Abstract

Stabilised rammed earth is receiving renewed attention by researchers across the globe due to its improved strength and durability vis-a-vis un-stabilised rammed earth. Rammed earth walls are predominantly subjected to compressive loading and occasionally to lateral loads. The present study focuses on evaluating shear bond strength of cement-stabilised rammed earth using triplet specimens in dry and wet conditions. Three types of bonding techniques were used while casting the specimens and tested at three normal stress levels. The influence of bonding techniques, moisture content and normal stress levels on the shear bond strength is discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Rammed earth walls are constructed by compacting processed soil–sand mixture with or without stabiliser in layers within a rigid formwork. In general, un-stabilised rammed earth walls are thick and bulky in comparison with brick or stone masonry walls. In order to improve the strength and durability properties of rammed earth, stabilising agents such as cement and lime are added to the soil–sand mixture. Cement-stabilised rammed earth (CSRE) walls have an increased load carrying capacity and are relatively slender. CSRE construction activity has witnessed a steady growth over the last decade, and several structures have been built worldwide. The renewed interest in earth-based materials for construction has necessitated the need for understanding their mechanical behaviour.

CSRE walls, like every other wall system, transmit loads from the overlying beam–slab system to the underlying support system (e.g. foundation). Hence, CSRE walls are primarily subjected to in-plane compressive loading. However, CSRE walls are subjected to in-plane shear loading and out-plane bending during seismic events, wind loading during a hurricane, flooding, uneven settlement of foundation etc. During the in-plane shear action on CSRE walls, shear stresses develop along the layer interface present in CSRE elements. A weak layer interface in rammed earth leads to a sliding shear failure of CSRE wall. Hence, knowledge of joint shear strength, its behaviour under normal stresses, is essential for the design of load-bearing CSRE wall elements. Techniques to improve the joint shear strength of CSRE may also be required and needs to be explored.

Until now, research studies have largely focused on understanding the mechanical behaviour of CSRE under compressive loading. Studies on the joint shear behaviour of CSRE have been limited. Cheah and da Silva (2007) conducted an experimental study to assess the shear strength of cement stabilised rammed earth reinforced with flax fibres. The test was conducted according to ASTM E519-00. Diagonal CSRE panels of size 1.2 m × 1.2 m were cast and subjected to compressive loading along the diagonal. Shear strength of CSRE was computed from the failure load using the formula suggested by ASTM E5519-00.

Cheah et al. (2012) assessed the performance of existing shear test methods for evaluating the shear strength of cement stabilised rammed earth reinforced with natural fibres. Cheah et al. (2012) considered two test methods: (i) triaxial compression test (ii) masonry triplet test. It was found that the shear strength of CSRE obtained from these two experimental methods was higher than the value of shear strength suggested by existing building codes. Among the two test methods, Cheah et al. (2012) advocated triaxial compression test method for determining the shear strength of CSRE rammed earth material. Nanjunda Rao et al. (2011) assessed the shear strength of CSRE parallel and perpendicular to compacting layers using shear box test apparatus. They have reported that shear strength increases with increase in normal stress in case of shear load parallel to compacting layers. However, there is no influence of normal stress on shear strength in case of shear load perpendicular to compacting layers.

However, several studies exist in literature (Ehsani et al. 1997; Tomaževič 2009; Roca and Araiza 2010; Mojsilović 2012; Alecci et al. 2013; Pavan and Nanjunda Rao 2015) that have adopted triplet test method for assessing the brick–mortar interface shear strength of masonry. Masonry triplet test is best suitable for determining the joint shear strength of both, brick–mortar interface strength of masonry and the interface joint shear strength of rammed earth. Joint shear strength of rammed earth is essential to avoid sliding shear failure mode. Shear strength of rammed earth material may be determined by either, geotechnical trial-axial compression test or the ASTM E519-00 diagonal shear-compression test.

The present study aims at assessing the joint shear strength of CSRE and the influence of normal stress on the joint shear strength of CSRE by adopting masonry triplet test protocol. In addition, three bonding techniques are explored to determine the shear strength of rammed earth joints. The combined influence of the each of these bonding techniques in the presence of normal stress on the joint shear strength of CSRE in wet and dry condition is explored in this study.

2 Experimental Program

2.1 Characteristic Studies on Materials and Mix Proportion

Locally available red loamy soil and river sand were used in preparation of rammed earth test specimens. The particle size distribution for soil was determined (IS 2386, Part I) to obtain sand, silt and clay size fraction of the soil. This information is essential for reconstituting the soil by adding sand to bring the clay content in the soil within the optimum range. Figure 6.1 shows grain size distribution of soil and sand used in the present study. The clay, silt and sand sized fraction in the soil were about 43, 15 and 42%, respectively. Hence, soil to sand ratio of 1: 1.8 was adopted so that the clay content in the reconstituted soil was about 15%. Ordinary Portland Cement conforming to Indian Standard (IS 8112) was used as the stabiliser for rammed earth and also in cement slurry used between rammed earth layers for few bonding techniques. The casting moisture content was 12.5% (based on optimum moisture content and maximum dry density relationship obtained through standard proctor test), and the dry density targeted was 1850 kg/m3 for which the specimens were cast with wet density of 2080 kg/m3.

2.2 Preparation of Test Specimens

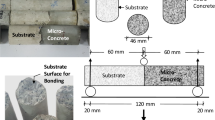

Triplet specimens similar to that widely used in evaluating the masonry shear strength were used in the present study. The size of the specimens was 230 mm × 230 mm × 75 mm and was cast in three layers of equal thickness. Figure 6.2 shows the dimensions of the triplet specimen. The specimens were cast in a battery of stiff wooden moulds. Three types of bonding techniques, namely (a) making conical dents on freshly made layer before casting the next layer (Tri-A), (b) applying a coat of fresh cement slurry (Tri-B) and (c) combination of both ‘A’ and ‘B’ (Tri-C) were examined. Figure 6.3 shows casting of the specimen using stiff wooden mould. The specimens were demoulded after 24 h of casting and cured under wet burlap for 28 days.

2.3 Testing of Specimens

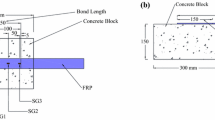

The rammed earth triplet specimens were tested in both dry condition (28 days burlap cured specimens stored inside the laboratory for four weeks prior to testing) and wet condition (28 days burlap cured specimens stored inside the laboratory for four weeks and soaked in water for two days prior to testing). The triplet specimens were tested using strain controlled material testing system where the required levels of pre-compressions (0.05, 0.3 and 0.9 MPa) perpendicular to the rammed earth layers were applied through screw jacks. Figure 6.4 shows the schematic of the experimental setup. The extreme layers were firmly supported at the base, and the longitudinal force (parallel to the joints) was applied on middle layer which was free to deform. The longitudinal displacement in the middle layer was recorded using LVDT. The moisture content in the specimens at the time of testing was determined and is reported in Sect. 6.3.

3 Results and Discussion

The results of the experimental investigations are presented in terms of shear strength and deformation for various types of bonding between rammed layers in dry and wet conditions. The curves presented are for average of four test specimens. As mentioned in earlier section, the moisture content in the specimens at the time of testing was determined. For CSRE triplet specimens in dry condition, the average moisture content was found to be about 4%, and in the wet condition, the moisture content was found to be about 12%. The influence of pre-compression normal to the rammed layers on the shear strength is also discussed. Figures 6.5, 6.6 and 6.7 presents the load versus displacement response of CSRE triplet specimens in dry condition for various values of pre-compression for three different bonding techniques discussed earlier. Figures 6.8, 6.9 and 6.10 presents the load versus displacement response of CSRE triplet specimens in wet condition for various values of pre-compression for three different bonding techniques. From the above figures, it can be observed that at low values of pre-compression (0.05 MPa) there is no significant influence of different bonding techniques on the shear strength of the triplet specimen in both dry and wet conditions. However, it can be seen that shear strength in the dry condition is more than in the wet condition by about 60–90% for the case of triplet specimens with only fresh cement slurry between rammed layers for all the three values of pre-compression considered in the present study. From Fig. 6.11, it can be observed that in the dry condition for pre-compression values greater than 0.05 MPa, the use of fresh cement slurry has enhanced the shear strength of the triplet specimens. The average value of cohesion (c) in dry condition is 0.781 MPa, and the friction angle (ϕ) ranges between 26.2° and 49.2°. In Fig. 6.12, it can be observed that in the wet condition for all the pre-compression values there is no significant influence of bonding techniques on the shear strength of triplet specimens. The value of cohesion (c) in wet condition is about 0.39 MPa, and the friction angle (ϕ) is about 39.2°. In general, the stiffness of the triplet specimen increases with increase in pre-compression in both dry and wet state.

The failure patterns of CSRE triplet specimens are shown in Fig. 6.13. In the case of Tri-A specimens which had only dents for bonding between rammed layers, the failure was essentially along the interface. However, in the case of specimens (Tri-B and Tri-C) with cement slurry only and both dents and cement slurry as bonding between rammed layers, there was material failure in the middle portion of the specimen indicating that shear strength of interface was more than that of the material.

4 Conclusions

Shear triplet specimen test is simple and commonly used procedure to evaluate shear bond strength of brick–mortar interface in masonry and this test procedure can be effectively used to understand the interface shear strength between rammed earth layers. The effect of various bonding techniques on shear bond strength depends on moisture content of the specimen at the time of testing. Amount of pre-compression applied normal to the interfacial layer influences the shear bond strength and stiffness of the CSRE triplet specimens.

References

Alecci V, Fagone M, Rotunno T, De Stefano M (2013) Shear strength of brick masonry walls assembled with different types of mortar. Constr Build Mater 40:1038–1045

ASTM E519-00 (2010) Standard test method for diagonal tension (shear) in masonry assemblages. American Society for Testing and Materials, West Conshohocken, Pa, USA

Cheah JS, da Silva R (2007) Material testing of flax-fibre reinforced rammed earth. The University of Auckland, Auckland

Cheah JS, Walker P, Heath A, Morgan TK (2012) Evaluating shear test methods for stabilised rammed earth. Proc Inst Civ Eng Constr Mater 165(6):325–334

Ehsani MR, Saadatmanesh H, Al-Saidy A (1997) Shear behavior of URM retrofitted with FRP overlays. J Compos Constr 1(1):17–25

IS: 2386 (Part I)–1963 (Reaffirmed 2007) Methods of test for aggregates for concrete: Part I Particle size and shape. Bureau of Indian Standards, New Delhi, India

IS: 8112–1989 (Reaffirmed 2005) 43 Grade ordinary Portland cement—Specification. Bureau of Indian Standards, New Delhi, India

Mojsilović N (2012) Masonry elements with damp-proof course membrane: assessment of shear strength parameters. Constr Build Mater 35:1002–1012

Nanjunda Rao KS, Venkatarama Reddy BV, Maheshreddy G (2011) Strength and elastic properties of cement stabilized rammed earth. In: National conference on recent developments in civil engineering, VVIET, Mysore, Karnataka, India

Pavan GS, Nanjunda Rao KS (2015) Behavior of Brick-Mortar interfaces in FRP-strengthened masonry assemblages under normal loading and shear loading. J Mater Civ Eng 28(2):04015120

Roca P, Araiza G (2010) Shear response of brick masonry small assemblages strengthened with bonded FRP laminates for in-plane reinforcement. Constr Build Mater 24(8):1372–1384

Tomaževič M (2009) Shear resistance of masonry walls and Eurocode 6: shear versus tensile strength of masonry. Mater Struct 42(7):889–907

Acknowledgements

The authors would like to gratefully acknowledge the financial support provided by DST, Govt. of India, New Delhi through the project Ref. No. SR/S3/MERC-0077/2010 for carrying out the research investigations reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Ullas, S.N., Pavan, G.S., Nanjunda Rao, K.S. (2019). Influence of Normal Stress and Bonding Techniques on Shear Bond Strength of Rammed Earth. In: Reddy, B., Mani, M., Walker, P. (eds) Earthen Dwellings and Structures. Springer Transactions in Civil and Environmental Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-5883-8_6

Download citation

DOI: https://doi.org/10.1007/978-981-13-5883-8_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-5882-1

Online ISBN: 978-981-13-5883-8

eBook Packages: EngineeringEngineering (R0)