Abstract

This research focuses on bio-inspired modeling and control system of an underwater flexible manipulator system (UFM). The dynamic behavior of the UFM was first modeled using system identification (SI) methods utilizing bio-inspired algorithms. The input–output data used for identification were acquired directly from a laboratory-sized UFM experimental rig developed earlier by the previous researcher. The models were developed using cuckoo search algorithm (CSA) and flower pollination algorithm (FPA) using parametric ARX model structured. For the controllers of the UFM, proportional-integral-derivative (PID) controllers were tuned using conventional heuristic and intelligent FPA methods. These algorithms were utilized to obtain the optimal values of controller parameters for trajectory tracking control of rigid-body motion of the UFM system. The PID controller is tuned offline based on the best identified SI model. The performance of these control schemes was analyzed via real-time PC-based control and observed in terms of trajectory tracking and error. The overall result of UFM described in this research revealed the superiority of the PID controllers tuned using bio-inspired flower pollination algorithm (FPA). It was found that the percentage of improvement achieved experimentally by the PID controller tuned by FPA indicates superiority compared to PID tuned heuristically with 45.6% improvement on overshoot and 66% improvement of MSE for negative pulse and 100% improvement on overshoot for positive pulse.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Modern underwater applications make use of solid manipulators built from high stiffness material. This is because solid manipulators have certain advantages such as strong and heavy metal compositions that lead to stable performance. However, major drawbacks of solid manipulators lie in their need for high energy consumption and limitations in their speed of operation. Moreover, it is desirable in manufacturing of engineering systems to keep the weight as low as possible. There is a growing trend in many applications to reduce the weight of mechanical structures to the barest minimum, especially in aircraft engineering and spacecraft. The utilization of weaker structures and/or lighter materials significantly reduces production cost. However, light materials can also lead to more flexibility which may limit the structure performance [1]. In recent years, the researchers focused on utilization of lightweight manipulators to build power-efficient robot manipulators in order to improve the industrial productivity [2]. Therefore, the use of lightweight manipulators is emerging in the field of space and various general-purpose industrial applications. The manipulators with rigid links are currently utilized in underwater applications because the heavy and strong metal leads to stable performance [3, 4]. However, major disadvantages of rigid link manipulators lie in their need for high energy consumption and limitation in speed of operation.

There is a motivation to use underwater manipulators with flexible link owing to the advantages offered by manipulator systems with flexible link compared with manipulator systems with rigid link such as fast response, lightweight, low inertia, cheap construction, less powerful actuators, longer reach, higher payload carrying capacity, and safer operation [5, 6]. Although several studies have been conducted on modeling and control schemes of land and space manipulator systems with flexible links, only very few literature discussed on underwater flexible manipulators [7,8,9].

Therefore, there is an open area of research to study and develop dynamic modeling and control strategies for underwater flexible manipulators. Thus, the main aim of this paper is to present a suitable computational comprehensive model governing the underwater flexible manipulator system (UFM) using system identification (SI) technique. The manipulator addressed in this study is restricted to move in horizontal plane. Also, there is a big challenge in controlling the UFM owing to the additional effects caused by underwater environment, namely disturbances by ocean currents, time variance and high nonlinearity [9]. Consequently, it is necessary to develop appropriate control approaches for this type of systems.

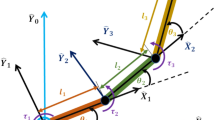

2 Underwater Manipulator Test Rig

An underwater manipulator test rig used in this research, as shown in Figs. 35.1 and 35.2, was designed and constructed in Faculty of Mechanical Engineering, Universiti Teknologi Malaysia, Johor in order to perform the underwater flexible manipulator experiments [9].

UFM experimental rig [9]

Experimental setup [9]

Several experimental testings have been conducted to check the similitude of the underwater and land manipulators [9]. The angular displacement was measured using encoder while the end-point vibration was measured by an accelerometer where the signals were transmitted to a data acquisition card for analog-to-digital conversion of the signal. Experimental work was conducted in order to acquire data to identify the model of the hub-angle of the UFM and demonstrate the practicality of the proposed control schemes. The dynamic model of the hub-angle of the UFM was developed using SI methods utilizing input–output data acquired experimentally. The modeling was conducted within MATLAB programming environment using CSA and FPA. After validating the developed models of the hub-angle of the UFM, the best model among the models thus developed has been utilized for the development of control approaches for hub-angle of the UFM.

Later, PID control strategies were developed using heuristic and bio-inspired algorithm tuning methods. The control algorithms were computing the amount of motor voltage required for trajectory tracking of the UFM. The bio-inspired PID control scheme tuned offline by using FPA and conventional tuning method using heuristic tuning. The performance of the intelligent PID control schemes was compared with a conventional PID control scheme. Both PID control schemes are implemented for trajectory tracking control of UFM via the developed experimental rig. The objective of the comparative study is to observe the differences in their performance simultaneously and to exploit the benefits of using the proposed strategies.

3 System Identification

System identification (SI) is one of the most fundamental requirements for several scientific and engineering applications. The aim of SI is to build exact or approximate model of a dynamic system based on measured data without knowledge of the actual system physics. After a system model is obtained, it can be utilized to predict the physical system behavior under different operating conditions or to control it [4].

Parametric modeling of UFM utilizing metaheuristic algorithm through cuckoo search algorithm (CSA) and flower pollination algorithm (FPA) is presented in this paper. The aim of the work is to represent the UFM behavior utilizing the applied voltage as input and hub-angle as output based on CSA and FPA. Model validations were also investigated using mean-squared error, one-step ahead prediction, and model residual analysis. The performances of the CSA and FPA were compared based on the validation mean-squared error, modeling mean-squared error, correlation tests, and stability. The aim of the identification process in this research is to allow for the design and implementation of controllers based on the identified model for trajectory tracking of UFM.

3.1 Cuckoo Search

CSA is a search algorithm developed by Yang and Deb [10]. The algorithm was inspired by the breeding behavior of cuckoos. Cuckoo birds lay their eggs in other birds’ nests and rely on those birds for hosting the eggs. If some of the host birds discover that an egg is not their own, it might throw out the alien egg or move to a new location elsewhere. A cuckoo might emulate the shape, color, and size of the host eggs to protect their egg from being discovered. To increase the hatching probability of cuckoo birds own eggs, some of them might throw out other native eggs from the host nest. On the other hand, a hatched cuckoo chick will also throw other eggs out of the nest to improve its feeding share [10]. It can be noted from the literature that the efficiency of CSA has been demonstrated by solving several engineering problems. In control system problems area, the utilization of metaheuristic optimization approaches is widely and clearly appreciated. To date, CSA has been utilized in various control system problems successfully. These literatures show that CSA has been utilized efficiently in tuning PID-based controller parameters in different control scheme.

The user-defined parameters required for optimization process using CSA are: number of generations, G, population size, N, problem dimension, D, flight step size, α, discovery rate of alien eggs, Pa, and boundary constraints, LHC. In this study, D refers to the number of unknown parameters in ARX model structure. The flight step size, α = 0.01, and the fraction of eggs to be discarded, Pa = 0.25, were used, as suggested by Yang and Deb [10]. It is worth noting that other CSA’s optimization parameters such as G, N, and LHC are difficult to choose in order to obtain promising results since there is no prior knowledge regarding the rules in selecting these parameters. Thus, these parameters were obtained by a trial-and-error method. The population needs to be initialized before the optimization starts and their fitness values need to be calculated. Therefore, (N) nests of dimension (D) are initialized randomly within the specified lower and upper range. Each nest in the initial population then updates the parameters of ARX model structure and its fitness value is calculated based on the error between the predicted and actual outputs. Among the nests in the initial population, the one with the minimum cost was considered as the best nest. Figure 35.3 shows the diagrammatic representation of initial population generation. The optimization process will run iteratively until the end of generations [9].

Diagrammatic representation of the initial population generation [9]

3.2 Flower Pollination Algorithm

Flower pollination algorithm (FPA) is a biology-based algorithm inspired by the flow pollination process of flowering plants. Pollination can take two major forms: biotic and abiotic. Biotic (cross-pollination), means pollination can occur from pollen of a flower of a different plant, while abiotic (self-pollination) is the pollination of one flower from pollen of the same flower or different flowers of the same plant. Biotic is considered as global pollination process with pollen carrying pollinators performing Levy flights. Abiotic is considered as local pollination. Local pollination and global pollination are controlled by a switch probability p ∈ [0, 1]. That means, the probability will specify each of solutions to search the local area or global area [10].

The user-defined parameters required for optimization process using FPA are: number of generations, G, population size, N, problem dimension, D, flight step size, α, probability switch, P, and boundary constraints, LHC. In this study, D refers to the number of the unknown parameters in ARX model. The flight step size, α = 0.01, and the probability switch, P = 0.8, were used as suggested by Yang and Deb [10]. It is worth noting that it is difficult to choose other FPA’s optimization parameters such as G, N, and LHC in order to obtain promising results since there is no prior knowledge regarding the rules in selecting these parameters. Thus, these parameters were obtained by a trial-and-error method.

The population needs to be initialized before the optimization starts and their fitness values need to be calculated. Therefore, (N) pollens of dimension (D) are initialized randomly in the given upper and lower bounds [10]. Each pollen in the initial population then updated the parameters of ARX model structure and its fitness value based on the error between predicted and actual outputs. The best pollen in the initial population is corresponding to the pollen with minimum cost. Figure 35.4 shows the diagrammatic representation of the initial population generation. The optimization process will run iteratively until the end of generations. The pollen with lower fitness value is selected as the best pollen for the next generation [9]. Detail description of CSA and FPA identification process is described by Al-Khafaji in [9].

Diagrammatic representation of generation the initial population [9]

4 Tuning of PID Controller Using FPA

To achieve an appropriate control action, the overall effect of PID controller gains, KP, KI, and KD should be in such a way optimum. Hence, the aim of this investigation is to tune the PID controller parameters offline utilizing two metaheuristic algorithm namely, CSA and FPA. Simulation study was conducted in order to highlight the performance of new metaheuristic optimization techniques to optimally tune the PID controller in the proposed control scheme. MATLAB/Simulink was used to tune the PID controller gains KP, KI, and KD in offline mode. The schematic diagram of the closed-loop system utilizing PID controller with the identified hub-angle model is shown in Fig. 35.5. Bang-bang signal was used as input reference with magnitude of ±0.3 rad for 21 s. The hub-angle model was excited with a disturbance signal at amplitude of 0.2608 m/s. The performance of both tuning methods has been observed in terms of overshoots, Mpi and Mpd, and steady-state errors, Essi and Essd. Then, the tuned parameters achieved from the simulation were tested experimentally using the UFM test rig [10]. Detail description of bio-inspired PID-FPA controller is described by Al-Khafaji in [10].

Schematic diagram of PID controller tuning by bio-inspired methods [9]

5 Results and Discussion

5.1 System Identification Using CSA and FPA

In this study, CSA was used to determine the ARX model structure parameters which represent the hub-angle of the UFM. Same control parameters were optimized for different arbitrarily selected model order to choose the best model order. The initial CSA optimization parameters used in modeling processes is as follows: number of generation, G = 600, population size, N = 20, problem dimension, D, depending on the model order, flight step size, α = 0.001, fraction of eggs to be discarded, Pa = 0.25, and boundary constraints, LHC = (3, 2). The ARX parameters are optimized via CSA by minimizing the fitness function, mean square error (MSE). The numerical results of the work carried out to select the best model order are summarized as shown in Table 35.1. The performances of CSA and FPA were compared based on the validation mean-squared error, modeling mean-squared error, stability, and correlation tests.

It can be noted from Table 35.1 that the best result was accomplished with third model order. Using third model order, the optimum values of b1, b2, b3, a1, a2, and a3 are 0.0005882, 0.0003957, 1.537 × 10−5, −2.206, 1.484, and 0.2782, respectively. The optimal ARX parameters have been searched randomly utilizing CSA optimization technique in such a way that a global minimum of MSE is reached. The results of the hub-angle and error in both modeling and validation phases using CSA-MSE optimization method are shown in Figs. 35.6 and 35.7, respectively. It can be noted from Figs. 35.6 and 35.7 that a satisfactory response was attained and the output of CSA-based model could follow the actual output very well with modeling MSE of 1.24101 × 10−4 and validation MSE of 1.82360 × 10−4.

Same control parameters of FPA were optimized for different arbitrarily selected model order to choose the best model order. Optimization of ARX model structure parameters utilizing FPA was achieved by initially initialized FPA control parameters as closed as possible to CSA control parameters. The population size and generation number are set to 20 and 600, respectively, while the flight step size, α and the probability switch, P are set 0.001 and 0.8, respectively. It is worth to know that the selection of flight step size and the probability switch is based on the guidelines from the previous literatures [10]. The numerical results of the work carried out to select the best model order are shown in Table 35.1.

It can be noted from Table 35.1 that the best result by FPA was accomplished with second order. After ARX optimization procedure was finished, the optimum values of ARX parameters are found as b1 = 0.0003741, b2 = 0.0007799, a1 = −1.925, and a2 = 0.9251. The optimal ARX parameters have been searched randomly utilizing FPA in such a way that a global minimum of MSE is reached. The results of hub-angle and error in both modeling and validation phases using FPA-MSE optimization method are shown in Figs. 35.8 and 35.9, respectively, where the division between the modeling data and validation data is indicated as a vertical red line located at point 400. It can be noted from Figs. 35.8 and 35.9 that the predicted response using FPA method could follow the actual output very well with MSE of 1.24723 × 10−4 during training and MSE of 1.82754 × 10−4 for validation data. The pole-zero diagram was used to confirm the model was stable; all the poles of the transfer function were inside the unit circle. The correlation functions were carried out for 20 samples. It was found that the model is biased because the results are not within the 95% confidence bands. Parametric modeling of the hub-angle of the UFM has been performed utilizing two optimization algorithms, namely FPA and CSA. The overall comparative performance of optimization methods in terms of validation MSE, modeling MSE, stability, and correlation tests are summarized in Table 35.2. It can be noted from Table 35.3 that CSA parametric identification technique provides the best estimation of UFM model, as compared to FPA. The UFM model obtained using CSA will be utilized in subsequent studies for the development of control approaches for hub-angle of the UFM.

The results of all modeling methods were validated using MSE of unseen data, correlation tests, and stability. The performances of CSA, FPA models were assessed based on the validation MSE, modeling MSE, correlation tests, and stability. It can be seen that the CSA has achieved slightly better MSE value in both modeling and validation phases and has approximated the system response very well. The best model of the UFM thus developed is utilized for the development of control approaches for hub-angle of the UFM.

5.2 PID Tuning Using FPA

PID controller parameters tuning utilizing FPA were achieved by initially initializing FPA control parameters as closed as possible to CSA control parameters. The population size N and generation number G were set to 10 and 150, respectively, while the flight step size α and the probability switch P were set to 0.01 and 0.8, respectively. It is worthy to note that the selection of flight step size and the probability switch is based on the guidelines from previous literatures. Figure 35.10 shows the typical convergence of objective function for 150 generation. It is noted from Fig. 35.10 that FPA converges in about 77 generations. After controller tuning procedure was finished, the optimal values of PID parameters were found to be KP = 6, KI = 4.4613, and KD = 0.5. Figure 35.11 shows the convergence profile of PID parameters. The result of the closed-loop bang-bang response using FPA-MSE tuning method for hub-angle is shown in Fig. 35.12. It can be concluded from Fig. 35.12 that a satisfactory response was attained and the proposed controller is capable of tracking the desired hub-angle.

Hub-angle control of the UFM has been established utilizing PID control structure. The PID controller parameters were tuned offline via heuristic and bio-inspired algorithm based on the best identified model using system identification method. The best two sets of tuned controllers’ parameters achieved from simulation were validated experimentally in real time using the UFM test rig where the manipulator is subjected to external disturbance. The performance of PID controller tuned by FPA indicates superiority compared to PID tuned heuristically with 45.6% improvement on overshoot and 66% improvement of MSE for negative pulse and 100% improvement on overshoot for positive pulse.

References

Darus, I.Z.M., Zahidi Rahman, T.A., Mailah, M.: Experimental evaluation of active force vibration control of a flexible structure using smart material. Int. Rev. Mech. Eng. 5(6), 1088–1094 (2011)

Jamali, A., Mat Darus, I.Z.M., Samin, P.M., Tokhi, M.O.: Intelligent modeling of double link flexible robotic manipulator using artificial neural network. J. VibroEng. 20(2), 1021–1034 (2018)

Al-Khafaji, A.A.M., Mat Darus, I.Z.: Finite element method to dynamic modelling of an underwater flexible single-link manipulator. J. VibroEng. 16(7), 3620–3636 (2014)

Mat Darus, I.Z., Tokhi, M.O.: Parametric and non-parametric identification of a two-dimensional flexible structure. J. Low Freq. Noise Vibr. Active Control 25(2), 119–143 (2006)

Annisa, J., Mat Darus, I.Z., Tokhi, M.O., Mohamaddan, S.: Implementation of PID based controller tuned by evolutionary algorithm for double link flexible robotic manipulator. In: 2018 International Conference on Computational Approach in Smart Systems Design and Applications, ICASSDA 2018

Jamali, A., Mat Darus, I.Z., Tokhi, M.O., Abidin, A.S.Z.: Utilizing P-type ILA in tuning hybrid PID controller for double link flexible robotic manipulator. In: 2nd International Conference on Smart Sensors and Application, ICSSA 2018, pp. 141–146

Ng, B.C., Darus, I.Z.M., Jamaluddin, H., Kamar, H.M.: Application of adaptive neural predictive control for an automotive air conditioning system. Appl. Therm. Eng. 73(1), 1244–1254 (2014)

Saad, M.S., Jamaluddin, H., Darus, I.Z.M.: Active vibration control of a flexible beam using system identification and controller tuning by evolutionary algorithm. J. Vibr. Control (JVC) 21(10), 2027–2042 (2015)

Al-Khafaji, A.A.M.: Modeling and Control of Underwater Flexible Single-Link Manipulator Employing Bio-Inspired Algorithms and PID Based Control Schemes, Ph.D. Thesis, Universiti Teknologi Malaysia, Malaysia (2016)

Yang, X.-S., Deb, S.: Cuckoo search: Recent advances and applications. Neural Comput. Appl. 24(1), 169–174 (2014)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Mat Darus, I.Z., Al-Khafaji, A.A.M. (2021). Bio-inspired Algorithms for Modeling and Control of Underwater Flexible Single-Link Manipulator. In: Peng, SL., Favorskaya, M., Chao, HC. (eds) Sensor Networks and Signal Processing. Smart Innovation, Systems and Technologies, vol 176. Springer, Singapore. https://doi.org/10.1007/978-981-15-4917-5_35

Download citation

DOI: https://doi.org/10.1007/978-981-15-4917-5_35

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-4916-8

Online ISBN: 978-981-15-4917-5

eBook Packages: EngineeringEngineering (R0)