Abstract

Carbon dioxide (CO2) injection to enhance the oil recovery help not only to increase the recovery efficiency of oil but also it helps to reduce greenhouse effects on environment. However, CO2 injection is not an easy procedure to follow as different oil reservoirs has different fracture pressures and accumulated oil possess different Minimum miscibility pressures (MMP), thus the selection of additives that can lower the minimum miscibility pressure. Therefore, this paper presents a comparative approach for different type of additives injected along with CO2 to observe optimistic MMP that can play significant role in succeeding the CO2 injection and achieving enhanced oil production. The injection profile for carbon dioxide injection is divided into three categories; that are: polar, semi polar and non-polar. Polar injection includes polar chemicals (Ethane); semi polar category comprises of higher chain alcohol and non-polar category is toluene based injection. The results of this paper presented that polar modifiers revealed the MMP of 14.75 MPa at 383.1 K. Additionally, semi polar modifier showed miscibility at 18.29 MPa since the gas and liquid phase got miscible totally at 416 K temperature. Further, non-polar modifiers showed the effects of alcohols over 17.65 MPa at 375.15 K. At the specific reservoir temperature polar injection showed more compromising results but overall recovery is better in semi polar injection. Moreover, non-polar injection is recommended only when reservoir possess complex characterization otherwise it has no fruitful effects on recovery.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The initial Enhanced Oil Recovery (EOR) project based on CO2 (Carbon dioxide) injection was kicked off in 1972 in Texas at Kelly-Snider oil field. According to experts once the success of CO2 EOR pilot project is observed, the practical execution of the project could be put in place (Abbasov 2007). Injection of miscible gas like CO2 into oil reservoir has many positive purposes, including effective production of methane from natural gas hydrates (Ahmad Al-adasani 2012). The basic objective of CO2 flooding as miscible gas in EOR process is to displace the oil, and reduce the residual oil saturation. CO2 can play as ideal recovery method in certain reservoir where recovery methods are not suitable (Beltran 1990) (Denmark 2005). Practical in deeper reservoir beyond 2000 ft the CO2 disguise in supercritical state. The other mechanism of CO2 EOR is also interesting one, the oil swell as CO2 gets dissolved in it, hence reducing the oil viscosity and proving ease to oil for mobilizing to production well (Yongan 2004). Commonly, water is injected in Co2 EOR candidate reservoir to restore the subsurface pressure, this activity also thrust the one third of Co2 to produce back to surface (Gu 2004). The produced back CO2 is later re-injected to optimize the cost of process. Similar like propane and butane Carbon dioxide is also an economical solvent for miscible enhanced oil recovery process. The “economical CO2” is the term refereed for the CO2 gas that is collected from flue gas of coal power plant, otherwise sufficient quantity of CO2 is not available easily for industrial usage (Irani and Solomon Jr 1986). The miscibility of CO2 is achieved within certain pressure range, thus the minimum pressure at which CO2 becomes miscible in oil is called Minimum Miscibility Pressure (MMP) and this pressure is considered as key to successful miscible injection process.

The theoretical study of miscible CO2 EOR displacement depict that a zone is formed in motion between two miscible fluids in reservoir. Mathematically, the size of that zone is proportional to the square root of time. Further, the volume of pure solvent decreases continuously as the mixing zone sweeps towards production well (Bahralolom and Orr Jr 1988). Here the most important phenomenon to focus is that, the volume of the solvent slug injected must be in estimated amount so that the slug should get dissolved in zone before reaching the producing well (Robertson 2011). Otherwise, the miscible zone and reservoir oil which cannot be mixed would come into contact and collapse the whole miscibility process. This phenomenon of bypassing the miscible zone is termed as “miscibility rupture”. The top challenge in planning of miscible displacement process by solvent lies in the estimation of “adequate slug volume”. The slug volume should not be very small to avoid the risk of miscibility rupture, also not very large to raise expenditures of the project (McGuire 1998).

Mutailipu (2019) Conducted the experimental study to measure the interfacial tension between CO2 and alkanes with respect to temperature with slight interval of temperature and pressure windows. The MMP of CO2 and alkanes was evaluated by the means of gas oil interface disappearance. Additionally, the required value of interfacial tension was calculated by exponentially extrapolating the values of interfacial tension up to vanishing point on pressure scale however this deduction suggested that interfacial tension decreases sharply with respect to pressure that is at high pressure the values for interfacial tension increases and decreases at low pressure at the specified values of temperature. Yang (2019) measured the miscibility of co2 with oil when additional alcohol is injected. The concept of injecting alcohol is based on the theory that reducing MMP between oil and CO2 can be reduced by decreasing the intermolecular force which can be done by alcohols easily. Therefore the miscibility of CO2 and oil were measured in presence of alcohol in high pressure and high temperature cells with specified temperature and pressure values. The core parameter to evaluate the study was interfacial tension and the final results of study leaded to the conclusion that using alcohol as injection additive with CO2 is highly recommended to improve miscibility process. Czarnota (2017) presented a unique technique called rapid pressure increase method to evaluate the MMP of CO2 and oil along with phase behavior. The method is based on determination of relation between pressure increase and volume decrease of binary system along with analysis of derivative of function with lowest values. Because at the lowest point of function derivative the ratio of increased pressure and decreased volume yield the required miscibility pressure and as it is the lowest pressure value hence it is considered to be the desired minimum miscibility pressure. Chen (2018) improved the already developed correlation used to estimate the MMP between oil and CO2 in its pure and impure forms with respect to basic scientific factors influencing the MMP value. The application of correlation was validated by comparing the outcomes with an experimental analysis using similar features as considered by correlation. Notably, the improved correlation provided revealed higher calibrated outcomes with experimental analysis with higher prediction accuracy. Thus verity of studies has been reported in the domain of minimum miscibility pressure evaluation when CO2 is injected in oil reservoir. However, most of the study suggest that the addition of certain additives can improvise the MMP achieving rate and values. Therefore, this study focus on selecting the type of additive that can improve the miscibility process over pressure and temperature conditions. Moreover, the important question that is answered in this study that what kind of additive should be added to the CO2 injection process so that it can lead to optimistic MMP achievement. Indeed, this study not only provides the fundamentals of modifier category selection but also provides the detailed experimental analysis to find the optimistic MMP values at lab scale. Figure 1 shows the comprehensive plan implemented to accomplish the study.

2 MMP Reduction

MMP is the pressure window for injection, as we know that injection pressure has to be chosen above MMP to attain miscibility, however we have to keep formation fracture pressure in mind, the MMP cannot be greater than reservoir pressure. That is the reason we only choose those formations for CO2 miscible flooding which have reservoir pressure above the minimum miscibility pressure (MMP) in order for formation to sustain the pressure increase caused by injection of CO2.

It is clear that efficiency and economics for CO2 flooding depends upon the pressure that needs to be applied at least for injection to attain miscibility. The need for reducing MMP comes in play for such reservoirs whose pressure is below MMP, by its reduction many reservoirs can become applicable for CO2 miscible flooding which were immiscible before. Below is the figure for the impacts of change in miscibility behaviour in Fig. 2 below.

2.1 Experimental Materials and Instruments

Miscible phase pressure test of carbon dioxide and crude oil:

-

The main materials used in this experiment are:

On-site crude oil in Xinjiang Oilfield;

Carbon dioxide with a purity of 99.9%;

Chemical Modifiers;

Petroleum ether.

-

Crude oil properties

Relationship between density and temperature of crude oil (Fig. 3):

It can be seen from the above curves that the density and viscosity of crude oil decrease with increasing temperature

-

The main instruments of this experiment are:

Hand pump, observation window, pressure gauge, carbon dioxide cylinder.

The flow chart of the experimental device is shown in the following Fig. 4:

2.2 Experimental Methods and Procedures

In the high pressure observation, the miscible phase fluid can be observed. As the pressure is gradually increased, there will be no obvious interface between the carbon dioxide and the simulated oil, that is, the oil and gas interface will gradually become clear and blur, and even the interface disappears. It can be considered that the miscible phase is reached. The pressure at which the oil and gas interface begins to become blurred is artificially the minimum miscible pressure of carbon dioxide and oil.

The determination of the minimum miscibility pressure is mainly carried out as follows:

-

(1)

The apparatus is cleaned and dried pipelines and observation windows are evacuated with carbon dioxide to make sure there is no impurity while performing experiment.

At first a measured amount of crude oil is added to the visual tube, until visible in the window below and is completely sealed. And a certain pressure of carbon dioxide gas is injected into the pipelines and the thin tubes. After the airflow is stabilized for a period of time, the gas injection valve is closed.

-

(2)

Using hand pump the more gas is pumped into the main apparatus until the injection cycle is completed, the intake line is drained, and the injection pressure is raised every iteration to make it equal to the injection pressure of the previous cycle;

-

(3)

This cycle goes on for a while until the pressure is reached when the two-phase interface is observed, record the pressure representation number, observe and record the interface change;

-

(4)

Gradually increase the pressure. After each increase of 1 to be stabilized, observe and record the interface change until the interface rises to the uppermost end of the observation window and stop the experiment;

-

(5)

Reduce the pressure, clean the pipeline with petroleum ether until the inlet petroleum ether and the petroleum ether are the same color. After the cleaned pipeline is dried with carbon dioxide, it is dried at the temperature required for the experiment for more than 6 h. Wait for the required temperature

Now the same experiment is conducted with different additives mixed with crude oil at different ratios, in a similar pattern the visual window is observed until a miscible phase is reached. Secondly the impact of that particular additive at a specific ratio is recorded upon its significance in lowering MMP.

After injecting crude oil in to the apparatus, the visual window has reading which shows the level of the liquid at the particular point. From the reading it can be seen that rise of oil level in the window is 10 cm.

With increasing Pressure any changes to the level as well as the interface is observed.

As the pressure increases gradually, we observe the liquid level in the observation window. When the two-phase interface is observed, the pressure is recorded and so the visual window.

From the Fig. 5 we can see that with the injection of co2 the oil level rises as CO2 replaces the crude oil. the oil level raised at a reading of 12.4 cm on the scale, after further increase of pressure the oil column seem to decline as miscibility takes place slowly into a single phase. that particular picture depicts the MMP physical of the crude oil in the system. The MMP was found to be 21.5 at the temperature of 65 C.

MMP (Physical): The MMP of this particular crude oil at the temperature was found to be 21.5 MPa.

2.3 MMP Improvement Strategies

-

Polar Modifiers

-

Polar injection includes polar chemicals (Alcohols);

-

-

Semi Polar Modifiers

-

Semi polar category comprises of higher chain alcohol

-

-

Non-Polar Modifiers

-

Non-polar category is toluene based injection (Fig. 7).

-

3 Results

3.1 Polar Modifiers

Figure 8 shows the visuals of miscibility achieved in experimental chamber when CO2 was injected along with Polar modifiers. The minimum pressure point was achieved at 14.75 MPa at the temperature of 383.1 K. however the length of experimental analysis was extended to examine the possibility of error in results but no change in oil color proved that no miscibility was taking place at higher pressures. Thus the concrete value of miscibility was achieved for polar modifiers.

3.2 Semi-polar Modifiers

The experimental analysis was repeated with CO2 injection in oil chamber along with Semi-polar modifiers. The visuals mentioned in Fig. 6 suggest that the miscibility of gas was initiated at the pressure of 18.29 MPa when the temperature was headed to 416 K. the most important observation in this experiment was elongated time taken by gas to get miscible in oil therefore in order to reduce the time factor temperature was increased because as a matter of fact the higher chain alcohols shows better miscibility at high temperatures. The overall miscibility also took a longer time to get fully miscible in oil (Fig. 9).

3.3 Non-polar Modifiers

Figure 10 shows the miscibility visuals of Co2 in oil when injected with Non-polar modifiers. The miscibility was achieved at the pressure of 17.65 MPa when the temperature was 375.15 K. thus this is the lowest temperature recorded among all the modifier categories. However, there is least effect of temperature when non-polar modifiers are injected because the stability of such modifiers is not linearly characteristic based. Hence, non-polar modifiers are beast fit the injection in reservoirs which have complex characteristics.

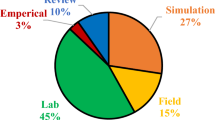

4 Comparative Breakdown of Categories

The MMP values of all the modifier categories are subjected to comparison so that optimistic modifier category can be selected hence Table 1 shows the magnitudes of MMP achieved at specific temperatures. In order to understand the miscibility performance of all the modifier categories the values of temperature and pressure of all the modifier categories are plotted over linear scale. The detailed analysis is mentioned in plots developed with different boundaries of temperature and pressure.

Figure 11 shows the linear plot of miscibility pressure of polar, semi-polar and non-polar modifiers. The least value of MMP achieved is revealed by polar modifiers, second least is Non-polar and last one to achieve miscibility is semi-polar modifiers, hence, the most prolific and optimistic MMP of Co2 with oil can be achieved by injecting polar modifiers. On the other hand the most unreasonable MMP will be achieved if miscibility injection is accompanied by semi-polar modifiers. Furthermore, non-polar modifiers also recommended in certain cases when reservoir has some complex geological and technical property based anomalies.

In order to achieve concrete analysis of optimistic modifier the temperature based behavior is also studies thoroughly in Fig. 12. The results suggest that polar modifiers require a little more temperature as compared to non-polar modifiers but the average temperature of oil reservoir has more acceptability for polar modifiers which has already shown optimistic miscibility pressure value. However, semi-polar modifiers.

Hence it can be seen that the most compromising and acceptable results with respect to temperature and pressure value is shown by polar modifiers but the concept of semi polar modifiers is also considered reasonable in oil industry because semi-polar modifiers provides better recovery. Besides, non-polar modifiers are the least recommended in usual Co2 injection projects because these are instable during the process but these modifiers are still considered the part of technical projects only when the reservoir containing oil has some irregular properties.

5 Conclusion

The interpretation of study derived from comparing the minimum miscibility pressure regulation and control between oil and CO2 along with modifiers lead to advocate the following conclusions.

-

1.

Polar modifiers are the most suitable minimum miscibility pressure modifying agents supposed to be injected with CO2 to achieve better MMP at acceptable temperature within optimistic time and recovery conventions.

-

2.

Semi-polar modifiers are the minors among recommendation list of modifiers because these modifiers provides less promising MMP values and require high operational temperature. But these modifiers are still part of recommendations because they reveal better recovery rates of oil.

-

3.

Non-polar modifiers are only recommended in the scenario where oil reservoir possess complex characteristics and irregular properties, for instance if the MMP is required to be achieved at low temperature or improvised time duration is required to achieve MMP. In fact, non-polar modifiers are only recommended to be injected to improve the miscibility process otherwise these modifiers has very inferior effect on oil recovery.

References

Abbasov, S.I.: Effect of surfactant on volume and pressure of generated CO2 gas. In: Production and Operations Symposium, Oklahoma City, Oklahoma, U.S.A, 31 March–3 April, pp. 1–5 (2007)

Ahmad Al-adasani, B.B.: A selection criterion for CO2-enhanced oil recovery and dispersion modeling of high-pressure CO2 release. In: SPE Western Regional Meeting, Bakersfield, California, USA, 21–23 March, pp. 1–19 (2012)

Beltran, J.C.: Case studies-proactive managed pressure drilling and underbalance drilling application in San Joaquin wells. In: SPE Annual Technical Conference and Exhibition, San Antonio, pp. 24–27 (1990). SPE 100927

Denmark, K.J.: Fluid characterization for miscible EOR projects and CO2 sequestration. In: SPE Annual Technical Conference and Exhibition, Dallas, Texas, 9–12 October, pp. 1–8. Society of Petroleum Engineers, Texas (2005)

Yongan, D.Y.: Visualization of interfacial interactions of crude oil-CO2 systems under reservoir conditions. In: SPE/DOE Symposium on Improved Oil Recovery, Tulsa, Oklahoma, 17–21 April, pp. 1–9 (2004)

Gu, D.Y.: Interfacial interactions of crude oil-brine-CO2 systems under reservoir conditions. In: SPE Annual Technical Conference and Exhibition, Houston, Texas, 26–29 September, pp. 1–12 (2004)

Irani, C.A., Solomon Jr., C.: Slim-tube investigation of CO2 foams. In: SPE Enhanced Oil Recovery Symposium, Tulsa, Oklahoma, 20–23 April, pp. 1–11 (1986)

Bahralolom, I.M., Orr Jr., F.M.: Solubility and extraction in multiple-contact miscible displacements: comparison of N2 and CO2 flow visualization experiments. SPE Reservoir Eng. 3(1), 1–7 (1988)

Robertson, A.E.: Mechanistic study of improved heavy oil recovery by CO2-foam injection. In: SPE Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 19–21 July, pp. 1–19 (2011)

McGuire, P.A.: Unconventional miscible EOR experience at Prudhoe Bay. In: SPE/DOE Improved Oil Recovery Symposium, Tulsa, Oklahoma, 19–22 April, pp. 1–15. Society of Petroleum Engineers, Oklahoma (1998)

Mutailipu, M.: CO2 and alkane minimum miscible pressure estimation by the extrapolation of interfacial tension. Fluid Phase Equilib. 494, 103–114 (2019)

Yang, Z.: Reducing the minimum miscibility pressure of CO2 and crude oil using alcohols. Colloids Surf. A 568, 105–112 (2019)

Czarnota, R.: Minimum miscibility pressure measurement for CO2 and oil using rapid pressure increase method. J. CO2 Utilization 21, 156–161 (2017)

Chen, G.: An improved correlation to determine minimum miscibility pressure of CO2–oil system. Green Energy Environ. (2018). (Available online 30 December 2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Nabi, A. et al. (2020). Comparative Analysis on the Minimum Miscible Pressure Regulation and Control Between Oil and CO2. In: Lin, J. (eds) Proceedings of the International Field Exploration and Development Conference 2019. IFEDC 2019. Springer Series in Geomechanics and Geoengineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-2485-1_326

Download citation

DOI: https://doi.org/10.1007/978-981-15-2485-1_326

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-2484-4

Online ISBN: 978-981-15-2485-1

eBook Packages: EngineeringEngineering (R0)