Abstract

Wastewater treatment operations are energy-intensive and often require operational and design optimisation to improve their energy efficiency. The application of an energy benchmarking approach presents opportunities for wastewater treatment plants (WWTPs) to reduce costs by enabling energy savings and energy recovery, whilst at the same time identifying operational issues for WWTP personnel to focus on to improve plant performance. Energy benchmarking broadly seeks to help the water sector identify and adopt best practice efficiency in the pursuit of better industry performance. This chapter provides an assessment of electricity-related greenhouse gas emissions from Australian wastewater treatment operations since energy benchmarking efforts began and a future outlook for best practice WWTP energy performance and benchmarking in the water sector.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Introduction

Due to the progressive development and implementation of ever more stringent human and environmental health regulations throughout the second half of the twentieth century, the water industry has largely been focused on meeting wastewater treatment and effluent quality criteria for regulatory compliance (Jenkins & Wanner 2014), with less emphasis placed on efficiency and innovation in its operations until quite recently. The same is largely true of energy use for wastewater treatment .

Historically, energy has been relatively inexpensive internationally and many wastewater treatment facilities were not designed or operated with energy use efficiency in mind (NYSERDA 2010). Moreover, the gradual progression from simple low-cost treatment processes to more advanced highly engineered processes in order to meet increasingly stringent regulatory criteria has led to a progressive increase in the energy intensity of wastewater treatment over time (Chang et al. 2008). This progressive intensification of energy demands for wastewater treatment has been brought sharply into focus in recent years by dramatic increases in the cost of energy , including electricity (AEMO 2016), as well as increasing volatility in energy tariffs linked to deregulation and structural changes to energy markets (Escribano, Ignacio Peña & Villaplana 2011). Increased environmental awareness and the relevance of energy use and greenhouse gas emissions has also progressively driven the need for energy efficiency and process optimisation in wastewater operations. In combination, these factors have increased the pressure on energy-intensive industries and facilities like wastewater treatment plants (WWTPs) to look for ways to minimise operational energy use .

Energy Use and Efficiency in Wastewater Treatment

While energy required for wastewater treatment on a per capita basis is some 10-fold lower than that of domestic water heating for example (Kenway et al. 2015), WWTPs as industrial facilities are typically among the largest single energy users within municipalities (Krampe 2013; Müller et al. 2010), thereby presenting important opportunities for energy optimisation and efficiency gains. WWTPs can represent one seventh (1/7th) of the total energy consumption of municipal public structures and facilities, with energy also constituting some 20–40% of total WWTP operating costs (US EPA 2013).

Inefficiencies in WWTPs are due to various factors, including: use of inefficient equipment, usually from the over design of pumps and processes; incorrect operational practices and/or lack of proper controls; and a lack of operator understanding of energy conservation measures (Chang et al. 2008; Ragazzo et al. 2015). Also, the recent adoption of energy-hungry ‘state-of-the-art’ technologies such as membrane bioreactors and UV disinfection has become increasingly common, in some cases without proper justification for such advanced technologies (Ragazzo et al. 2015). Practically all WWTPs present opportunities for energy savings , including —or perhaps especially—new plants (Müller et al. 2010). To improve energy efficiency in the water sector, energy benchmarking has been applied internationally with the broad goal of helping the sector identify and adopt best practice efficiency in the pursuit of better industry performance (Cabrera et al. 2011).

ISO 50001: Energy Management Systems

Energy benchmarking in the water sector is a sub-set of the broader benchmarking approach and falls under the International Standard ISO 50001:2011 Energy Management Systems (ISO 2011). Energy benchmarking enables different water utilities to equate their operational energy performance with other water utilities and comparatively measure their performance, as well as identifying the source of differences for targeted implementation of energy efficiency improvement measures (GHD 2014b; Krampe & Trautvetter 2012). Once best practices are identified, the water industry then sets the best practice values (so-called Target Values) for ongoing improvement and efficiency gains (de Haas et al. 2015).

One of the key activities in energy benchmarking involves the undertaking of an initial energy review to establish an energy performance baseline. This baseline is then used for ongoing performance monitoring and setting improvement targets in relation to future energy performance . Adjustments to this baseline may be made if the performance indicators no longer reflect the industry energy consumption (ISO 2011). Under ISO 50001:2011, the industry is required to develop, record and maintain an energy review, and document the process. Energy consumption should be analysed based on industry data, with identification of the areas where energy use is significant throughout the facility to determine current energy performance.

While ISO 50001 provides the overall framework for energy auditing and identifying areas for optimisation , it does not prescribe the energy performance indicators (benchmarks) nor does it prescribe or recommend a standard/best practice approach to develop them. This leaves the water industry to determine the best approach for energy benchmarking and the setting of energy performance benchmarks . The first European energy benchmarking manual was developed in Switzerland in the mid-1990s and since then, considerable effort has gone into developing and refining these methods, with European methodology now considered world’s best practice (Crawford 2010) and today embraced and replicated in many other countries, including Australia .

Australian Energy Benchmarking in Wastewater Treatment

In 2006, the Commonwealth Government of Australia established an Energy Efficiency Opportunities (EEO) programme (enacted by the EEO Act 2006) to encourage industry and commercial sectors to pursue cost-effective energy efficiency initiatives. An essential function of the EEO programme was the undertaking of a comprehensive assessment of energy use , the purpose being to identify cost-effective energy savings with a payback period of up to four years. Participation in the programme was compulsory for businesses that individually, or as part of a corporate group, had energy use exceeding 0.5 PJ/year. As at June 2013, EEO member corporations accounted for 56% of Australia’s total energy use (Australian Government 2006, 2010); however, the EEO program was closed in 2014 with the repeal of the EEO Act.

Following on from its first EEO report and energy baseline in 2009 (SA Water 2009), the South Australian water utility SA Water undertook the first ever Australian energy benchmarking assessment of its wastewater treatment operations in 2012, with 24 WWTPs subject to detailed assessments (Krampe & Trautvetter 2012). The study followed the German methodology (Müller et al. 1999), incorporating benchmark optimisation values from Baumann and Roth (2008) and Haberkern, Maier and Schneider (2008) to enable a wider variety of treatment processes and WWTP sizes to be captured (Krampe & Trautvetter 2012). The methodology followed the same WWTP size classifications as determined in German benchmarking methodology for consistency with the benchmarks of Baumann and Roth (2008) and Haberkern, Maier and Schneider (2008).

This pioneering benchmarking work from South Australia recognised that the European benchmarks may not be fully applicable to Australian contexts; for example, due to higher nitrogen loads in Australian wastewater (Krampe 2013). The energy requirements of nutrient-removing WWTPs is strongly dependent on the nitrogen-to-organic carbon (N:COD ) ratio in the raw wastewater , due to the oxygen consumption for nitrification and also because of the need for reduced COD removal by primary sedimentation in the case of a high N:COD ratio (Nowak 2003). Nevertheless, the effluent targets between Europe and Australia were considered to be comparable (Krampe 2013). Despite some issues with data coverage quality, this initial energy benchmarking work was extremely useful and helped to identify significant potential for energy efficiency optimisation , whilst also identifying data gaps for future such assessments (Krampe 2013).

Following South Australia’s lead, in 2012 the Australian water industry peak body (the Water Services Association of Australia ; WSAA) conducted an energy survey with the participation of 16 water utilities . This first national energy survey captured 134 WWTPs, recording a total energy consumption of approximately 16 GWh/y (Krampe 2012). Based on this initial survey, the first national Australian energy benchmarking assessment commenced in 2013. The study involved the collection of data from 17 water utilities spread across seven states and territories, including in total 142 WWTPs (GHD 2014a, 2014b). The study applied the same approach of SA Water (Krampe 2013; Krampe & Trautvetter 2012) and based its evaluation on 2013–2014 financial year data.

Results showed that 10% of assessed WWTPs had energy efficiency performance close to the best practice Target Values (GHD 2014a; as specified by Baumann and Roth (2008) and Haberkern, Maier and Schneider (2008))—a good outcome given that Target Values represent 10th percentile energy performance in category. When referring to Guide Value performance (50th percentile), Australian WWTPs performed significantly below expectations, with only 16% approaching these values (GHD 2014a, 2014b), highlighting the substantial future scope for energy efficiency improvements. Usefully, this initial study identified the minimum requirements for data collection, serving as a useful guide to water utilities in future energy optimisation efforts. It also provided a good baseline for understanding and improving future energy benchmarking and performance assessments by providing a reference manual for water utilities on to how identify WWTPs that represent best opportunity for energy efficiency improvements .

In 2017 a second study was commissioned by WSAA , this time evaluating 245 WWTPs across Australia and New Zealand. The results showed that although there had been improvement in data recording and collection and overall WWTPs showed improvement in energy efficiency (when compared to 2014 data), there was still much more to be done to improve energy performance and refine energy benchmarks (de Haas et al. 2018; GHD 2017).

Overview of National WWTP Energy Performance Assessments

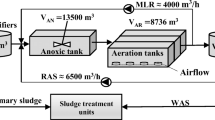

The 2016–2017 survey by WSAA gathered information relevant to energy benchmarking analysis, including: general information (name, location and design capacity of WWTP expressed as megalitres (ML)/d and kg BOD5/d, overall process description, pumping head); secondary effluent quality (chemical oxygen demand (COD), ammonia- and oxidised-nitrogen—all in mg/L); influent loads (flow in ML/d, COD in kg/d, total nitrogen (TN) load in kg/d); biogas production and on site power generation (biogas volume produced in ML/y or m3/y, amount of biogas wasted/flared in ML/y, electricity generated from biogas in MWh/y, analysis data of the heat value of biogas or the percentage methane content); energy consumption of the plant (total electricity consumed, total external fuel source consumed, electricity consumption for the aeration of the secondary treatment stage). These data were assessed and a results summary of energy performance for the Australian state and territories, considering WWTP size and operational configuration, is presented below.

Some 87% of the Australian population is connected to sewage systems (UNSTAT 2011), or approximately 21.8 million people. There are 74 Australian urban water utilities with a combined 673 municipal WWTPs (Bureau of Meteorology 2018) collecting a combined wastewater volume of 1,896,641 ML during the 2015–2016 period (ABS 2017). The WSAA benchmarking study captured data from 245 WWTPs, 243 of which were Australian and the remainder from New Zealand. This chapter deals only with the performance of Australian WWTPs. These 243 WWTPs have a total annual operational capacity of 24,659,180 PECOD, 1 with a total treated wastewater volume of 1,528,210 ML, or some 4185 ML/d. Though representing some 36% of all WWTPs nationally, the 243 Australian WWTPs surveyed include the largest metropolitan plants and so collect and treat around 81% of the total national sewage flow (ABS 2017).

The assessment of WWTPs was carried out according to predefined WWTPs size classes (SC) and the distribution of WWTPs per SC is shown in Fig. 16.1. Notably, plants in SC 5 (>100,000 population equivalents; PE), while representing only 16% of the surveyed WWTPs, are responsible for 81.6% of WSAA surveyed wastewater flow treated (1,209,151 ML) or some 63.8% of the total treated wastewater flow nationally. In addition to size class, the WWTPs were assessed according to the plant’s process configuration typology, being plant Types 1–5 (GHD 2014b, 2017). When assessed according to WWTP process configuration or type, 133 of the total 243 WWTPs (≈55% of total) were classified as Type 3 extended aeration activated sludge systems. The next most common process types were Type 5 aerated lagoons with 52 WWTPs (21.3% of total), Type 2 activated sludge systems with separate sludge stabilisation but without on-site biogas co-generation with 24 WWTPs (9.8% of total), Type 1 activated sludge systems with separate sludge stabilisation and on-site biogas co-generation with 22 WWTPs (9% of total) and Type 4 trickling filters with 13 WWTPs (5.3% of total surveyed plants).

Wastewater Treatment Performance Results

Table 16.1 summarises the 2016 national WWTP load and performance characteristics by Australian state and territory, including population equivalent-normalised wastewater volumes , pollutant loads , electricity use performance, and related carbon dioxide -equivalent (CO2-e) emissions.

Type 3 extended aeration activated sludge systems were shown to have the lowest effluent COD discharge values on average, achieving COD removal ratios of 66.1–99.2% (median 95.5%), followed by Type 1 activated sludge systems with COD removals of 88.8–97.7% (median 93.85%), Type 2 activated sludge systems with COD removals of 90–98.2% (median 93.37%), and Type 5 aerated lagoons with the poorest COD removals at 46.9–93% (median 87.2%).

In the case of total nitrogen, the Type 3 activated sludge systems achieved the best results with a median effluent value of 5.3 mg/l (range 1–30.16 mg/l) followed by Type 2 activated sludge systems with a median effluent value of 8.15 mg/l (range 2.39–40.69 mg/l). Type 5 aerated lagoon WWTPs achieved median effluent TN levels of 11.72 mg/l (range 2.10–76.25 mg/l), followed by Type 1 activated sludge systems with median effluent TN of 16.02 mg/l (range 3.70–57.62 mg/l) and lastly Type 4 trickling filters which achieved a median effluent TN of 30.04 mg/l (range 3.77–44.12 mg/l).

Regarding energy use efficiency, trickling filters displayed the best energy performance with a median of 30.7 kWh/(PE/y) and associated carbon emissions 27.9 kg CO2-e/(PE/y), with Type 3 extended aeration activated sludge systems having the highest median specific electricity use of 62.5 kWh/(PE/y) and associated carbon emissions intensity of 56.8 kg CO2-e/(PE/y).

WWTP Energy Efficiency and Carbon Emissions Trends

Referring to 2016 national WWTP performance data (Table 16.1), Australian national average specific energy performance was 56.1 kWh/(PE/y) and per capita equivalent greenhouse gas emissions were 51.1 kg CO2-e/(PE/y). Total WWTP annual energy use in both 2014 and 2016 survey years and total associated carbon emissions is shown in Fig. 16.2. The energy use patterns for wastewater treatment operations largely reflect state population sizes, with the performance of NSW disproportionately lower than its relative population size due to several large capacity primary-only treatment WWTPs (combined PE of these primary-only plants is some 4 million). Overall, total WWTP energy use and carbon emissions were relatively consistent between 2014 and 2016 survey years, with the exception of South Australia which achieved an approximately 50% reduction in both total annual energy use and carbon emissions due to significant investment in WWTP process efficiencies and optimisation .

Figure 16.3 gives the per capita equivalent specific energy use and associated carbon emissions intensity of WWTPs in both 2014 and 2016 survey years according to state. At the national level, specific energy use efficiency of these plants improved overall by some 13% from 54.7 kWh/(PE/y) in 2014 to 47.5 kWh/(PE/y) in 2016. At the state level, most states performed similarly to the national average values. Notable exceptions were Tasmania which performed best in terms of both specific energy consumption (41.8 kWh/(PE/y)) and per capita equivalent greenhouse gas emissions (7.52 kg CO2-e/(PE/y)), with the very low carbon emissions intensity there due to the predominance of hydroelectricity in this state. South Australia was the next best performer for both specific energy consumption (44.8 kWh/(PE/y)) and per capita equivalent greenhouse gas emissions (27.8 kg CO2-e/(PE/y)). Large differences in carbon emissions intensity performance between states are a reflection of differing WWTP specific energy performance combined with variable state-based emission factors for grid electricity .

Future Outlook for Energy Efficiency and Low Carbon Wastewater Treatment

The Australian water industry has invested considerable resources toward energy efficiency initiatives in recent years and many water authorities now recognise the important role of optimising wastewater treatment operations in achieving their corporate energy and carbon neutrality objectives. This chapter has presented a summary of WWTP energy benchmarking work to date, with WWTP energy use and carbon emissions intensity performance data given for wastewater treatment operations covering the majority of the Australian population. National median per capita equivalent specific energy consumption was some 56 kWh/(PE/y), with an associated average per capita equivalent carbon emission intensity of 51 kg CO2-e/(PE/y). While wastewater treatment operations are a dominant source of greenhouse gas emissions for the water industry, greenhouse gas emissions from WWTPs are a relatively minor component of the total national CO2-e emissions inventory, contributing less than 1% to the total inventory.

The undertaking of energy benchmarking and subsequent WWTP energy efficiency optimisations have delivered measurable gains for some state water authorities in recent years; however, considerable scope exists to further optimise WWTP processes for future energy and carbon reductions . Participation in national energy benchmarking projects is currently voluntary, but international experience has demonstrated the importance of comprehensive industry participation in benchmarking exercises to develop robust performance metrics and ensure industry gets the most from benchmarking efforts. Regular and consistent updates of energy benchmarks are also required to ensure that they reflect current industry best practice, technological advancements and regulated environmental performance criteria.

Note

-

1.

Number of connected population equivalents is expressed as the sum of population pollution load in domestic wastewater (served inhabitants) and the measured pollution (organic) load from commercial sources entering a sewage treatment plant. A standard population-specific COD load of 120 g/PE/d was applied.

References

ABS 2017, 4610.0—water account, Australia, 2015–2016, Australian Bureau of Statistics, Belconnen ACT, Australia.

AEMO 2016, National electricity market, electricity, average price tables, data dashboard, Australian Energy Market Operator (AEMO), viewed 22 August 2018, <http://www.aemo.com.au/Electricity/Data/Price-and-Demand/Average-Price-Tables>.

Australian Government 2006, Energy efficiency opportunities industry guidelines, Commonwealth of Australia, Canberra.

Australian Government 2010, First opportunities: a look at results from 2006–2008 for the energy efficiency opportunities program, National Framework for Energy Efficiency, Commonwealth of Australia, Canberra.

Australian Government 2018, National greenhouse accounts factors: Australian national greenhouse accounts, Department of the Environment and Energy, Commonwealth of Australia.

Baumann, P & Roth, M 2008, Senkung des stromverbrauchs auf kläranlagen, leitfaden für das betriebspersonal [Reduction of the energy consumption of WWTPs—manual for operators], Heft 4, DWA Landesverband Baden-Württemberg, Stuttgart.

Bureau of Meteorology 2018, National performance report 2016–17: urban water utilities, part A, Commonwealth of Australia, Canberra.

Cabrera, E, Dane, P, Haskins, S & Theuretzbacher-Fritz, H 2011, Benchmarking water services: guiding water utilities to excellence, IWA Publishing, London, UK and American Water Works Association, Denver, Colorado.

Chang, Y, Reardon, DJ, Kwan, P, Boyd, G, Brant, J, Rakness, KL et al. 2008, Evaluation of dynamic energy consumption of advanced water and wastewater treatment technologies, Awwa Research Foundation (AwwaRF), Denver, Colorado.

Crawford, GV 2010, Best practices for sustainable wastewater treatment: initial case study incorporating European experience and evaluation tool concept, Water Environment Research Foundation, USA and IWA Publishing, UK.

de Haas, D, Appleby, G, Charakos, G & Dinesh, N 2018, ‘Benchmarking energy use for wastewater treatment plants—a summary of the 2015–16 benchmarking study’, Water e-Journal, vol. 3, no. 2, pp. 1–26.

de Haas, DW, Foley, J, Marshall, B, Dancey, M, Vierboom, S & Bartle-Smith, J 2015, ‘Benchmarking wastewater treatment plant energy use in Australia’, Proceedings of Ozwater 2015, 12–14 May, Adelaide, Australia.

Escribano, A, Ignacio Peña, J & Villaplana, P 2011, ‘Modelling electricity prices: international evidence’, Oxford Bulletin of Economics and Statistics, vol. 73, no. 5, pp. 622–650.

GHD 2014a, WWTP energy efficiency benchmarking, part 1—summary report, Water Services Association of Australia.

GHD 2014b, WWTP energy efficiency benchmarking, part 2—technical report, Water Services Association of Australia.

GHD 2017, WWTP energy benchmarking 2015–2016, part 2—technical report, Water Services Association of Australia.

Haberkern, B, Maier, W & Schneider, U 2008, Steigerung der energieeffizienz auf kommunalen klaeranlagen [Improving energy efficiency in municipal sewage treatment plants], s.l.: Umweltbundesamt (German Federal Environment Agency), Dessau-Roßlau, Germany.

ISO 2011, Energy management systems—requirements with guidance for use, ISO 50001:2011(E), International Organization for Standardization, Geneva, Switzerland.

Jenkins, D & Wanner, J 2014, Activated sludge—100 years and counting, IWA Publishing, London, UK.

Kenway, SJ, Binks, A, Lane, J, Lant, PA, Lam, KL & Simms, A 2015, ‘A systemic framework and analysis of urban water energy’, Environmental Modelling & Software, vol. 73, pp. 272–285.

Krampe, J 2012, Energy benchmarking of Australian WWTPs, initial results of the 2012 WSAA energy survey, SA Water Corporation, Adelaide, SA.

Krampe, J 2013, ‘Energy benchmarking of South Australian WWTPs’, Water Science & Technology, vol. 67, no. 9, pp. 2059–2066.

Krampe, J & Trautvetter, H 2012, Energy benchmarking of SA Water’s WWTPs, SA Water Corporation, Adelaide, SA.

Müller, E, Kobel, B, Künti, T, Pinnekamp, J, Seibert-Erling, G, Schaab, R et al. 1999, Handbuch, energie in kläranlagen [Handbook, Energy in wastewater treatment plants], Ministerium fuer Umwelt, Raumordnung und Landwirtschaft des Landes Nordrhein-Westfalen (Hrsg.) [Ministry of Environment, Regional Planning and Agriculture of North Rhine-Westphalia].

Müller, E, Kobel, B, Schmid, F, Levy, G, Kind, E, Moser, R et al. 2010, Handbuch energie in ARA: leitfaden zur energieoptimierung auf abwasserreinigungsanlagen [Manual, energy in WWTP: guide to energy optimization on wastewater treatment plants], Bundesamt für Energie, Verband Schweizer Abwasser- und Gewässer-schutzfachleute (VSA), [Federal Office of Energy, Association of Swiss Wastewater and Water Protection Professionals (VSA)].

Nowak, O 2003, ‘Benchmarks for the energy demand of nutrient removal plants’, Water Science & Technology, vol. 47, no. 12, pp. 125–132.

NYSERDA 2010, Water and wastewater energy management: best practices handbook, New York State Energy Research and Development Authority, New York.

Ragazzo, P, Falletti, L, Chiucchini, N & Serra, G 2015, ‘Chapter 12, Management optimisation and technologies application: a right approach to balance energy saving needs and process goals’, in K Stamatelatou & KP Tsagarakis (eds), Sewage treatment plants: economic evaluation of innovative technologies for energy efficiency, Water Intelligence Online, IWA Publishing, London, UK.

SA Water 2009, SA Water: energy efficiency opportunities Bolivar Waste Water Treatment Plant—final report, Energetics Pty Ltd.

UNSTAT 2011, Environmental indicators, inland water resources, viewed 6 February 2019, <https://unstats.un.org/unsd/environment/wastewater.htm>.

US EPA 2013, Energy efficiency in water and wastewater facilities: a guide to developing and implementing greenhouse gas reduction programs, EPA-430-R-09-038, US Environmental Protection Agency, Washington, DC.

Acknowledgements

Participating water authorities are thanked for benchmarking data contributions and The Water Services Association of Australia is acknowledged for facilitating data access.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 The Author(s)

About this chapter

Cite this chapter

Clos, I., Alvarez-Gaitan, J.P., Saint, C.P., Short, M.D. (2019). Energy Benchmarking for Efficient, Lower Carbon Wastewater Treatment Operations in Australia. In: Newton, P., Prasad, D., Sproul, A., White, S. (eds) Decarbonising the Built Environment. Palgrave Macmillan, Singapore. https://doi.org/10.1007/978-981-13-7940-6_16

Download citation

DOI: https://doi.org/10.1007/978-981-13-7940-6_16

Published:

Publisher Name: Palgrave Macmillan, Singapore

Print ISBN: 978-981-13-7939-0

Online ISBN: 978-981-13-7940-6

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)