Abstract

In this article, energetic and exergetic analyses of a natural gas-fueled solid oxide fuel cell (SOFC) and organic Rankine cycle (ORC)-integrated power generation system are presented. In the topping, SOFC cycle of the proposed power generation system, anode channel as well as cathode channel recirculation has been done. Toluene has been used as a working fluid in the ORC. Influence of major operating and design parameters, viz. current density of SOFC, cell temperature on the performance of the proposed system has been examined. Results show that maximum energetic and exergetic efficiencies of the proposed power generation are found to be 67.06 and 58.17%, respectively.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Conventional fossil-fired power plant yields lower efficiency and emits a huge amount of greenhouse gases. Nowadays, focus has been given on developing new and renewable power plants having higher energy efficiency with lower environmental impact. In that context, high-temperature fuel cells, viz. solid oxide fuel cell (SOFC) and molten carbonate fuel cell (MCFC) can be considered to be a suitable alternative to conventional coal-fired power plants specifically in small-scale distributed power generation systems. These fuel cells emit lesser carbon dioxide and exhibit higher electrical efficiency. Organic Rankine cycle (ORC) is suitable for generating power by utilizing low-temperature waste heat. The ORCs are similar to the conventional Rankine cycles having organic fluids as a working fluid. In previous years, several SOFC-integrated thermodynamic models have been developed and analyzed. Akkaya et al. [1] modeled and analyzed methane-fed tubular SOFC module exergetically. Mahmoudi and Khani [2] proposed an indirect incorporation of methane-fueled SOFC with a gas turbine cycle and a pressurized warm water generation system. Meratizaman et al. [3] proposed a methane-driven SOFC-GT power plant in the range of 11–42.9 kW for household application. Akikur et al. [4] modeled a solar powered SOFC-integrated cogeneration system. Al-Sulaiman et al. [5] studied the performance analysis of a tri-generation system driven by methane-fueled SOFC. In this paper, an attempt has been made to integrate SOFC with ORC. Methane-fueled SOFC-based power generation system with bottoming ORC has been proposed. As SOFC is the major power production component of the system, the influence of its major designing and operating parameters on thermodynamic performance of the designed power generation system have been conducted.

2 System Description

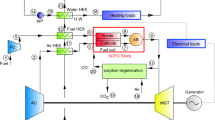

Schematic representation of the proposed system is shown in Fig. 1. It is comprised of a topping SOFC module with a bottoming ORC. In the topping SOFC cycle of the proposed system, anode channel as well as cathode channel recirculation have been done. Compressed natural gas is first heated by a heat exchanger (HEX1) and mixed with the recirculated stream before feeding to the SOFC anode channel. On the other hand, heated compressed air is supplied to the SOFC cathode channel. Due to the chemical and electrochemical reactions, chemical energy stored at the natural gas is transformed into electrical energy at the SOFC unit. After recirculation, unutilized methane from the SOFC unit is completely burned at the after burner (AB) unit. Heat exchangers, viz. HEX1 and HEX2 are used to preheat the compressed methane and air, respectively, by using the flue gas from the AB exhaust. Waste heat from the heat recovery vapor generator (HRVG) unit is utilized to operate ORC. Toluene has been selected as working fluid at the ORC.

3 Thermodynamic Modeling

SOFC considered for the system analysis is of internal reforming type. Three simultaneous reactions are supposed to be taken place, viz. steam reforming, water gas shift, and electrochemical reaction. These reactions are shown below.

Reversible cell voltage is obtained by considering Nernst equation [1]

Cell voltage (Vc) is determined by deducting the total voltage losses from the Nernst voltage as follows

Three major voltage losses developed in the SOFC cell are ohmic loss (VOHM), activation loss (VACT), and concentration loss (VCONC). Total voltage losses developed in the cell are the summation of these three losses.

Ohmic loss is determined as follows [6]

where

Activation over-potential is calculated as follows [7, 8]

Concentration loss is determined as follows [9, 10]

Current flow during an individual cell is estimated as

where Acell represents cell area.

Power developed in a single SOFC stack is calculated as follows

where Ncell is the quantity of cells in a SOFC stack

Power achieved by the SOFC module is estimated as follows

Where NSOFC is the total number of stacks in the SOFC module

Power consumed by compressors is determined as follows

Power consumed by organic liquid pump (OLP) is calculated as follows

The power output of organic vapor turbine (OVT) is given by:

4 Exergy Analysis

Exergy associated with any stream consists of physical exergy (Exphy) and chemical exergy (Exche). It is written as follows

Exergy destruction (ExD) taking place in any system component, during a process, can be calculated as [11]

Exergy destruction of any component of the proposed system is calculated as a function of incoming fuel exergy. It is represented as follows

Exergy loss is determined as a function of incoming fuel exergy. It is shown as follows

5 Performance Parameters

The total power developed from the system is estimated as

where WAux denotes auxiliary power consumption and is estimated as follows

The net energetic efficiency of the designed power plant can be written as

Exergetic efficiency of the proposed system is determined as

6 Results and Discussions

Base case input parameters are shown in Table 1. System performance at base case is given in Table 2. In this section, the effect of major operating and designing plant parameters, viz. SOFC current density and cell temperature (Tcell) on major plant performance parameters has been examined.

Figure 2 depicts the effect of SOFC current density from 1000 to 9000 A/m2 on WSOFC, WOVT, and WNET. It is seen from Fig. 3 that with the increase of current density, WSOFC first increases, then reaches an optimal point, then decreases. Optimum power of SOFC found to be 280 kW at a current density of 6000 A/m2. With the increase of current density, fuel consumption at the SOFC unit increases. Thus, WSOFC increases with the increase of current density. It is also found that, WOVT increases with the increase of current density. Increase of fuel and air consumption at the SOFC unit results in higher molar flow rate of flue gas. It results in higher amount of heat recovery in the HRGH unit. Thus, WOVT also increases. It is observed that WNET first increases, then reaches an optimal point, then decreases. Optimum Wnet is found to be 307 kW at a current density of 6000 A/m2.

Figure 3 illustrates the effect of SOFC current density in the operating range of 1000–9000 A/m2 on energetic and exergetic efficiency of the power plant. It is observed that as the SOFC current density rises, energetic as well as exergetic efficiency decreases. As the current density increases, energetic efficiency as well as exergetic efficiency of the power plant decreases due to drop in cell voltage. Highest energetic and exergetic efficiencies of the power plant are estimated to be 67.05 and 58.17%, respectively.

Figure 4 depicts the effect of Tcell on WSOFC, WOVT, and WNET. It is found that WSOFC and WNET reduce with the rise of Tcell. As the voltage decreases with the rise of Tcell, WSOFC and WNET also decreases. Maximum WNET is obtained to be 168.76 kW at Tcell = 700 °C. Effect of Tcell does not have much effect of the performance of WOVT.

Figure 5 illustrates the influence of Tcell on energetic and exergetic efficiency of the power plant. Performance of the system has been observed for the cell temperature in the range of 700–900 °C. It is found that as the Tcell increases, energetic as well as exergetic efficiency decreases. Drop of efficiency of the system is highly attributed to the decrease of WNET. Thus, as the cell temperature increases, both energetic efficiency and exergetic efficiency of the system decreases.

Useful exergy, total exergy destruction, and stack loss of the integrated system with respect to total fuel exergy input have been depicted in the pie chart as shown in Fig. 6. The useful exergy, total exergetic destruction, and stack loss of the proposed power plant are found to be 53.8, 44.92, and 1.29%, respectively.

7 Conclusion

In this paper, a methane-fueled SOFC and ORC incorporated power plant is modeled and analyzed. Performances of the proposed system are found to be influenced by the major operating and design parameters, viz. current density of SOFC and cell temperature. The main conclusions are as follows:

-

As the current density of SOFC increases, WNET first increases, then reaches an optimal point, then decreases. Optimum WNET is found to be 307 kW at a current density of 6000 A/m2.

-

Highest energetic and exergetic efficiency of the power plant are found to be 67.05 and 58.17%, respectively.

-

Increase in cell temperature results in decrease of both energetic efficiency as well as exergetic efficiency of the system.

-

The useful exergy, total exergetic destruction, and stack loss of the proposed power plant are found to be 53.8, 44.92, and 1.29%, respectively.

References

Akkaya AV, Sahin B, Erdem HH (2008) An analysis of SOFC/GT CHP system based on exergetic performance criteria. Int J Hydrogen Energy 33:2566–2577

Mahmoudi SMS, Khani L (2016) Thermodynamic and exergoeconomic assessments of a new solid oxide fuel cell-gas turbine cogeneration system. Energy Convers Manag 123:324–337

Meratizaman M, Monadizadeh S, Amidpour M (2014) Techno-economic assessment of high efficient energy production (SOFC-GT) for residential application from natural gas. J Nat Gas Sci Eng 21:118–133

Akikur RK, Saidur R, Ping HW, Ullah KR (2014) Performance analysis of a co-generation system using solar energy and SOFC technology. Energy Convers Manag 79:415–430

Al-Sulaiman FA, Dincer I, Hamdullahpur F (2010) Energy analysis of a trigeneration plant based on solid oxide fuel cell and organic Rankine cycle. Int J Hydrogen Energy 35:5104–5113

Bossel UG (1992) Final report on SOFC data facts and figures. Swiss Federal Office of Energy

Calise F, Palombo A, Vanoli L (2006) Design and partial load exergy analysis of hybrid SOFC-GT power plant. J Power Sour 158(1):225–244

Roy D, Ghosh S (2017) Energy and exergy analyses of an integrated biomass gasification combined cycle employing solid oxide fuel cell and organic Rankine cycle. Clean Technol Environ Policy 19(6):1693–1709

Chan SH, Khor KA, Xia ZT (2001) A complete polarization model of a solid oxide fuel cell and its sensitivity to the change of cell component thickness. J Power Sourc 93(1–2):130–140

Pirkandi J, Ghassemi M, Hamedi MH, Mohammadi R (2012) Electrochemical and thermodynamic modeling of a CHP system using tubular solid oxide fuel cell (SOFC-CHP). J Clean Prod 29–30:151–162

Kotas TJ (1985) The exergy method of thermal plant analysis. Butterworths, London

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Roy, D., Samanta, S., Ghosh, S. (2019). Energetic and Exergetic Analyses of a Solid Oxide Fuel Cell (SOFC) Module Coupled with an Organic Rankine Cycle. In: Saha, P., Subbarao, P., Sikarwar, B. (eds) Advances in Fluid and Thermal Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-6416-7_2

Download citation

DOI: https://doi.org/10.1007/978-981-13-6416-7_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-6415-0

Online ISBN: 978-981-13-6416-7

eBook Packages: EngineeringEngineering (R0)