Abstract

This work discusses the suitability of inclined internal skirts along with outer vertical plates or skirts on bearing capacity of skirted footings on c-Φ soils. The parameters considered are thickness and depth of vertical plates and the spacing of inclined internal skirts. The scaled model footings were made up of mild steel which was considered for this research work. Square and rectangle are the two shapes adopted. The size was designed in such a way that the lateral confinement effect does not affect the test results. The foundation soil was in dry condition. The various parameters considered are thickness, depth and spacing of internal skirts. In square footing, for a 5-mm-thick skirt, 40-mm-skirt depth and 10-mm-internal skirt spacing, increase in bearing capacity observed was 2.4 times. If the depth of skirt is increased to 120 mm keeping all other parameters unchanged, the bearing capacity was increased to 13 times. For square footing, the highest improvement in bearing capacity was 14 times for skirt depth of 120 mm with skirt thickness of 5 mm and internal skirts spacing of 10 mm. Increase in spacing of internal skirts from 10 to 30 mm for square footing with 5-mm-thick skirt with 40-mm-skirt depth showed a reduction in bearing capacity from 238 to 150%. Numerical validation of experimental test results was carried out by using Plaxis software.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

9.1 Introduction

The present study aims at improving the bearing capacity of foundations soil by confinement. The confinement of soil is achieved by providing vertical insertions along with the periphery of footings. These vertical insertions resist the lateral movement of foundation soil. These vertical insertions are termed as skirts, and foundations with these skirts are termed as skirted footings or bucket foundations. These foundations are employed in offshore structures to replace deep foundations. However, skirted foundations are yet to be adopted for onshore structures. Presently, researchers are focusing on this aspect. Most of the previous research focused on footings with vertical insertions. In this work, apart from outer vertical insertions, footings are provided with additional inner inclined insertions for improved load-carrying capacity.

9.2 Literature Survey

Eid [1] conducted numerical studies on axially loaded skirted shallow foundations. The results showed that bearing capacity and settlement values of skirted foundations were close to pier foundations of the same width and depth. Bearing capacity of shallow foundation increased with increase in skirt depth and decrease in relative density of sand. Settlement reduction exceeds 70% for a ratio of skirt depth/foundation width equal to 2.

Finite element limit analysis conducted by Mana et al. [2] identifies the critical internal skirt spacing. With the increasing skirt depth, fewer internal skirts are required. But increasing soil strength heterogeneity requires more internal skirts. The results also indicate that the reduction in number of skirts reduced bearing capacity.

Laboratory tests were conducted by El Sawwaf and Nazer [3] to study the influence of soil confinement on the behaviour of a footing resting on granular soil. The parameters considered are the diameter and depth of cell and the embedded depth of footing. The results showed soil confinement increase bearing capacity of circular footing. The cells with small cell diameters exhibit deep foundation behaviour, while this pattern was not found with large cell diameters.

9.3 Methodology

9.3.1 Model Footings Without Skirt

In the present work, square-shaped footing with and without skirts are used for the testing. The footing sizes were smaller than (1/5) B (where B = width of container) to avoid lateral confinement effect. The plan area of footings is 80 mm × 80 mm. The thickness of footings is 10 mm made of mild steel. Vertical plates of thickness 1, 3 and 5 mm are used as skirts. The skirt depths of 0.5B, 1.0B and 1.5B were used to understand the effect of bearing capacity due to variation in skirt depth where B is the least lateral dimension of the model footing.

9.3.2 Model Footings with Skirts

Model footings and skirts are connected by welded joints so as to form a monolithic footing. The line diagrams of square footing are shown in Figs. 9.1 and 9.2. Totally, 18 model square footings of varying skirt depths (40–120 mm) and skirt thicknesses (1–5 mm) were used for the study.

9.3.3 c-Φ Soil

An oven-dried soil was used in the experiment program. The soil was sieved as per Indian Standard specifications. The geotechnical properties of the soil are given in Table 9.1.

9.3.4 Test Tank and Loading Frame

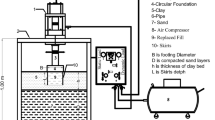

The steel tank of size of 0.75 m (length), 0.45 m (width) and 0.75 m (depth) as shown in Fig. 9.3 was used to hold foundation soil. To avoid buckling of sidewalls of the tank during loading, stiffeners were provided. Static vertical loads were applied, and load-settlement readings were taken.

9.3.5 Test Procedure

Raining technique was adopted to prepare the bed of soil. This was done in lift of 50 mm thick up to full tank height. The soil was poured from a predetermined height and with controlled intensity of pouring, required relative density of soil was obtained. To keep the model footing in full contact with the soil, the top of soil layer was levelled. This will also facilitate the load applied to the footing was vertical (normal). The unit weight of the soil was maintained at 13.73 kN/m3 in dry state. After each test cycle, the soil beneath the footing was excavated to a depth of 1.5B. The footing was placed on the predetermined prepared surface of the soil in the tank. The vertical load at a constant rate was gradually applied to the footing until the settlement is seized. Two dial gauges were used to record the settlements of the footing. For each cycle, the load-settlement readings were recorded.

9.3.6 Numerical Modelling

An extensive 2D finite element modelling and analysis was carried out to evaluate the behaviour of the footing with and without structural skirts. The axisymmetry model is used for square footing with 15-node triangular element, and the dimensions were set for modelling. The dimensions of c-ɸ soil 450 mm × 750 mm and thickness of 750 mm are modelled in the drawing area, and the standard boundary condition is assigned. The footing model with and without structural skirts with varying skirt thickness of 1 and 3 mm, skirt depths of 0.5B where ‘B’ is the least lateral dimension of the footing is modelled. The interface is given between footing and soil structure and between the structural skirt and soil structure. The point load is applied concentrically on the footing. The geometry of the finite element soil model adopted for the analysis is 450 mm × 750 mm × 750 mm shown. Soft soil model is adopted for soil modelling. The main feature of soft soil model is that the stiffness of soil is dependent on stress applied. The failure behaviour of soil is in accordance with the Mohr–Coulomb criterion. The material properties of c-ɸ soil are defined according to soft soil model.

The stresses initially are more at the bottom of the soil model and gradually decrease towards the surface of the soil model due to the fixity at the bottom and sides. The load is applied concentrically as in experimental study for 24 mm settlement. Stress point nodes are selected to get the load. The deformation of the footing and soil model is obtained as shown in Fig. 9.4. From the analysis, vertical displacement is obtained.

9.4 Results and Discussions

Extensive pressure-settlement experiments on square-shaped skirted footings on c-Φ soil were carried out. The pressure-settlement curves for a square footing of size 80 mm × 80 mm with thickness varying from 1 to 5 mm with constant depth of 40 mm are shown in Fig. 9.5. It is evident from the figure that the bearing capacity increases with an increase in the skirt thickness. The bearing capacity was improved by 55.50% (6.90–10.73 kN/m2) for a skirt thickness of 1 mm, 125.60% (6.90–15.56 kN/m2) for 3 mm skirt thickness and 238.90% (6.90–23.38 kN/m2) for 5 mm skirt thickness for a constant skirt depth of 40 mm. It is due to increased thickness of skirts increase rigidity of skirt and hence higher resistance to lateral pressure.

The pressure-settlement curves for a model square footing of size 80 mm × 80 mm are shown in Fig. 9.6. For a concentric load, the variation in bearing capacity without skirts and with skirts of thickness 1, 3 and 5 mm with internal skirts having 30 mm spacing and constant skirt depth of 40 mm is plotted. The values of bearing capacity of footings with skirts are compared with the bearing capacity values of footings without skirts.

From Fig. 9.6, it is evident that the bearing capacity increases with increase in the skirt thickness. The bearing capacity was improved by 44.40% (6.90–9.96 kN/m2) for a skirt thickness of 1 mm, 73.40% (6.90–11.96 kN/m2) for 3 mm skirt thickness and 150% (6.90–17.24 kN/m2) for 5 mm skirt thickness in c-ɸ soil for a constant skirt depth of 40 mm.

Figures 9.5 and 9.6 indicate that the bearing capacity for the square footing with 10-mm-internal skirt spacing is greater when compared to the model square footing with 30-mm-internal skirt spacing. The comparison of bearing capacity improvements in model square footings with 10- and 30-mm-internal skirt spacing for a skirt depth of 40 mm is discussed in Table 9.2.

The pressure-settlement curves for a model square footing of size 80 mm × 80 mm are shown in Fig. 9.7. For a concentric load, the variation in bearing capacity without skirts and with internal skirts of thickness 1, 3 and 5 mm having 10 mm spacing and constant skirt depth of 80 mm is plotted. The values of bearing capacity of model footings with skirts are compared with the bearing capacity values of model footings without skirts.

Figure 9.8 shows that the bearing capacity increases with increase in the skirt thickness. The bearing capacity was improved by 198.80% (6.90–20.62 kN/m2) for a skirt thickness of 1 mm, 269.90% (6.90–25.52 kN/m2) for 3 mm skirt thickness and 375.40% (6.90–32.80 kN/m2) for 5 mm skirt thickness in c-ɸ soil for a constant skirt depth of 80 mm.

In Fig. 9.8, pressure-settlement curve for different thickness of internal skirt with constant depth and spacing of 80 mm and 30 mm, respectively, is shown. It is evident that the bearing capacity increases with increase in the skirt thickness. The bearing capacity was improved by 177.70% (6.90–19.16 kN/m2) for a skirt thickness of 1 mm, 211% (6.90–21.46 kN/m2) for 3 mm skirt thickness and 255.50% (6.90–24.53 kN/m2) for 5 mm skirt thickness for a constant skirt depth of 80 mm. From Figs. 9.7 and 9.8, it is clear that the bearing capacity for the same square footing with 10-mm-internal skirt spacing is greater when compared to the square footing with 30-mm-internal skirt spacing. The comparison of bearing capacity improvements with increasing skirt thickness in model square footings with 10 and 30 mm spacing for a skirt depth of 80 mm is shown in Table 9.3. Table 9.4 shows similar trend for 120-mm-skirt depth.

-

Figures 9.9, 9.10 and 9.11 show numerical analysis results of square footings with skirts (d = 40 mm, s = 10 mm and t = 1, 3 and 5 mm). From the figures, the effect of thickness of skirts on the deformation in the foundation soil and stress concentration in the footing and the skirts can be compared.

-

The higher intensity of stress is found in the internal inclined skirts as compared to peripheral vertical skirts as shown in Figs. 9.12, 9.13 and 9.14. The maximum deformation is found between the skirts and deformation reduces significantly below the skirt tip.

-

Further, the deformation between the inclined skirts is significantly lesser as compared to outside the inclined skirts indicating that inclined skirts resist vertical loads better than the vertical loads as shown in Figs. 9.15, 9.16 and 9.17.

9.5 Summary

-

Results showed that spacing of internal inclined skirts has a significant effect on the bearing capacity of square footings on c-Φ soil. Increase in spacing of internal skirts from 10 to 30 mm for square footing with 5-mm-thick skirt with 40-mm-skirt depth showed reduction in bearing capacity from 238 to 150%. This trend confirms that smaller cells are more effective in confining foundation soil.

-

Pressure-settlement curves showed improvement in bearing capacity with the increase in skirt depth for both square footings. The maximum effect on bearing capacity value was found to be for a skirt depth of 1.5B. For example, in square footing, for a 5-mm-thick skirt, 40-mm-skirt depth and 10-mm-internal skirt spacing, increase in bearing capacity observed was 2.4 times. If the depth of skirt is increased to 120 mm keeping all other parameters constant, the bearing capacity was increased by 13 times.

-

Increase in skirt thickness for square footing increased the bearing capacity. For a skirt thickness of 5 mm, the bearing capacity was found to be higher when compared to 1- and 3-mm-thick skirts. For square footing, the highest improvement in bearing capacity was 14 times for skirt depth of 120 mm with skirt thickness of 5 mm and internal skirts spacing of 10 mm. This trend is attributed to the increased thickness of skirts increase rigidity of skirt and hence higher resistance to lateral pressure.

-

The percentage of difference in settlement for square footing (for 40 mm skirt depth) ranges between 5.5 and 19.83%. Similar trend is observed for 80 mm skirt depth. The percentage of difference ranges between 6.58 and 29.25%.

-

The higher intensity of stress is found in the internal inclined skirts as compared to peripheral vertical skirts. The maximum deformation is found between the skirts and deformation reduces significantly below the skirt tip. Further, the deformation between the inclined skirts is significantly lesser as compared to outside the inclined skirts indicating that inclined skirts resist vertical loads better than the vertical loads. It may be concluded that the analytical result closely matches with experimental results in terms of percentage difference in settlement.

References

Eid, H.: Bearing capacity and settlement of skirted shallow foundations on sand. Int. J. Geomech., 645–652 (2013). https://doi.org/10.1061/(asce)gm.1943-5622.0000237

Mana, D.S.K., Gourvenec, S., Martin, C.M.: Critical skirt spacing for shallow foundations under general loading. J. Geotech. Geoenviron. Eng. 139(9), 1554–1566 (2013)

El Sawwaf, M., Nazer, A.: Behavior of circular footings resting on confined granular soil. J. Geotech. Geoenviron. Eng. 131(3), 359–366 (2005)

Acknowledgements

The authors appreciate the KS School of Engineering and Management for providing the necessary infrastructure and cooperation to carry out this work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Vijay, A., Akella, V., Raghu Prasad, B.K. (2020). Experimental Studies and Numerical Validation on Bearing Capacity of Skirted Footings on c-Φ Soils. In: Vinyas, M., Loja, A., Reddy, K. (eds) Advances in Structures, Systems and Materials. Lecture Notes on Multidisciplinary Industrial Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-3254-2_9

Download citation

DOI: https://doi.org/10.1007/978-981-15-3254-2_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-3253-5

Online ISBN: 978-981-15-3254-2

eBook Packages: EngineeringEngineering (R0)