Abstract

The conventional solar stills have a poor distillate production capacity. This makes the system highly uneconomical. According to the type of input energy, the solar stills are classified into passive and active solar stills. A lot of research works have been carried out to improve the performance of the still by adopting different techniques using both experimental and software analysis. Software application is essential in design and optimization of the performance-effecting parameters for solar stills before fabrication. CFD simulations technique is being done with the help of ANSYS and FLUENT. TRNSYS is to examine the temperature profile and vapor flow pattern inside solar stills. MATLAB and FORTRAN are very useful tools for developing computer code of mathematical models for yield prediction. This chapter is focused on the research work being done in the software application and its analysis of solar still. All recently employed and developed software for the utility of solar still system are being discussed. This research will help researcher and other scientist about the scope of the research possible in the software-oriented research.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Solar energy is an inexhaustible source of energy, available in abundance and is pollution free. Everyday earth receives plenty of energy from the sun. Solar distillation is one of the methods to extract drinkable water from saline water with the help of solar radiation. Solar still works on the principle of solar distillation and provides potable water for direct human consumption. This distillation process is based on the evaporation and condensation phenomenon. Using commercial methods to extract pure water via distillation in remote areas is not feasible as the availability of fossil fuel or electricity is limited in those areas, and total cost of the system is very high [1]. Therefore, to provide clean water in remote villages, solar still has emerged as the most effective alternative. Solar radiation is used to heat up the still basin water, which leads to evaporation of basin water. By this, evaporated vapor condenses on inner glass cover surface. The collected distillate output through the collecting channel is the fresh water.

Solar stills are available in the large variety depending upon their mode of operation as an active or passive mode. For the better performance, it is needed to do a parametric evaluation and its analysis. The design of solar still can be optimized with the help of relevant software. Computational fluid dynamics (CFD) analyze and investigate the flow pattern of moist air and temperature distribution, stress pattern of adjacent wall, and humid zone. CFD-based simulation software is also being used for the prediction of behavior of flow pattern near wall, and condensing cover. The CFD simulation shows the zones where in solar still where condensation and evaporation occurs like moisture zone, condensing zone, evaporation zone, etc. [2]. It also gives the information regarding the temperature of glass cover, water temperature, and vapor temperature, etc. Programming languages such as FORTRAN are being used in simulation process for the solution of energy balance equations. Comsol Multiphysics coding is also used for numerical simulations for solar still. MATLAB is an essential tool used for the development of mathematical models and to predict the performance.

This chapter provides the information of the existing design software applied in solar still system for simulation procedures and optimization techniques. The flow behavior, velocity pattern, and operating parameters effects on distillation rate. The effects of inclination angle and shear stress analyzation near wall are also being discussed for different types of solar stills. The relevant data regarding vapor zones, shear stress zones, condensation zone, and its temperatures ranges are taken in account during analysis.

2 Experimentation and Mathematical Modeling on Solar Stills

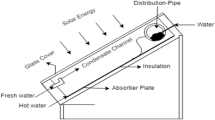

Sampathkumar et al. [1] have done research work on active-type single-slope solar still system. For the enhancement of productivity, yield output of still, the system was coupled with evacuated tube collector. The solar still with collector was working as a hybrid system. The experiment was done on various days at different timings. Result shows that after coupling collector, solar still gives a rise output of 77% in yield as compared to passive solar still. It was also noticed that a temperature increment of about 60 °C due to the collector input. The experimental result had a good agreement with the theoretical result. The schematic diagram of the experimental setup of the hybrid solar still system is being shown in Fig. 1.

Schematic diagram of the experimental setup [1]

The energy balance equation used for the active solar still system coupled with evacuated tube collector is mentioned below.

During the formation of these equations, the following assumptions were made:

-

i.

The basin water depth of the solar still is being kept constant during the experimentation.

-

ii.

The condensation phenomenon occurred inside the inner glass cover is of film type.

-

iii.

The heat capacity of stored mass of water is being neglected.

-

iv.

The water carrying pipes are properly insulated.

-

v.

The entire solar still system is leakage proof.

These energy equations are for outer glass cover, inner glass cover, and basin liner at the base and water mass system, respectively.

For the solution of these energy balance equation, the boundary conditions are:

Panchal et al. [2] worked on the experimental and CFD modeling of the solar still. The experimental setup had a single-slope still with black coating at the bottom most part in order to increase the absorption of the solar radiation. The theoretical result was done using ANSYS CFD 11. The experiment was performed at 40 cm of water depth in clear sky condition. The data were taken using four thermocouples in an interval of 1 h.

Fathy et al. [3] did an experimental work on double-slope active-type solar still. In this research work, the still system was coupled with parabolic trough collector for the enhancement of heat transfer. The solar energy incident on parabolic trough collector was delivered to the still system with the help of finned pipe heat exchanger. The experimental work was compared among different types of combinations like, one with conventional type fixed collector and another was tracked collector system for water depth of 20 mm. Result shows that productivity is maximum during summer days as compared with winter season. A photograph of the experimental setup is being shown in Fig. 2. The angle of inclination of glass surface was 26.5°. It was noticed that the water productivity for the conventional solar still was 4.51, 8.53 kg/m2 for still with fixed PTC, and 10.93 kg/m2 for tracked PTC.

A photograph of the experimental setup [3]

Kumar et al. [4] had performed an experimental work for active-type single-slope solar still. In this system, solar air heater was coupled with solar still to increase the temperature difference between the basin water and condensing cover. The variation of temperature with solar radiation was noticed and an increment of 24% in daily productivity of solar still with solar air heater as compared with conventional system. It can be also concluded that basin temperature, water temperature, and glass temperature increased when coupled with air heater. During the formation of energy balance equation, it was assumed that heat loss from basin to ambient is neglected. The energy balance for the glass cover is,

The energy equation for the saline water mass

Energy balance for the basin plate

Energy balance for the bottom surface

Kumar [5] carried out research on the economic evaluation of hybrid-type active solar still system. In this work, an analysis was done on various terms of parameters related to the economics of still system. These are maintenance cost, tax benefits, annual costing of still, energy production factor, life cycle efficiency of solar still, CO2 mitigation, revenue earned, and payback period. An experimental setup photograph of hybrid-type solar still is being shown in Fig. 3.

Photograph of hybrid (PVT) active solar still [5]

Lovedeep et al. [6] did an experimental work using nano-fluids with the motive to increase the heat transfer in fluids for increasing production from potable water for passive-type double-slope solar still. In this research work, nano-fluids were used due to their exceptional thermo-physical and optical properties. Nano-fluids were Al2O3, TiO2, and CuO-water. In this communication, the energy matrices, economic analysis, and exergo-economic analysis of passive-type double-slope solar still were discussed, and energy payback period and life cycle conversion efficiency were estimated. Result shows that annual productivity using nanoparticle has increased different for different nanoparticles. For Al2O3 is 19.10%, TiO2 is 10.38%, and CuO is 5.25% and exergy efficiency for Al2O3 is 27.77%, TiO2 is 25.55%, and CuO is 11.99%, as compared to conventional solar still. A heat transfer mechanism is shown in double-slope solar still with nano-fluids particle (Fig. 4).

Schematic of double-slope passive-type solar still with metallic nanoparticles [6]

Madhlopa et al. [7] performed a research on computation of solar radiation distribution in single-slope solar still with external and internal reflectors. In this communication, parameters considered for the estimation are surface finish and optical view factor. This analysis was performed for the conventional single-slope solar still and another with still coupled with condenser. The proposed model diagram of the setup is shown in Fig. 5.

Model showing the distribution of solar radiation inside the solar still with reflectors [7]

While developing the energy balance equation for the proposed model, following assumptions were made.

-

i.

There was no any leakage of vapors and distilled water inside the solar still.

-

ii.

Solar radiation intercepted by external surfaces of wall was not considered.

-

iii.

Solar still system was air-tight.

-

iv.

Solar radiation after reflection from ground did not reach the saline water.

Badran [8] did an experimental work for the enhancement technique of solar still to increase the productivity of single-slope solar still. For this, two different types of basin liner were used: one was of asphalt and another of sprinkle. The depth of water basin and ambient conditions were observed. Result shows the 51% increment in productivity with these basin liner as compared with conventional still system. When both basin liners were used as combination, then improvement in production was 29% as compared to 22% when alone liner was used. It was also noticed that decreasing water basin depth leads to an increase in daily production.

Gnanadason et al. [9] did an experimental work for the performance analysis of single-slope solar still with copper and GI sheet. For both the experimental setup, all dimensions were same and ambient conditions were similar. Parameters considered for evaluation were wind speed, water temperature, and water depth. Result shows that solar still with copper basin material has higher productivity yield as compared to GI sheet material. The reason is that copper has a higher conductivity as compared to GI sheet. Analysis of result shows that 80% increment of efficiency was found in comparison to GI sheet made of solar still. Results also show that decreasing wind speed leads to less heat loss and hence increased productivity. It is also observed that as water temperature is lowered, evaporation rate decreased, and hence yield output was less. As water depth increases, the water productivity decreases due to higher thermal capacity and decreases the water temperature.

Singh [10] carried an experimental work on passive-type single-slope solar still for the analysis of better inclination angle for yield output. For this, indoor simulation setup was fabricated for different inclination angles of 15°, 30°, and 45°, respectively. The results of experimental work were compared to Dunkle’s result and validated. Results show that maximum evaporation was noticed at inclination angle of 45°. The results of the present model yield data are higher than that of Dunkle’s model. The conclusion derived from study was that with increase in inclination angle, evaporation rate and temperature difference between the glass cover and water surface increased and this leads to higher productivity.

For the determination of convective heat transfer coefficients, few parameters are needed for evaluation. Among those parameters, characteristics length is an important one. To estimate the characteristics length of solar still, following equation was used.

where \({\text{Difference}} = {\text{Height}}\;{\text{of}}\;{\text{the}}\;{\text{bath}} - {\text{Height}}\;{\text{of}}\;{\text{water}}\).

It was also assumed that the water bath temperature for the solar still is constant.

Panchal [11] did experimental work for the enhancement of heat transfer inside the active-type single-slope double-basin solar still. For the enhancement of heat transfer, black gravel and vacuum tubes were used. A comparative analysis was done to estimate the better result of enhancement technique. Result shows that black gravel has the higher productivity yield output of distilled water than the vacuum tubes. Daily output was 56 and 65% for vacuum tubes and black gravel, respectively.

Sridharan et al. [12] performed experimental work for the heat transfer enhancement technique in active-type single-basin double-slope solar still. For this, an experimental setup was built. The main objective of this research work was to increase the temperature of water input to the solar still system. For this, a flat-plate collector was used as solar water heater to heat the input water. Result shows an increment of 77% higher yield in comparison to simple single-basin double-slope solar still. For the experimental work, the water basin depth of height 2 cm was opted and kept constant. Distillate output for active system was 4.76 kg/m2 and theoretical result for conventional was 3.55 kg/m2.

Tiwari et al. [13] done research work on active-type single-slope solar still coupled with flat-plate collector. In that, an attempt was made to evaluate the effect of inner and outer glass temperature in different situation. The parameters involved in the study were thickness of glass cover, absorbing surface area of collector, wind speed, and water depth. Different absorbing glass surface materials were used namely copper, glass, and plastic material. Result showed that copper gave a higher yield output as compared with another absorbing surface material. Higher conductivity of copper material and lower water depth are key parameters for increased output of distillate. Conclusion obtained from study was that active-type solar still has higher yield output as compared to passive-type solar still. The experimental setup of the active solar still coupled with flat-plate collector is shown in Fig. 6.

Experimental setup of the active solar still coupled with flat-plate collector [13]

Khader et al. [14] performed experimental work for the improvement of performance of single-slope solar still. Different modeling techniques were used to enhance the production rate such as reflecting mirror, sun-tracking system, and stepwise basin. Conventional-type solar still gives lesser production rate; hence, modification was attempted in the present study. Result shows that by including reflecting mirrors in place of flat basin in solar still, system leads to an increment of 30%, stepwise basin used gives a 180% increment in distillate output and with sun-tracking system highest performance rate of 380% was noticed.

Tripathi and Tiwari [15] did experimental work for the active-type single-slope solar still system. In this research work, an attempt has been made to evaluate the better water basin depth for which the heat transfer coefficients will be high. This solar system is coupled with flat-plate collector for increased inlet water temperature. Experiments have been done for different basin water depth of (0.05, 0.1, and 0.15 m). Result showed that heat transfer coefficients of water and glass cover mainly depends on water depth. It is also observed that more yields are obtained at a basin water depth of 0.05 m. Higher depth of heat storage effect is seen at night, i.e., during off-sun shine hours, because of same basin water depth, it showed a higher productivity at nights as compared to day time.

3 Simulation Modeling of Solar Stills

Setoodeh et al. [16] used CFD simulation tool for a three-dimensional two-phase models to show the evaporation and condensation process in single-slope solar still. This model was developed in the volume of liquid (VOF) framework for fluid water, a mixture of air and water vapors in quasi-static state condition. Model geometry and its meshing were done using ANSYS Workbench 11. The tetrahedral meshing type was used. Simulations were carried out with 47,179 nodes. The energy balance equations considered for the numerical modeling was heat transfer, mass transfer, and continuity equations. The results obtained from CFD are clearly evident with the fact that it is efficient and sharp modeling software for design.

Singh and Mittal [17] have done simulation work for passive-type single-slope solar still to find out the suitable inclination angle for the better productivity result. Simulation work is done with the help of ANSYS CFX 13. Geometric model was created in ANSYS CAD module and imported to ANSYS meshing module for the generation of mesh. Boundary condition was applied to solve the momentum and continuity equation. For the simulation process of solar still, two condensing glass covers having slopes equal to 15° and 30° were chosen. Simulation is carried out in the temperature difference between 40 and 60 °C at an interval of 2 °C for each reading. The simulation result is shown in Fig. 7. For droplet formation on condensing cover, adhesive forces are taken into consideration and it is observed that condensing cover at inclination of 30° obtains the highest convective and evaporative heat transfer coefficient. The condensing cover at 30° slope gives higher production efficiency rate of 29.4% than 15° slope.

Meshed structure of the solar still for CFD simulation [17]

During the simulation processes, following assumption were made:

-

i.

Bottom temperature is equal to the water temperature inside the solar still.

-

ii.

Temperature of the distillate collector is assumed to be equal of glass temperature.

-

iii.

Only adhesive forces are considered for the droplet formation.

-

iv.

All the side wall of solar still assumed to be adiabatic since there is no heat loss to the surrounding.

-

v.

No slip boundary is being specified for the liquid phase, and it is specified for the vapor phase.

Following boundary conditions were applied during simulation process and its various conditions are being presented in Table 1.

Panchal et al. [18] worked in ANSYS CFX tool for modeling and simulation technique to represent a model of passive single-slope solar still. To study the simulation process of evaporation as well as condensation phenomenon in solar still, the two-phase, three-dimensional model was created. The model geometry and meshing were done with help of ANSYS workbench 10. Meshing type of tetrahedron used and number of cells was 84,121. Convection heat transfer was took place due to buoyancy force. This buoyancy force is caused by difference in density due to temperature difference of mixture in the gas-phase droplets. The climatic condition of working system was Mehsana (23°12′N, 72°30′S). Differences between the experimental and simulation results of production rate and water temperature were reported as 6 and 10.25%, respectively.

Energy balance equation was developed for energy flow mechanism in solar still with following assumptions.

-

i.

Negligible heat capacity of glass cover, absorbing material, and insulation material.

-

ii.

No any temperature gradient inside the solar still system between water and glass cover.

-

iii.

No any heat losses occurring.

-

iv.

Constant basin water level is maintained.

-

v.

Condensation occurring at the inner glass surface is of film type.

Energy balance for glass cover

Energy balance for basin water

Energy balance for basin

Boundary conditions were same as of the Setoodeh et al. simulation work.

-

i.

ANSYS run time was 8 h for modeling of solar still, i.e., it comes into category of unsteady state. To overcome this, it was considered steady state of operation.

-

ii.

For effective result, it was considered adiabatic condition for walls.

-

iii.

No any slip boundary was specified for the liquid phase, but it was specified for the vapor phase.

-

iv.

Distillate output temperature was considered same as the glass cover temperature.

-

v.

Only adhesive forces are taken into consideration.

Tripathi and Tiwari [19] have worked for the thermal analysis of single-slope solar still for both active and passive mode by considering the parameter of solar fraction. For 3-D model, geometry construction of a single-slope solar still in AUTOCAD 2000 is being used. Specification of system was 1 m × 1 m basin area with 10.2° slope of glass cover. Experiments were carried out under the weather condition of New Delhi (latitude 28°35′N, longitude 77°12′E). MATLAB program was developed to compute the convective and evaporative heat transfer coefficients and estimation of solar fraction. Result shows that there was a fair agreement between the heat transfer coefficients of theoretical and experimental. In this modeling technique for the evaluation of solar fraction of a particular wall, following formula was used:

Photograph of the active solar still experimental setup is given.

Chaibi [20] developed a simulation model for distilled water generation and performance parameters for passive double-slope solar still incorporated in greenhouse rooftop. For the calculation of solar irradiation, transient system simulation (TRNSYS) program was used. This program helps for the hourly calculated values of radiation values for inclined glass surface. The effect of solar irradiation and visual material properties are considered in this system. The energy balance equation was solved with help of engineering equation solver (EES). Result shows that solar radiation proportionally affects the efficiency of the rooftop-incorporated framework. The thermal performance of greenhouse-integrated solar still can be improved by maximizing solar irradiation. It was found that there is a fair agreement between the experimental and simulation results.

Hamadou et al. [21] studied an active-type single-slope solar still having copper heating plate at basin for enhanced heat transfer rate. In this modeling technique, Chilton-colburn model and Dunkle model both were used under steady state condition. MATLAB program was developed on the command ode 15s to solve the nonlinear differential explicit equations in matrix form. Optimization technique was used to find the suitable parameters like wind speed, inlet temperature, fluid transfer rate, relative humidity, and water basin depth. The simulation result states that wind speed has significant impact efficiency on distilled water while humidity shows negligible appearance toward it.

Khare et al. [22] developed a 3-D CFD model to understand the evaporation and condensation phenomena in passive-type single-slope solar still. The model is developed with the help of ANSYS workbench and then simulated with Fluent. ANSYS FLUENT v14.0 software package is used in the study. It uses the finite volume method (FVM) to convert the governing equations into numerically solvable algebraic equations. A multiphase model was developed for three phases present in the solar still, i.e., air, liquid water, and water vapors. The three-dimensional model was meshed utilizing 3-D hexahedral meshing which comprises aggregate 1.5 million cells (components) at a development rate of 1.2. The parameters considered for the study was water depth, solar radiation, and basin material. Simulation results showed that with increase in solar radiation with reflecting mirror leads to enhancement of productivity by 22%. It also discussed about effect on the productivity of different absorbing basin materials like rubber, gravel, etc. The simulation results have a fair agreement with experimental data.

The following energy balance equations were used for the solar still system. For the solution of energy balance equation, same boundary conditions were considered as steady state condition. A constant temperature of glass, bottom surface, and collecting surface of solar still was assumed. All the thermo-physical properties of the glass and air are considered as constant.

The energy equation used for the mixture of the water vapors and air inside the solar still system is:

where Keff is the conductivity, and Kt is the turbulent thermal conductivity as per the turbulence model.

Arjunan et al. [23] did computational work for the performance analysis of passive-type single-slope solar still. For the CFD analysis, ANSYS CFX 13 software was used. Model geometry was modeled in ANSYS workbench 13. Two-phase three-dimensional model was created in volume of framework (VOF) for liquid water and its mixture with air. Meshing was created with tetrahedral type meshing. The simulation was performed for the evaporation and condensation phenomenon in still with CFD techniques. The simulation result and experimental work have been validated and good agreement was found between them. An average error of 5.5 and 3.01% occurred in evaporative and convective heat transfer coefficients, respectively.

Thakur et al. [24] did the computational work to optimize the different water depth of solar still. This work was done for the passive-type single-slope solar still for water depth of 0.01, 0.02, and 0.03 m. In this research work, the optimization work was done for the grid size of solar still. Researchers also calculated the heat and mass transfer coefficients of solar still. The meshing geometry has a number of nodes 632,088 and elements were 553,048. Meshing type of hex-dominant was used. Result obtained through CFD work has a good agreement with experimental data. It was observed that the optimum depth for the good productivity was 0.01 m.

Kannadasan et al. [25] performed modeling work using CFD tool and experimental work for single-slope solar still. The objective for the CFD work is to simulate the temperature distribution inside the solar still. For the geometry and meshing, ANSYS workbench 14.5 was used. Attention was given for the pattern near the glass cover to simulate its behavior. Simulated water temperature was in a good agreement with experimental result. Solar evaporation phenomenon was simulated using ANSYS CFX. The conclusion from the result was that CFD is a powerful tool for the analysis of design of solar still.

Ileri et al. [26] worked for solar stills to analyze the effect of glass cover thickness on the productivity yield. Thermal modeling was developed for the solar still and for the solution of these equations, programming software FORTRAN-77 was used. This programming was executed for 24 h and each for 30 experiments. The numerical solutions of equations were compared with the experimental result. It was found in agreement with them and 15% deviation was observed. For finding the roots of radiative heat transfer coefficients for glass and water temperature, Newton–Raphson method was used for solving the mathematical model. For a glass cover of thickness 3 mm, an increased efficiency of 26.22% was noticed as compared to 5 and 6 mm thickness of glass cover. It can be inferred that increment in glass thickness leads to decrement in efficiency due to reduced transmittance of glass surface.

Zerrouki et al. [27] worked for the numerical simulation of capillary film solar still coupled with the conventional solar still in series. Mathematical modeling was developed for both the solar still. Various thermo-physical properties of the solar still were determined. For the solution of the nonlinear equations, a computer program is being used which is written in FORTRAN-90 language. Runge–Kutta method was applied in this programming technique. Investigation result shows that distillate yield is more as compared to conventional still system.

Maalem et al. [28] used COMSOL Multiphysics software to solve the heat and mass transfer equations of a trapezoidal solar still system. For the modeling purpose, three non-adiabatic walls are being considered. The energy balance equations were solved by the finite element method. The result shows that the temperature curves and condensed water production are in fair agreement with the experimental data. For total production, the deviation from experimental data is less than 7%.

Adhikari et al. [29] done research work for the multistage stacked tray solar still. A computer simulation has been created under steady-state condition. The solar still coupled with solar collector for enhancement of heat transfer. Mathematical modeling has been done for the active-type solar still. Thermo-physical properties have been estimated for the evaluation of heat transfer coefficients. For the measurement of temperatures and monitoring the observations, HP-BASIC language is used. A computer program was written in FORTRAN-77 to predict the steady-state temperature of water, and corresponding yield output. Result shows that the estimated performance of still gives very satisfactory result and can be used to predict the parameters.

Mahendren et al. [30] worked for the numerical analysis of double-slope solar still. A specific enhancement is being done in this still for the enhancement of efficiency. MATLAB software is used for the calculation of various heat transfer coefficients. Complete analysis was done with graphical solutions which were plotted in MATLAB. To show the simulation model Simulink tool box was used. M-files of ASCII text were used for coding in MATLAB language. The application of software, its benefits, and limitation have been listed in Table 2.

4 Conclusion

Based rigorous literature review, it is being observed that solar still is one of the most prominent solar thermal applications. Solar still works on the principle of solar distillation and provides potable water for direct human consumption. It fulfills the needs of the potable water with least expenditure. In this system, raw water gets distilled without any use of the fossil fuel. In this study, a comprehensive review of the various types of the solar still is being presented. In this work, a state-of-the-art review on both experimental work as well as computational work on the solar still is being presented. By properly utilizing the computation study, one can save time of the tedious experimental work. This work will be useful for the scientists, industrialists, and researchers who are working in this field.

References

Sampathkumar K, Senthilkumar P (2012) Utilization of solar water heater in a single basin solar still-an experimental study. Desalination 297:8–19

Panchal HN, Patel N (2017) ANSYS CFD and experimental comparison of various parameters of a solar still. Int J Ambient Energy:1–7

Fathy M, Hassan H, Ahmed MS (2018) Experimental study on the effect of coupling parabolic trough collector with double slope solar still on its performance. Sol Energy 163:54–61

Hind, Banaras (2015) Theoretical investigation of solar still coupled with solar air heater. SSRG Int J Mech Eng (SSRG-IJME) 2(9):0–5

Kumar S (2013) Thermal-economic analysis of a hybrid photovoltaic thermal (PVT) active solar distillation system: role of carbon credit. Urban Clim 5:112–124

Sahota L, Shyam, Tiwari GN (2017) Energy matrices, enviroeconomic and exergoeconomic analysis of passive double slope solar still with water based nanofluids. Desalination 409:66–79

Madhlopa A, Johnstone CM (2011) Computation of solar radiation distribution in a solar still with internal and external reflectors. Sol Energy 85(2):217–233

Badran OO (2007) Experimental study of the enhancement parameters on a single slope solar still productivity. Desalination 209(1–3 SPEC. ISS.):136–143

Gnanadason MK, Kumar SP, Wilson VH, Kumaravel A, Jebadason B (2013) Comparison of performance analysis between single basin solar still made up of copper and GI. Int J Innov Res Sci Eng Technol (IJIREST) 2(7):3175–3183

Singh N (2013) Performance analysis of single slope solar stills at different inclination angles: an indoor simulation. Int J Curr Eng Technol 3(2):677–684

Panchal HN (2015) Enhancement of distillate output of double basin solar still with vacuum tubes. J King Saud Univ Eng Sci 27(2):170–175

Chinnathambi S, Sridharan M (2014) Performance enhancement study on single basin double slope solar still using flat plate collector. Int J Innov Res Sci Eng Technol 3(3):1303–1308

Dimri V, Sarkar B, Singh U, Tiwari GN (2008) Effect of condensing cover material on yield of an active solar still: an experimental validation. Desalination 227(1–3):178–189

Abdallah S, Badran O, Abu-Khader MM (2008) Performance evaluation of a modified design of a single slope solar still. Desalination 219(1–3):222–230

Tripathi R, Tiwari GN (2005) Effect of water depth on internal heat and mass transfer for active solar distillation. Desalination 173(2):187–200

Setoodeh N, Rahimi R, Ameri A (2011) Modeling and determination of heat transfer coefficient in a basin solar still using CFD. Desalination 268(1–3):103–110

Singh A, Mittal MK (2014) Simulation of single slope solar still at different inclinations using CFD. Int Conf Adv Res Innov:512–519

Panchal HN, Shah PK (2011) Modelling and verification of single slope solar still using ANSYS-CFX. Int J Energy Environ 2(6):985–998

Tripathi R, Tiwari GN (2006) Thermal modeling of passive and active solar stills for different depths of water by using the concept of solar fraction. Sol Energy 80(8):956–967

Chaibi MT (2000) Analysis by simulation of a solar still integrated in a greenhouse roof. Desalination 128(2):123–138

Hamadou OA, Abdellatif K (2014) Modeling an active solar still for sea water desalination process optimization. Desalination 354:1–8

Khare VR, Singh AP, Kumar H, Khatri R (2017) Modelling and performance enhancement of single slope solar still using CFD. Energy Procedia 109:447–455

Kumar D, Himanshu P, Ahmad Z (2013) Performance analysis of single slope solar still. Int J Mech Robot Res 3(3):66–72

Thakur AK, Pathak SK (2017) Single basin solar still with varying depth of water: optimization by computational method. Iran J Energy Environ 8:216–223

Gokilavani NS, Prabhakaran D, Kannadasan T (2014) Experimental studies and CFD modeling on solar distillation system. Int J Innov Res Sci Eng Technol 3(9):15818–15822

Ghoneyem A, Ileri A (1997) Software to analyze solar stills and an experimental study on the effects of the cover. Desalination 114(1):37–44

Zerrouki M, Settou N, Marif Y, Belhadj MM (2014) Simulation study of a capillary film solar still coupled with a conventional solar still in South Algeria. Energy Convers Manag 85:112–119

Maalem MS, Benzaoui A, Bouhenna A (2014) Modeling of simultaneous transfers of heat and mass in a trapezoidal solar distiller. Desalination 344:371–382

Adhikari RS, Kumar A, Sootha GD (1995) Simulation studies on a multi-stage stacked tray solar still. Sol Energy 54:317–325

Ali I, Senthilkumar R, Mahendren R (2011) Modelling of solar still using granular activated carbon in matlab. Bonfring Int J Power Syst Integr Circ 1:5–10

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Kumar, D., Pandey, A., Prakash, O., Kumar, A., DevRoy, A. (2019). Simulation, Modeling, and Experimental Studies of Solar Distillation Systems. In: Kumar, A., Prakash, O. (eds) Solar Desalination Technology. Green Energy and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-13-6887-5_6

Download citation

DOI: https://doi.org/10.1007/978-981-13-6887-5_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-6886-8

Online ISBN: 978-981-13-6887-5

eBook Packages: EnergyEnergy (R0)