Abstract

Liquefied natural gas (LNG) rollover refers to the sudden mixing of stratified LNG layers, which can cause the generation of significant amounts of boil-off gas which create safety issues significantly in LNG storage tanks. Therefore, understanding of the phenomenon is very important for prevention purpose. Heat leak is a major challenge as it causes slow LNG boil-off leading to LNG stratification and LNG rollover phenomenon which has negative impact on people, environment, company asset and reputation. In this work, rollover phenomenon evolution is modeled and simulated using ANSYS FLUENT 16.0 software to study and analyze the effect of different ambient temperatures on the rollover phenomenon in LNG storage tanks and to study the stress distribution due to rollover and its effects on inner wall of the tank and determine the rollover time. This study examined the effect of different ambient temperatures ranged from 283 to 323 K on the LNG rollover inside a 5000 m3 LNG storage tank. Results show that higher temperature will cause higher heat transfer leaks to the LNG tank. The heat transfer through the tank walls is higher than the heat leaks to the tank through tank base. The pressure inside the LNG storage tank is strongly affected by the surrounding temperature. Higher temperature will cause higher pressure to build up in the tank especially along the area between the roof of the tank and the side walls. The simulations results show that significant initial density differences (∆ρ) between the stratified layers lead to late rollover events but last for longer time. At ∆ρ = 30, 15 and 7 kg/m3, the rollover will last for 3.1, 2.5 and 2.2 h, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Natural gas is progressively being utilized for many applications, mostly for power generation sector and feedstock for many petrochemicals. Nowadays, natural gas is very important source of energy with currently overall consumption equal to 3.5 Tm3/annum, which accounts for almost one-fifth of overall global energy consumption, with expectation of increase in the demand to be 50% higher by 2035 [1]. One of the important aspects in gas supply demand value chain is the transportation in order to secure a reliability and stability in the relationship among producers, shippers, distribution companies and end users [2].

Liquefied natural gas (LNG) is a natural gas in its liquid state with distinguished properties such as transparent, colorless, odorless, non-corrosive and non-toxic. LNG is fully produced from natural gas and can be utilized in many sectors such as power generation, industrial and commercial heating applications, and chemical feedstock to produce valuable products [3]. LNG is a liquid mixture of hydrocarbons mostly comprising of methane, with less fractions of other light hydrocarbons such as ethane, propane, butane and some other gases such as carbon dioxide and nitrogen. Generally, the liquefaction of natural gas reduces its origin volume to almost 600 times less than its original volume as in gas form [4,5,6]. This reduction in volume will increase the energy density stored in the fuel and make LNG more reliable and practical to store and transport to long distances where the pipeline construction is infeasible. LNG can be stored in three well-known types of storage tanks such as single-containment, double-containment and full-containment storage tank [7].

Different LNG sources have different densities; therefore, the addition of new batch liquid of LNG to the existing LNG quantity in a storage tank can form stratification of two or more layers within the tank. Rollover is the phenomenon of rapid release of large amount of LNG vapor because of stratification [8,9,10,11]. The potential stratification appears when two or more layers with different densities exist in the LNG storage tank. This difference in densities might occur due to different LNG sources or compositions [12]. This type of stratification is known as fill-induced stratification.

Rollover phenomenon at LNG storage tanks had considerable attention after the huge venting incident at La Spezia, Italy, in 1971 [13]. The tank was over-pressurized due to the release of a massive amount of LNG vapor from a rapid boil-off. The relieve valve system was not able to discharge vapor at a fast enough rate to protect the tank. This phenomenon can lead to tank failure, resulting in release of a massive amount of LNG to environment [14]. As time goes, the two layers ultimately approach equality in density due to mass and heat transfer between the two adjacent layers and boil-off from the surface of the top layer, as shown in Fig. 1.

LNG storage tank rollover phenomenon [15]

During stratification, the heavier layer at the bottom of stratified tank receives heat from the bottom as well as the tank’s sidewalls. The lower layer eventually becomes superheated, but it cannot release LNG vapor due to the upper layer which acts as a cover to hinder vapor releasing from the heavier layer at the bottom [16], as shown in Fig. 2. The temperature of the top layer in LNG tank is lower than the that of bottom layer. This is because the heat leakage through the bottom of the tank is greater than that through tank side walls which causes a decrease in the density of the lower layer at faster rates. The system stability depends on the density of the upper layer. If the density of the upper layer increases due to the increase in temperature and the mass transfer with the vapor layer, then there is a potential of rollover phenomenon [17].

Schematic of stratified LNG storage tank [16]

Rollover Phenomena Mechanisms

Stratification can rise at LNG storage tank either by supplying the tank with different-density LNG cargo or by auto-stratification (or nitrogen-induced stratification) due to loss of nitrogen preferentially resulting in density differences between the layers [15]. Rollover is a merging process that takes place when the two separated (stratified) layers approach equality in density by the heat and mass transfer. This event is normally caused by a rapid vaporization of large amount of LNG.

The heat input from the surroundings is absorbed by the liquid LNG in the tank and then transferred by convection transmission mode to the surface where the vaporization of LNG takes place, as shown in Fig. 3. As time goes, the lower layer becomes superheated and less dense due to the heat absorbed.

Stratified tank behavior [8]

Heat Leak

Heat leak into the liquid LNG is the main cause for boil-off gas (BOG) generation in the storage tanks. This heat is determined by the structure of the tank. Several types of storage tanks are available. The aboveground full-containment tank will be selected as main LNG storage tank in this study. This is because the full containment is the most commonly used type of LNG storage tank by the industry due to its high safety aspects [2].

The heat flows into the LNG storage tank through heat transfer from sidewalls, roof and base of the tank. The prediction of heat transferred into the LNG tank and solving energy balance for BOG estimation are mainly related to the thermal analysis of the tank. The estimation of the heat in-leak rate into the LNG is crucial and directly linked with geometry of LNG tank and the precise availability of thermal properties of the insulation and tank wall materials.

Previous Simulation Studies of LNG Rollover

Most simulation studies to simulate industrial incidents of LNG rollover have benchmarked their simulations based on the technical and operational data documented by Sarsten [13] for La Spezia LNG rollover incident. LNG rollover simulation studies done so far can be categorized into two recognizable intervals which are summarized in Table 1. The first one was started from 1972 when the Sarsten [13] documented La Spezia rollover incident until the successful simulation study on this incident introduced by the later study of Heestand et al. [14]. The second interval started from 1983 onward. This period has experienced the introduction of computational fluid dynamics (CFD) methods.

In 2007, Koyama [20] conducted a simulation study using computational fluid dynamics (CFD) on LNG storage tank of 200,000 m3 with a diameter of 72 m. The study was conducted to investigate filling procedures of different-density LNG cargo. He used ANSYS FLUENT software with a liquid–liquid, Eulerian–Eulerian homogeneous multiphase model. Standard k–ε turbulent model was used in this study with tetra, wedge, pyramid-type 3D mesh, 62,286 nodes and 152,795 elements. The LNG tank was filled using bottom filling nozzle with lighter LNG. The results showed a change in the volume fractions of the LNG over time in a turbulent system, as shown in Fig. 4. He also found that many factors can contribute to the LNG stratification in the storage tanks such as the filling rate, initial density difference between layers and the initial LNG depth.

CFD simulation results for LNG tank filling [20]

The evolution of rollover phenomenon in different capacities LNG storage tanks was studied by previous researcher [21]. In this study, rollover was modeled and simulated using FLUENT software from the time of stratification breakdown to the rollover occurrence. Furthermore, the study was conducted at different initial density differences between layers on various storage tanks of 5000, 30,000 and 160,000 m3. Their results showed that the evolution of rollover passed through three phases: The rollover took place near the tank side walls, then the rollover approached the center, and last phase was the rollover between the layers. Besides, they found that the rollover coefficient increases with the increment of initial density difference. In addition, they also managed to determine the rollover threshold which is defined as the critical density difference. This simulation study showed that the critical density differences of the 5000, 30,000 and 160,000 m3 storage tanks are 7, 5 and 3 kg/m3, respectively. Therefore, research on the effect of different ambient temperatures can predict rollover accurately and ensure the safety of LNG storage tanks.

Simulation Work

Tank Sizing and Design

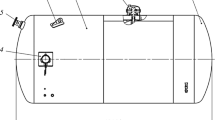

This simulation study started with designing the geometry of LNG storage tank with the dimensions listed in Table 2.

Turbulent model for this study should be selected to be used in the rollover simulation. k–ε model was selected due to its accuracy [20]. The physical properties of LNG and insulation material (perlite) in the storage tank used in the simulation are listed in Table 3.

Simulation Procedures

The simulation procedures are as follows:

-

1.

Create LNG tank geometry: It illustrates the shape of the main problem. Based on the parameters listed in Table 2, Fig. 5 depicts the generated LNG tank geometry.

-

2.

Meshing the created geometry: For accurate results, high-quality meshes are required, i.e., orthogonal quality value should be close to 1. Fine mesh was used with total number of grid cells equal to 40,000 cells as shown in Fig. 6.

-

3.

Set up the problem as a transient state time as well as choose the standard k–ε model as viscous model.

-

4.

Material properties: The LNG and perlite properties were selected as described in Table 3.

-

5.

Operating conditions: Ambient temperature ranging from 283 to 323 K was used. The operating temperature inside the tank was 112 K. The operating pressure and gravity were 101.3 kPa and 9.81 m/s2, respectively.

-

6.

Boundary condition for this work is shown in Table 3.

-

7.

Solution and iterations.

Rollover Time Prediction

The simulation started by defining two different LNG layers which are the top and the bottom layers. These two layers have different densities because of supplying LNG from two different sources. This study was conducted to investigate the reaction between the two layers and predict the rollover time and instability inside the tank. The properties of the two layers are listed in Table 4.

Results and Discussion

Effect of Different Ambient Temperatures on LNG Storage

Figure 7 shows the data collected from simulation works, whereby the heat transfer through the tank wall and the base was recorded to investigate the effect of different ambient temperatures around the globe on the LNG stored in the tank. Higher ambient temperatures will cause higher heat transfer leaks to the LNG tank. The heat transfer through the tank base is much less than the heat leaks to the tank through tank walls. This is basically because of the small area of the base which has the value of 380 m2 compared to the area of the walls which was 899 m2. In this case, the search for unique material with very low thermal conductivity is crucial matter to insulate the tank contents from the higher ambient temperatures. In this study, perlite insulation material with thermal conductivity of 0.029 W/m K was used which is considered to have relatively low conductivity value. The heat input from the surroundings is absorbed by the liquid LNG in the tank and then transferred by convection transmission mode to the surface where the vaporization of LNG takes place.

Stress Distribution on LNG Tank

Figure 8 shows that the highest pressure inside the tank during rollover phenomenon is along the area between the roof of the tank and the side walls (shown by red circle; the pressure at red zone is equal to 727 kPa and at blue zone is equal to 181 kPa at 303 K ambient temperature). The pressures detected in this area are plotted in Fig. 9 at various different ambient temperatures. These pressures are higher compared to the operating pressure of 101.3 kPa. As the vapor pressure of liquid increases, the structural integrity of vessel will weaken if the vent valves on the tank are not capable of handling the large amount of LNG vapor released which causes a gradual increase in the vessel pressure leading to vessel rupture that can lead to leakage of flammable LNG such as La Spezia incident [13], where 2000 tons of LNG was vented to the surrounding area.

Figure 9 clearly shows that the pressure inside the LNG storage tank is strongly affected by the surrounding temperature. Higher temperature will cause higher pressure to build up in the tank especially along the area between the roof of the tank and the side walls. This is because the high temperature will boil off more LNG liquid that accumulates at the top zone of the storage tank.

Density Behavior of LNG Layers During Storage

Initially, as shown in Fig. 10, there were two dissimilar LNG layers in terms of density and temperature: The bottom layer in red color was set as a primary layer with density value of 460 kg/m3, and the upper layer in the blue color was set as a secondary layer in the tank with density value of 430 kg/m3. The layers are divided by a sharp interface.

The density contours in Fig. 11 show the density changes of LNG layers in the storage tank over time. The difference in density is primarily because of the disparity in composition and temperature because of supplying LNG from different sources. After filling process, diffusion between the LNG layers takes place due to heat leaks from the surrounding to the tank through the insulated walls. The difference in density in the storage tank can cause unstable LNG storage conditions which may lead to evolution of rollover phenomenon. The diffusion intensity between the two layers is increasing gradually especially along and near to the walls of the tank. This diffusive heat transfer will make the sharp interface between the two layers becomes in transition state, leading to natural convection circulation flow.

The interface zone between the two layers (Fig. 12) shows that the difference in density in the tank causes the rollover incident, causing the instability situation of LNG storage and rollover evolution. The natural convection circulation starts at the interface zone and increase as more heat leaks from the outside area to the tank. As time goes, the circulation increases till the layers of LNG are fully mixed and boil off large amount of LNG vapor. At the beginning, the rollover takes place near to the tank walls and finally transfers to the center of the LNG storage tank.

Rollover Time

The initial density difference between the bottom and the upper layer (Δρ = ρBOTTOM − ρTOP) was set at 30, 15 and 7 kg/m3 to determine the rollover starting time and its duration in the tank after the filling process immediately. As time goes, the differences in density between the top and bottom layer will gradually decrease to zero. The variation in density fluctuation with time was recorded and is plotted in Figs. 13, 14 and 15.

Figure 13 shows that at t = 0 h, the density difference between the stratified layers was 30 kg/m3, but due to the mass diffusion and natural convection circulation between the two layers, there will be a density equalization which acts as a driving force for evaporating large amount of LNG. The rollover will start at t = 7.7 h and end at t = 10.8 h which means 3.1 h of rollover and instability inside the LNG storage tank.

Table 5 summarizes rollover time for various initial density differences. It clearly shows that the initial density difference between the stratified layers has strong effect on the rollover starting time and duration. It is found that bigger initial density difference leads to late rollover events, but lasts for longer time. At Δρ = 30, 15 and 7 kg/m3, the rollover will last for 3.1, 2.5 and 2.2 h, respectively.

By the heat and mass transfer, this rapid mixing of stratified LNG liquid results in rollover, whereby the merging process takes place when the two separated (stratified) layers approach the equality in density. This event basically will lead to the rapid vaporization of significant amount of LNG. After density equalization was achieved, the top surface will become denser than the bottom due to continuous evaporation process which means density differences become negative (Δρ = ρBOTTOM − ρTOP) that is caused by higher density at the top part. This will force the top layer to go down and bottom to rise up because the top layer is the lighter layer, and the same process will continue for some hours till the stability is achieved in the tank which means the end of rollover phenomenon.

Conclusion

Rollover phenomenon evolution was simulated using ANSYS FLUENT 16.0 software to study the effect of ambient temperatures on the rollover phenomenon. It is found that the surrounding temperature significantly affects the heat leak. Increased temperature will increase heat transfer leaks to the tank. The heat leaks via tank walls are much higher than the heat leaks via tank base due to the small area of the base itself. The pressure inside LNG tank is strongly affected by the surrounding temperature. Higher temperature leads to the higher pressure buildup especially along the area between the roof of the tank and the side walls, and this area may act as a failure point which leads to the tank rupture. Besides, larger initial density differences between the stratified layers caused late rollover events but lasts for longer time.

References

F. Birol, J. Corben, M. Argiri, M. Baroni, A. Corbeau, L. Cozzi, A. Yangisawa, in Are We Entering a Golden Age of Gas? ed. By R. Priddle. World Energy Outlook (International Energy Agency, Paris, 2011)

C. Migliore Cappello, Modelling the Weathering Process of Stored Liquefied Natural Gas (LNG) (Imperial College London, London, 2015)

A. Bahadori, Natural Gas Processing: Technology and Engineering Design (Gulf Professional Publishing, Houston, 2014)

D.A. Wood, C. Nwaoha, B.F. Towler, Gas-to-liquids (GTL): a review of an industry offering several routes for monetizing natural gas. J. Nat. Gas Sci. Eng. 9, 196–208 (2012)

K. Arrhenius, A. Karlsson, A. Hakonen, L. Ohlson, H. Yaghooby, O. Büker, Variations of fuel composition during storage at liquefied natural gas refuelling stations. J. Nat. Gas Sci. Eng. 49, 317–323 (2018)

F.E. Banks, The Political Economy of Natural Gas (Routledge, London, 2017)

N. Masad, D. Zollinger, S.-M. Kim, Z. Grasley, Meso-scale model for simulations of concrete subjected to cryogenic temperatures. Mater. Struct. 49(6), 2141–2159 (2016)

N. Baker, M. Creed, Stratification and rollover in liquefied natural gas storage tanks. Process Saf. Environ. Prot. 74(1), 25–30 (1996)

S. Bates, D.S. Morrison, Modelling the behaviour of stratified liquid natural gas in storage tanks: a study of the rollover phenomenon. Int. J. Heat Mass Transf. 40(8), 1875–1884 (1997)

R.G. Scurlock, Factors creating stratification: management of LNG rollover, in Stratification, Rollover and Handling of LNG, LPG and Other Cryogenic Liquid Mixturesed (Springer, Berlin, 2016), p. 85–100

R.G. Scurlock, Stratification, Rollover and Handling of LNG, LPG and Other Cryogenic Liquid Mixtures (Springer, Berlin, 2015)

A. Bashiri, L. Fatehnejad, Modeling and simulation of rollover in LNG storage tanks, in International Gas Union 23rd World Gas Conference (Amsterdam, 2006)

J.A. Sarsten, LNG stratification and rollover. Pipeline Gas J. 199(9), 37–39 (1972)

J. Heestand, C.W. Shipman, J.W. Meader, A predictive model for rollover in stratified LNG tanks. AIChE J. 29(2), 199–207 (1983)

P. Arjomandnia, M.O. Tade, V. Pareek, E.F. May, Analysis of available data from liquefied natural gas rollover incidents to determine critical stability ratios. AIChE J. 60(1), 362–374 (2014)

K.B. Deshpande, W.B. Zimmerman, M.T. Tennant, M.B. Webster, M.W. Lukaszewski, Optimization methods for the real-time inverse problem posed by modelling of liquefied natural gas storage. Chem. Eng. J. 170(1), 44–52 (2011)

P. Arjomandnia, Simulation of LNG Rollover in Storage Tanks (Curtin University, Bentley, 2015)

N. Chatterjee, J.M. Geist, The effects of stratification on boil-off rates in LNG tanks. Pipeline Gas J. 199(40), 40–45 (1972)

A.E. Germeles, A model for LNG tank rollover, in Advances in Cryogenic Engineering, ed. by K.D. Timmerhaus, D.H. Weitzel (Springer, New York, 1975), pp. 326–336

K. Koyama, CFD simulation on LNG storage tank to improve safety and reduce cost, in Systems Modeling and Simulation (Springer, Berlin, 2007), p. 39–43

Y. Li, Z. Li, W. Wang, Simulating on rollover phenomenon in LNG storage tanks and determination of the rollover threshold. J. Loss Prev. Process Ind. 37, 132–142 (2015)

Acknowledgments

The author is grateful to the UTM for interest and encouragement.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zakaria, Z., Baslasl, M.S.O., Samsuri, A. et al. Rollover Phenomenon in Liquefied Natural Gas Storage Tank. J Fail. Anal. and Preven. 19, 1439–1447 (2019). https://doi.org/10.1007/s11668-019-00739-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-019-00739-2