Abstract

As the world oil reserves are draining day by day, new resources of carbon and hydrogen must be investigated to supply our energy and industrial needs. An extensive amount of biomass is accessible in many parts of the world and could be utilized either directly or as crude material for the production of different fuels. The motivation behind the present research is to find an appropriate strain for the fermentation of watermelon waste to get ethanol. Saccharification and fermentation (SSF) of watermelon waste were carried out simultaneously in the presence of A. niger and S. cerevisiae (toddy origin and baker’s yeast). Toddy originated S. cerevisiae culture is found to be more active than that of baker’s yeast. For the ethanol production, the optimized conditions for different parameters like temperature, time, strain and pH are finalized.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

14.1 Introduction

14.1.1 Watermelon Waste and Its Products

Food demand of growing population is fulfilled by the progression in agricultural production, but the same generates large amounts of waste known as “food chain supply wastes” [1]. Substantial amounts of food wastage happen in developed countries at the stage of consumption, whereas, in under developed countries, huge wastage of food is mainly produced in different stages of food supply chain [2]. Food waste, especially from perishable fruits and vegetables, is produced chiefly due to poor storage conditions and various post-harvest unit operations [3]. The usage of food waste to generate value-added products is in alignment with the contemporary notion—sustainable development that is targeted towards security of food, protection of environment as well as energy efficiency. About 15% of total fruit yield is wasted [4]. So the generated large quantities of food or fruit waste can be used to harvest energy and chemicals [5]. Another advantage is that it is renewable.

Watermelon (Citrullus vulgaris Schräd) belongs to Cucurbitaceae family and grows in tropical areas. It is cultivated in the south and central regions of India and stands in 26th position of its production [6]. In addition to the consumption of fresh fruit, watermelon is also used in the preparation of different food products like sauces, jellies, salads, juices and marmalades. It is considered as medicinal plant due to the pharmacological activities of compounds present in it [7] and its seeds [8]. Hence, the researchers are concentrating on the extraction of oil from seeds of watermelon [9]. As per the available recent literature, watermelon production in India is about 1.83 × 106 metric tonnes [10]. Its biomass contains three major components, viz. flesh (68% w/w), rind (30%) and seeds (2%) [11]. Watermelon waste is generated from fruit juice stalls, restaurants and food industries. Though a small quantity is used as animal feed, a large quantity of watermelon waste (> 90%) is disposed off causing environmental challenges.

A number of products were reported using watermelon waste. Jam was prepared from watermelon waste [12]. It is a source of nutraceuticals like lycopene, useful antioxidant carotenoid, and is useful for health of prostate [13]. Another available neutraceutical is L-citrulline, a precursor of L-arginine and also helpful in detoxifying the catabolic ammonia [14]. Oil and proteins were extracted from watermelon seeds [6]. Sugar was extracted from its rind [11]. Xylanase and polygalacturonase were produced by solid-state fermentation of watermelon rinds by Trichoderma species [15]. Cutin was prepared from watermelon peels by using Fusarium oxysporum MTCC 2480 [16], and similarly glucose was synthesized using far IR radiated energy [17]. Its shell was used as an adsorbent for the removal of heavy metals [18] and pesticides [19].

14.1.2 Alternatives to Fossil Fuels and Ethanol from Watermelon Waste

Rates of petroleum products are increasing regularly due to fast diminishing of their reserves. To meet the rising needs of chemical industries and automobiles, worldwide search is motivated for different alternatives [20]. Due to the presence of 35% oxygen in ethanol, it undergoes total combustion reaction with a diminished amount of emissions in contrast to the incomplete oxidation of fossil fuels associated with release of harmful gases. In India, the contribution of domestic crude oil towards country energy demand is 23% and the balance is met from imports [21]. A considerably reduced emission of greenhouse gases is possible by the usage of fuels blended with ethanol [22]. MNRE, India, is aimed at blending of 5% ethanol to the fuels to meet the demands [23]. Hence, a thrust on the field of fermented ethanol production is observed during recent decades.

Biorefinery concept suggests the usage of entire biomass of a biological product to generate a range of value-added products (like commodities, fuels and chemicals) by processing (physical, thermal, chemical or biological) leading to minimization or nil wastage [24]. Successful implementation of this concept is reported in a number of biological products including microalgae [25], lignocellulose [26] and sugarcane [27]. The concept of biorefinery was also extended to watermelon by converting its different components into value-added products including ethanol. In 1925 itself, Henry Ford described ethanol as “the fuel of the future”. He also indicated that “the fuel of the future is going to come from apples, weeds, sawdust—almost anything. There is fuel in every bit of vegetable matter that can be fermented” [28]. His visionary speculations came into true from the recent research outcomes in this area. In 2017, the total fuel ethanol produced worldwide is 17,500 million gallons and the contribution of India is 280 [29]. Even after the extraction of these nutraceuticals, the remaining watermelon waste consists of sugars (about 10% w/v), and the same can be fermented directly to ethanol. Watermelon juice was fermented to get the vinegar as the final product via ethanol production [30]. Bioethanol was produced by the fermentation of watermelon seeds with S. cerevisiae after removal of linoleic acid [31]. Zymomonas mobilis and Saccharomyces cerevisiae were used, respectively, for SSF of watermelon rind for effective ethanol production compared to the usage of single organism for both steps [32]. Ethanol production was reported as 5.86%. Native microorganisms were used for hydrolysis (Aspergillus fumigatus and Leuconostoc dextranicum) and fermentation (Z. mobilis) of watermelon waste to produce 27.62% higher amounts of ethanol [33].

14.1.3 Objective of the Present Work

Whole watermelon waste is chosen as the raw materials in the present work for the production of ethanol. Fermentation has been carried out by using S. cerevisiae of toddy and baker’s yeast origin in order to assess the best performer of these two strains. Aspergillus niger is used as a saccharifying agent so that a high concentration of ethanol can be produced. The effect of time, temperature, concentration of S. cerevisiae, concentration of A. niger and variation of pH were studied in the presence of both the strains.

14.2 Experimental

Analytical grade purity chemicals were used throughout the present research work. Aspergillus niger (MTCC 281) and baker’s yeast obtained from local market were used.

14.2.1 S. cerevisiae (Toddy Origin)

Toddy is produced profusely in India, and its availability is high. So, it is selected as an inexpensive source for the development of an appropriate yeast strain which can be used for ethanol fermentation. The Saccharomyces yeast was isolated from toddy using serial dilution technique in our laboratory. Isolated the S. cerevisiae strain from toddy using the malt extract medium. On the basis of the morphological and physiological properties, the strain was identified as S. cerevisiae [34]. Agar slants were prepared comprising agar-agar (2%), glucose (1%), malt extract (3%), beef extract (0.3%) and peptone (0.5%). The culture was maintained for five days at room temperature and then stored at 4 °C. To prepare the yeast inoculum, colonies of growing phase S. cerevisiae were taken from PDA slant which were having an age of one week and transferred to dextrose broth (10.0 ml) and then incubated for 24 h at 25 °C.

14.2.2 Aspergillus niger

About 200 g of peeled potato slices were taken and boiled for one hour in 500 ml of distilled water to obtain potato infusion. To this, 200 g of dextrose and 20 g of agar-agar were added and then made up to 1000 ml. Then, A. niger spores were dispersed in 100 ml sterile water, and it was added to PDA medium. This was maintained at 37 °C for 48 h in orbital shaking incubator. Hemocytometer and binocular microscope were used to count the spore number, and 9.55 × 107 per ml was the spore load.

14.2.3 Fermentation Inocula Preparation

It is prepared by using sucrose (10 g), potassium dihydrogen phosphate (0.5 g), MgSO4 (0.04 g), NH4SO4 (0.2 g) and beef extract (0.2 g). Medium pH was maintained at 4.25 using a solution of 1 N H2SO4. Later, it was retained in an autoclave for fifteen minutes at a pressure of fifteen psi. The obtained broth was brought to ambient temperature and then inoculated with S. cerevisiae colonies. Then, the culture was grown in orbital shaking incubator at 110 rpm.

14.2.4 Preparation of Fruit Extract

Fruit waste of watermelon was obtained from the local fruit market, Guntur city, India. After washing it a number of times using sterile water, the fruit waste was peeled. Both seeds and placenta from the sliced pulp were removed and afterwards stored at 4 °C inside a deep freezer. A sterile blender was used to convert the fruit waste into slurry. Cheesecloth was used to filter the slurry to obtain the fruit extract. Retained the extract in a sterile container. Measured 200 ml of extract and then sterilized it in conical flasks (250 ml). Then added a carbon supplement to each flask in the form of glucose (2% w/v). Loose plugging is done to the conical flasks using non-absorbent cotton wool as well as aluminium foil. The contents were sterilized for fifteen minutes at pressure of 1.0 kg/cm2 to achieve the sterilization and then cooled. Separate inoculation of medium was done using S. cerevisiae (1.1 × 105 cells/ml) and A. niger (4 × 105 spores/ml). Orbital shaker was shaked at 200 rpm to accomplish aeration. Appropriate temperature was maintained to incubate the inoculated flasks. Digital pH metre was used to measure the medium pH.

14.2.5 Estimation of Alcohol

Distillation column was used to distil the contents and heating was done slowly at 78 °C to collect the distillate. Spectrophotometry was used to determine the ethanol concentration. Fermentation was carried out in triplicates. The concentrations of ethanol were monitored using UV-Vis spectrophotometer, after the separation of the cells by centrifugation and by measuring absorbance at 600 nm after following the standard method of using potassium dichromate solution [35]. A calibration curve was used to determine ethanol concentration.

14.3 Results and Discussion

14.3.1 Fermentation of Watermelon Waste

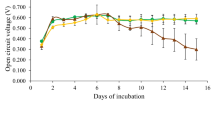

The effect of temperature as well as time on ethanol production from watermelon waste by using S. cerevisiae (toddy origin and baker’s yeast) was studied by adding S. cerevisiae (1.1 × 105 cells/ml) to a broth of 200 ml containing 40 g watermelon waste. Fermentation experiments were conducted up to 93 h under varying temperature in the range 25–40 °C to investigate the temperature effect on alcohol production from watermelon waste using S. cerevisiae strains (toddy origin and baker’s yeast). With an increase in time, the percentage of ethanol production also increased till 47 h and then there was no appreciable change in ethanol production. From 25 to 35 °C, the ethanol production increased, but a decrease in the ethanol production was observed with the increase in temperature to 40 °C. It shows that at 35 °C, the S. cerevisiae can sustain well with highest activity on watermelon fermentation. From Figs. 14.1 and 14.2, it is clear that the optimum time and temperature are 47 h and 35 °C for the production of ethanol from watermelon waste using S. cerevisiae of both origins (toddy and baker’s yeast). The comparison of the effect of S. cerevisiae of toddy origin and baker’s yeast on ethanol production using waste of watermelon was carried out at 17 h and 93 h fermentation. Both at the shorter (17 h) and longer times (93 h), S. cerevisiae (3.3 × 105 cells) of toddy origin is more active than that of baker’s yeast (Fig. 14.3).

The effect of the concentration of S. cerevisiae (toddy origin and baker’s yeast) on ethanol production from the waste of watermelon was carried out at 30 °C. In both instances, with an increase in the concentration of S. cerevisiae, the percentage of ethanol produced also increased till 3.3 × 105 cells and then no appreciable effect of concentration is observed (Fig. 14.4). Hence, the optimum concentration of S. cerevisiae is 3.3 × 105 cells/200 ml.

pH has a significant influence on alcoholic fermentation in controlling bacterial contamination, yeast growth and by-product formation. Therefore, the maintenance of pH is of paramount importance in fermentation process. In the present study, experiments were conducted at diverse pH conditions in the range of 1–10.5 to appraise the efficiency of the S. cerevisiae yeast strain. The temperature (30 °C), time period (44 h), amount of fruit waste (40 g/200 ml) and number of cells of S. cerevisiae (1.1 × 105) were kept constant throughout the experiments. The optimum pH is nearly neutral (i.e. pH 6.9) for cells of toddy origin, and it is 4.6 for cells of baker’s yeast (Fig. 14.5).

14.3.2 Simultaneous Saccharification and Fermentation of Watermelon Waste

In comparison to the traditional SHF (separate hydrolysis followed by fermentation), SSF has many advantages. Energy efficiency is one of them. Another one is poor substrate inhibition as the organism involved in fermentation is engaged in ready consumption of sugars released in hydrolysis process. These advantages were noticed and reported previously by other researchers for other substrates [36]. In view of the above advantages, simultaneous saccharification and fermentation of watermelon waste were carried out at 30 °C, where A. niger and S. cerevisiae (toddy origin and baker’s yeast, 3.3 × 105 cells) are saccharifying and fermenting organisms, respectively. With the addition of A. niger, the percentage of ethanol production increased compared to simple fermentation by S. cerevisiae. This improvement could be endorsed mainly to the accelerated hydrolysis of polysaccharides followed by the improved discharge of fermentable sugars [37]. With an increase in the concentration of A. niger, the percentage of ethanol production was also increased and the optimum concentration was found to be at 12 × 105 spores/200 ml broth (Fig. 14.6). Improvement in ethanol production in SSF (presence of A. niger spores) compared to simple fermentation (zero spores of A. niger) process is also visible.

Microorganisms’ morphology and growth are determined by various factors, and pH is important among them. It shows their sensitivity towards [H+] available in the medium. In the present study, the experiments were carried out at diverse pH conditions in the range of 1–10.5 in order to appraise the efficiency of the S. cerevisiae yeast strain (toddy and baker’s yeast origin) in the presence of A. niger. The temperature of 30 °C, time of 44 h and the amount of fruit waste of 40 gm/200 ml were kept constant throughout the experiments. The experimental results for the variation of pH on ethanol production are displayed in Fig. 14.7. The optimum pH is found to be nearly neutral (i.e. pH 6.9) and pH 4.6, respectively, for toddy and baker’s yeast origin. The previous studies reveal that slightly acidic and neutral pH conditions are suitable for optimal growth of fungi and bacteria, respectively. Fish et al. [38] reported maximum ethanol yield at pH 5 in the fermentation of watermelon juice. Synthesis, secretion and stability of α-amylase are influenced by pH [39]. Noteworthy α-amylase yields were reported in submerged fermentation by fungi, viz. A. oryzae, ficuum and A. niger in pH range of 5.0–6.0 [40,41,42]. S. cerevisiae and S. kluyveri produce maximum amount of α-amylase at pH = 5.0 [43, 44].

Two reasons are assigned to the reported higher yield of ethanol in the present study compared to the values of the literature. For example, 8.35% ethanol production was reported from hydrolysis by 1.5 M acid followed by the fermentation of watermelon peel [45]. Saccharification followed by the fermentation of watermelon rinds by Trichoderma viride and Saccharomyces cerevisiae produced 3.08 g L−1 ethanol [46].

The first probable reason is the consideration of whole watermelon waste as raw material instead of peel or rind or seeds as in the case of others. Whole watermelon waste as a raw material can be justified as follows. Approximately 20% of its annual yield is left behind in agricultural fields because of blemishes on their surface and misshapes as it is rejected in local fresh fruit market [38]. But most of them are internally healthy. Its juice has sugars, viz. glucose, fructose and sucrose (7–10% w/v in total) which can be directly fermentable to ethanol [38].

The second and third reasons are non-addition and addition of nitrogen source and of glucose (carbon source) to the fermentation medium. It can be substantiated as follows. In general, an adequate amount of nitrogen is required for the maximum growth of yeast and the production of ethanol, but it is not available in some of fermentable sources like molasses. In such cases, watermelon juice also acts as a nitrogen supplement due to the presence of amino acids in free form (15–35 μmol/ml) [38]. Hence, its juice was used as a feedstock, diluent to dilute the concentrated fermentable sugars like molasses and nitrogen supplement in the production of ethanol [38]. In addition, the minor effect of nitrogen source addition on ethanol production by the fermentation of watermelon waste was reported by Kim et al. [30]. However, ethanol yield was directly dependent upon the initial sugar level [47]. And also, 12% glucose was used for fortification of juice and 5.3% ethanol was obtained at pH 5.73 [30]. Hence, 2% w/v sugar was added to the fermentation medium in addition to the 7.1–11.3% of sugar in watermelon [48] but not any addition of nitrogen source.

14.4 Conclusion

SSF yields higher % of ethanol compared to simple fermentation. S. cerevisiae of toddy origin is more active than that of baker’s yeast. Both in presence and absence of A. niger, the optimum pH is nearly neutral (i.e. pH 6.9) and pH 4.6, respectively, for S. cerevisiae of toddy origin baker’s yeast. Three reasons are assigned to the reported higher yield of ethanol in the present study compared to the values of the literature. The first probable reason is the consideration of whole watermelon waste as raw material instead of peel or rind or seeds as in the case of others. The second and third reasons are non-addition and addition of nitrogen source and of glucose (carbon source) to the fermentation medium.

References

Matharu, A.S., de Melo, E.M., Houghton, J.A.: Opportunity for high value-added chemicals from food supply chain wastes. Bioresour. Technol. 215, 123–130 (2016). https://doi.org/10.1016/j.biortech.2016.03.039

Ong, K.L., Kaur, G., Pensupa, N., Uisan, K., Lin, C.S.: Trends in food waste valorization for the production of chemicals, materials and fuels: case study South and Southeast Asia. Bioresour. Technol. 248, 100–112 (2018). https://doi.org/10.1016/j.biortech.2017.06.076

Jha, S.N., Vishwakarma, R.K., Ahmad, T., Rai, A., Dixit, A.K.: Report on Assessment of Quantitative Harvest and Post-harvest Losses of Major Crops and Commodities in India. All India Coordinated Research Project on Post-Harvest Technology, ICAR-CIPHET (2015)

Mannepula, S., Bathal, V.K., Obulam, V.S.: A comparative study on utilisation of citrus and mango peels for lactic acid production and optimisation by Rhizopus oryzae in submerged fermentation. Eur. J. Biotechnol. Biosci. 3, 18–26 (2015)

Lin, C.S., Pfaltzgraff, L.A., Herrero-Davila, L., Mubofu, E.B., Abderrahim, S., Clark, J.H., Koutinas, A.A., Kopsahelis, N., Stamatelatou, K., Dickson, F., Thankappan, S.: Food waste as a valuable resource for the production of chemicals, materials and fuels. Current situation and global perspective. Energy Environ Sc. 6(2), 426–464 (2013)

Fakir, A.D., Waghmare, J.S.: Watermelon waste: a potential source of omega-6 fatty acid and proteins. Int. J. Chem. Tech. Res. 10(6), 384–392 (2017)

Simpson, R., Morris, G.A.: The anti-diabetic potential of polysaccharides extracted from members of the cucurbit family: a review. Bioact. Carbohydr. Dietary Fibre 3(2), 106–114 (2014)

Rahman, H., Manjula, K., Anoosha, T., Nagaveni, K., Eswaraiah, C.M., Bardalai, D.: In-vitro antioxidant activity of Citrullus lanatus seed extracts. Asian J. Pharm. Clin. Res. 6(3), 152–157 (2013)

Colivet, J., Oliveira, A.L., Carvalho, R.A.: Influence of the bed height on the kinetics of watermelon seed oil extraction with pressurized ethanol. Sep. Purif. Technol. 169, 187–195 (2016). https://doi.org/10.1016/j.seppur.2016.06.020

Directorate of Economics and Statistics: Agricultural Statistics at a Glance 2014, p. 206. Oxford University Press, New Delhi (2014)

Kumar, C., Mythily, R., Chandraju, S.: Studies on sugars extracted from water melon (Citrullus lanatus) rind, a remedy for related waste and its management. Int. J. Chem. Anal. Sci. 3(8), 1527–1529 (2012)

Souad, A.M., Jamal, P., Olorunnisola, K.S.: Effective jam preparations from watermelon waste. Int. Food Res. J. 19(4), 1545–1549 (2012)

Fang, Y.Z., Yang, S., Wu, G.: Free radicals, antioxidants, and nutrition. Nutrition 18(10), 872–879 (2002). https://doi.org/10.1016/S0899-9007(02)00916-4

Marletta, M.A.: Nitric oxide: biosynthesis and biological significance. Trends Biochem. Sci. 14(12), 488–492 (1989). https://doi.org/10.1016/0968-0004(89)90181-3

Mohamed, S.A., Al-Malki, A.L., Khan, J.A., Kabli, S.A., Al-Garni, S.M.: Solid state production of polygalacturonase and xylanase by Trichoderma species using cantaloupe and watermelon rinds. J. Microbiol. 51(5), 605–611 (2013). https://doi.org/10.1007/s12275-013-3016-x

Chaudhari, S.A., Singhal, R.S.: Cutin from watermelon peels: a novel inducer for cutinase production and its physicochemical characterization. Int. J. Biol. Macromol. 79, 398–404 (2015). https://doi.org/10.1016/j.ijbiomac.2015.05.006

Chatterjee, S., Barman, S., Chakraborty, R.: Far infrared radiated energy-proficient rapid one-pot green hydrolysis of waste watermelon peel: optimization and heterogeneous kinetics of glucose synthesis. RSC Adv. 6(78), 74278–74287 (2016). https://doi.org/10.1039/C6RA13391

Banerjee, K., Ramesh, S.T., Gandhimathi, R., Nidheesh, P.V., Bharathi, K.S.: A novel agricultural waste adsorbent, watermelon shell for the removal of copper from aqueous solutions. Iran J. Energy Environ. 3(2), 143–156 (2012). https://doi.org/10.5829/idosi.ijee.2012.03.02.0396

Memon, G.Z., Bhanger, M.I., Akhtar, M., Talpur, F.N., Memon, J.R.: Adsorption of methyl parathion pesticide from water using watermelon peels as a low cost adsorbent. Chem. Eng. J. 138(1–3), 616–621 (2008). https://doi.org/10.1016/j.cej.2007.09.027

Lee, S.J., Shin, J.S, Park, K.W., Hong, Y.P.: Detection of genetic diversity using RAPD-PCR and sugar analysis in watermelon [Citrullus lanantus (Thunb.) Mansf.] germplasm. Theor. Appl. Genet. 92(6), 719–725. https://doi.org/10.1007/bf00226094

Ministry of New and Renewable Energy: Annual report. New Delhi. http://mnre.gov.in/mission-and-vision-2/publications/annual-report-2/ (2016). Accessed on 15 Mar 2017

Wang, M.C., Saricks, D.S.: Effects on Fuel Ethanol Use on Fuel-Cycle Energy and Green House Gas Emissions. Agronne National Laboratory, Agrone, IL (1999)

Ministry of New and renewable Energy: National Policy on Biofuels. http://mnre.gov.in/file-manager/UserFiles/biofuel_policy.pdf (2013). Accessed on 15 Mar 2017

Kamm, B., Kamm, M.: Principles of biorefineries. Appl. Microbiol. Biotechnol. 64(2), 137–145 (2004). https://doi.org/10.1007/s00253-003-1537-7

Postma, P.R., Barbosa, M.J., Wijffels, R.H., Eppink, M.H., Olivieri, G.: Microalgal biorefinery for bulk and high-value products. In: Handbook of Electroporation, vol 3, pp. 2205–2224. Springer International Publishing (2017)

Shinde, S.D., Meng, X., Kumar, R., Ragauskas, A.J.: Recent advances in understanding the pseudo-lignin formation in a lignocellulosic biorefinery. Green Chem. 20(10), 2192–2205 (2018). https://doi.org/10.1039/C8GC00353J

Oliveira, C.M., Pavao, L.V., Ravagnani, M.A., Cruz, A.J., Costa, C.B.: Process integration of a multiperiod sugarcane biorefinery. Appl. Energy 213, 520–539 (2018). https://doi.org/10.1016/j.apenergy.2017.11.020

Agarwal, A.K., Agarwal, R.A., Gupta, T., Gurjar, B.R. (eds.): Biofuels: Technology, Challenges and Prospects. Springer (2017)

Fuel ethanol production worldwide in 2017, by country (in million gallons). https://www.statista.com/statistics/281606/ethanol-production-in-selected-countries/

Kim, S.L., Kim, W.J., Lee, S.Y., Byun, S.M.: Alcohol fermentation of Korean watermelon juice. Appl. Biol. Chem. 27(3), 139–145 (1984)

Song, B.Y.: Inventor method for production of bio-ethanol using watermelon seeds. United States patent US 8,642,300

Alex, S., Saira, A., Nair, D.S., Soni, K.B., Sreekantan, L., Rajmohan, K., Reghunath, B.R.: Bioethanol production from watermelon rind by fermentation using Saccharomyces cerevisiae and Zymomonas mobilis. Indian J. Biotechnol. 16, 663–666 (2017)

Darwin, R.O., Alexandra, A., Elena, M., Manjunatha, B., Bryan, R.B., Subbareddy, G.V., Maddela, N.R., Rajeswari, B.: Comparative study of native microorganisms isolated from watermelon (Citrullus lanatus) waste and commercial microorganism (Clostridium thermocellum) used for bioethanol production. Afr. J. Biotechnol. 16(9), 380–387 (2017). https://doi.org/10.5897/AJB2016.15643

Barnett, J.A., Payne, R.W., Yarrow, D.: Yeasts: Characteristics and Identification. Cambridge University Press (1983)

Caputi, A., Ueda, M., Brown, T.: Spectrophotometric determination of ethanol in wine. Am. J. Enol. Vitic. 19(3), 160–165 (1968)

Svetlana, N., Ljiljana, M., Marica, R., Dusanka, P., Savic, D.: A microwave-assisted liquefaction as a pretreatment for the bioethanol production by the simultaneous saccharification and fermentation of corn meal. Chem. Ind. ChemnEng. Q. 14(4), 231–234 (2008)

Kunlan, L., Lixin, X., Jun, L., Jun, P., Guoyoing, C., Zuwei, X.: Salt-assisted acid hydrolysis of starch to d-glucose under microwave irradiation. Carbohydr. Res. 331, 9–12 (2001). https://doi.org/10.1016/S0008-6215(00)00311-6

Fish, W.W., Bruton, B.D., Russo, V.M.: Watermelon juice: a promising feedstock supplement, diluent, and nitrogen supplement for ethanol biofuel production. Biotechnol. Biofuel. 2(1), 18 (2009). https://doi.org/10.1186/1754-6834-2-18

Fogarty, M.W.: Microbial amylases. In: Fogarty, W.M. (ed.) Microbial Enzymes and Biotechnology, pp. 1–92. Applied Science Publishers Ltd., London, UK (1983)

Hayashida, S., Teramoto, Y.: Production and characteristics of raw-starch-digesting a-amylase from a protease negative Aspergillus ficuum mutant. Appl. Environ. Microbiol. 52, 1068–1073 (1986)

Carlsen, M., Nielsen, J., Nielsen, J.: Growth and a-amylase production by Aspergillus oryzae during continuous cultivations. J. Biotechnol. 45, 81–93 (1996). https://doi.org/10.1016/0168-1656(95)00147-6

Djekrif-Dakhmouche, S., Gheribi-Aoulmi, Z., Meraihi, Z., Bennamoun, L.: Application of a statistical design to the optimization of culture medium for a-amylase production by Aspergillus niger ATCC 16404 grown on orange waste powder. J. Food Eng. 73, 190–197 (2005). https://doi.org/10.1016/j.jfoodeng.2005.01.021

Moller, K., Sharif, M.Z., Olsson, L.: Production of fungal a-amylase by Saccharomyces kluyveri in glucose-limited cultivations. J. Biotechnol. 111, 311–318 (2004). https://doi.org/10.1016/j.jbiotec.2004.04.013

Knox, A.M., du Preez, J.C., Kilian, S.G.: Starch fermentation characteristics of Saccharomyces cerevisiae strains transformed with amylase genes from Lipomyces kononenkoae and Saccharomyces fibuligera. Enzym. Microb. Technol. 34, 453–460 (2004). https://doi.org/10.1016/j.enzmictec.2003.12.010

Ezejiofor, T.I., Enenebeaku, U.E., Enenebeaku, C.K., Nwankwo, M.U., Ogbonnaya, C.I.: Comparative study of bioethanol yield from yam, potato, watermelon, and pineapple peels using different concentrations of hydrochloric acid. World News Nat. Sci. 16, 18–32 (2018)

Bhandari, S.V., Panchapakesan, A., Shankar, N., Kumar, H.A.: Production of bioethanol from fruit rinds by saccharification and fermentation. Int. J. Sci. Res. Eng. Technol. 2(6), 362–365 (2013)

Sandhu, H., Bajaj, K.L., Arneja, J.S.: Cellulolytic saccharification of rice straw and ethanol production. Indian J. Agric. Biochem. 10(1&2), 19–22 (1997)

Lee, J.M., Pollard, J.F., Coulman, G.A.: Ethanol fermentation with cell recycling: computer simulation. Biotechnol. Bioeng. 22, 497 (1983). https://doi.org/10.1002/bit.260250215

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ratnakaram, V.N., Prakasa Rao, C.G., Sree, S. (2020). Simultaneous Saccharification and Fermentation of Watermelon Waste for Ethanol Production. In: Subramanian, B., Chen, SS., Reddy, K. (eds) Emerging Technologies for Agriculture and Environment. Lecture Notes on Multidisciplinary Industrial Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-7968-0_14

Download citation

DOI: https://doi.org/10.1007/978-981-13-7968-0_14

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-7967-3

Online ISBN: 978-981-13-7968-0

eBook Packages: EngineeringEngineering (R0)