Abstract

About 60 and 95% of the road network comprised of rural roads in United States and India, respectively. Everyday rural roads are being constructed by the engineers all around the world to meet the traffic needs, for which, the traditional pavement design and construction practices require high-quality materials for fulfillment of construction standards. Quality materials are unavailable or short of supply in many parts of the world. Design engineers are often forced to seek alternatives using substandard materials, commercial construction aids, and innovative design practices to improve the structural support to the pavement structure when weak subgrades are encountered. In this research, results from a series of large-scale laboratory tests on a simulated rural road consisting of a reinforced and unreinforced dense base/sub-base layer overlying weak subgrade were considered. A series of large-scale laboratory testing were conducted on geocell reinforced rural road under traffic loading conditions. The base/sub-base and weak subgrades were prepared at 75 and 30% relative densities, respectively, by pluviation technic in a large steel tank. An equivalent single axle wheel load (ESAL) of 550 kPa was considered which was applied through a circular steel plate using dynamic hydraulic actuator of 100 kN capacity. Several earth pressure cells were placed at the interface of the dense base/sub-base and weak subgrade layers to measure the contact pressure transmitted on to the weak subgrade. Results indicated that the pressures exerted by the traffic loads can be reduced to about 60% by introducing geocell mattress in base/sub-base layers over weak subgrades.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

A low volume road (LVR), also known as rural road in India and farm to market (FM) road in the United States, can be defined as a road in which the average annual daily traffic (AADT) is about 500 commercial vehicles per day (Behrens 1999; Keller and Sherar 2003). (AASHTO) LVRs are defined as roads with 0.7–1 million Equivalent Single Axel Loads (ESALs) for a given performance period (Mallick and Veeraragava 2010). Generally LVRs are designed as paved or unpaved roads, which depend on the purpose and subgrade soil conditions. Unpaved roads are preferred if the subgrade soils are strong. However, the performance of LVRs can be improved by surfacing the unpaved roads (Muench et al. 2004; Pinard 2006). Generally, rural roads consist of either a base/sub-base layers. The thickness of these layers always depends on the support extended by the underlying subgrades.

The total road network of India covers over 4.2 million kilometers, out of which, village and other roads (LVR) share is about 80% (MORTH 2011). It was estimated United States is comprised of about 60% LVRs. The construction, maintenance, and rehabilitation of these roads are a major task and involve about 54% of the total annual investment of transportation systems in USA (Praticò et al. 2011).

The Ministry of Rural Development (MORD) of legislature of India propelled the “Pradhan Mantri Gram Sadak Yojana (PMGSY)”—a Prime Minister’s Rural Road Program in year 2000 to associate with every single climate street all residences with populace more than 500 (250 in bumpy, deserts, and inborn areas) in the primary example. The PMGSY targets incorporate new availability to around 1,78,000 homes including development of around 3,75,000 km of streets separated from overhauling of 3,72,000 km of existing country streets which are in poor condition (Saride and Umashankar 2010; Praticò et al. 2011).

These figures plainly exhibit that the streets are a critical part of the universes’ transportation foundation and economy, in this manner calling for feasible plans and development procedures to guarantee advanced asphalt development (Saride and Umashankar 2010). The execution of the LVRs can be enhanced by embracing appropriate adjustment methods (Bushman et al. 2005; Croft 1967), receiving optional materials and novel development methods, for example, incorporation of geosynthetic support in base/sub-base layers or feeble subgrades (Little 1995).

Fifty years prior, out of the blue, geocell support for asphalt applications were begun by US Army Corps of Engineers for enhancing the bearing limit of inadequately evaluated sand by utilizing it as a parallel control (Webster 1979). Sidelong control, expanded bearing limit, and tensioned layer impact are primary support instruments for geocell fortification (Giroud and Noiray 1981; Dash et al. 2001; Han et al. 2008). Pokharel (2010) examined substantial scale cyclic stacking tests on geocells and watched that the geocells have enhanced the quality, expanded the level of versatile twisting and life of the unpaved street segments over frail subgrade. Saride et al. (2013, 2015) watched that the perpetual misshapenings were diminished by 8 overlap, and TRBs were expanded to 45 for the instance of sleeping cushion estimate h/D = 1, b/D = 4 against the unreinforced bed at 5% plate settlement under rehashed movement stacking.

Han et al. (2008) detailed by that the situation of geocell from the surface of stacking is likewise urgent. In opposite, the arrangement profundity of geocell ought to be kept up at around 1–5% of the width of the stacking zone in static load tests as seen in Dash et al. (2001) and Sitharam and Saride (2005).

However, literature study reveals that the quantification of performance of the geocell reinforced granular base/sub-base layers in terms of reduction in contact pressure over weak subgrades supporting LVRs has not well documented. In this study, an attempt has been made to quantify the contact stress reduction over weak subgrades due to provision of geocell mattress in base/sub-base layers through dynamic earth pressure cells.

2 Experimental Program

In this study, the dry sand placed at its 30% relative density has been considered as weak subgrade supporting low volume roads. A granular base/sub-base of the LVR was formed, over the weak subgrade, at 75% relative density of sand.

Dry sieve analysis gave the soils distribution of particles as seen in Fig. 1 and is stated as poorly graded sand denoted by SP according to the Unified Soil Classification System (USCS).

The physical properties of sand such as G, emax and emin were determined according to the ASTM standards and given as 2.63, 0.74, and 0.51. The angle of shearing resistance of sand at its 75% relative densities was determined to be 37° by conducting shear tests on plain sand in a box with 100 mm × 100 mm × 30 mm sizes.

Geocell mattress is made of ultrasonically Welded high density polyethylene (HDPE) Which is strong, light weight, 3D cellular confinement system. These strips were placed and spread on the weak sand subgrade to prepare a geocell reinforced granular (sand or aggregate) mattress. The geocell is manufactured from a polymer of HDPE material with a density ranging between 0.935 and 0.965 g/cm3 having a weld at regular intervals of 356 mm which is used in the present study. The properties of the geocells are listed in Table 1.

3 Test Setup

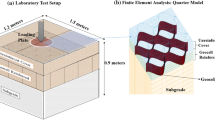

Weak subgrade overlying reinforced stiff geocell reinforced sand beds with 30 and 75% relative density were prepared in a tank. The inner dimensions of test tank are 1 m × 1 m × 1 m (length × width × height). To apply a repeated traffic loading on the sand subgrades, a rigid steel plate of diameter 150 mm and thickness 15 mm was used in the experiment. The dimension of the tank and diameter of loading plate were determined based on the literature. Chummar (1972) has found that the failure wedge, stretched around 2–2.5D on either side of the footing and to a depth of around 1.1D from the bottom of the footing which is below footing plate on a sand bed, where D is the diameter of the footing. Edil et al. (2009) were adopted similar kind of test tank and plate diameter in their laboratory experiments on geosynthetic reinforced pavements. The schematic of the test bed and experimental setup used in the present study has been shown in Figs. 2 and 3.

Strain-type soil earth pressure transducers were used to check the boundary effects on the experimental results from reinforced test beds. The pressures were measured during the repeated load tests by pacing them at the boundaries of the tank. Minimal pressures (less than 1% of the applied pressure) were recorded confirming the influence of the boundary on the test results is negligible. Loading was given by graphical user interfaced multi-purpose test software along with the help of hydraulic power unit, hydraulic service manifold, and sophisticated double acting linear dynamic 100 kN capacity actuator which is attached to a 3.5 m high, 200 kN capacity reaction frame.

4 Testing Procedure

All figures and tables shall be numbered sequentially and cited with discussion in the main body of the paper.

4.1 Sand Bed Preparation

Sand raining or sand pluviation is a technic used to maintain the relative density of the sand in the test tank. The subgrade was prepared with sand placed at 30% relative density until the height H1 in all the tests. A 75% relative density of sand was used as a granular base/sub-base layer over the weak subgrade to a thickness of H2 in all the tests. The height, H2, depends on the height of the geocell mattress, h and the depth of placement of geocell mattress from surface, u and sand cushion maintained between the dynamic earth pressure cells and the mattress. By taking samples at different depths during the pluviation, the density of the test bed was frequently monitored. The densities were well within the range of 2% error. A total of nine (9) dynamic earth pressure cells were placed right at the interface of weak subgrade and stiff granular base/sub-base layer to measure the pressure transmitted to the subgrade through the base/sub-base layer during the repeated load test. Out of nine earth pressure cells, five were placed right at the center line of the loading across the width of the base/sub-base layer. Rest of the four earth pressure cells were placed at four boundaries of the test tank to measure the pressure transmitted to the boundaries.

After filling the test tank with the sand up to the desired height, the fill surface was leveled and the loading plate was placed on a predetermined alignment such that the loads from the actuator applied would be transferred concentrically to the footing. To facilitate this, a recess was made into the loading plate at its center to accommodate a ball bearing through which vertical loads were applied to the plate. In the case of reinforced beds, upon ceasing the pluviation at predetermined depth, the geocell was positioned and stretched on the leveled subgrade and continued the sand pluviation to fill the geocell mattress with mentioned relative density.

4.2 Repeated Load Tests (RLT)

The repeated load tests were completed with a most extreme heap of 550 kPa (ESAL) and at least 55 kPa (10% of the greatest weight) utilizing a PC controlled servo pressure driven actuator with a persistent haversine stacking design as appeared in Fig. 4 at a recurrence of 1.0 Hz as portrayed in Saride et al. (2015) and Rayabharapu and Saride (2019).

The loading was picked such that it repeats the moving activity on the asphalt. Multi-reason test product programming was set up to control and gain the connected load information and in addition the distortion information. The stacking example of the repeated load test and relating contact pressures is found in Figs. 4 and 5.

A typical Contact pressure with time and number of cycles is shown in Fig. 5. The pressures are obtained from the pressure cells placed at the interface for unreinforced and geocell reinforced bed under cycling loading conditions. It can be noticed that the pressures are little higher for the initial loading cycles which are considered to be the initial data acquired to set, while their magnitude attenuates thereafter.

To verify the efficiency of the geocell layers in the base/sub-base layers, a series of repeated load model tests were conducted to reduce the stresses coming on to the weak subgrade as listed in Table 2. The height and width of geocell mattress are expressed in terms of normalized ratios with respect to the diameter of the loading plate as h/D and b/D, respectively. The model tests include unreinforced tests, single geocell layers with different sizes (width and height) with respect to the plate diameter.

5 Results and Discussion

The pressures at the subgrade have reduced as the amount of geocell reinforcement increases, against the unreinforced subgrade for which pressures are higher. Pressure cells are placed at a distances of 1, 1.5. 2.0 times the width of the loading plate on either sides of the loading plate at the interface.

To quantify the reduction in contact pressures and the efficacy of geocell, the contact pressures of each configuration at 1, 5, 50, 75, and 100 cycles are considered and presented from series B of testing in Figs. 6, 7 and 8. It is clearly evident that the contact pressures of geocell reinforced beds are reducing with increase in the geocell width. The pressures reduced from 160 kPa in case of h/D = 1.33, b/D = 4 to almost 100 kPa in case of h/D = 1.33, b/D = 2 which is a reduction of about 40% between the least and highest reinforced case in this series.

Figures 6, 7, and 8 show the variation of the pressures transmitted on to the subgrade with distance from center line corresponding to the geocell reinforced sections of h/D = 1.33 and b/D = 2, 3.5, 4 for various cycles, respectively. From the figures, it is evident that, the pressures transmitted on to the subgrade with distance from center line in a geocell reinforced are reduced compared to the unreinforced for the same applied pressure. In reinforced beds as the width of the geocell reinforcement increases, the pressure transmitted on to the subgrade is reduced at the center and the pressure transmitted on to the either sides of the loading plate increased. This is because as the width of the reinforcement increases number of cells in the geocell increases which yields to more all-round confinement preventing the lateral spreading of the infill material.

Hoop stresses within the geocell walls and earth pressures in the adjacent cells are mobilized when the vertical loads are applied which reduces the lateral deformation of the infill material. This increases the stiffness and the load deformation behavior of the soil. The soil geocell layer with increased stiffness acts as a stiff mat resulting in the vertical pressures distribution spreads across the area of the subgrade soil by redistributing the applied pressures away from the center and reducing the pressures transferred at the center below the loading plate.

The contact pressures of each configuration from series C as discussed earlier are presented in Figs. 9, 10, 11 and 12. The contact pressures of geocell reinforced beds are reducing with increase in the geocell height. The pressures reduced from 350 kPa in case of b/D = 4, h/D = 0.5 to almost 100 kPa in case of b/D = 4, h/D = 1.33 which is a reduction of about 70% between the least and highest reinforced case in this series.

Figs. 9, 10, 11 and 12 show the variation of the pressures transmitted on to the subgrade with distance from center line corresponding to the geocell reinforced sections of b/D = 4 and h/D = 0.5, 0.67, 1.0, 1.33 for various cycles. From the figures, it is seen that, as the height of the geocell reinforcement increases, the pressure transmitted on to the subgrade is reduced. The pressures transmitted on to the subgrade with distance from center line in a geocell reinforced bed are lesser compared to the unreinforced for the same applied pressure. The pressures transmitted are higher for lesser height of the geocell reinforced beds compared to the widths of the geocell as the heights of the dense bed are lesser by which the pressure is directly transferred below the center plate as in case punching failure. The pressures transmitted on to the either sides of the loading plate increased with heights. This is attributed to the flexural rigidity of the geocell reinforced beds for higher heights resulting in transmitting less pressure at the center and more pressures away from the center by redistributing the applied pressures on to the subgrade. Vertical loading of the geocell reinforced sections creates a semi-rigid slab or beam effect. This distributes loads evenly, reduces settlement, and reduces surface degradation resulting in less rutting, potholes, and distortions, means less wear and tear on vehicles, tires, and drivers.

To further quantify the contact pressures of the beds under repeated loading, a parameter contact pressure reduction (CPR), expressed in percentage, for different cases studied as per Table 2 is introduced. CPR is the ratio between contact pressure of the unreinforced bed and geocell reinforced bed difference to that of the unreinforced bed for a pressure applied. Hence, CPR for the particular pressure applied can be expressed as:

Results from test series A show that the unreinforced test beds could not sustain any number of loading cycles before they reach the prescribed plate settlement of 20%. Hence, the pressures in increments are applied until its failure and the pressure corresponding are noted. In all cases, the bed failed even before reaching the pressure applied on the reinforced cases, i.e., 550 kPa. The data are then extrapolated to get the contact pressure on the subgrade for all the unreinforced cases for the corresponding pressure applied.

All contact pressure reduction (CPR) were analyzed from the series of experiments. The variation of CPR with b/D ratios and h/D ratios for different geocell configurations from the testing considered in this study of series B and series C are demonstrated in Figs. 13 and 14.

From Fig. 13, the pressures transmitted on to the subgrade of an unreinforced and reinforced bed at the center for a particular pressure applied are considered. CPR is calculated for varying b/D’s and given as 29, 35 and 50%, respectively, for h/D = 1.33, b/D = 2, 3, 4. From the figure, it is clear that the maximum reduction in pressures coming on to the subgrade is 50% in the case of h/D = 1.33, b/D = 4 case of geocell reinforcement.

From Fig. 14, the pressures transmitted on to the subgrade of an unreinforced and reinforced bed at the center for a particular pressure applied are considered. CPR is calculated for varying h/D’s and given as 23, 25 58 and 50%, respectively, for b/D = 4, h/D = 0.5, 0.67, 1.0, 1.33. From the figure, it is clear that the maximum reduction in pressures coming on to the subgrade is 58% in the case of b/D = 4, h/D = 1.0 case of geocell reinforcement.

Hence, it can be summarized that the geocell of sufficient size (b) and thickness (h) will provide a higher contact pressure reduction for a given level of traffic loading conditions.

Further study is required to understand the optimal benefits from the critical geocell geometry. It is also important to determine the depth of this kind of reinforcement and number of layers of reinforcement for optimum performance.

6 Conclusions

From a large-scale cyclic model tests on unreinforced and geocell reinforced beds, following conclusions can be drawn:

-

1.

Geocell can be used as reinforcement in pavement subgrade layers to increase the stiffness of the subgrade.

-

2.

Contact pressures of geocell reinforced beds reduced with increase in the geocell widths. The pressures reduced from 160 kPa in case of h/D = 1.33, b/D = 4–100 kPa in case of h/D = 1.33, b/D = 2 which is a reduction of about 40% between the least and highest reinforced case.

-

3.

Contact pressures of geocell reinforced beds reduced with increase in the geocell height. The pressures reduced from 350 kPa in case of b/D = 4, h/D = 0.5–100 kPa in case of b/D = 4, h/D = 1.33 which is a reduction of about 70% between the least and highest reinforced case.

-

4.

Contact Pressure Reduction (CPR) for varying b/D’s are 29, 35, and 50%, respectively, for h/D = 1.33, b/D = 2, 3, 4.

-

5.

Contact Pressure Reduction (CPR) for varying h/D’s are 23, 25, 58, and 50%, respectively, for b/D = 4, h/D = 0.5, 0.67, 1.0, 1.33

-

6.

The maximum reduction in pressures coming on to the subgrade is 58% in the case of b/D = 4, h/D = 1.0 case of geocell reinforcement. Hence, it is important to choose an optimum size geocell for higher structural support for a given traffic loading system.

-

7.

Further systematic study is required to completely understand the geocell material in pavement layers such as base and sub-base layers with aggregate infill.

References

Behrens ILC (1999) Overview of low-volume roads. Transportation research record 1652. Transportation Research Board, pp 1–4

Bushman WH, Freeman TE, Hoppe EJ (2005) Stabilization techniques for unpaved roads, vol 1936. Transportation Research Board, pp 28–33

Chummar AV (1972) Bearing capacity theory from experimental results. J Geotech Eng ASCE 98(12):1311–1324

Croft JB (1967) The structures of soils stabilized with cementitious agents. Eng Geol 2(2):63–80

Dash SK, Krishnaswamy NR, Rajagopal K (2001) Bearing capacity of strip footings supported on geocell-reinforced sand. Geotext Geomembr 19(4):235–256

Edil TB, Fratta D, Shuettpelz CC (2009) Development of testing methods to determine interaction of geogrid-reinforced granular material for mechanistic pavement analysis. Wisconsin DOT and FHWA project report

Giroud JP, Noiray L (1981) Geotextile-reinforced unpaved road design. J Geotech Eng Div 107(GT9):1233–1254

Han J, Yang XM, Leshchinsky D, Parsons RL (2008) Behavior of geocell-reinforced sand under a vertical load. J Transp Res Board (2045):95–101

Keller G, Sherar J (2003) Low-volume roads engineering—best management practices field guide. USDA, Forest Service

Little ND (1995) Stabilization of pavement subgrades and base courses with lime. Kendall/Hunt Publishing Co., Dubuque, Iowa

Mallick RB, Veeraragava A (2010) Sustainable pavements in India—the time to start is now. New Build Mater Constr World (NBM&CW) Mag 16(3):128–140

Ministry of Road Transport and Highways (MORTH) (2011) Annual report on Indian roads 2010–11. Government of India

Muench ST, White GC, Mahoney JP, Pierce LM, Sivaneswaren N (2004) Long-lasting low-volume pavements in Washington state. In: International symposium on design and construction of long lasting asphalt pavements. International Society for Asphalt Pavements, Auburn, AL, pp 729–773

Pinard M (2006) New approaches to sustainable provision of low volume sealed roads. In: International workshop, Bamako, Mali, 18–19 Jan 2006

Pokharel SK (2010) Experimental study on geocell-reinforced bases under static and dynamic loading. Ph.D. thesis, University of Kansas, USA

Praticò F, Saride S, Puppala AJ (2011) Comprehensive life cycle cost analysis for the selection of subgrade stabilizers for better performance of low volume roads. Transportation research record 2204, TRB, National Research Council, Washington D.C., pp 120–112

Rayabharapu VK, Saride S (2019) Geocell reinforced dense sand bases overlying weak sand sub-grades under repeated loading. In: Ground improvement techniques and geosynthetics, lecture notes in civil engineering, vol 14. pp 285–294

Saride S, Umashankar B (2010) Towards green pavements in India. In: First US-India workshop on global geoenvironmental engineering challenges, New Delhi, India, 7 Nov 2010

Saride S, Vijay KR, Suraj V, Anand JP (2013) Repeated load tests on geocell reinforced sand subgrades. In: Proceedings of the geosynthetics international conference, Long Beach, CA, vol 3, no 4, pp 537–549

Saride S, Rayabharapu VK, Vedpathak S (2015) Evaluation of rutting behaviour of geocell reinforced sand subgrades under repeated loading. Indian Geotech J 45(4):378–388

Sitharam TG, Saride S (2005) Behaviour of embedded footings supported on geocell reinforced foundation beds. ASTM Geotech Test J 28:452–463

Webster SL (1979) Investigation of beach and trafficability enhancement using sand-grid confinement and membrane reinforcement concepts. Report GL-79-20, US Army Engineer Waterways Experiment Station, Vicksburg, MS, USA

Acknowledgements

The authors would like to express their appreciation to STRATA Geosystems India Pvt. Ltd. for providing the geocell material for this research.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Rayabharapu, V.K., Saride, S. (2019). Contact Pressure Distribution in Geocell Reinforced Rural Roads. In: Sundaram, R., Shahu, J., Havanagi, V. (eds) Geotechnics for Transportation Infrastructure. Lecture Notes in Civil Engineering , vol 29. Springer, Singapore. https://doi.org/10.1007/978-981-13-6713-7_31

Download citation

DOI: https://doi.org/10.1007/978-981-13-6713-7_31

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-6712-0

Online ISBN: 978-981-13-6713-7

eBook Packages: EngineeringEngineering (R0)