Abstract

Enhanced Oil Recovery is a method to increase oil recovery from 30% till 60% depend on primary and secondary recovery. One of the proven EOR method to increase oil recovery is CO2 injection. This injection has 2 conditions: miscible and immiscible. In this research, the purpose of MMP determination is to know the effect of temperature, pure and impurities CO2 (methane, ethane, propane and H2S). Simulator is used to determine of MMP. The result is the increase in temperature will increase the MMP. The influence of pure and impure from CO2 with 80% CO2 + 20% non CO2 (C1, C2, C3) components. With CO2 100% as reference, the additions of 20% methane will increase 86% MMP, 20% ethane will decrease 13% MMP and for 20% propane will decrease 33% MMP.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Enhanced oil recovery (EOR) is implementation of various techniques to increase the amount of crude oil that can be the extraction from reservoir. EOR also called the increasing of oil recovery factor or tertiary recovery. By using EOR, oil recovery in reservoir can be extraction 30% till 60% depend on primary and secondary recovery. One of the EOR method is CO2 injection. It is method can increase the recovery factor. CO2 EOR has been proven in The Hansford Marmaton Field (Flanders et al. 1990).

CO2 injection has 2 conditions: miscible and immiscible. From those conditions, recovery factor using miscible condition is greater than immiscible condition. Because it make crude oil volume is swollen, viscosity is decreased, interfacial tension is reduced, crude oil driven by solution gas, and light components are extracted to the injected CO2 phase (Ghedan 2009). To achieve the condition, need to know the Minimum Miscibility Pressure (MMP). MMP is minimum pressure for CO2 miscibility with crude oil.

However, although the recovery factor for miscible condition is greater. Keep attention with the reservoir condition, like pressure reservoir and fracture pressure to prevent fracture or CO2 injected can deep penetrate reservoir and not dissolve yet. Because of greater MMP value, injection pressure must be greater than MMP.

Because of that, it is important to attention the result of MMP according to reservoir condition by mixing the CO2 that will be injected with another natural gas such as, methane, ethane and others. So, in this paper the writer try to calculate MMP by pure gas injection, and mixing the CO2 with various component such as methane, ethane, propane, sulfur (impure), and CO2 with flare gas by using Compositional simulator (Computer Modeling Group 2009).

Determination of Mmp

Determination of MMP has some methods, such as rising bubble technique, vanishing interfacial tension test and others. But, there are 4 primary methods that have been used in recent years to determine MMP for specific fluid displacement are: slim tube experiments, compositional simulation (Rathmell et al. 1971), mixing cell models and analytical methods.

Slimtube Experiments

Slimtube measurement is one of the standard experimental techniques that used for determining the Minimum Miscibility Pressure (MMP) of an oil and injection gas before initiation of Enhanced oil recovery (EOR) projects. Slimtube is a cylinder tube with a diameter of 0.25 in. with length ranging from 25 to 75 ft. The tube is initially saturated with the reservoir oil above is bubble point pressure. Then, the oil is then displaced by the gas injection from the tube at a fixed experimental pressure controlled by a back pressure regulator. Miscibility conditions are determined by conducting the experiment at a various pressures and recording the oil recovery. Then, MMP can be predicting with plotted curve oil recovery with pressure (Amao et al. 2012).

Mixing Cell Methods

The basic idea in this multiple mixing cell is to mix gas and oil in repeated contacts, resulting in new equilibrium compositions. This Mixing cell methods can give reliable MMP for either Condensing (enriched gas injection) or Vaporizing (lean gas injection). In case of the vaporizing drive, the intermediate component in oil is vaporized into the more mobile gas phase, and miscibility is developed when the equilibrium gas is repeatedly mixed with oil, causing the equilibrium gas composition to move toward the oil tie line. Thus, in vaporizing drive the tie line that extends through the oil control the development of miscibility. For condensing drive, the intermediate component gas is condensed into oil, and the gas tie line controls miscibility (Ahmadi and Johns 2008).

Analytical Methods

Analytical method (MOC) are based on methods of characteristic (Amao et al. 2012), or analytical method are based on the analytical solution of dispersion free 1D flow equation. MOC depend of finding the key tie lines. This key tie line are found such that key tie line when extended out of two phase region must intersect two neighboring key tie lines. As pressure is increase the key tie line are determined until one of them first intersects a critical point. MMP is the pressure at which the first key tie line become zero length (Ahmadi and Johns 2008).

Correlation

Correlations are often used to estimate MMP that the injected fluid is pure or impure. There are many correlations that can be used for calculate MMP such as Yellig and Metcalf, Helm and Josendal, Cronquist, and Glaso correlation. Glaso correlation for pure CO2 injection is more accurate (Yuan 2004).

In this paper, the writer use Glaso correlation with if percent mol C2–6 > 18% with equation,

And for C2–6 < 18%,

where T is reservoir temperature, \( {\text{M}}_{{{\text{C}}7 + }} \) is the molecular weight of \( {\text{C}}_{7 + } \).

The purpose of using correlation is to know the different MMP between simulator with glaso correlation. From Eq. (1), MMP value is 5869 psia, whereas with simulator is 5125 psia, so percent error from glaso correlation and simulator is 12.67%.

Result and Discussion

Compositional simulator is used to determine MMP. This determination is to know MMP with pure injection gas and combining. MMP is depending by temperature, oil composition, pure and impure gas injection. (Yellig and Metcalfe 1982; Alston et al. 1982; Sebastian et al. 1985) Where the oil composition (Al-Qasim et al. 2017) as the dependent variable, while the composition of gas injection and temperature as the independent variable.

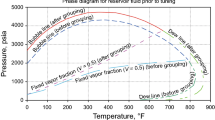

In Fig. 1 can be seen the MMP value influenced by temperature. MMP for CO2 increase with temperature and suggest that this occur, it take a higher pressure to achieve the same CO2 density at a higher temperature. (Karimale 2010) By doing injection 100% on each component (CO2, Methane, Ethane, H2S, and Propane). To see how the ability on each component and know the influenced from increasing temperature with minimum miscibility pressure. So the result is the increase in temperature will increase the MMP value. Sequentially the MMP value from greater till smaller are Methane, CO2, Ethane, H2S, and Propane.

C1 100% injection has a greater MMP value than CO2 100%. Because of, the density from methane is small so, requires the big pressure to dissolve methane in fluid. It maked C1 injection can improve the oil recovery, but CO2 injection is a very efficient to recovery method. (Holm 1982) While, component intermediate and H2S has a smaller MMP value. However, that gas injection can’t used 100% to reach target of MMP, because of being attention with reservoir condition and also about cost. To achieve the MMP value, the necessity of mixing the CO2 with another natural gas.

So, to know the influenced of pure and impure from CO2 is in Fig. 2. Where in the same of temperature with 80% CO2 + 20% non CO2 (C1, C2, C3) components. With CO2 100% as reference, the additions of 20% methane will increase 86% MMP, 20% ethane will decrease 13% MMP and for 20% propane will decrease 33% MMP.

From the result above, the effect of CO2 impurities component on the CO2 minimum miscible pressure at the same temperature, whereas C1 higher negative impact on the MMP, because the component increase the CO2 MMP. But H2S and intermediate component (C2 and C3) have positive impact on the MMP. It have been reported (Shokir and Eissa 2007).

Because H2S is a dangerous gas. So, In this research also show that the use of H2S can be replaced by using C2 with ratio 1:2 and Will be achieve the same of MMP at the same temperature (Fig. 3).

As a comparison materials, we also present flare gas data. With the purpose to compare the MMP flare gas with MMP CO2 100%. Can be seen in the graph below, CO2 100% has a lower MMP than MMP flare gas. Because of the flare gas composition contains more methane (Fig. 4).

Conclusions

The main conclusion from this research are as follow:

-

Temperature influence The MMP.

-

The effect of mixing the CO2 (impurities) with natural gas such as methane, ethane is helpful in achieving of MMP according to reservoir condition.

-

The influence of component methane will increase MMP, While Component intermediate will decrease MMP.

References

Ahmadi, K., and R.T. Johns. 2008. Multiple Mixing-Cell Method for MMP Calculations. Paper SPE 116823.

Al-Qasim, Abdulaziz, and Mudhish A. Al Dewsari. 2017. Comparison Study of Asphaltene Precipitation Models Using UTCOMP, CMG/GEM and Eclipse Simulator. Paper SPE 185370.

Alston, R.B., G.P. Kokolis, C.F. James. 1982. CO2 Minimum Miscibility Pressure a Correlation for Impure CO2 Stream and Live al System. SPEJ 268–274.

Amao, A.M., S. Siddiqui, and H.A. Menouar. 2012. New Look at the Minimum Miscibility Pressure (MMP) Determination from Slimtube Measurements. Paper SPE 153383.

Computer Modeling Group. 2009. Winprop.

Flanders, William A., Stanbary, Wallace A., and Martinez, Manuel. 1990. CO2 Injection Increases Hansford Marmaton Production. Journal Petroleum Technology 68–73.

Ghedan, S. 2009. Global Laboratory Experience of CO 2 —EOR Flooding. Paper SPE 125581.

Holm, L.W., and V.A. Josendal. 1982. Effect of Oil Composition on Miscible Type Displacement by Carbon Dioksida. JSPE 87–98.

Karimale, H., and O. Terseater. 2010. CO 2 and C 1 Gas Injection for Enhanced Oil Recovery in Fracture Reservoir. Paper SPE 139703.

Rathmell, J.J., F.I. Stalkup, and R.C. Hassinger. 1971. A Laboratory Investigation of Miscible Displacement by Carbon Dioxide. Paper SPE 3483.

Sebastian, H.M., R.S. Wanger, and T.A. Renner. 1985. Correlation of Minimum Miscibility Pressure for Impure CO2 Stream. JPT.

Shokir, El.-M., and M. Eissa. 2007. CO2-Oil Minimum Miscibility Pressure Model for Impure and Pure CO2 Stream. OMC.

Yellig, W.F., and R.S. Metcalfe. 1982. Determination and Prediction of CO2 Minimum Miscibility Pressure. Journal Petroleum Technology 87–98.

Yuan, H., R.T. Johns, and A.M. Egwuenu. 2004. Improved MMP Correlations for CO 2 Floods Using Analytical Gas Flooding Theory. Paper SPE 89359.

Acknowledgements

We would like to thank Department of Petroleum Engineering, Universitas Islam Riau and Dr. Eng. Muslim for the support in writing this paper.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Asmara, D., Sari, R.P. (2018). Minimum Miscible Pressure on the CO2 Impurities. In: Negash, B., et al. Selected Topics on Improved Oil Recovery. Springer, Singapore. https://doi.org/10.1007/978-981-10-8450-8_10

Download citation

DOI: https://doi.org/10.1007/978-981-10-8450-8_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-8449-2

Online ISBN: 978-981-10-8450-8

eBook Packages: EnergyEnergy (R0)