Abstract

Brick masonry wall is the more common walling system being used in residential buildings. As the demand for housing is increasing, new construction materials are coming up in the market and being utilized in the construction. Solid concrete blocks (SCB) and autoclave aerated concrete (AAC) blocks are the two materials which are most commonly used in most of the construction sites apart from the clay bricks (CB). The thermal behaviour of the buildings with these materials needs to be studied. It is also necessary to reduce the heat inside the building to improve the human comfort. Effect of coating material over roof also needs to be studied. Living comfort inside any building mainly depends on the “thermal comfort”. Thermal comfort mainly involves the interior conditions of the rooms, i.e. mainly temperature and humidity, maintaining and distributing it evenly, and the quality of air (purity, humidity rate, healthiness). By providing a thermal insulation to all the surfaces combined with seasonal adoption of ventilation, thermal comfort can be achieved in different climate conditions. By keeping these points in a view, a thorough study was conducted to know the thermal variations in various house models by varying the wall type. Results indicated the superior thermal performance of the model with AAC block in comparison with the models made with solid concrete block and clay brick.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Anyone who lived in the building or a different climate conditions may have experienced the discomfort of particularly very higher temperatures during the summer season compared with the other seasons. In India, most of the newly constructed buildings are constructed of concrete with a flat roof. These surfaces absorb sunlight and transfer the heat inside the building [1]. This hot roof continues to heat up the space in day and night and making the building more hotter especially in the summer season.

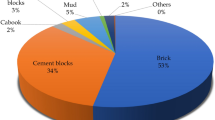

Thermal insulation of wall components and cool roof coating of roof is provided to control heat transfer [2]. Temperature and humidity in the building are important factors influencing the human discomfort. The wall components in most of the buildings are constructed either with clay bricks or solid concrete blocks or autoclaved aerated concrete blocks. Out of which, brick is one of the most extensively used construction material which is used in the construction of the walls [3]. Introduction of holes in the clay bricks reduces volume and as well as it increases the insulation.

Autoclave aerated concrete blocks are made by using sand, quick lime, water, gypsum, cement and small amount of chemical used as foaming agent. AAC has good thermal insulation and good absorption properties. AAC blocks are lightweight and offer ultimate workability, flexibility and durability.

A solid cement concrete block (SCB) is extensively used as a building material in the construction of walls. These blocks are available in different sizes. In manufacturing of the solid cement concrete block, concrete mixes use cement, sand, gravel and water in the suitable proportion for the construction. The solid concrete block are water resistant, aesthetic appearance and fire resistant [4].

The main objective of the present work is to study the temperature variations of various building models with different walling systems and also to study the reduction in roof temperature by applying the roof coatings.

2 Literature Review

Vengala et al. [5] conducted limited studies on two models one with AAC blocks and another with solid concrete blocks. The studies indicated that AAC block model showed better thermal comfort in comparison with the solid concrete block model, i.e. during day time cooler by 1–2 °C. Between these two models, the maximum temperature difference observed was 3 °C.

Patil et al. [6] carried out a theoretical analysis on thermal analysis of RC Roofing with various composite materials. Composite materials comprised of RC Roofing with polyurethane foam, RC Roofing with polystyrene, RC Roofing with polyurethane foam and GI sheet, RC Roofing with polystyrene. Based on the analysis, the combination of RC Roofing with polystyrene and GI sheet was found to be feasible in improving the thermal comfort. Techno-economical analysis carried out showed the least cost for a combination of RC Roofing with polystyrene and GI sheet.

Perez et al. [7] studied the thermal performance of a solid roof top with and without insulation by varying two colours using the finite volume method. The insulating material comprised of polystyrene, and colour variation considered was grey and white. The roofing with white coloured coating significantly reduced the interior surface temperature when compared with grey coloured coating.

Dharek et al. [8] investigated the efficacy of cool roof coatings w.r.t thermal analysis for the Bengaluru region. Aluminium-based coating and acrylic-based coating were considered as part of the study. The temperature variations were recorded with sensor-based digital temperature data loggers on the scaled models with these coatings. The models coated with aluminium-based coatings showed better performance in bringing down the temperature levels inside the scaled building models. Parametric analysis carried out as part of this study indicated total heat loss being more for models without coating.

3 Experimental Programme

The house models were set up on the roof portion of a building in the college. The models are directly exposed to the sun to simulate the real-time conditions. The models were constructed in the month of May. Based on the temperature data obtained [9] in Fig. 1, the temperature values in Vijayawada used to reach peak in the month of May.

Vijayawada temperature map [9]

For temperature measurements, three model houses were built. The size of the house model was 1.5 m × 1.5 m × 0.87 m. Each model building has same size and shape, but each one was built with different building materials. One was constructed using solid concrete blocks (SCB) and clay brick (CB), and the other was constructed using autoclave aerated concrete blocks (AAC). Table 1 gives the details of the materials used in both the model rooms used for thermal comfort studies.

The model buildings were equipped with DH11 sensors to measure the internal temperature and the humidity. Raspberry Pi module was used to record the temperature measurements. Figure 2 shows the testing of the sensor set-up before installing on to the models.

The model buildings are constructed in the Vijayawada region. The models have the two windows on either side with dimension of 0.3 m × 0.6 m one on the southern wall and another on northern wall. The height between the inner slab surface and floor level is 0.87 m, i.e. inside model. Figure 3 shows the view of building models.

To understand the effect of coating on the roof surface, three more building models constructed using AAC Block, CB and SCB, and white acrylic cool roof coating was applied on these models as shown in Fig. 4. Before applying the coating, surface preparation was carried out. Two coats was applied on the surface. Temperature values were measured for the building models with and without coating.

4 Results and Discussions

This section presents the temperature and humidity results of block specimens for 30 days under varying climate conditions. The temperature readings were obtained after continuous monitoring. Data loggers were placed on the top surface of roof and inside the model house. DH11 sensors were placed in each type of building model. Temperature and humidity data was recorded for all the models, and average temperatures were calculated. Table 2 gives the temperature and humidity data of a typical day in the month of May for model house with AAC Block. The table gives the average hourly temperature and humidity data between 10 AM to 4 PM. The peak temperature values were observed between 1 and 2 PM. From Table 2, it can be seen that the difference in temperature is almost 9–10 °C during the peak hours.

Tables 3 and 4 give the temperature and humidity data for the house model with CB and SCB, respectively. Even in these house models, significant difference in temperature was observed during the peak hours.

Table 5 presents the average hourly temperature during the entire month, i.e. May for the model house with AAC blocks.

Figure 5 represents the average hourly temperature values for all the three houses during the peak hour. From the figure, it is evident that AAC block house model has the less value followed by SCB model and CB model. From Fig. 6, it can be seen that the temperature difference with ambient is high in case of AAC block house model followed by SCB model and CB model. This clearly shows the better performance of AAC block house model in comparison with other two house models. Table 6 presents the average hourly humidity values during the entire month, i.e. May for the model house with AAC blocks. Table 7 gives the average temperature difference (Fig. 7) and humidity values for all the three houses during the month of May.

Relative humidity affects both thermal comfort and indoor air quality. As air temperature increases, the RH decreases. High RH make people hot and sticky in warm weather. Low RH (very dry air) can cause dryness and discomfort in the nose and make skin feel dry and itchy.

From Fig. 8, it can be seen that the humidity difference with external value is high in case of AAC block house model; hence, the humidity inside the model is less when compared with other two house models. This indicates the good thermal comfort inside the AAC house model.

Table 8 gives the details of the average difference in temperature values for the models with and without white acrylic coating. The effect of coating over the roof surfaces reduces an internal temperature of 2 °C for all the house models.

Based on the studies conducted on house models, AAC model shown better thermal comfort in comparison with the model with SCB and clay brick (CB). The thermal conductivity of clay bricks and solid concrete blocks is comparably high in comparison with AAC blocks, and hence, heat transfer from solid block/clay brick is more than AAC block.

5 Conclusions of the Present Study

The following conclusions have been drawn from the above study.

-

Average difference of outside ambient temperature and internal temperature variation of nearly 4 °C in the brick model, 6 °C in a solid cement block and 8 °C in an autoclaved aerated concrete block in models without coating.

-

With a white acrylic coating (cool roof based coating), the difference in temperature with and without coating was 10 °C, 8 °C and 6 °C, respectively for AAC block model, SCB model and clay brick building model.

-

Among the three models, AAC block house model showed the more reduction in humidity inside the model when compared to external humidity. This resulted in better comfort inside the AAC model.

-

Among the solid concrete block model and clay brick model, SCB showed better performance and this may be due to the thickness of the walling material when compared with the clay brick wall.

References

Vengala J, Nath SK, Pandey CN (2011) Energy consumption of wood based panel products: a review. J Indian Acad Wood Sci 8:80–83. https://doi.org/10.1007/s13196-012-0052-9

Vengala J, Dharek MS, Sachin D, Ghanashyam TB (2021) Thermal analysis of building model with acrylic and aluminium based roof coating materials. Materials today: Proceedings. https://doi.org/10.1016/j.matpr.2021.03.008

Vengala J (2020) Comparison of embodied energy in different bamboo-based houses. In: Pancharathi R, Sangoju B, Chaudhary S (eds) Advances in sustainable construction materials. Lecture notes in civil engineering, vol 68. Springer, Singapore. https://doi.org/10.1007/978-981-15-3361-7_15

Vengala J, Raju S, Shiva B, Manjunatha LR, Yogananda MV (2020) Use of GGBS in manufacturing of solid concrete blocks. In: Babu K, Rao H, Amarnath Y (eds) Emerging trends in civil engineering. Lecture notes in civil engineering, vol 61. Springer, Singapore. https://doi.org/10.1007/978-981-15-1404-3_16

Vengala J, Mangloor S, Goud TKC (2019) Performance of autoclaved aerated concrete blocks under varying temperatures. Int J Recent Technol Eng (IJRTE) 7(6C2). ISSN: 2277-3878

Patil SE, Shinde Nn (2014) Theoretical analysis of composite roof with respect to comfort in building envelope. Curr Trends Technol Sci 3(3):168–172

Hernández-Pérez I, Álvarez G, Gilbert H, Xamán J, Chávez Y, Shah B (2014) Thermal performance of a concrete cool roof under different climatic conditions of Mexico. Energy Procedia 57:1753–1762. https://doi.org/10.1016/j.egypro.2014.10.164

Dharek MS, Vengala J, Sachin D, Ghanashyam TB (2020) Model based comparative thermal analysis on cool roof coatings in Bengaluru. Int J Adv Sci Technol 29(7):4272–4280. Retrieved from http://sersc.org/journals/index.php/IJAST/article/view/23219

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Vengala, J., Chava, S., Pydipati, P. (2022). Thermal Comfort Studies of Residential Building Models in Vijayawada. In: Nandagiri, L., Narasimhan, M.C., Marathe, S., Dinesh, S. (eds) Sustainability Trends and Challenges in Civil Engineering. Lecture Notes in Civil Engineering, vol 162. Springer, Singapore. https://doi.org/10.1007/978-981-16-2826-9_8

Download citation

DOI: https://doi.org/10.1007/978-981-16-2826-9_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-2825-2

Online ISBN: 978-981-16-2826-9

eBook Packages: EngineeringEngineering (R0)