Abstract

More effective preservation strategies need to be found to fight increasing emergence of food-borne diseases. Preservation is a process of prevention of decay and spoilage of food. One of the potent sources of antimicrobial compounds is plant essential oils which can be used for food preservation. The antimicrobial effect of essential oils is reduced in food system due to its hydrophobic nature. Nanoemulsion is a fine dispersion of two immiscible liquids which are thermodynamically more stable and optically isotropic. Therefore, nanoemulsion can be used as potent antimicrobial delivery system for preservation. The purpose of this study was to develop different thyme oil in water nanoemulsion formulations by optimizing different parameters such as oil concentration, surfactant concentration and co-surfactant concentration. Nanoemulsion formulations were characterized by dynamic light scattering, stability test and turbidity. Nanoemulsion formulation with oil-surfactant (Thyme oil-Tween80) concentration ratio of 1:5 v/v was found to be stable (more than 3 months) and translucent having droplet diameter of 83 nm. The selected thyme oil nanoemulsion formulation was found to be exhibiting its antibacterial activity against S. aureus. The in situ taxation of the nanoemulsion in fruit juice demonstrated significant decline in inherent microbial population.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

12.1 Introduction

Bioprocessing and food industries are facing challenges in maintaining good quality of food. Food spoilage by microbial contamination is one of the major problems of food industries. The research for new safe food preservation strategies is being performed worldwide [1]. Development of synthetic food preservatives requires great money and time for their formation and approval process [2]. One of the potent alternatives to synthetic food additives is bioactive compounds arising from plants which have antimicrobial and antioxidant properties [3]. One of the effective sources of antimicrobial compounds is plant essential oils which can be used for food preservation. Essential oils derived from plants have been reported to exhibit noteworthy antimicrobial power in contradiction of spoilage and pathogenic microorganisms [4]. Various bio-active compounds of essential oils are benzaldehyde, carvacrol, carvone, cineole, cinnamaldehyde, citral, cymene, estragole, eugenol, geraniol, limonene, methanol, pinene, terpinene, terpineol, thymol and vanillin [5,6,7]. To improve the dispersion of the essential oil in water and also to protect it from degradation, nanoemulsions have emerged as a great alternative [8]. Nanoemulsion can serve as a potent delivery system for essential oils [9]. Nanoemulsion is a fine dispersion of two immiscible liquids (oil and water) with each oil droplet circumvented by a thin interfacial layer consisting of surfactant molecules [10,11,12]. Different methods are there for the formulation of nanoemulsion. These methods are mainly divided into two categories: high-energy methods and low-energy methods [10, 12, 13]. High-energy methods mostly require sophisticated instruments and high energy for the formulation of nanoemulsion, e.g. high-pressure homogenizer, microfluidizer and ultrasonication [13,14,15,16]. Emulsions formulated with low-energy method are generally called as coarse emulsions which can be further treated with high-energy method to reduce the droplet size [17]. Spontaneous emulsion method, phase inversion composition, phase inversion temperature and emulsion inversion point are examples of low-energy methods. Ultrasound cavitation can be used for reduction of droplet size with the help of high-frequency sound waves (20 kHz). It can yield emulsion having smaller droplet size, greater stability and lesser polydispersity.

12.2 Materials and Methods

12.2.1 Chemical Reagents

Thyme essential oil (extracted from Thymus vulgaris), refined and food grade, was obtained from local market. Tween 80 (polyoxyethylene (20) sorbitan monooleate), a non-ionic surfactant, was obtained (SDFCL, Mumbai) and utilized. Distilled water was used for all experiments throughout the study.

12.2.2 Nanoemulsion Formulation

Nanoemulsion was formulated using thyme oil, non-ionic surfactant Tween 80 and water. Thyme oil (4%) used was refined and food grade. Non-ionic surfactant Tween 80 was used due to its high hydrophilic-lipophilic balance (HLB) value of 15 which is suitable for formation of oil in water emulsion. The effectiveness of Tween 80 in minimizing droplet diameter of nanoemulsion is due to their rapid adsorption on droplet surface. Initially coarse emulsion was prepared by mixing organic phase (oil and surfactant) and water. Organic phase was added drop-wise to water under continuous stirring using a magnetic stirrer. The coarse emulsion was then subjected to ultrasonic emulsification using probe sonicator (PCI Analytics KS-250F) with power of 250 W. Energy is supplied through probe horn. The probe generates high-frequency sound waves which forms emulsion droplet by process of cavitation. Different formulations were prepared by optimizing process parameter (surfactant concentration), keeping oil concentration constant (4%), which were mixed in various ratios (1:1, 1:2, 1:3, 1:4, 1:5) and labelled as T1, T2, T3, T4 and T5. The characterization of all the formulated emulsions was done and their stability was determined.

12.3 Characterization of Nanoemulsion

12.3.1 Droplet Size Measurement

The measurement of droplet size of the formulated emulsion was performed by particle size analyser (Zetasizer Nano ZS90) using technique of dynamic light scattering (DLS). The polydispersity index and droplet size of formulated emulsions were measured.

12.3.2 Physicochemical Characterization

The pH value of the formulated emulsions was measured by pH meter (Arvind Industries SV4, India) at room temperature. The absorbance of the undiluted emulsion samples was measured at 600 nm using spectrophotometer (SHIMADZU UV-1800) to determine the turbidity of the formulated emulsion.

12.3.3 Stability

To determine the stability, formulated emulsions were subjected to centrifugation at 10000 rpm for half an hour, and phase separation was checked (if any).

All the formulated emulsions were stored at room temperature for prolonged storage time to determine the intrinsic stability. Phase separation or creaming (if any) was then observed. All the experiments were performed in duplicates.

12.4 Antibacterial Activity

12.4.1 Inactivation Kinetics of Bacterial Population

For assessment of antibacterial activity, thyme oil nanoemulsion T5 was chosen due to its low droplet size and high stability than other formulations. Killing of S. aureus population upon treatment with thyme oil nanoemulsion was determined depending on two parameters, i.e. time and nanoemulsion concentration. Overnight culture of S. aureus was centrifuged at 6000 rpm for 10 min and washed twice in phosphate buffer saline (pH 7.4). Test culture with known inoculum size was then prepared (107 CFU/ml). The test culture was then treated with undiluted and diluted (10-fold, 100-fold, 1000-fold) T5 thyme oil nanoemulsion for different time intervals. For viable count enumeration, 100 μl of the interacted sample was spread onto nutrient agar plates and incubated for 24 h at 37 °C. After incubation, colonies were counted. All experiments were performed in duplicates.

12.4.2 Preservation of Juice

The antimicrobial activity of Thyme oil nanoemulsion against microbial spoilage for preservation of fruit juice was examined, over a time period of 24 h. In laboratory, fresh sweet lime juice was prepared under sterile condition. Its microbial count was evaluated by spreading 10 μl of juice onto nutrient agar plates and incubated overnight at 37 °C, and numbers of colonies were enumerated. Juice was then treated with 10% nanoemulsion and sodium benzoate. Bactericidal effect of nanoemulsion and sodium benzoate in fruit juice was examined by determining the effect of two distinct process variables, i.e. time and temperature.

12.5 Results and Discussion

12.5.1 Selection of Nanoemulsion Formulation

Thyme oil, Tween 80 and water were used to prepare different nanoemulsion formulations by mixing oil and surfactant in different ratios. Nanoemulsion formulation T5 with oil-surfactant ratio of 1:5 showed highest stability as compared to other formulations. Centrifugation of formulations resulted into phase separation of T1, T2 and T3. Intrinsic stability was not observed in formulation T4 upon storage, but nanoemulsion T5 was found to be stable. In addition, nanoemulsion T5 was translucent as compared to other formulations which were turbid indicating low droplet size of nanoemulsion T5.

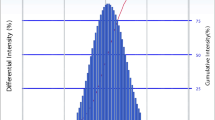

12.5.2 Droplet Size

Nanoemulsion formulations were obtained as a result of ultrasonic emulsification of coarse emulsion for 20 min using sonicator. Tween 80 being a small molecule surfactant gets rapidly adsorbed onto droplet surface, and hence they are more efficient in minimizing droplet diameter than other polymers. The mean droplet diameter of the formulation T5 was found to be 83 nm. The homogeneity of the nanoemulsion droplets was indicated by polydispersity index (PDI) of 0.24.

12.5.3 Physicochemical Characterization

Thyme oil nanoemulsion T5 was optically translucent while other formulations were turbid. Initially coarse emulsion prepared was turbid. However, after ultrasonic emulsification, the emulsion became optically translucent. The absorbance at 600 nm was 0.6 abs. The pH of nanoemulsion at room temperature was 6.8.

12.5.4 Stability

Stability was assessed by centrifuging nanoemulsion formulations for half an hour at 10000 rpm. Nanoemulsion formulation T5 was found to be stable as phase separation was not observed. In addition, formulation T5 was more stable than other formulations when stored at room temperature for prolonged period of time.

12.5.5 Antibacterial Activity

12.5.5.1 Inactivation Kinetics of Bacterial Population

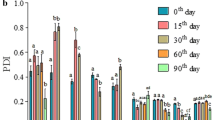

Thyme oil nanoemulsion T5 was used due to its low droplet size and higher stability. Loss in viability of S. aureus was observed over a short period of time upon treatment with thyme oil nanoemulsion depending on time and concentration in experiment of inactivation of kinetics. The reduction of S. aureus upon treatment with different dilutions (10-fold, 100-fold, 1000-fold) of thyme oil nanoemulsion is shown in Fig. 12.1.

Inactivation with tenfold diluted nanoemulsion demonstrated approximately 3 log reduction in cell viability within half an hour of exposure; complete loss of viability was observed in 2 h. Treatment with 100-fold diluted nanoemulsion showed 40% loss in viability in 60 min, 3 log reduction in population within 120 min. In case of 1000-fold diluted nanoemulsion, 2 log reduction in S. aureus population was observed within 60 min and 3 log reduction within 120 min. In this study, effective bactericidal activity was observed even after dilution (10-fold, 100-fold, 1000-fold) of nanoemulsion with sterile water. However, microemulsion loses their bactericidal activity when diluted with water (Fig. 12.2).

12.5.5.2 Preservation of Fruit Juice

Thyme oil nanoemulsion T5 demonstrated antibacterial activity on inherent bacterial population in sweet lime juice. A reduction in bacterial population was observed up to 4 h by both 10% nanoemulsion and sodium benzoate upon storage at 4 °C and room temperature. Approximately 40% loss of viability was observed at 2 h and 4 h upon treatment with 10% nanoemulsion in case of both 4 °C and room temperature. Further gradual increase in bacterial population was observed at 24 h for storage temperature of 4 °C and room temperature. Nanoemulsion exhibited enhanced antibacterial activity as compared to sodium benzoate at both 4 °C and room temperature (Fig. 12.3).

12.6 Conclusion

Different thyme oil nanoemulsion formulations were prepared by optimizing process parameters such as oil and surfactant concentration. Thyme oil nanoemulsion T5 was found to be most stable and had lower droplet size as compared to other formulations. Therefore, formulation T5 was selected for antibacterial assay. Nanoemulsion T5 exhibited bactericidal activity against S. aureus even after dilution. Further, thyme oil nanoemulsion T5 was also effective in reducing bacterial population in sweet lime juice and hence can be utilized for prevention of microbial spoilage for preservation of juice.

References

Magnuson B, Munro I, Abbot P, Baldwin N, Lopez-Garcia R, Ly K, McGirr L, Roberts A, Socolovsky S (2013) Review of the regulation and safety assessment of food substances in various countries and jurisdictions. Food Addit Contam Part A 30(7):1147–1220

Tajkarimi MM, Ibrahim SA, Cliver DO (2010) Antimicrobial herb and spice compounds in food. Food Control 21:1199–1218

Ortega-Ramirez LA, Rodriguez-Garcia I, Leyva JM, Cruz-Valenzuela MR, Silva-Espinoza BA, Gonzalez-Aguilar GA, Siddiqui Wasim MD, Ayala-Zavala JF (2014) Potential of medicinal plants as antimicrobial and antioxidant agents in food industry: a hypothesis. J Food Sci 79(2):R129–R137

Jayasena DD, Jo C (2013) Essential oils as potential antimicrobial agents in meat and meat products: a review. Trends Food Sci Technol 34(2):96–108

Burt S (2004) Essential oils: their antibacterial properties and potential applications in foods – a review. Int J Food Microbiol 94(3):223–253

Singh G, Maurya S, deLampasona MP, Catalan CAN (2007) A comparison of chemical, antioxidant and antimicrobial studies of cinnamon leaf and bark volatile oils, oleoresins and their constituents. Food Chem Toxicol 45(9):1650–1661

Wang R, Yang B (2009) Extraction of essential oils from five cinnamon leaves and identification of their volatile compound compositions. Innovative Food Sci Emerg Technol 10(2):289–292

Acevedo-Fani A, Salvia-Trujillo L, Rojas-Graü MA, Martín-Belloso O (2015) Edible films from essential-oil-loaded nanoemulsions: physicochemical characterization and antimicrobial properties. Food Hydrocoll 47:168–177

Donsì F, Cuomo A, Marchese E, Ferrari G (2014) Infusion of essential oils for food stabilization: unraveling the role of nanoemulsion-based delivery systems on mass transfer and antimicrobial activity. Innovative Food Sci Emerg Technol 22:212–220

Tadros T, Izquierdo P, Esquena J, Solans C (2004) Formation and stability of nano-emulsions. Adv Colloid Interf Sci 108–109:303–318

McClements DJ, Decker EA, Weiss J (2007) Emulsion-based delivery systems for lipophilic bioactive components. J Food Sci 72(8):R109–R124

Acosta E (2009) Bioavailability of nanoparticles in nutrient and nutraceutical delivery. Curr Opin Colloid Interface Sci 14(1):3–15

Leong TSH, Wooster TJ, Kentish SE, Ashokkumar M (2009) Minimising oil droplet size using ultrasonic emulsification. Ultrason Sonochem 16(6):721–727

Gutiérrez JM, González C, Maestro A, Solè I, Pey CM, Nolla J (2008) Nano-emulsions: new applications and optimization of their preparation. Curr Opin Colloid Interface Sci 13(4):245–251

Velikov KP, Pelan E (2008) Colloidal delivery systems for micronutrients and nutraceuticals. Soft Matter 4(10):1964–1980

Wooster TJ, Golding M, Sanguansri P (2008) Impact of oil type on nanoemulsion formation and Ostwald ripening stability. Langmuir 24(22):1275–1276

Ghosh V, Mukherjee A, Chandrasekaran N (2013) Ultrasonic emulsification of food-grade nanoemulsion formulation and evaluation of its bactericidal activity. Ultrason Sonochem 20(1):338–344

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Patel, A., Ghosh, V. (2020). Thyme (Thymus vulgaris) Essential Oil–Based Antimicrobial Nanoemulsion Formulation for Fruit Juice Preservation. In: Sadhukhan, P., Premi, S. (eds) Biotechnological Applications in Human Health. Springer, Singapore. https://doi.org/10.1007/978-981-15-3453-9_12

Download citation

DOI: https://doi.org/10.1007/978-981-15-3453-9_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-3452-2

Online ISBN: 978-981-15-3453-9

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)