Abstract

No country in the world today, developed or developing, can afford to overlook the critical advantages of Artificial Intelligence (AI) for sustainable economic growth and innovation. Beyond nations, the same argument applies to the manufacturing sector. Innovation creates wealth and improves overall quality of life, which is a legitimate expectation of a citizen of any country. AI is set to become the next frontier of innovation as the cost of computing power becomes increasingly affordable. AI’s impact will be immensely beneficial provided the right regulatory framework (privacy and security) and policies (labour, education & training, re-skilling, etc.) are implemented to sustain the AI ecosystem.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Artificial Intelligence (AI) is powered by data. Large datasets improve and sharpen the output capabilities of AI systems. AI used intelligently can help the textile industry (both traditional and technical textiles) mine a lot of data to improve productivity, enable myriad forms of value addition, avoid machine down time, improve quality control, optimize processes and resource utilisation, smarten predictive maintenance, among other potential benefits. The above-mentioned areas are the ‘low-hanging fruits’ of research & development and innovation in the textile value chain.

One of the major weaknesses of textile plants is that they possess a lot of process and operations data, but have not yet invested in the tools to extract tangible business value. In textile production, AI will potentially offer enhanced flexibility, reactivity, forward planning and decision-making freedom on the shop floor as some decision-making responsibilities are transferred to the AI-enabled System. In short, AI has the capability to transform textile factories, making them more resource-efficient while also improving their environmental footprint.

This paper will also try to dispel the myth and misconceptions that AI will soon surpass human intelligence, somehow ‘take over’ the world and render billions of workers jobless. AI is not even close to replacing human ingenuity, empathy, creativity and imagination. AI will effectively replace jobs that follow a fixed pattern, are repetitive and are routine. It is just a matter of time before algorithms replace such jobs with phenomenal increase in productivity. Nevertheless, entirely new jobs would be created although some degree of re-skilling might be necessary to ensure best fit and inclusiveness. After all, the textile sector has since quite some time adopted state-of-the-art fully automated spinning plants, where human intervention has been drastically reduced. Both India and Mauritius have recently launched their national AI strategies. The strategy papers indeed offer good potential for collaborative research, development and innovation in the textile sector.

2 Methodology

The views and insights reported in this paper are based on semi-structured interviews and telephonic conversations carried out with the managing directors of six textile factories in Mauritius. In most cases, their views reflect their future investment plans in AI-driven technologies, mainly to improve profitability and environmental footprint.

3 Impacts of AI

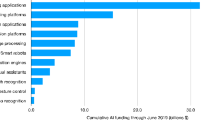

The textile industry’s product range is one of the most diverse in the manufacturing sector. The industry processes a variety of textile fibres; processing parameters and methods vary; the product mix is relatively high; value-added depends on end-use. With so many variables in the production set-up, the impact of AI is proving to be positive, wide-ranging and constructive. AI has nurtured a number of fast growing technology-enabled branches, Fig. 1. These established tools— machine learning (ML), machine vision, expert systems and robotics, etc.— will potentially augment the expertise of textile professionals and help them in their main mission, i.e. to produce according to specifications and fulfil customer requirements.

Myriad types of production/processes-related data that are deemed useless today and applications that are thought to be impossible are being enabled by sophisticated AI and ML algorithms. Smart algorithms are already delivering new insights about selection of raw materials, fabric construction parameters in order to engineer the thermo-physiological comfort properties of woven fabrics [1].

Thus the textile industry is expected to be a major beneficiary of AI based solutions, through flexible and adaptable technical systems to automate processes and machinery to respond to unfamiliar or unexpected situations by making processing decisions smarter. Other major potential impact areas include research & development, supply chain management (demand forecasting), and production as AI is poised to achieve cost reduction and increase productivity & efficiency.

According to market intelligence agency TrendForce (2019) [2], smart manufacturing supported by industrial IoT and AI is projected to grow noticeably in the next 3–5 years. The cost of smart manufacturing systems is expected to drop as the market grows from $200 billion in 2018 to over $320 billion by 2020. Another low-hanging fruit where AI can have major cost-benefit will be Plant Maintenance (predictive maintenance and reduced machine downtime) and increased asset utilization. Root Cause Analysis based on machine learning is a potential game changer as well. Given the variety of inputs in textile production (fibres, yarns, process parameters, water, dyeing and finishing chemicals, machine settings, etc.). ML-driven root cause analysis is a major area of interest for the Mauritian textile industry [3]. The directors interviewed reported that they are eager to collaborate with academia (local & overseas) in order to develop such a tool.

By 2030, all regions and sectors of the global economy will benefit from the tangible multiplier effects of AI. AI is expected to generate 15trillion USD of ‘value-added’ to the world economy, an amount greater than the combined GDP of China and India. By 2030, AI’s value-added to the Chinese economy is expected to reach 7.0 trillion USD, while that of the USA will be about 3.7 trillion USD. Europe and developed Asia would also experience significant economic gains from AI [4]. Thus, the overarching impact of AI in textiles research and development is expected to be highly dynamic. AI will create entirely new areas of research that can help the textile industry, especially those operating in the developing world, to comfortably align with Sustainable Development Goals (SDGs). This paper will not over-emphasise on the socio-economic and environmental challenges posed by the textile industry in developing countries.

3.1 Real Time Fabric Inspection

Since AI’s first successful commercial application was linked to pattern and image recognition, it is being adopted by Mauritian textile manufacturers for real-time fabric inspection. A simple system (adapted from existing commercial systems) is shown, Fig. 2. A smart camera unit acquires images of the fabric in real time. The images are processed by a local processing unit and then fed to the AI-driven fabric defect detection system. The system is equipped with a machine-learning algorithm, trained with a fairly comprehensive fabric data set, to identify defects and deviations from product specifications.

Real-time fabric inspection replaces operators’ visual fabric inspection, which is error-prone mainly due to fatigue. Mauritian fabric manufacturers argue that it has the potential to reduce claims for compensation from garment manufacturers to whom they supply finished goods. Compensation claims are a perpetual drain on their profit margins, which is quite slim owing to global competition. It is to be noted that claims made by garment manufacturers can sometimes amount to 50% of the invoice value, which makes the acquisition of such a system cost-effective and pertinent to the survival of the business.

3.2 Machine Maintenance

A systematic machine maintenance schedule or plan is a key pillar of an efficient textile manufacturing plant. Mauritian manufacturers believe that adoption of machine learning and data analytics may result in 10% reduction in annual maintenance costs, up to 20% machine downtime reduction and 25% reduction in inspection costs through predictive maintenance.

3.3 Supply Chain Management

Machine learning (ML) is a tool that is being increasingly used for supply chain forecasting. ML is expected to reduce forecasting errors by 50%; consequently reducing costs related to transport and warehousing and supply chain administration by 5–10% and 25–40%, respectively. AI and machine-learning algorithms are being integrated into purchasing, strategic sourcing and cost management.

3.4 The Human Factor

Textile and garment manufacturing has historically been labour-intensive. The industry generally recruited among the low-skilled and provided training on-the-job. Over the years, low-skilled labour has helped to keep production costs down. The automation of production processes was gradual but has been accelerating in the last quarter of the twentieth century. However, recent advances in artificial intelligence and cheaper cost of computing power have made expert systems more powerful and more affordable. Still, a human is required to decide where and how AI is deployed, and which key decisions are turned over to AI. Although automation has made the process of turning data into useful information faster than ever, it has not done away with the human task of endowing information with meaning, and acting on that information creatively. Nevertheless, AI is poised to replace jobs that are routine, repetitive and follow a specific pattern. Textile factories would gain by kick-starting training and re-skilling programmes to boost employee motivation and productivity. The textile and garment industry in Mauritius has already embarked on such training and re-skilling programmes. Stakeholders have emphasised that prior to the adoption of AI technologies, it is crucial to develop a coherent communication strategy with employees so that AI is not perceived as a job security risk factor.

3.5 Conclusions

Artificial intelligence is a potential game changer. It might revolutionise the way we manufacture textiles at scale, improve productivity and reduce negative environmental impacts. It will inevitably trigger the creation of new business models, possibly the Ubers and Airbnbs of the textile business.

Employees will need to become ‘AI literate’, adapt to the new work environment and to anticipate how AI can transform their career and role in the company. In general people are getting accustomed to the idea that automated decision-making by algorithms is increasingly going to be part of our daily lives and work-life. Workers will need to have a working knowledge of how algorithms work and how automated decisions are made, so that they can flag biased decisions, which may arise if the AI system has been trained with compromised data.

Finally, given the multi-pronged nature of AI and the fact that it is driving so many other technologies, developing a robust ethical framework is an absolute necessity, mainly for privacy and data security. This framework must also deal with AI’s impact on workers’ rights, which is at the core of sound industrial relations in Mauritius.

References

Abel J (Oct 2019) Predictive modelling of thermal contact feeling & thermal physiological comfort parameters of single layer cotton woven fabric. Ph.D. Thesis, University of Mauritius

http://mtci.govmu.org/English/Documents/2018/Launching%20Digital%20Transformation%20Strategy%20191218/Mauritius%20AI%20Strategy%20(7).pdf (Mauritius Artificial Intelligence Strategy, 2018)

https://www.pwc.com/us/en/press-releases/2017/report-on-global-impact-and-adoption-of-ai.html (PWC Report, 2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Rosunee, S. (2021). Leveraging Artificial Intelligence to Foster Innovation and Inclusive Growth in the Textile Value Chain. In: Midha, V., Mukhopadhyay, A. (eds) Recent Trends in Traditional and Technical Textiles. Springer, Singapore. https://doi.org/10.1007/978-981-15-9995-8_4

Download citation

DOI: https://doi.org/10.1007/978-981-15-9995-8_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9994-1

Online ISBN: 978-981-15-9995-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)