Abstract

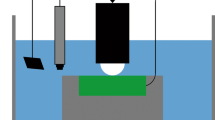

The study investigates the microstructure and electrochemical corrosion characteristics of 316L stainless steel joints brazed with BNi5. The experiment was carried out at 1150 °C and the holding time was 10 and 30 min respectively. The gap size was 30, 60 and 100 μm. The interface microstructures of the brazing joint were analyzed by Scanning Electron Microscopy (SEM) and the element composition was measured by Energy Dispersion Spectrum (EDS). The potentiodynamic polarization tests were conducted in the 3.5% NaCl solution using the CHI660E electrochemical workstation. The result shows that there are three zones in the brazing joint: Athermally Solidification Zone (ASZ), Isothermally Solidified Zone (ISZ) Diffusion Affected Zone (DAZ). A lot of Ni based solid solutions are formed in the ISZ and some intermetallics distribute in the solid solution layer parallel to the boundary. The ASZ is in the center of the gap, which contains eutectic structure and some brittle compounds. The Tafel curves reveal that the corrosion resistances of the brazing joints are poorer than base metal because the different phases in the joint form many micro batteries. With the decrease of gap size smaller or the increase of holding time, the corrosion resistance becomes better, because the longer holding time and smaller gap size are beneficial to the formation of Ni based solid solution with high corrosion potential.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Liu L, Ling X, Peng H (2013) Complex turbulent flow and heat transfer characteristics of tubes with internal longitudinal plate-rectangle fins in EGR cooler. Appl Therm Eng 54:145

Abd-Elhady MS, Zornek T, Malayeri MR (2011) Influence of gas velocity on particulate fouling of exhaust gas recirculation coolers. Int J Heat Mass Transf 54:838

Park SK, Lee JK, Kim HM (2014) Experimental study on the spiral and oval spiral EGR cooler efficiencies in a diesel engine. Heat Mass Transf 50:1783

Hong KS, Park JS, Lee KS (2011) Experimental evaluation of SOF effects on EGR cooler fouling under various flow conditions. Int J Automot Technol 12(6):813

Jang SH, Hwang SJ, Park SK et al (2012) Effects of PM fouling on the heat exchange effectiveness of wave fin type EGR cooler for diesel engine use. Heat Mass Transf 48:1081

Philips NR, Levi CG, Evans AG (2008) Mechanisms of microstructure evolution in an austenitic stainless steel bond generated using a quaternary braze alloy. Metall Mater Trans A 39:142

Lugscheider E, Humm S (2002) High-temperature brazing of superalloys and stainless steels with novel ductile Ni-Hf-based filler metals. Adv Eng Mater 4(3):138–142

Kangdao, Tsunoda T et al (2016) Microstructure and electrochemical corrosion behavior of fe-cr system alloys as substitutes for ni-based brazing filler metal. Acta Metall Sin (Engl Lett) 29(8):697–706

Shabani-Nooshabadi M, Ghoreishi SM, Jafari Y et al (2014) Electrodeposition of polyaniline-montmorrilonite nanocomposite coatings on 316L stainless steel for corrosion prevention. J Polym Res 21(4):416

Yuan XJ, Kang CY, Kim MB et al (2009) Microstructure and XRD analysis of brazing joint for duplex stainless steel using a Ni-Si-B filler metal. Mater Charact 60(9):923–931

Sun R, Zhu Y, Guo W et al (2018) Microstructural evolution and thermal stress relaxation of Al2O3/1Cr18Ni9Ti brazed joints with nickel foam. Vacuum 148:18–26

Yu XY, Xing WQ, Ding M (2016) Ultrasonic semi-solid coating soldering 6061 aluminum alloys with Sn-Pb-Zn alloys. Ultrason Sonochem 31:216–221

Zaharinie T, Yusof F, Hamdi M et al (2014) Effect of brazing temperature on the shear strength of Inconel 600 joint. Int J Adv Manuf Technol 73(5–8):1133–1140

Li G, Zhang P, Shi H et al (2018) Microstructure and properties of Cr18-Ni8 steel joints brazed with BNi7 + 3%Cu composite solder. Vacuum 148:303–311

Luo Y, Zhang Q, Jiang W et al (2017) The microstructure, mechanical properties and fracture behavior of hastelloy C276-BNi2 brazed joint. Mater Des 115:458–466

Zhishui Yu, Kun Shi, Zhi Yan (2011) Microstructural evolution during vacuum brazing of 316L stainless steel using nickel-based filler metal. Rare Metal Mater Eng 40(S2):342–346

Furong Chen, Jun Liu, Junhui Dong (2014) Microstructure and mechanical properties of vacuum brazed joints of 1cr18Ni9Ti stainless steel. Weld Join 6:18–21

Chen ZJ, Yang CJ, Gu XL et al (2012) Effect of brazing temperature and gap on microstructure and mechanical properties of 316L stainless steel brazed joints. Adv Mater Res 418–420(5):1242–1245

Chen YY, Hong UT, Shih HC et al (2005) Electrochemical kinetics of the high entropy alloys in aqueous environments—a comparison with type 304 stainless steel. Corros Sci 47(11):2679–2699

James JP, Fitzgerald JM, Scully JR (2008) Localized corrosion of a super-austenitic stainless steel (Fe-24Ni-20Cr-6.3Mo-0.22 N) brazed with Ni-based braze (Ni-22Cr-6.3Si-3.8P): effect of braze gap on corrosion resistance. Naunyn-Schmiedebergs Archiv für experimentelle Pathologie und Pharmakologie 226(3):278–300

Acknowledgments

The work was supported by the National Natural Science Foundation of China (51405297, 51575347 and 51805316) and the Shanghai Science and Technology Development Funds (18FY1424900).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Zhao, G. et al. (2019). Microstructure and Electrochemical Corrosion Properties of 316L Stainless Steel Joints Brazed with BNi5. In: Chen, S., Zhang, Y., Feng, Z. (eds) Transactions on Intelligent Welding Manufacturing. Transactions on Intelligent Welding Manufacturing. Springer, Singapore. https://doi.org/10.1007/978-981-13-8668-8_8

Download citation

DOI: https://doi.org/10.1007/978-981-13-8668-8_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-8667-1

Online ISBN: 978-981-13-8668-8

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)