Abstract

Pavement performance depends mainly on the strength characteristics of subgrades. California Bearing Ratio (CBR) plays a vital role in the evaluation of subgrade strength in pavement design. Determination of the field bearing resistance of subgrades requires an equipment, labors, and is time consuming, therefore, several researchers have attempted to predict CBR value of a subgrade in the field from other nondestructive testing devices. One of the most versatile, rapid, and in situ nondestructive testing device is a lightweight deflectometer (LWD) which is used in estimating subgrade properties in various pavement projects. Developing correlations between CBR and LWD parameters including surface deflection, dynamic modulus, and degree of compatibility makes LWD an important alternative test used in the performance evaluation of pavement layers. In this paper, an attempt has been made to evaluate in situ strength by selecting two under construction street sites located at Karbala: Al-Takahe district and Al-Emam Ali district. The subgrade soils et al. -Takahe district and Al-Emam Ali district were classified according to AASHTO as A-1-b and A-3, respectively. The initial results showed the ability to predict bearing resistance of subgrades based on their basic physical properties and dynamic measurement obtained by an LWD test device.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

During the 1930s, an empirical testing method was developed by California Department of Transportation to evaluate the strength of subgrade soils and unbound base materials designated as the California Bearing Ratio (CBR) [1]. This test method was widely utilized by highway agencies which considered an essential design parameter that needs to be considered in the design of highway and airport pavements is the characteristic of the subgrade where the pavement is placed on. Subgrade materials are typically characterized by their resistance to deformation under load, which can be either a measure of their strength or stiffness. In general, subgrade resistance to deformation which can be expressed in terms of stiffness, modulus, density, and California Bearing Ratio (CBR) could reflect its load-carrying capacity before reaching a critical deformation value. However, many researchers developed correlative models to relate CBR with other test results to estimate the strength and stiffness of subgrades using different tests such as Dynamic Cone Penetration (DCP), Portable Light Weight Deflectometer (PFWD), Cyclic Triaxial (CT), Clegg Impact Values (CIV), and Miniaturized Pressuremeter Test (MPMT).

A lightweight deflectometer (LWD) is a portable device used to measure the in situ elastic modulus of pavement layers and fill embankments. The LWD is primarily used for soil subgrade evaluation before pavement design (mechanistic approach) and verification [2]. Although LWD is widely utilized for compaction quality control of soil layers in highway construction projects by determining the deflection (δ) of flexible pavement layers, it can also be used to determine the stiffness of surface soils (ELWD). The method of calculation of LWD modulus (ELWD) was based on Boussinesq elastic half-space theory [3]. LWD is gaining acceptance and has been widely used over the years as the pavement and transportation geotechnics community is currently moving toward more mechanistic-based design and quality control evaluation of pavement layers and embankment fills. The developments in testing methods such as LWD display more precise, ease of use, ease of portability, fast, non-distractive, and modern methods, in addition to the ability of determining the surface deflection and surface stiffness of compacted soil [4].

The main purpose of this research is to investigate the validity and reliability of two statistical models developed to predict the bearing resistance of local subgrade soil properties depending on either their physical properties or their dynamic measurement determined by an LWD test device. The first model was developed using LWD parameters which include surface deflection Sd, dynamic modulus Ed, degree of compatibility Dc as independent variables, and the second model was represented by considering Wc, and γdf as independent variables while the dependent variable is represented by the CBR value. This verification process could facilitate the understanding of the role of LWD parameters in determining the in situ bearing resistance of a subgrade.

2 Site Location and Layout of the Tests

In this study, two roadway projects in Karbala were selected to evaluate the strength of their subgrade soils: the first site project was Al-Takahe district, and the second was Al-Emam Ali district. The Al-Takahe zone is located at the west of Karbala which includes an arterial two-lane roadway with length 2000 m, and width 40 m, while Al-Emam Ali district is located at southwestern Karbala, which consists of four local streets with length 150 m and width 12 m and a collector with length 200 m and width 12 m; see Fig. (2). A construction project was conducted in Al-Takahe district, and 20 test points were selected for every 100 m on the center for constructed roadway, which starts from station 00 + 00 to station 20 + 00. Two testing techniques, including field density by core cutter method (CCM) and the LWD test, were performed, while eight test points were conducted for Al-Emam Ali district which starts from station 00 + 100 and to station 00 + 800. The LWD test was conducted in the same location of the field density test at both sites, as clarified in Figs. 1 and 2. After completing the field tests, a disturbed-soil sample has been collected and tested in a laboratory for identifying their basic properties. Standard laboratory tests according to ASTM and AASHTO procedures were conducted on each soil type to define the basic soil properties including sieve analysis, Atterberg limits, modified Proctor tests, and laboratory California bearing ratio test (CBR). Also, chemical tests were included to investigate the content of deleterious materials in subgrade soils (i.e., SO3, gypsum content, and total soluble salts).

3 Experimental Program

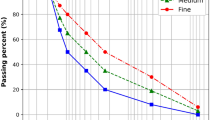

Laboratory Tests. Disturbed soil samples collected from the natural subgrade layers were subjected to standard laboratory tests for purposes of characterization. The results of physical and chemical tests are summarized in Table 1. The grain size distribution of the selected subgrade soils is presented in Fig. 3. Additionally, the maximum dry density and optimum moisture content from the modified Proctor test are clarified in Fig. 4.

Field Tests. Two test methods were adopted in this experimental work: lightweight deflectometer test (LWD) according to ASTM E2583 and core cutter method (CCM) according to ASTM D2937. Subgrades’ dynamic properties in terms of dynamic modulus, surface deflection, and the degree of compatibility were obtained by performing the LWD test whereas, dry unit weight, wet unit weight, moisture content, and degree of compaction of compacted natural subgrade layers were determined by conducting the CCM test.

Lightweight Deflectometer (LWD). A portable LWD device which is manufactured by ZORN instruments (Type ZFG 3.0) was utilized in the work. The main purpose of using this device was to evaluate subgrades’ dynamic and compaction characteristics. As shown in Fig. 5, the LWD consists of three main components: 1) loading device which includes a (10 kg) drop weight, 2) 30-cm loading plate equipped with an accelerometer to measure the vertical surface deflection of a soil, and 3) a portable control unit utilized to display and record LWD testing measurements [12].

Analysis of Lightweight Deflectometer (LWD) Data. LWD is defined as a nondestructive testing device used to determine in situ stiffness properties of pavement materials under the effect of dynamic impact loads at in situ conditions. This device provides a single dynamic stiffness back-calculated based on actual wave velocity propagated inside a pavement layer [12]. The influence depth of LWD pulse is at range 1.5–2.0 times the diameter of the loading plate; for this reason, the LWD device is considered as not a suitable device to evaluate in situ stiffness for depth that is often greater than 20 inches (50.8 mm).

The LWD parameters measured during this test are listed below:

-

Surface Deflection (Sd): it is derived by double integrating the acceleration data concerning time of pulse waves. The acceleration data are recorded using an accelerometer subjected inside the loading plate.

-

Dynamic Modulus (Ed): it is back-calculated from Sd depending on Boussinesq elastic half-space theory that can be presented by the following expression [13].

where is the Ed (MPa), σo is peak applied stress (MPa), a is the radius of loading plate (mm), and υ is the Poisson’s ratio, δ is peak vertical deflection (mm), and f = plate rigidity factor which is typically assumed (f = 2) for LWD ZFG model.

-

Degree of Compatibility (Dc): a soil parameter that gives an indication about compaction characteristics of the pavement layer and can be determined by dividing the mean surface deflection by the mean pulse velocity of dynamic impact load applied in the surface layer. Generally, the compaction effort is good if the degree of compatibility is less than or equal to 3.5, while further compaction effort is recommended if the Dc is greater than 3.5 [14].

Determination of In situ Density by Core Cutter Method (CCM). Dry unit weight (gm/cm3), wet unit weight (gm/cm3), moisture content (%), and degree of compaction (%) can be determined using a core cutter test method according to ASTM D2937. This method can be used successfully whenever soil conditions permit pushing of cutter for sampling and taking it out in the laboratory without much disturbance. AASHTO restricted CCM for determining the in-place density in soils containing particles not larger than 50 mm (2 in.) in diameter.

4 Results and Discussion

Table 2 summarizes the LWD measurements of soil samples collected from the designated sections. The average of surface deflection indicates that the data extracted from the integration process for 20 test points performed was recoded as 0.301 mm for A-1-b and 0.316 mm for A-3 subgrade soil, while the values of average dynamic modulus for A-1-b was 86.25 Mpa and 73.648 Mpa for A-3. Lastly, the average value of the degree of compatibility of subgrade soil was 2.50 ms and 2.687 ms for A-1-b and A-3, respectively.

The data of moisture and density of soil samples from the pavement layers at the designated sections are presented in Table 3. The results of A-1-b indicate that the wet unit weight average was 1.919 gm/cm3 and A-3 average results were 2.177 gm/cm3, while the average moisture content was 4.912% for A-1-b and 7.895% for A-3. Lastly, the average of dry unit weight for A-1-b and A-3 was 1.927 gm/cm3 and 2.018 gm/cm3, respectively.

To evaluate a bearing resistance of subgrade soils, a comparison analysis was performed between two developed statistical models developed in the previous work by Al-Fatteh Allah et al. (2019) [14]. Experimental results and regression analyses by using SPSS software was employed to develop two models: the first model was represented by considering LWD parameters (Ed, Sd, Dc) as independent variables; see Eq. (1), while the second model was represented by considering Wc and γdf as independent variables to predict CBR value as a dependent variable for subgrade soils as shown in Eq. (2):

The bivariate Pearson correlation between variables for statistical analysis was present a correlation between dependent variables CBR and independent variables (LWD parameters), that caused to absent the effect of surface deflection (Sd) and illustrate Ed has the most significant correlation to bearing soil capacity, then Sd, and lastly Dc [15]. A comparison between two predicted models was conducted; the bearing resistance of the subgrade layer A-1-b depending on LWD parameters ranged 23.78 to 28.71% with an average of 26.22%, and for A-3 it ranged 26.62 to 27.56% with an average of 26.98%, while the bearing resistance of subgrade depending on physical properties ranged 20.59 to 57.75% with an average of 32.92% for A-1-b and 50.61–52.70% with an average of 52.7 for A-3. See Fig. 6.

Comparison and verification between results for two predicted models to determine the bearing resistance of subgrade according to LWD parameters once and to their basic physical properties otherwise were conducted and they show that the in situ CBR value is lower than that of the laboratory results, this decrease in results is due to the difference in environmental conditions, such as a change in moisture content including the temperature and evaporation effect, in addition to the effect of boundary restricted and applied compaction effort which is an effect in the degree of compactions, which affect during field tests and hence will change the particle size distribution at remolded CBR specimens of the laboratory tests. Also, the results indicate that the ratio between two developed models (CBR predicted according to LWD parameters/CBR predicted according to the physical properties) were 1.03; this result indicates that the developed models were acceptable to predict bearing resistance for A-1-b subgrade soils, while the difference between predicted CBR value for A-3 subgrade soil is equal to 1.96 due to the effect of gypsum content of subgrade which employed to build the models and hence caused to increase CBR value for the developed model that agreed completely with Ahmed [16] reported that the compressive strength values for poorly graded sandy soil samples stabilized with recycled gypsum increased from 14.42 kPa to 25.43, 81.99 and 331.18 kPa due to adding 5, 10, and 20% content of recycled gypsum, respectively. This can be explained by the addition of recycled gypsum to the soil causing cementation or hardening of soil particles; thus, cohesion strength between soil particles is developed for this reason and this developed model is considered unreliable to predict the CBR value.

5 Conclusion

From experimental works of this research study, the following can be concluded:

-

Modeling the CBR value for A-1-b subgrade soil concerning the dynamic measurement of LWD parameter inputs is achievable and satisfactory in terms of predicting the bearing resistance of subgrade soils.

-

Modeling the CBR value for A-3 subgrade soil regarding their basic physical properties is unsatisfactory to the prediction of the bearing resistance of subgrade soils.

-

The experimental works show that the LWD parameters have the most significant correlation than the field dry density and moisture content to predict bearing resistance of subgrade soils.

References

Shaban AM, Cosentino PJ (2017) Characterizing structural performance of unbound pavement materials using california bearing ratio tests. J Testing Evaluation. ASTM, 3–45

Jitareekul P, Sawangsuriya A, Singhatiraj P (2017) Integration of pavement layer evaluation using LWD for road safety control. Procedia Engineering. (May), 111–117

Fleming P, Frost M, Lambert J (2009) Lightweight deflectometers for quality assurance in road construction, Bearing Capacity of Roads; Railways and Airfields: Proceeding of the 8th International Conference, 809–818

Kongkitkul W, Saisawang T, Thitithavoranan P, Kaewluan P, Posribink T (2014) Correlations between the surface stiffness evaluated by light-weight deflectometer and degree of compaction. In Tunneling and Underground Construction, 65–75

ASTM D2487 (2011) Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System)

AASHTO M145 (2012) American association of state and highway transportation officials. Standard Specification for Classification of Soils and Soil-Aggregate Mixtures for Highway Construction Purposes

ASTM D1557 (2012) Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort

ASTM D4643 (2008) Standard Test Method for Determination of Water ( Moisture ) Content of Soil by Microwave Oven Heating 1

ASTM standard D1883 (2014) Standard Test Method for CBR (California Bearing Ratio) of Laboratory-Compacted Soils. ASTM Int West Conshohocken, PA

BS1377–3 (2010) Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils 1. 1990 (March)

BS1377–3 (1990) Soils for civil engineering purposes—Chemical and electro-chemical tests (1)

Ryden N, Mooney MA (2009) Analysis of surface waves from the light weight deflectometer

Shaban AM, Cosentino PJ (2016) Comparative analyses of granular pavement moduli measured from lightweight deflectometer and miniaturized pressuremeter tests. Transportation Research Boar

Shaban AM (2016) Evaluation of unbound pavement layers moduli using the miniaturized pressuremeter test

Al-Fatteh Allah R, Al-Busaltan SMA (2019) Determining field bearing resistance of subgrade soils using physical characteristics. Fourth Scientific Conference for Engineering and Postgraduate Research, 8–14

Ahmed KI (2013) Effect of gypsum on the hydro-mechanical characteristics of partially saturated sandy soil [Ph.D. thesis]. Geoenvironmental Research Centre, Cardiff School of Engineering, UK: Cardiff University

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Al-Fattehallah, R., M. Shaban, A., Al-Busaltan, S. (2021). Use of Lightweight Deflectometer for Evaluating in Situ Strength Characteristics of Pavement Foundations in Kerbala. In: Karkush, M.O., Choudhury, D. (eds) Modern Applications of Geotechnical Engineering and Construction. Lecture Notes in Civil Engineering, vol 112. Springer, Singapore. https://doi.org/10.1007/978-981-15-9399-4_16

Download citation

DOI: https://doi.org/10.1007/978-981-15-9399-4_16

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9398-7

Online ISBN: 978-981-15-9399-4

eBook Packages: EngineeringEngineering (R0)