Abstract

In order to increase the safety of reduced volume of LNG (Liquefied Natural Gas) at the extremely low temperature, the IGC code establishes international standards. IGC code suggested with the filling limits which is a rate of maximum LNG by total volume of tank to prevent the accident by LNG at a sealed tank. The filling limits of LNG storage tank was calculated with the safety factors. The calculation progress of the filling limits is very complicated and time consuming because the tank volume and LNG volume for several situations must be calculated under various factors. The objective of this study is to develop the algorithm of filling limit calculation based on the 3D CAD model according to 2018 IGC Code. The developed algorithm carries out applying a “scenario in which isolated vapor pockets are not generated in cargo tank” which required by new IGC as well as a “scenario where the pressure relief valve inlets are maintained as vapor zones” which required by existing IGC. It supports CAD interface of vessel tank 3d model as well as parametric modeling of various tank shapes. It not only carries out a numerical calculation on tank volume under the condition of the Trim & List, but also reviews the various accident risks by using the viewer of 3D model and VR environment.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

1.1 Filling Limits

If LNG in a sealed cargo tank expands and its volume expands, a major accident can occur. Especially, the risk of LNG is higher because the volume of LNG is increased about 600 times when LNG is vaporized. To prevent these accidents, the IGC Code specifies the cargo tank filling limits, which are the ratio of the maximum liquid volume of the cargo to the total volume of the tanks. Basically the filling limits are defined as 98%, but if additional safety factors are considered, the filling limits may be increased correspondingly with the approval of the class or the flag State concerned. The conditions to consider are the following, which is for the New IGC Code to be applied to gas carriers built after July 1, 2016 [2].

-

An isolated vapor pocket is not created in the cargo tank.

-

The pressure relief valve (PRV) inlet is maintained as a vapor zone.

-

Recognition of the allowance for cargo volume expansion at 1.2 times the set pressure of the safety valve of the cargo tank.

-

Recognition of the allowance for operational margins of at least 0.1% of tank volume.

-

Recognition of the tolerance of measuring instruments such as liquid level gauges and temperature gauges.

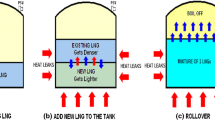

“Isolated vapor pocket” is spaces where the PRV can not relieve pressure as the cargo tank are tilted. Figure 1 shows the state of isolated vapor pockets. which means that the PRV can not control its pressure. Figure 2 shows the PRV suction port is submerged in LNG. Both cases are dangerous conditions that can lead to major accidents since the pressure in a specific space can not be controlled. Therefore, the charge limit must be calculated to meet the requirements.

1.2 Research Background

For verification of the filling limits above 98%, Several variables such as the placement of the safety valve, the accuracy of the level and temperature measurement, the loading temperature, etc. must be considered simultaneously. The LNG volumes for “scenario in which isolated vapor pockets are not generated in cargo tank” and “scenario where the pressure relief valve inlets are maintained as vapor zones” should be calculated respectively under the four conditions of trim and list given in the IGC Code. The LNG volume calculation is largely affected by the shape of the cargo tank, the position of the safety valve and the dome, so tank 3D modeling is basically necessary. It requires a lot of work since LNG conditions and various variables according to various situations must be considered together.

Among of them, “scenario in which isolated vapor pockets are not generated in cargo tank” recently applied to the New IGC Code has a great influence to the filling limits. In particular, the tanks of prismatic shape are more likely to generate isolated vapor pockets when they are tilted, because the upper space is horizontal. Their influence is greater since the most widely used membrane LNG cargo tanks in the world are prismatic shapes.

Since the filling limits directly affect the amount of LNG cargo, careful verification is required by stakeholders such as shipowners, shippers and class. In particular, the class is obliged to check that the filling limits higher than 98% are possible accurately considering the presence of isolated vapor pockets. Thus, this study has developed a algorithm to calculate the filling limits accurately and time-efficiently. In addition, we have developed the SeaTrust-FillingLimits software with the development algorithm, which is intended to provide not only accuracy but also convenience of verification through additional auxiliary functions.

2 Development

2.1 Algorithm Overview

Figure 3 represents the entire development algorithm process. A parametric 3D tank is created by parameter input corresponding to each initial tank shape. Basically, 3D models of Cylindrical shape like Type C tank and prismatic shape like No. 96 & Mark lll tank are supported. Even a special shape that is not supported by default can be extended to the development algorithm if only its 3D shape is input, because the development algorithm is fundamentally based on the 3D model.

From the generated 3D tank, each tilted tank is created with ± 0.015L Trim, ±15° List specified by IGC Code. And a 3D LNG corresponding to each tilted tank is generated. Two scenarios defined by the IGC Code apply to slanted 3D LNG.

This study defines “the state where LNG is the lowest amount in the situation where the tilted LNG touches the PRV” as “scenario where the pressure relief valve inlets are maintained as vapor zones”, and defines “the state where is the lowest amount in situation where the isolated vapor pockets occur at the sloped LNG” as “scenario in which isolated vapor pockets are not generated in cargo tank”.

Figure 4 shows the tilted tank shapes and the LNG status corresponding to each scenario. (a), (b), (c) and (d) are states of “scenario in which isolated vapor pockets are generated in cargo tank”, (e), (f), (g) and (h) show the states of “scenario where the pressure relief valve inlets are not maintained as vapor zones” at each tilted condition.

The volume of each LNG generated from the scenario definition is calculated. Among of them, the volume corresponding to the severe case is extracted. The filling limit of the tank, which reflects the total volume and the expansion coefficient in the severe volume, is calculated. This process applies to all tanks placed on a LNG carrier, and the final filling limits are calculated.

2.2 Parametric 3D CAD Modeling

Tank modeling is basically required for calculation of filling limits since filling limits are heavily influenced by the shape of the cargo tank and dome, the position of the safety valve and the dome. In this study, parametric tank 3D CAD modeling technique is applied to development algorithm to flexibly correspond to variable shape.

The shape of the membrane tank is based on bilateral symmetry. Its shape parameters include the left half width of the lower horizontal part on the front, the width and height of the lower left side on the front, the height of the vertical part on the front, the width and height of the upper left side on the front. The shape of the cylindrical tank is exactly capsule form. Its shape parameters are the radius of the cylinder part, the length of the cylinder part on the side, and the length of the front and rear partial sphere. If the membrane or cylindrical tank is tapered, an additional tapering height parameter is used. The arrangement parameters of the tank are the distance from the ship aft perpendicular (A.P.) to the back of the tank, the distance from the ship centerline (C.L.) to the tank centerline, and the distance from the ship baseline (B.L.) to the bottom of the tank.

The shape parameters of the hexahedral dome are width, height, and length. The shape parameter of the cylindrical dome is the radius and height. The arrangement parameters of the hexahedral and cylindrical dome are the distance from the front of the tank to the front of the dome, and the distance from ship centerline to tank centerline.

If the inner thickness of the tank and dome is to be taken into account, then thickness parameters are additionally used. This creates 3D models offset by thickness in the generated tank and dome 3D model, and is computed as an internal model.

The shape parameters of PRV are radius and height. The arrangement parameters of the vertical PRV on the hexahedral and cylindrical dome are the distance from the back of the dome to the center of the PRV, the distance from the dome centerline to the PRV centerline. The arrangement parameters of the horizontal PRV on the hexahedral dome are the head direction of the PRV (left to right, right to left, front to back, front to back), and distance from the bottom of the dome to the center of the PRV. The arrangement parameters of the horizontal PRV on the cylindrical dome are the angle on the top view (0 to 360°) and distance from the bottom of the dome to the center of the PRV.

Additional tank 3D models have a rotational arrangement parameter, which allows the tank to be rotated by ±90 degrees to allow for special cases. A parametric 3D model with the final shape and placement is created through the entire parameter.

Finally, a parametric 3D model of shape and arrangement is created through the entire parameters. Typical tanks produced by parametric modeling are shown in Fig. 5, tapering tank in Fig. 6 and dome and PRV in Fig. 7.

2.3 Expansion Coefficient Calculation

Since LNG can be expanded by human error and equipment accuracy, filling limits should be considered for expansion coefficient. The expansion coefficient is a value that subtracts the scenario calculation volume. The following items in “Acceptance criteria for cargo tank filling limits higher than 98%” of the International Association of Classification Societies (IACS) are involved in the expansion coefficient [3].

-

Level and temperature gauge accuracy.

-

pressure rise above opening pressure.

-

an operational margin to account for liquid loading lines drained back to cargo.

-

tanks and closing time of loading valves and operators reaction time.

The expansion coefficient (\( a_{t} \)) is given by:

-

\( a_{1} \) = relative increase in liquid volume due to tolerance of level gauges.

-

\( a_{2} \) = relative increase in liquid volume due to the tolerance of temperature gauges.

-

\( a_{3} \) = expansion of cargo volume due to pressure rise when pressure relief valves are relieving at maximum flow rate.

-

\( a_{4} \) = operational margin of 0.1%.

$$ a_{1} = \frac{dV}{dh} \times \frac{\Delta h}{V} \left( \% \right) $$(2) -

\( \frac{dV}{dh} \) = variation of tank volume per meter filling height at the filling height h (\( m^{3} /m \))

-

\( h \) = filling height (\( m \)) at the filling limit FL to be investigated (FL > 98%)

-

\( V \) = accepted total tank volume (\( m^{3} \))

-

\( \Delta h \) = max. total tolerance of level gauges (\( m \))

$$ a_{2} \, = \,\beta \, \times \,\Delta T \left( \% \right) $$(3) -

\( \beta \) = volumetric thermal expansion coefficient at reference temperature (%/°K)

-

\( \Delta T \) = max. tolerance of temperature gauge (°K)

$$ a_{3} \, = \,\left( {\frac{{\rho_{PRV} }}{{\rho_{PRV1.2} }} - 1} \right)\, \times \,100 \left( \% \right) $$(4) -

\( \rho_{PRV} \) = cargo density (\( \rho_{R} ) \) at reference conditions, i.e. corresponding to the temperature of the cargo at set opening pressure of the pressure relief valve (PRV)

-

\( \rho_{PRV1.2} \) = cargo density corresponding to the temperature of the cargo at 1.2 times the set opening pressure of the pressure relief valve (PRV)

3 SeaTrust-FillingLimits

3.1 CAD Interface & Virtual Reality

The development algorithm calculates the filling limits based on parametric 3D CAD geometry. 3D CAD geometry data of created parametric tanks and domes are exportable. The exported data can be imported into the development algorithm and can be calculated in the imported 3D CAD geometry. The Export & Import CAD Interface function works separately for tank and dome for development algorithm.

Since this is the manufacturer’s confidential information, only the difference between the result of the parametric function and the resulting filling limit of the CAD interface function is compared. The two shapes of GTT MARK lll was compared. There was an error of 0.00001847% p in the first case and 0.00001430% p in the second case. It is estimated to be due to the number of polygons. This error seems to be able to be reduced from the number of export polygons, but it is already very slight.

Additionally, exported CAD data can be extended to other software or virtual reality. Figure 8 shows the virtual reality simulator for the surveyor under development by the Korean Register [1]. The Surveyor is looking at the hold of the cargo ship for learning the structure and being educated about the inspection method. Therefore, the LNG tank model exported from the development algorithm can be extended to the virtual reality simulator, so that the training related to the LNG tank can be performed.

3.2 Implementation

This study develops additionally SeaTrust-FillingLimits software that can operate the development algorithm so that it can be easily utilized by users. SeaTrust-FillingLimits includes not only the development algorithm, but also additional features such as contour graphs of volume trend by angle, calculation of loading limits, and report generation (Figs. 9, 10, 11 and 12).

4 Conclusion

The calculation progress of the filling limits is very complicated and time consuming because the tank volume and LNG volume for several situations must be calculated under various factors. “scenario where the pressure relief valve inlets are maintained as vapor zones” was mainly considered in the case of the existing IGC Code. However, the revised New IGC Code should take into account “scenario in which isolated vapor pockets are not generated in cargo tank” as well as existing scenario. So the filling limits calculation becomes more complicated and time consuming. This research improves this problem by developing automated and optimized the filling limits calculation algorithm based on parametric 3D CAD geometry. The development algorithm does the following:

-

Is applied to the parametric 3D CAD geometry concept. so easily make 3d models of tanks, dome and PRV.

-

Supports basically 3D models of Cylinderical shape like Type C tank and prismatic shape like No. 96 & Mark lll tank. In addition, it supports cylindrical and hexahedral dome, vertical and horizontal PRV type.

-

Even applies to special shape that is not supported by default, if only its 3D shape is input

-

Simultaneously calculates multiple tanks that are placed within a vessel.

-

Is based on a parametric arrangement of tanks, so it is usually arranged in 3-axis coordinates and can arrange specially like a rotated tank.

-

Simultaneously calculates all slope conditions to derive the most severe values, and derives final filling limits reflecting the calculated expansion coefficient.

-

Because it is based on 3D CAD geometry, the parametric model created in the calculation algorithm can be exported to the common CAD format.

-

Imports existing geometric models as well as models with parametric modeling.

-

The CAD geometry exported from it can be extended to the virtual reality simulator.

In addition, this study develops SeaTrust-FillingLimits software with development algorithm. This includes not only filling limits calculation but also additional functions such as tank shape and LNG status 3D viewer, volume trend graph by angle, calculation of loading limits, and report generation.

In the future, it will be possible to carry out a study to directly interface the CAD geometry exported from other software where use ship 3D model data [4].

References

Kil, W.S., Son, M.J., Lee, J.Y.: Development of VR ship environment for the educational training of ship survey. J. Soc. Naval Architects Korea 55(4), 361–369 (2018)

International Maritime Organization (IMO): International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code). Consolidated Edition (2018)

International Association of Classification Societies (IACS): Acceptance criteria for cargo tank filling limits higher than 98% (on ships constructed before 1 July 2016), vol. 109, pp. 1–3 (2017)

Son, M.J., Lee, J.Y., Park, H.G., Kim, J.O., Woo, J.J., Lee, J.H.: Development of 3D CAD/CAE interface in initial structural ship design. Korean J. Comput. Des. Eng. 21(2), 186–195 (2016)

Acknowledgements

This research was performed as a part of the research project below and supported by the organizations indicated. We acknowledge and appreciate the support provided. “Development and commercialization of safety education and training VR contents of sailor using virtual reality technology” project funded by Ministry of Science and ICT of Korea (NO. S0602-17-1016)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Byun, SH., Kil, WS., Son, MJ., Lee, JY., Park, MH. (2021). IGC Code-Based LNG Filling Limits Computation Using 3D CAD Model. In: Okada, T., Suzuki, K., Kawamura, Y. (eds) Practical Design of Ships and Other Floating Structures. PRADS 2019. Lecture Notes in Civil Engineering, vol 65. Springer, Singapore. https://doi.org/10.1007/978-981-15-4680-8_6

Download citation

DOI: https://doi.org/10.1007/978-981-15-4680-8_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-4679-2

Online ISBN: 978-981-15-4680-8

eBook Packages: EngineeringEngineering (R0)