Abstract

This chapter aims to increase awareness related to the assessment of embodied greenhouse gas emissions (GHGE) of the built environment in Australia—a critical step to achieve meaningful emissions reduction. A summary of existing methods, data, tools, guidance and gaps in quantifying embodied GHGE in the Australian built environment is provided. A quick evaluation of embodied GHGE is an important aid for the design decision-making process within the architecture, engineering and construction industries. The newly developed Embodied Carbon Explorer (ECE) online tool is introduced to rapidly assess embodied GHGE for built environment projects with National Carbon Offset Standard-performance objectives. A case study using the ECE tool is described that quantifies the total carbon footprint of Australia’s construction industry and identifies the main contributors of embodied GHGE.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Introduction

The built environment has adverse environmental impacts that are attributable to its use of natural resources, fossil fuel energy consumption and greenhouse gas emissions (GHGE). Buildings account for nearly 40% of annual global energy use and approximately 30% of the GHGE emitted throughout all stages in their life cycle (i.e. cradle-to-grave ), contributing significantly to climate change (IPCC 2014; UNEP 2009).

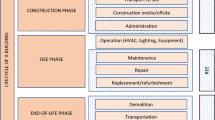

Most carbon reduction regulations place more emphasis on decreasing operational energy and their associated emissions, and fail to take a more holistic approach. Whilst operational energy impacts are generally bigger than embodied impacts over the life cycle, their relative proportions are affected by many factors, such as climate, geographic location, and sources of fuel (Dixit et al. 2012; Hegner 2007). A review by Ibn-Mohammed et al. (2013) and IEA (2016) showed that embodied impacts (energy or emissions ) of buildings and infrastructure in different countries can vary from 2 to 80%. Miller and Doh (2015) for example, identified that the total life cycle energy of a typical concrete building generally comprises 80% operational energy and 20% embodied energy . However, the ratio of operational emissions in total building life cycle emissions has decreased due to recent improvements in building design and energy efficiency (Dixit et al. 2010, 2012). As a result, this increases the comparative significance of embodied GHGE, which includes emissions from extraction of natural resources, manufacture of building materials , transportation to site, construction, renovation, demolition and disposal of the building (Ibn-Mohammed et al. 2013; Langston & Langston 2008). The current trend towards ‘net zero carbon buildings’ focuses on significantly reducing operational energy impacts , which will further increase the proportion of embodied impacts in the life cycle (IEA 2016; Lützkendorf et al. 2015). Therefore, the growing importance of embodied emissions when assessing the total carbon footprint of the built environment should be duly recognised. However, embodied GHGE are still rarely assessed in many countries, including Australia .

This chapter provides a summary of current life cycle inventory (LCI) methods and Australian LCI databases , tools and guidance that support the analysis of embodied GHGE related to the built environment . The gaps in extant methodologies, databases and tools applied to assessing embodied GHGE are identified. The newly developed Embodied Carbon Explorer (ECE) online tool is introduced to provide a quick evaluation of embodied GHGE for built environment projects. The ECE tool is used to provide the most recent carbon footprint (year 2015) for Australia’s construction industry and identify the main contributors of embodied GHGE.

Data, Tools and Methods for Assessing Embodied Greenhouse Gas Emissions

This section describes the main data, tools and methods available for assessing embodied GHGE of construction projects. Three broad approaches for quantifying embodied GHGE are available. These are known as process analysis , environmentally extended input–output analysis and hybrid analysis . The distinctive difference between these approaches lies in the data used and the scope of analysis. Each of these approaches involves modelling a system, based on either specific production processes or entire economic systems.

Process Analysis

Process analysis is a bottom-up approach where a product system (such as a building) is broken down into a series of processes linked to the manufacture and supply of material products used in the construction of the built environment . Process analysis uses data specific to the product under study, enabling the highest possible level of accuracy. This data is typically sourced from the organisations responsible for particular processes, such as miners of raw materials or manufacturers of building materials . GHGE data is obtained for each process and then summed to determine the total embodied GHGE for the product.

While the representativeness of this data for particular products and processes is typically very high, process analysis suffers from systemic incompleteness as it is impossible to exhaustively assess the supply chain of any given product, mainly due to cost and time constraints (Crawford 2008; Lenzen 2000; Suh et al. 2004). Data gaps are most common for higher order or upstream processes (such as the extraction of a particular raw material at the very start of the supply chain , e.g. mining of bauxite); intermediate processes (for instance the manufacturing processes occurring between the production of a material —such as aluminium—and the final product—a window frame); and non-material processes such as the provision of services, or physical inputs considered small enough to be excluded (Crawford 2011).

Databases of process data can be used to streamline a process analysis . The Australian Life Cycle Inventory Database (www.auslci.com.au) or AusLCI, includes data on building and packaging materials , energy and transport as well as data on agriculture , fuels, food, raw materials and waste management . It covers a broad range of resource inputs and outputs for each of the products covered, including emissions of various GHG. In addition, the Building Products Innovation Council (BPIC) has established the Building Products Life Cycle Inventory (BP LCI) (www.bpic.asn.au), a database of physical process data for over 100 different building materials and products, including concrete, concrete blocks, concrete and terracotta roof tiles, bricks, gypsum board, steel, timber and timber products, windows, glass and insulation materials. For each material , data on inputs such as fuels, raw materials , water as well as emissions of waste and pollutants are provided.

Environmentally Extended Input–Output Analysis

Environmentally extended input–output analysis (EEIOA) is a top-down approach that uses input–output (IO) tables containing information on monetary transactions between sectors of an economy, combined with national environmental accounts (e.g. Department of the Environment and Energy 2018). The resulting environmentally extended IO (EEIO) data provides information on the embodied environmental flows per monetary value of output from a particular sector (e.g. tonnes of GHGE per dollar value of construction). With a product’s cost information, an estimate of its embodied GHGE can then be calculated. As this data is based on an economy-wide system boundary, it is considered to be systemically complete. IO tables are usually produced on an annual basis with the latest tables covering 114 industry groups (ABS 2018), including four main construction sectors —Residential Building Construction, Non-Residential Building Construction, Heavy and Civil Engineering Construction, and Construction Services.

EEIOA assumes that a dollar spent on two different products from the same sector results in the same GHGE. This means that it can be difficult to assess specific products and differentiate between practices that take place within the same sector (Lenzen 2000; Treloar 1997). Because of this, EEIOA in its pure form is most useful for assessing entire economies or industries, particularly as an initial scoping tool to help identify the areas with the greatest potential for reducing GHGE.

EEIO data for Australia has been made available within a number of databases , including Eora and The Australian Industrial Ecology Virtual Laboratory (IELab) (https://ielab-aus.info). IELab is a collaborative cloud-based platform for compiling large-scale, high-resolution, economic, social and environmental accounts based on IO tables. The IELab uses a spatial classification based on the Australian Statistical Geography Standard (ASGS) which includes a Statistical Area Level 2 (SA2) subdivision of Australia into 2196 geographical entities (ABS 2010), each containing an average population of 10,000 persons. The Input–Output Product Categories (IOPC) sectoral classification is used, which distinguishes 1284 product groups (ABS 2012). Theoretically, this means that it can be applied to model embodied GHGE for any sector/product group or subnational region.

Global IO databases , including IDE-JETRO, EXIOBASE, GLIO, GTAP, OECD, WIOD and Eora (see Murray & Lenzen 2013 for details), can also be used to model the embodied GHGE of products or regions outside of Australia . This enables inclusion of GHGE resulting from products traded between geographic regions. Such an application is important as GHGE are very rarely confined within the boundaries of a single region.

Hybrid Analysis

In an attempt to address the limitations of both process analysis and EEIOA, hybrid analysis was developed, combining process and input–output data . Four main hybrid approaches exist, namely Tiered, Path Exchange, Matrix Augmentation and Integrated. These different hybrid approaches are described in detail by Crawford et al. (2018). Each one represents a slightly different approach for filling data gaps in a process analysis (Fig. 7.1).

(Source Crawford et al. 2018 with permission)

Hybrid analysis approaches for quantifying embodied greenhouse gas emissions

A hybrid analysis tends to accentuate the complexity of quantifying embodied GHGE because of the need to work with and combine two distinctively different data types. However, the benefits have shown it to be worth the effort as process analyses that rely on a more limited system boundary may significantly underestimate embodied environmental flows . For example, a hybrid embodied energy analysis of a range of different building types showed that on average 64% of energy inputs would be excluded if a process analysis were used (Crawford 2008).

To alleviate some of the complexity in quantifying embodied GHGE, databases of precompiled embodied GHGE coefficients for products and processes can be used. Coefficients (typically in kg CO2e per unit of product) are multiplied by specific product quantities (e.g. tonnes of steel) to determine total embodied GHGE of a product. A number of coefficient databases exist (Table 7.1), compiled for different geographic regions and using the three different analysis approaches. These most commonly include embodied energy coefficients, which can easily be converted to GHGE using emissions intensity values for different energy types. The values for identical products can vary substantially between databases , due to factors such as region-specific fuel mix and emissions intensity , analysis approach, data source, and process/system boundary coverage. For this reason, when selecting coefficients to use, consideration must be given to using those which are most representative of the product under study, while also striving to maximise supply chain coverage. This helps ensure that analysis results reflect the actual embodied GHGE of a product as closely as possible. The most comprehensive database of embodied GHGE coefficients of construction materials for Australia is that produced by Crawford (2018). This database covers 95 materials and a range of environmental flows , compiled using a hybrid analysis . Developed by the Cooperative Research Centre for Low Carbon Living (CRCLCL ), the Integrated Carbon Metrics (ICM) database on embodied GHGE provides coefficients that are specific to Australian construction and building materials .

The next section describes how the Australian construction industry is currently addressing embodied GHGE.

Current Industry Practice in Reducing Embodied GHGE of Australia’s Buildings

Even though Australia is at the forefront of embodied GHGE research , the consideration of embodied GHGE in practice has been slow. A recent survey of the Australian construction industry conducted by Fouché and Crawford (2015), found that over 85% of construction industry consultants providing environmentally related advice tended to focus on providing operational GHGE assessment services. In total, 60% of the survey respondents, consisting predominately of life cycle assessment (LCA) practitioners and sustainability consultants, provided some form of embodied GHGE assessment. For the organisations that did not provide this service, almost 70% said that they would consider providing it as part of their services in the future . This demonstrates that there is an increasing awareness of the need to address these emissions. When asked what software tools are used for embodied GHGE assessment, SimaPro (simapro.com) was the most popular tool used, followed by eToolLCD (etoolglobal.com), a building-specific LCA tool developed in Australia . There was a preference for locally developed tools, but also a need to address the weaknesses in existing data and tools available for embodied GHGE assessment. These weaknesses include a lack of Australian-specific data, inconsistent methodologies, time-intensive assessments, a need for expert knowledge, and a lack of benchmarks and compatibility with building information modelling (BIM). When asked to indicate the top features desired in new or improved tools, over 80% indicated ‘material cost’ as the most beneficial feature followed by data on recycled materials (62%) and the source of materials (57%). Other recommendations included adherence to Australian regulations and standards , options for quick analysis, integration with existing tools, ease of updating and more transparency and consistency. These tend to coincide with the key barriers affecting the uptake of embodied GHGE assessment within the construction industry , as highlighted in a report published by ASBP (2014). This placed consistency of method at the top of the list followed by availability of comparable data, and mandatory legislation. The inconsistency and poor availability of comprehensive embodied GHGE data are often quoted as key barriers affecting the uptake of both embodied GHGE and LCA (Ariyaratne & Moncaster 2014; Dixit et al. 2015; Schinabeck et al. 2016). The study by Fouché and Crawford (2015) identified several other critical barriers such as a lack of project budget , client disinterest and no clear financial incentive. The effect of budgetary constraints on the uptake of embodied GHGE considerations was also identified by Ariyaratne and Moncaster (2014) and Wu et al. (2016). These studies found that the cost of embodied GHGE reduction is not well understood and more research is required to further understand the financial implications of embodied and life cycle GHGE reduction .

In an attempt to address this, Schmidt and Crawford (2018) developed a framework for comparing the financial and environmental performance of GHGE reduction strategies for buildings. This can be used to assess the life cycle emissions and costs associated with a particular design strategy and inform the design decision-making process in balancing the GHGE reduction and financial goals of a project. For example, the life cycle GHGE and cost of different insulation options for a project can be compared. An appropriate solution can then be selected, prioritising any that lead to the lowest life cycle GHGE and cost , followed by those that reduce GHGE but come at a cost premium. This decision will ultimately be made in relation to a client’s ‘willingness-to-pay’ for a certain degree of GHGE reduction and in the context of other project constraints and priorities.

National Standards and Guidance on Embodied GHGE

Full life cycle assessment that includes both operational and embodied impacts has been regulated in countries including The Netherlands and Germany (Giesekam et al. 2015). However, legislation to measure and reduce embodied GHGE of buildings are not yet in place in most countries including Australia (Birgisdottir et al. 2017). This is due to long-standing limitations such as data, methodological issues, system boundary, uncertainties and lack of consistent framework in the analysis of embodied GHGE (Ibn-Mohammed et al. 2013; Patchell 2018).

In Australia, companies and organisations are required to report Scope 1 (operational ) and 2 (electricity) emissions under the National Greenhouse and Energy Reporting (NGER) scheme while Scope 3 (all other indirect/embodied emissions ) is not mandatory.

For the built environment in Australia , the building certification schemes which address embodied GHGE are currently voluntary. The Federal Department of the Environment recently released a voluntary National Carbon Offset Standard (NCOS ) which provides guidelines for carbon neutral buildings and precincts (Commonwealth of Australia 2017a, 2017b). This is done by (i) preparing a carbon account for Scopes 1–3, (ii) reducing emissions where possible, (iii) offsetting emissions that cannot be reduced or avoided, (iv) preparing a public report on carbon neutrality , and (v) arranging for an audit of the carbon account and public report. Scope 3 emissions deemed to be relevant that are listed in the NCOS are from electricity consumption , fuel use, waste, water supply, wastewater treatment , transport and all other emissions identified (which are assessed for relevance according to a relevance test). However, it is encouraged to include as many emission contributors as possible, and any Scope 3 emissions of more than 1% of the total account is considered to be material and should be reported.

To date, there are no tools in the market directly targeting assessments under the NCOS for Buildings and Precincts, although certifications can be sought through National Australian Built Environment Rating System (NABERS) and Green Building Council of Australia (GBCA) for building operations. Accounting for the multitude of contributions from supply chains is usually a complicated and a time-intensive task using a bottom-up approach. Alternatively, a top-down approach can quantify Scope 3 emissions more easily and expeditiously by using Australia-specific input–output data, making it a more efficient technique. Furthermore, methods and tools based on input–output analysis are referenced in the NCOS to measure Scope 3 materiality thresholds (Commonwealth of Australia 2017a, p. 13).

Based on the top-down approach, the Embodied Carbon Explorer (ECE) online tool was developed by the CRCLCL, specifically to enable a swift evaluation of embodied (Scope 3) GHGE for a project at any level (e.g. precinct, building, organisation, material , etc.). It is well suited for a quick screening assessment before full, detailed assessments are undertaken. The ECE tool (i) quantifies the total impacts related to project life (based on expenditure data), (ii) identifies main contributors to total impacts, and (iii) provides NCOS-suitable functionality. Any contributor (e.g. product or service) can be tested for its Scope 3 emissions in accordance with the NCOS materiality threshold, and those playing a relevant role can be selected for reporting purposes.

The ECE tool supports the realisation of the NCOS and has the theoretical potential to assess carbon neutrality for all new building and precinct developments and refurbishments.

Embodied Carbon Explorer Tool Case Study

Tracking Emissions in Australia’s Built Environment

For this case study , the carbon footprint of the Australian construction sector is assessed for the year 2015 using the ECE tool . The aim of this case study is to provide the most up-to-date total carbon footprint (Scopes 1–3 emissions ) of Australia’s construction sector , to identify the main contributing industries and products, to provide NCOS-aligned carbon footprint results, as well as to provide a national average benchmark for other projects and buildings for the ECE tool . This study will assess the initial embodied emissions of the construction sector encompassing the cradle-to-site system boundary (Fig. 7.2). Identification of the key contributing industries and products will enable emission mitigation strategies as an important part of the solution to achieve carbon neutrality .

Method and Data

The ECE Tool is based on EEIOA, which couples input–output tables with environmental information (e.g. GHGE) to provide an analysis of embodied environmental flows per unit dollar of a sector’s output. This data is systematically complete as it is based on a system boundary encapsulating the entire economy. The ECE online tool is hosted on the IELab research platform (https://ece.ielab-aus.info).

The ECE tool uses three main data sources. Firstly, IO data is sourced from the IELab (Lenzen et al. 2014), which provides the most detailed Australian IO data with a granularity of up to 1284 sectors. The ECE tool consists of the latest IO data from the year 2014–2015, which are categorised into 334 economic sectors in the form of a national Supply-and-Use Table (SUT).

Secondly, rest-of-the-world (RoW) data is derived from the Eora multiregional input–output database (Lenzen et al. 2013) to account for trades of goods and services between countries. RoW data of all other countries are aggregated into a simplified 26-sector table, and then attached to the 344-sector Australian SUT to construct a two-region, globally closed model of Australia and the RoW for 2015 (see also supplementary information in Wiedmann et al. 2016). Thirdly, GHGE data for 2015 are obtained from the Australian Greenhouse Emissions Information System (AGEIS).

Carbon footprint from the production of goods and services as well as imports are allocated to the intermediate demand of industries. Carbon footprints are calculated by multiplying the amount of GHGE embodied in each dollar of demand of the products from the construction industry with the construction industry’s expenditure data. This facilitates an assessment of the most significant contributors of embodied GHGE in a particular industry.

Results

This case study considers carbon footprint as embodied GHGE in the intermediate demand products of the construction sector (i.e. buildings and infrastructure). Embodied GHGE can be either emissions within Australia or embodied in construction products and services that are imported into Australia as necessitated by local intermediate demand. The 344 sectors are aggregated into Scope 3 categories provided in NCOS (i.e. Stationary energy, Water, wastewater and waste, and Transport) as well as additional emissions categories (i.e. Agriculture , Forestry and fishing, Mining and quarrying, Food, Consumer goods, Industrial products, Machinery and equipment, Construction and Services).

National Average Benchmark of the Construction Sector in 2015

The construction sector is responsible for 9.7 Mt carbon dioxide equivalent (CO2e) of direct emissions (Scope 1 emissions) and 55.9 Mt CO2e of carbon footprint (Scope 2 and 3 emissions). The construction sector comprised eight sectors (from the 334 sectors), namely Residential building repair and maintenance, Residential building construction, Non-residential building construction, Non-residential building repair and maintenance, Prefabricated buildings, Roads and bridges, Non-building construction and Non-building repair. Within the construction sector , the largest carbon footprint stems from Residential building construction 20.2 Mt CO2e (36%), Non-residential building construction 16 Mt CO2e (29%), Other heavy and civil engineering construction (labelled as non-building construction in the ECE tool ) 9.8 Mt CO2e (18%), and Roads and bridges 5.2 Mt CO2e (9%). The increase in construction activity of residential and non-residential buildings is linked to population growth and increasing demand, whilst heavy and civil engineering works have declined since the peak of the mining boom (Ai Group 2015).

The total impacts of all upstream supply chains to produce the total demand for the main construction sub-sectors are shown in Fig. 7.3. These can be referenced as a national average benchmark against which to compare the environmental performance of a project or building being analysed using the ECE tool . For example, an assessment of an office building can be benchmarked against the Non-residential building construction sector in Fig. 7.3. The comparison can be made on a level playing field by normalising the impacts by the total economic output of the sector (i.e. total impacts per dollar of output).

Carbon Footprint Breakdown of the Construction Sector in 2015

The total carbon footprint of Australia’s construction sector is the total of Scopes 1, 2 and 3 emissions. Scope 1 emissions (9.67 Mt CO2e) and Scope 2 emissions (4.82 Mt CO2e) constitute only 22%, whilst Scope 3 emissions (51.03 Mt CO2e) make up the most substantial proportion (78%) of total emissions. Scope 1 emissions are direct GHGE stemming from the construction industry , such as onsite energy generation , and petrol and gas used for transport. Scope 2 emissions refer to embodied emissions from electricity supply , which depends heavily on fossil fuels at present. Scope 3 emissions include all embodied GHGE from the large upstream supply chains .

The main contributors to the Scope 3 emissions of the Australian construction sector (51.03 Mt CO2e) are identified as Services (32%), Industrial products (28%) and Machinery and equipment (4%) (Fig. 7.4).

A further breakdown of Services shows that Trade, such as wholesaling of building materials is responsible for 48% of embodied Services GHGE, followed by Professional, scientific and technical (19%) which includes architectural and engineering services (Fig. 7.5). The largest contributors within the total embodied GHGE of Industrial products are identified as Cement , lime, plaster and concrete products (39%), Iron and steel products (38%), and Wood products (7%) (Fig. 7.5). This is because Australia manufactures around 30 Mt of building products annually, which are predominantly concrete (56%), bricks (23%), and steel (6%) (Miller et al. 2015; Walker-Morison et al. 2007). The choice of building and construction products can play a vital role in reducing embodied impacts. Mitigation strategies to reduce embodied GHGE of building products include substituting emission-intensive products with low-carbon alternative products, reducing the use of carbon-intensive products, and increasing the reuse and recycle of building products (Teh et al. 2017a, 2017b, 2018). Within the Machinery and equipment sector, the main source is Construction machinery (62%), followed by Electrical equipment (18%), and Transport equipment (15%) (Fig. 7.5).

Conclusion

This case study using the ECE tool provided the most recent assessment of direct emissions and carbon footprint of Australia ’s construction sector (for the year 2015). The carbon footprint of the construction industry is almost five times more (478%) than the direct emissions, as emissions are embodied in upstream supply chains mainly stemming from Services, Industrial products, and Machinery and equipment. Carbon footprint results by NCOS-aligned categories allow the identification of specified Scope 3 categories as well as embodied GHGE from other additional categories such as Stationary energy, Mining and quarrying, Construction, Consumer goods, Agriculture , forestry and fishing, and Food. The total impacts of the main construction sub-sectors were established as a national average benchmark against which the environmental performance of an analysed project or building can be compared using the ECE tool .

Research on embodied GHGE in the built environment is fast growing and evolving, as evidenced by the increasing number of guidance publications on the subject. Although some aspects require further study, the immediate aim is to promote adoption of the assessment and reporting frameworks in the construction sector . Some of the concerns, including complexity of method, time requirement, region-specific data, and alignment with existing standards can be tackled with the newly developed ECE tool . When substantive guidance materials have been made available to foster the adoption of these assessment methodologies, it will provide an important aid to both the public and private sectors to commit to addressing climate change by applying the available frameworks to reduce carbon impact.

References

ABS 2010, Australian statistical geography standard: design of the statistical areas level 2, ABS cat. no. 8731.0, Australian Bureau of Statstics, Canberra, Australia.

ABS 2012, Australian national accounts, input–output tables, 2008–09, ABS cat. no. 5209.0.55.001, Australian Bureau of Statistics, Canberra, Australia, <www.abs.gov.au/AUSSTATS/abs@.nsf/Lookup/5209.0.55.001Main+Features12008-09?OpenDocument>.

ABS 2018, Australian national accounts, input–output tables, 2015–16, ABS cat. no. 5209.0, Australian Bureau of Statistics, Canberra, Australia.

Ai Group 2015, Australia’s construction industry: profile and outlook, Ai Group, Australia, <http://cdn.aigroup.com.au/Economic_Indicators/Construction_Survey/2015/Construction_industry_profile_and_Outlook.pdf>.

Alcorn, A 2003, Embodied Energy and CO2 Coefficients for New Zealand Building Materials, Centre for Building Performance Research, Victoria University of Wellington, Wellington.

Ariyaratne, CI & Moncaster, AM 2014, ‘Stand-alone calculation tools are not the answer to embodied carbon assessment’, Energy Procedia, vol. 62, pp. 150–159.

ASBP 2014, Embodied Carbon Industry task force recommendations, The Alliance for Sustainable Building Products, London, <https://asbp.org.uk/resource-report/embodied-carbon-industry-task-force-recommendations>.

Birgisdottir, H, Moncaster, A, Wiberg, AH, Chae, C, Yokoyama, K, Balouktsi, M et al. 2017, IEA EBC Annex 57, ‘Evaluation of embodied energy and CO2 eq for building construction’, Energy and Buildings, vol. 154, pp. 72–80.

Commonwealth of Australia 2017a, National carbon offset standard for buildings, Commonwealth of Australia, Canberra, Australia, <http://www.environment.gov.au/system/files/resources/88f3280a-ebc9-47f3-8f28-7537dafd7056/files/ncos-buildings.pdf>.

Commonwealth of Australia 2017b, National carbon offset standard for precincts, Commonwealth of Australia, Canberra, Australia, <http://www.environment.gov.au/system/files/resources/91aadf60-1454-4cde-81dd-587df7cdadd7/files/ncos-precincts.pdf>.

Crawford, RH 2008, ‘Validation of a hybrid life-cycle inventory analysis method’, Journal of Environmental Management, vol. 88, no. 3, 496–506.

Crawford, RH 2011, Life cycle assessment in the built environment, Routledge, Florence, USA.

Crawford, RH 2018, Database of environmental flow coefficients for construction materials, The University of Melbourne, Melbourne, https://doi.org/10.26188/5b7c83f3dc239.

Crawford, RH, Treloar, GJ 2010, Database of Embodied Energy and Water Values for Materials, The University of Melbourne, Melbourne, https://doi.org/10.4225/49/588eeeeda28af.

Crawford, RH, Bontinck, P-A, Stephan, A, Wiedmann, T & Yu, M 2018, ‘Hybrid life cycle inventory methods—a review’, Journal of Cleaner Production, vol. 172, pp. 1273–1288.

Department of the Environment and Energy 2018, National inventory report 2016, Australian national greenhouse accounts, Commonwealth of Australia, Canberra, <http://www.environment.gov.au/climate-change/climate-science-data/greenhouse-gas-measurement/publications/national-inventory-report-2016>.

Dixit, MK, Culp, CH & Fernandez-Solis, J 2015, ‘Embodied energy of construction materials: integrating human and capital energy into an IO-based hybrid model’, Environmental Science & Technology, vol. 49, no. 3, pp. 1936–1945.

Dixit, MK, Fernández-Solís, JL, Lavy, S & Culp, CH 2010, ‘Identification of parameters for embodied energy measurement: a literature review’, Energy and Buildings, vol. 42, no. 8, pp. 1238–1247.

Dixit, MK, Fernández-Solís, JL, Lavy, S & Culp, CH 2012, ‘Need for an embodied energy measurement protocol for buildings: a review paper’, Renewable and Sustainable Energy Reviews, vol. 16, no. 6, pp. 3730–3743.

Foran, B, Lenzen, M & Dey, C 2005, Balancing Act—a Triple Bottom Line Account of the Australian Economy, CSIRO Resource Futures and The University of Sydney, Canberra, <https://publications.csiro.au/rpr/pub?pid=procite:ef189bac-499a-46db-be4d-b391a3cb05dc>.

Fouché, M & Crawford, RH 2015, ‘The Australian construction industry’s approach to embodied carbon assessment: a scoping study’, Living and Learning: Research for a Better Built Environment, 49th International Conference of the Architectural Science Association, Melbourne, 2–4 December, pp. 578–587.

Giesekam, J, Barrett, JR & Taylor, P 2015, ‘Construction sector views on low-carbon building materials’, Building Research & Information, vol. 44, no. 4, pp. 1–23.

Hegner, S 2007, ‘Embodied energy for energy efficiency measures, an assessment of embodied energy’s relevance for energy saving in the Swiss residential building sector’, Diploma thesis, Department of Environment Science, ETH, Zurich, Switzerland.

Ibn-Mohammed, T, Greenough, R, Taylor, S, Ozawa-Meida, L & Acquaye, A 2013, ‘Operational vs. embodied emissions in buildings—a review of current trends’, Energy and Buildings, vol. 66, no. 0, pp. 232–245.

IEA 2016, Evaluation of embodied energy and CO2 eq for building construction (Annex 57), subtask 1: basics, actors and concepts, Institute for Building Environment and Energy Conservation, Tokyo, Japan, <http://www.annex57.org/wp/wp-content/uploads/2017/05/ST1-Report.pdf>.

IPCC 2014, Climate change 2014: mitigation of climate change. Contribution of Working Group III to the fifth assessment report of the Intergovernmental Panel on Climate Change, Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA, <https://www.ipcc.ch/pdf/assessment-report/ar5/wg3/ipcc_wg3_ar5_frontmatter.pdf>.

Langston, YL & Langston, CA 2008, ‘Reliability of building embodied energy modelling: an analysis of 30 Melbourne case studies’, Construction Management and Economics, vol. 26, no. 2, pp. 147–160.

Lawson, B 1996, Building Materials, Energy and the Environment: Towards Ecologically Sustainable Development, Royal Australian Institute of Architects, Red Hill, A.C.T.

Lenzen, M 2000, ‘Errors in conventional and input–output-based life-cycle inventories’, Journal of Industrial Ecology, vol. 4, no. 4, pp. 127–148.

Lenzen, M, Moran, D, Kanemoto, K & Geschke, A 2013, ‘Building Eora: a global multi-regional input–output database at high country and sector resolution’, Economic Systems Research, vol. 25, no. 1, pp. 20–49.

Lenzen, M, Geschke, A, Wiedmann, T, Lane, J, Anderson, N, Baynes, T et al. 2014, ‘Compiling and using input–output frameworks through collaborative virtual laboratories’, Science of the Total Environment, vol. 485–486, no. 0, pp. 241–251.

Lützkendorf, T, Foliente, G, Balouktsi, M & Wiberg, AH 2015, ‘Net-zero buildings: incorporating embodied impacts’, Building Research & Information, vol. 43, no. 1, pp. 62–81.

Miller, D & Doh, J-H 2015, ‘Incorporating sustainable development principles into building design: a review from a structural perspective including case study’, The Structural Design of Tall and Special Buildings, vol. 24, no. 6, pp. 421–439.

Miller, D, Doh, J-H, Panuwatwanich, K & Van Oers, N 2015, ‘The contribution of structural design to green building rating systems: an industry perspective and comparison of life cycle energy considerations’, Sustainable Cities and Society, vol. 16, no. 0, pp. 39–48.

Murray, J & Lenzen, M 2013, The sustainability practitioner’s guide to multi-regional input–output analysis, Common Ground, Champaign, Illinois.

NIST 2007, Building for Environmental and Economic Sustainability Version 4.0, United States National Institute of Standards and Technology, Washington.

Patchell, J 2018, ‘Can the implications of the GHG Protocol’s Scope 3 standard be realized?’, Journal of Cleaner Production, vol. 185, pp. 941–958.

Schinabeck, J, Wiedmann, T & Lundie, S 2016, Assessing embodied carbon in the Australian built environment, Fifth Estate, viewed 26 April 2016, <http://www.thefifthestate.com.au/columns/spinifex/assessingembodied-carbon-in-the-australian-built-environment/81887>.

Schmidt, M & Crawford, RH 2018, ‘A framework for the integrated optimisation of the life cycle greenhouse gas emissions and cost of buildings’, Energy and Buildings, vol. 171, pp. 155–167.

Suh, S, Lenzen, M, Treloar, GJ, Hondo, H, Horvath, A, Huppes, G et al. 2004, ‘System boundary selection in life-cycle inventories using hybrid approaches’, Environmental Science & Technology, vol. 38, no. 3, pp. 657–664.

Teh, SH 2018, Integrated carbon metrics and assessment for the built environment, PhD thesis, University of New South Wales, Sydney, https://doi.org/10.26190/5bc3c083d0433.

Teh, SH, Wiedmann, T, Schinabeck, J, Rowley, H & Moore, S 2015, ‘Integrated Carbon Metrics and Assessment for the Built Environment’, Procedia CIRP, vol. 29, pp. 480–485.

Teh, SH, Wiedmann, T, Castel, A & De Burgh, J. 2017a, ‘Hybrid Life Cycle Assessment of Greenhouse Gas Emissions from Cement, Concrete and Geopolymer Concrete in Australia’, Journal of Cleaner Production, vol. 152, pp. 312–320.

Teh, SH, Wiedmann, T, Schinabeck, J & Moore, S 2017b, ‘Replacement scenarios for construction materials based on economy-wide hybrid LCA’, Procedia Engineering, vol. 180, pp. 179–189.

Teh, SH, Wiedmann, T & Moore, S 2018, ‘Mixed-unit hybrid life cycle assessment applied to the recycling of construction materials’, Journal of Economic Structures, vol. 7, no. 1, p. 13.

Treloar, GJ 1997, ‘Extracting embodied energy paths from input–output tables: towards an input–output-based hybrid energy analysis method’, Economic Systems Research, vol. 9, no. 4, pp. 375–391.

UNEP 2009, Buildings and climate change: a summary for decision-makers, United Nations Environmental Programme, Sustainable Buildings and Climate Initiative, Paris, <https://europa.eu/capacity4dev/unep/document/buildings-and-climate-change-summary-decision-makers>.

University of Bath 2011, Inventory of Carbon and Energy (ICE) Version 2.0, Sustainable Energy Research Team (SERT), Department of Mechanical Engineering, University of Bath, Bath.

Walker-Morison, A, Grant, T & McAlister, S 2007, ‘The environmental impact of building materials’, Environment Design Guide, Acumen Practice Notes, Australian Institute of Architects, pp. 1–9.

Wiedmann, T, Chen, G & Barrett, J 2016, ‘The concept of city carbon maps: a case study of Melbourne, Australia’, Journal of Industrial Ecology, vol. 20, no. 4, pp. 676–691.

Wu, H, Crawford, RH, Warren-Myers, G, Dave, M & Noguchi, M 2016, ‘The economic value of low-energy housing’, Pacific Rim Property Research Journal, vol. 22, no. 1, pp. 1–14.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 The Author(s)

About this chapter

Cite this chapter

Teh, S.H., Wiedmann, T., Crawford, R.H., Xing, K. (2019). Assessing Embodied Greenhouse Gas Emissions in the Built Environment. In: Newton, P., Prasad, D., Sproul, A., White, S. (eds) Decarbonising the Built Environment. Palgrave Macmillan, Singapore. https://doi.org/10.1007/978-981-13-7940-6_7

Download citation

DOI: https://doi.org/10.1007/978-981-13-7940-6_7

Published:

Publisher Name: Palgrave Macmillan, Singapore

Print ISBN: 978-981-13-7939-0

Online ISBN: 978-981-13-7940-6

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)