Abstract

The improvement in thermal comfort of a building passively helps in reducing its energy utilization, throughout the year. Several factors are directly related to reducing the cooling and heating load of the building such as orientation and the material used in it. In this study, authors have proposed a new wall and roof panel system namely Ferro Cellular lightweight-concrete Insulated Panel Assembly (FCIPA) for a building. This panel system has been tested experimentally in direct axial compression and is compared with brick masonry wall at small scale. Further, it has been tested theoretically for thermal analysis using eQUEST energy simulation program. The thermal study was conducted on an existing residential building of New Delhi, India, by changing the components of wall and roof of the building with three different kinds of construction material namely brick, concrete, and FCIPA. Moreover, the effect of orientation and the type of window glass on the thermal efficiency of the building were also studied. It was found that the FCIPA has the load-bearing capacity equivalent to half brick thick (120 mm) masonry wall. In addition, in terms of the energy use, FCIPA based building consumes nearly half of the thermal energy to that of the precast concrete and brick masonry based buildings. The results of the theoretical analysis also show that the north-south orientated building with longer axis running toward east-west having gray glasses window/doors openings is the most energy-efficient.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Protection from extreme weather and environmental conditions is one of the basic needs of a human being. Energy consumption and thermal insulation are two major factors which are effective in this problem. Energy management has emerged as a critical economic issue and a top priority for policymakers. Unsustainable energy supply and demand have serious implications spectrum from household budgets to international relations [1]. Developing and developed countries spend a huge amount of money for the thermal comfort of the buildings, in these countries, the consumption of energy in both residential and commercial buildings has been increasing very rapidly. The best possible solution to overcome this problem is to introduce insulating materials in building envelope which can efficiently enhance the thermal performance of walls, roof and other parts of the building. Due to low thermal conductivity values of insulating materials, the heat flow through building envelope is reduced effectively which results in the balance of indoor temperature.

It can be seen from Fig. 1 that the usage of heating and air conditioning energy is maximum for residential and commercial buildings. It is driven by the heat transferred through the exterior walls of the building and the roof which is the largest component of energy load for cooling or heating the spaces inside the building. Any reduction in the rate of transfer of heat will result in a drastic decline in power consumption by the air conditioner. The passive insulated building system also indirectly supports the green building approach by reducing the release of harmful emissions due to the production of electricity through the power plant. Hence proper insulation of building walls and roof with optimal insulation thickness is an easy solution to reduced cooling/heating load over the lifetime of the building.

Energy use in U.S. residential and commercial buildings by end-use, 2014 [2]

Researchers have suggested several factors which are responsible for cooling and heating of the building. At the time of construction if these factors are taken into account, then it will be possible to further reduce the electricity load to a large extent. The first factor is the orientation of the building, it is well recognized that the amount of heat gained in a building from the sun also depends on the orientation and layout of the building. Hence in order to improve the thermal behavior of buildings in warm climates, solar heat gain should be reduced and preferably controlled. It is reported in the literature that the best orientation for warm climatic zones is true north-south orientation with the longer axis of the building running from east to west. In a composite climate (Climate that displays the characteristics of hot and dry, warm and humid as well as cold climate) such as New Delhi, it is found that there can be a difference of as much as 2.7 °C in air temperature in a building on summer afternoons between the worst and best orientation [3]. The importance of orientation on indoor climate is emphasized by many researchers [4, 5].

The second factor and the most important one is the insertion of insulation material in the building envelope with the optimal thickness. In this aspect, a mathematical study was carried out with XPS and EPS to check the effect of insulation thickness for different building materials such as concrete, brick, briquette, blokbims, and autoclaved aerated concrete (AAC) in climatic condition of Elazig, Turkey. The value of optimum insulation thicknesses of walls constructed of concrete, briquette, brick, blokbims, and AAC were obtained as 5.6, 5.3, 5, 3.4 and 2 cm with XPS insulation, and as 8.2 cm, 7.8 cm, 7.4 cm, 5.4 cm and 3.6 cm with EPS insulation, respectively. Similarly energy saving in $/m2 were 98, 67, 48, 11, 2.7 for XPS and 102, 70, 51, 13, 4 for EPS respectively [6]. This study shows the dependence of thermal conductivity and thickness of insulation material for better thermal insulation of the building.

The third factor that plays a significant role in maintaining the temperature, as well as the other daylight factors in the building, is the type of glass used in making windows/doors. In this aspect, when six different types of glasses were studied using a MATLAB program i.e. bronze, green, gray, bronze-reflective, green-reflective and gray-reflective glasses, the green-reflective glass placed in south orientation was found to be the best due to its adequate daylight factor (2.05–2.06%) in summer season and bronze glass window placed in north orientation was observed to be the best due to its sufficient daylight factor (2.2–2.8%) in winter among six studied window glass materials [7].

From the above discussion, it can be seen that most of the previous studies just emphasized to reduce the lifetime running cost of the building by applying various energy stabilization techniques. However, the applications of these techniques are not enough for the safety and strength of the residential buildings and also add an extra effort and cost in building construction. Similarly Structure Insulated Panels (SIPs) are not feasible for the application of external walls of a residential building due to their unsatisfactory results in impact, axial and flexural type of loading conditions as reported in reference [8,9,10,11].

On the other hand, the traditional construction through brick-and-mortar does not provide the temperature control insulated homes, and furthermore, it is time-consuming, costlier and responsible for the heavy dead load of the structure.

Therefore, in the present study, authors have proposed a new wall and roof panel system (comparable to brick masonry wall and structure insulated panels (SIPs) in terms of mechanical strength and energy efficiency respectively) namely Ferro Cellular lightweight-concrete Insulated Panel Assembly (FCIPA) for a building. This panel system has been tested experimentally in direct axial compression and compared with brick masonry wall at a small scale. Additionally it has been tested theoretically in full-scale building for thermal analysis using eQUEST energy simulation program. Moreover, the effect of orientation and the type of window glass on the thermal efficiency of the building was also studied.

2 Proposed FCIPA

The proposed system is based on the assembly consisting of three layers of different materials bonded to each other with the help of structural adhesive to one side and self-bonded to the other side at the time of fabrication. The 10 mm of thick fiber cement sheet of the panel is bonded with XPS insulation which is directly attached with cellular lightweight concrete (CLC) with the help of insulated fasteners. Different layers of the assembly are shown in Fig. 2.

3 Behavior of FCIPA Under Direct Compression

4 Thermal Analysis of Building

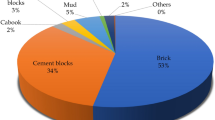

The theoretical study was conducted on an existing residential building using eQUEST energy simulation module. The eQUEST is a widely accepted building and HVAC system energy analysis tool available as an interface to the Department of Energy’s calculation engine, DOE-2. It is used to provide energy simulation for the public building that uses real localized weather data and can be operated by professionals [12]. The emphasis has been given to incorporate all the important factors influencing the temperature variation in the buildings, i.e. (a) orientation of the building (b) Material used in the construction of walls and roof (c) Glass in window/door. Initially, in the first stage, the effect of orientation has been worked out on a building with precast concrete wall and roof system. In the second stage, the material behavior has been compared for the best possible orientation selected at stage first. In this stage, the authors have compared two common types of building a wall and roof members made up of concrete and brick material with a FCIPA. The specifications of the different materials used in the study are shown in Table 2.

The thermal conductivity values of all the materials used in forming the FCIPA was given by the supplier, while the U value was calculated using the formula given in reference [13]. In the last phase, the effect of different windows and door glasses on the thermal efficiency of the building was studied.

The composite climate of New Delhi is an overlap between monsoon-influenced humid subtropical and semi-arid with high variation between summer and winter temperatures and precipitation. The monthly average temperature data of New Delhi is shown in Table 3.

To perform the energy simulation, a two floor 2BHK, building with 125 square meters of the covered area was chosen. The location of the building is in New Delhi, India. The 3D image of the building model made produced by eQuest program for energy simulation is shown in Fig. 4. This building was analyzed at different temperature conditions and was divided into different conditioned and unconditioned zones based on the usage. The simulation occurs by considering only 30% full day occupancy throughout the year. The air conditioning system used was DX coil based Split AC system having the compatibility for both summer and winter season.

4.1 Building Orientation

The first simulation was carried out by assuming all the components of building as made up of precast concrete to obtain the best value of the building orientation in terms of thermal efficiency. To analyze this criterion four simulation runs were performed at different angles of orientation. The results of all parametric runs are shown in Table 4.

4.2 Building Material and Insulation Type

Now by keeping the orientation along the longer axis running toward E-W, the authors have differed the form of material for the wall and roof of the building according to the details given in Table 2.

The results of the three separate parametric runs namely Run 1 for concrete walls, Run 2 for brick walls and Run 3 for FCIPA is shown in Fig. 5. Whereas Fig. 6 shows the detailed energy consumption for the most energy-efficient building envelope.

4.3 Building Glass Window/Door

The final simulation was conducted by keeping the building orientation along the long axis toward E-W direction and material of wall and roof construction is of FCIPA. Two different types of window glasses were studied to check the effect of the window for the thermal comfort of the building. The properties of two glasses used in the parametric runs are given in Table 5. The result of the simulation is shown in Fig. 7.

5 Results and Discussions

5.1 Strength Tests on FCIPA

FCIPA shows no transverse movement in axial compression throughout the loading period, however the downward deflection occurs uniformly with every unit increase of load. Finally above 80 kN the outer side of the panel made up of cellular lightweight concrete (CLC) starts crushing from the bottom, while the inner side of fiber cement board debonded and buckle. On the other hand, the brick masonry wall shows brittle failure at the load of 90 kN and the longitudinal crack developed from top to bottom of the specimen. This result ensures that the three times lighter in weight FCIPA has comparable axial compressive strength that of brick masonry wall. Hence it can be replaceable to brick masonry in the construction of high strength building wall panels.

5.2 Effect of Orientation on Building Thermal Efficiency

From Table 4 It can be seen clearly that, the least amount of energy consumption occurred when the long axis of the building was running toward the E-W direction. While maximum energy consumption was found for S-N direction. The possible explanation for this case is that in E-W direction there is single opening for window along the southern part of the building while in comparison, S-N directed building has maximum amount of exposure to external environment/sunlight. Hence this result shows that the building should be constructed in such a way that it has oriented along N-W direction while longer axis running toward E-W so that less number of openings can be made along the south wall of the building. These results also confirm the previous studies conducted in reference [3,4,5].

5.3 Effect of Material on Building Thermal Efficiency

The results of Fig. 5 show that, there was a change in energy consumption from 4789 to 4173 kWh for the year 2018, when the concrete wall was replaced by conventional brick masonry wall, On the other hand when the brick masonry wall was replaced by FCIPA, the drastic fall in electric energy consumption was seen from 4173 to 2508 kWh per year. The reason for this behavior is the low thermal conductivity values of all the materials used in FCIPA.

With the help of Fig. 8, it can be observed that throughout the year the electricity consumption is less in case of FCIPA building envelope in comparison to brick masonry and concrete-based building envelope. Additionally, when the weather becomes hot and the temperature rises from the month of April to end of September, FCIPA based building shows more energy-efficient behavior and the electricity consumption reduced to very low.

5.4 Effect of Window/Door Glass on Building Thermal Efficiency

It can be seen from Fig. 7 that 137 kWh of electrical energy can be conserved yearly when clear window glass was replaced by the single gray glass in all windows and doors opening of the building. As lower the value of all properties for window and door glass given in Table 5, lesser will be the energy consumption for the building.

6 Cost and Benefit Analysis

The cost of masonry wall construction was calculated based on the local market rate while the cost of FCIPA was calculated after including individual item cost of assembly, fabrication and installation cost. It has been found that the total cost increases 1.6 times when Brick masonry was replaced by FCIPA. The cost of the FCIPA and brick masonry for the construction of the walls and roof of the building are given in Table 6.

7 Conclusions

The following are the conclusions made from the above study

-

The most efficient method to reduce energy consumption in a residential or commercial buildings is the incorporation of insulation materials in building envelope.

-

FCIPA can replace brick masonry wall, as it has equivalent mechanical strength values to that of brick masonry wall while three times lesser in weight. On the other hand in terms of energy efficiency, it consumes just 2508 kWh of electrical energy per year, whereas concrete-based wall consumes 4789 kWh electrical energy per year. Thus the energy consumption in FCIPA was nearly half of the value of the concrete-based precast system and 60% to that of brick masonry system.

-

The most thermally efficient buildings are those, which are oriented along the N-S direction with the longer axis running from E-W.

-

The incorporation of a suitable window and door glasses having lower values of thermal conductivity, shading coefficient, and visible transmittance can help to reduce the electrical energy consumption in buildings of composite or hot climate regions throughout the year.

References

Green Building. Available: https://www.usgbc.org/articles/green-building-101-why-energy-efficiency-important

Quadrennial Technology Review: An assessment of energy technologies and research opportunities, Chapter 5 : Increasing Efficiency of Building (2015)

Sodha, M.S., Kaur, J., Sawhney, R.L.: Effect of orientation on thermal performance of a building. IJER 16, 709–715 (1992)

Mazria, E.: Passive solar energy book (1979)

Saeed, S.A.R.: Indoor climate as a function of building orientation. Int. J. Ambient Energy 8, 41–47 (1987)

Ozel, M.: Thermal performance and optimum insulation thickness of building walls with different structure materials. Appl. Therm. Eng. 31, 3854–3863 (2011)

Kumar, G.K., Babu, T.A.K.: Study of various glass materials to provide adequate day lighting in office buildings of warm and humid climatic zone in India. Energy Procedia. 109, 181–189 (2017)

Sharaf, T., Shawkat, W., Fam, A.: Structural performance of sandwich wall panels with different foam core densities in one-way bending. J. Compos. Mater. 44, 2249–2263 (2010)

Mousa, M.A., Uddin, N.: Structural behavior and modeling of full-scale composite structural insulated wall panels. Eng. Struct. 41, 320–334 (2012)

Vaidya, A., Uddin, N., Vaidya, U.: Structural characterization of composite structural insulated panels for exterior wall applications. J. Compos. Constr. 14, 464–469 (2010)

Smakosz, T., Tejchman, J.: Evaluation of strength, deformability and failure mode of composite structural insulated panels. Mater. Des. 54, 1068–1082 (2014)

Birdsall, B., Buhl, W.F., Ellington, K.L., Erdem, A.E., Winkelmann, F.C.: Overview of the DOE-2 building energy analysis program, version 2.1 D (1990)

Brennan, J., Lecturer, S.: U-values : definition

Temperature data. https://en.wikipedia.org/wiki/Climate_of_Delhi#cite_note-29

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Khan, M.Y., Baqi, A., Talib, A. (2021). Energy Efficiency Analysis of a Building Envelope. In: Bose, M., Modi, A. (eds) Proceedings of the 7th International Conference on Advances in Energy Research. Springer Proceedings in Energy. Springer, Singapore. https://doi.org/10.1007/978-981-15-5955-6_160

Download citation

DOI: https://doi.org/10.1007/978-981-15-5955-6_160

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-5954-9

Online ISBN: 978-981-15-5955-6

eBook Packages: EnergyEnergy (R0)