, phenyl-C60-butyric acid methyl ester (PC61BM), and indene-C60 bisadduct (ICBA) were firstly employed as ETL layers in MAPbI3-based PSCs (Jeng et al. 2013). The open-circuit voltage of corresponding PSCs was achieved as 0.55, 0.65, and 0.75 V, respectively. The higher open-circuit voltage was achieved for ICBA because of its higher LUMO level compared to C60 and PC61BM. The PCE of fullerene-based PSCs is mostly related to electron mobility of these transport layers (C60, ICBA, PC61BM) (Liang et al. 2015). High mobility fullerene will beneficial for the charge transportation. Fullerene materials can also passivate the interfacial trap states of perovskite layer and reduce the energy barrier between the electrode and perovskite layer.

The new fullerene derivative C70-DPM-OE was synthesized by phenyl groups of diphenyl methano fullerene (DPM) moiety with oligoether chain (Xing et al. 2016). This oligoether chain can reduce the work function of the metal cathode and passivate the trap states of the perovskite layer. The device fabricated with C70-DPM-OE as an ETL have achieved the PCE of 16% which was much higher than the conventional PC61BM as electron transport layer. Another fullerene pyrrolidine derivative, N-methyl-2-pentyl-(Santra et al. 2013) fullerene pyrrolidine (NMPFP) was prepared by a simple solution process (Chen et al. 2019). The NMPFP thin film revealed a higher conductivity than the PC61BM thin film. The device fabricated with NMPFP as an ETL layer exhibited a PCE of 13.83% (Fig. 19; Table 13).

Doping in the fullerenes is a good way to improve the mobility and the device efficiency of PSCs. MAI-doped fullerene C60, exhibited dramatically increased conductivity by over 100 times (Bai et al. 2016). The iodide as a Lewis base anion in the MAI-dopant acted as an electron donor. When the iodide contacts fullerene after solvent drying, the electron density would redistribute from iodide to fullerene. Enhanced free electron density in fullerene presented a higher conductivity. The improved conductivity plays a significant role in boosting the device performance; the perovskite solar cell delivered an efficiency of 19.5% with a high fill factor of 80.6%.

Low-dimensional lead halide perovskites

In recent years, quasi-2D halide perovskites have intensively investigated as active layers in solar cells comparing with the conventional 3D perovskites structures. Smith et al. reported the solar cell from quasi-2D halide perovskites with a device structure of FTO/TiO2/(PEA)2(MA)2[Pb3I10]/spiro-OMeTAD/Au and the device showed a PCE of 4.71% (Quan et al. 2016). In this work, the quasi-2D halide perovskite was obtained by mixing C6H5(CH3)2NH3I (PEAI), MAI and PbI2 with a molar ratio of 2:2:3 and form a quasi-2D perovskite structure of (PEA)2(MA)2[Pb3I10]. The number of layers (n) was determined to be 3. It was observed that the decrease in dimension resulting an increase in the band-gap and exciton binding energy. It was shown that the devices were more stable when fabricated with quasi-2D halide perovskites and remained stable after 46 days, whereas the 3D halide perovskite started to decompose after 4–5 days, as it was evident from the XRD spectra. Improved stability of the perovskites was observed using all-inorganic halide perovskite (CsPbX3), reported by many groups. CsPbI3 having band-gap of 1.73 eV was the suitable for solar cells. Swarnakar et al. had grown α-CsPbI3 perovskite QDs which was found stable for several months in ambient air (Fang et al. 2015). These QDs were also used as active layer in PSCs and deposited on TiO2/FTO substrates. The CsPbI3 QDs-coated substrates were then immersed in saturated methyl acetate (MeOAc) solution for several times to yield a desired thick perovskite thin film. Such QDs-based solar cells revealed a PCE of 10.77% with a Voc of 1.23 eV and fill factor of 0.65. More recently, Sanehira et al. boosted the PCE up to 13.43% by using CsPbI3 QDs in the device and resulted in enhancement of charge carrier mobility of QD films (Sanehira et al. 2017).

Mixed cations

FA/MA-Cs mixed-cation perovskite

The α-CsxFA1−xPbI3 perovskite layer was fabricated via a regular one-step solvent engineering method with different Cs/FA ratios. Such thin films showed comparatively more stable and do not transform from α-phase to δH-phase (Li et al. 2016b). FA0.9Cs0.1PbI3 thin-film-based PSCs displayed both the superior stability and efficiency (16.5%) in solar cell devices compared to pure FAPbI3 perovskite (Lee et al. 2015c). Later, Yi et al. had achieved the improved PCE to 18% by replacing both a small fraction of the iodide and bromide anions as Cs0.2FA0.8PbI2.84Br0.16. McMeekin et al. also reported a FA/Cs mixed cation perovskite of FA0.83Cs0.17PbI3 with some added bromide achieve a band-gap of 1.75 eV (Yi et al. 2016). The structure of perovskite FA0.83Cs0.17Pb(I0.6Br0.4)3 was used in a solar cell and achieved an open-circuit voltage 1.2 volts with PCE of over 17%. The mixed perovskites of FA0.83Cs0.17Pb(I0.6Br0.4)3 absorber layer was used in a p-i-n solar cell structure where n-doped C60 used as an electron collecting layer where 80% of the original efficiency sustained after 650 h under ambient air without encapsulation and stable over 3400 h with encapsulation (Wu et al. 2016). MA cation had also been alloyed with Cs+ to form the MA/Cs mixed perovskites. Chio et al. represented the use of perovskite containing Cs+ and MA+ with [6,6]-phenyl-C60 butyric acid methyl ester (PCBM) as an electron acceptor (Choi et al. 2014). 10% of Cs+ ions doping in MAPbI3 perovskite improved the efficiency from 5.51 to 7.68%.

Ternary cation perovskite

The successful exhibition of binary cation perovskites with enhanced performance and stability might open a new way to use of ternary cation perovskite using MA+, FA+, and Cs+ cations-based perovskite in solar cells. Saliba et al. first reported the triple cation perovskite with FA/MA/Cs where Cs+ ions could improve the film quality for FA/MA mixture (Saliba et al. 2016a). 5% CsI was incorporated into the mixed-cation perovskite which was known as (FAPbI3)0.83(MAPbBr3)0.17 to suppress non-perovskite phase and enhanced the crystallization process with a highly stabilized PCE (21.1%) and stability was reported. The solar cells still maintained an efficiency at 18% after 250 h. Saliba et al. investigated several alkali cations and found the radii of Rb+ was only slightly smaller than the favorable cations of Cs+, MA+, and FA+. They have successfully alloyed a small amount of RbI (about 5–10%) into Cs/MA/FA mixed-cation perovskite to achieve a record efficiency of 21.6% on small areas and 19.0% on large area (0.5 cm2) under AM 1.5G. The addition of Rb+ ions suppresses the formation of unwanted yellow phase of Cs- or FA-based perovskite structures and improves the stability of solar cells. These devices based on Rb/Cs/MA/FA perovskite were found 95% efficient from its initial value after 500 h at 85 °C under continuous illumination, which could meet the industrial standards for reliable solar cells (Saliba et al. 2016b). However, more than 10% RbI addition into the mixed-cation perovskite resulted in a Rb-rich phase and was destructive to the solar cells.

Mixed Cation to stabilize the Pb-Sn alloy metal halide perovskite

Due to the similar electronic structure and the similar ionic radii of Sn2+ (1.35 Å) to Pb2+ (1.49 Å), tin is a useful candidate for the application of lead-free perovskites. Hao et al. had reported the optical band-gap 1.3 eV in MASnI3 with high absorption at 950 nm, which is ideal for solar cell application (Hao et al. 2014a). It was found that the presence of Pb and Sn in methylammonium iodide perovskite showed a narrower band-gap of 1.3 eV which extend the absorption onset to the near-IR region (Hao et al. 2014b; Ogomi et al. 2014; Im et al. 2015). According to Shockley–Queisser theory, the PCE of approximately 30% can be achieved by replacing 15% Pb+2 by Sn+2 ions in the perovskite structure (Anaya et al. 2016). Pure Sn-based PSCs had shown relatively low PCE apart from that their tendency of oxidizing to Sn+2 to Sn+4 state damage the perovskite structure. Zhao and co-workers had found the lesser oxidation probability observed for Sn atom in FASnI3 than in MASnI3 due to the stronger hydrogen bond in FASnI3 (Wang et al. 2016f). Liao et al. had used the mixed cation (FA/MA) and (Sn/Pb) perovskite materials in the inverted device structure by using FASnI3 and MAPbI3 precursor solutions (Liao et al. 2016). The as-fabricated device structure with this perovskite ITO/PEDOT:PSS/(FASnI3)0.6(MAPbI3)0.4/C60/BCP/Ag showed a PCE of 15.08%. The MA0.5FA0.5Pb0.75Sn0.25I3 PSCs were fabricated using one-step spin-coating method and resulted in a PCE of 14.19% with a great stability (Yang et al. 2016d). The fabricated solar cells maintained PCE of 94% of its initial value after 30 days when kept in an inert atmosphere and retained 80% of initial PCE value after 12 days when exposed to an ambient atmosphere (30–40% R.H.) (Table 14).

6 Challenges of PSCs

6.1 Hysteresis

The current–voltage hysteresis behavior in PSCs appeared due to several internal factors, such that (a) hysteresis is mostly depending on the perovskite material, (b) selective contact materials, i.e., HTM, ETM, play crucial roles in this behavior, including the material and the morphology, and (c) the typical charge generation/recombination processes (≈ns) in PSCs (Snaith et al. 2014). These effects cause non-uniform current flow in forward and reverse biasing condition. The shape of measured J–V curves and corresponding device efficiency hugely depends on scan direction, light source, delay in measurement time, and voltage bias conditions before measurement. In last few years, different mechanisms have been proposed to be responsible such hysteresis effects, like, ferroelectricity, charge trapping/detrapping, and ionic migration. Out of them ionic migration seems to appear as dominative factor.

Ferroelectricity. Ferroelectricity of a material depends on the hysteretic swapping of ferroelectric domains in an external electric field. Even though the MAPbI3 perovskite crystal structure possesses centrosymmetric tetragonal space group, however the reorientation of the organic cations and the distortion of the [PbI6]4− cages can result in a polarization (Sherkar and Jan Anton Koster 2016). Secondly, the ability of the perovskite crystal structure to switch this polarization by an external field can originate the hysteresis effect. Several research groups have confirmed the polarization switching in both amplitude and phase by using piezoelectric force microscopy (PFM) in the perovskite materials (Chen et al. 2015f; Coll et al. 2015).