Abstract

The Laboratory of Ophthalmic Instrumentation (LIO) from the University of Sao Paulo—Brazil, is involved in research about Sunglasses and its standards, and has already contributed for changing parameters in the previous Brazilian sunglasses standard, the ABNT NBR 15111-2013. The focus of the work presented in this paper is to investigate on the long-term solar exposure effects in sunglasses lenses and to conduct this study, we have developed an automated exposure system dedicated to expose sunglasses lenses towards the sun. The system also measures the dose of ultraviolet radiation which the lenses were subjected to and other weather variables, like temperature and relative humidity of the air. In this paper, we discuss about the materials used to manufacture sunglasses lenses, about the machine we developed to exposes the lenses and the methods used to measure the lenses transmittance characteristics over the time and to determine if and how long-term solar exposure may affect the samples.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Sunglasses may assure ultraviolet (UV) safety when adequate UV protection filters are used. There are evidences that sunglasses UV protection can degrade with exposure to the Sun, but such an experiment has never been done. In our current research, we propose to evaluate the changes of luminous and UV transmittances in sunglasses lenses after long periods of controlled solar exposition, by using an automated sunglasses lens exposure station that we developed.

1.1 Sunglasses Standards

The Brazilian standard for sunglasses for general use (ABNT NBR ISO 12312-1:2015) is a translation of the international one (ISO 12312-1:2013) [1, 2]. According to the standard used in Brazil, depending on luminous spectral transmittance, lenses are classified into different categories and for each category there is a required UV protection (Table 1). In this standard is established a lens aging test that involves exposing sunglasses lenses in solar simulator for 50 h and analyze transmittance difference before and after the test.

Some sunglasses lenses show luminous transmittance changes after long solar exposure, becoming lighter. There are evidences that solar exposure can increase sunglasses UV transmittance and there is no experimental study in the literature showing how much solar exposure time corresponds to 50 h in solar simulator.

1.2 Previous Works

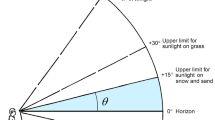

In a previous study conducted in LIO [3], we discussed the parameters for the solar simulator test (distance between lamp and samples, and exposure time) to make the test equivalent to the real solar exposure conditions that population are subjected to when wearing sunglasses. The present test parameters, as specified by the Brazilian standard, should be revisited to establish safe limits for UV filters of sunglasses.

2 Materials and Methods

The automatic solar exposition station for sunglasses is a machine which the main function is to expose a set of sunglasses lenses to the sun while favorable weather conditions and, in the absence of such conditions, to protect the lenses. The favorable weather conditions are during the daylight, i.e. after sunrise and before sunset, and when it is not raining. It is desired to avoid rain on the samples because it would facilitate the deposition and accumulation dirt particles on the lens surface and compromise the action of UV radiation on them.

The system mechanics was designed to protect the set of five acrylic panels that houses 60 lenses (12 each). It was designed a metallic frame with four of each sides covered by UV protected polycarbonate sheet. The box could slide through a metallic rail, with double of the box length, to cover or uncover the panels when needed, and the motion is driven by a garage door motor. After the manufacture of the system, we installed it on the rooftop terrace because it was a restricted access place; in addition to permit the samples would be free of shadows during all day. Along with the automatic solar exposition station, we installed an IP camera for monitoring the system’s functioning, weather sensors for providing information about the conditions that lenses would be exposed and to alert when rain begins and the UV sensors for registering the total radiation dose that lenses would be exposed (Fig. 1).

The analysis of lens transmittance changes after exposition to the Sun depends on measures of the transmittance spectrum of each lens. The visible (380–780 nm) and UV (280–400 nm) transmittances are measured in 5 points of lenses: one central point and 4 points located 5 mm above, below, on the left and right of the central point. Transmittance measures are taken from 780 to 280 nm, with steps of 5 nm. For doing these measures, it was used the VARIAN Cary 5000 UV-Vis-NIR spectrophotometer. A mechanical device is used for holding the lens, which should be placed with its central point aligned with a mark on the device. The device is placed inside the spectrophotometer and measures of transmittance in the central point are taken. After this step, the mechanical device is adjusted to move the lens 5 mm up, 5 mm down and so on. Measures of transmittance in all 5 points of each lens are recorded in a text file, with 5 nm step for each spectral response, in compliance with ISO 12312-1 [2].

3 Results and Discussion

After setting up the machine and the controlling hardware and software, we tested the functioning of the machine in the real conditions it would work when exposing the sunglasses lenses. The system was programmed to detect the current time and open or close the enclosure to expose or protecting the lenses respectively. By the online control panel (Fig. 2) it was possible to manually open or close the enclosure if any problems were detected, in addition to live monitoring the machine through the IP camera video stream. The control panel also shows the opening and closing time for the current day, the current UV index level and other information regarding the total time of lenses exposure to the sun and weather conditions report.

The closing time length for protecting the lenses is about 18 s, which is enough for protecting the most rains in São Carlos city. We tested the machine for 5 months before installing the first set of 60 lenses to be exposed, and by monitoring the machine functioning and the system reports, we verified that the system worked as expected, with minor bugs that were easily repaired.

With the evaluation of the automated panel system concluded, the next step of the research is to expose the lenses to the natural sunlight and measure the effects of the exposition to the changes in UV and visible transmittances. The lenses of our sample set are manufactured of the following materials: 80% polycarbonate, 2% polymethyl methacrylate (PMMA), 5% CR-39 (with polarizing filter inside), 12.8% polyamide and 0.2% glass. Our research team is engaged in determining if the parameters of the tests of the certification standards for sunglasses are enough for the safety of users and ultraviolet radiation levels in Brazil [4], and we’ve already exposed the lenses set in a solar simulator. The test was conducted for a total of 3000 h and we’ve already detected transmittance changes, which will be compared with the future results after exposition in the automated sunglasses lens exposure station.

4 Conclusion

In this paper we presented the automatic solar exposure station for sunglasses lenses, which was developed in our laboratory (LIO—EESC/USP). From the construction of the machine, a study about the behavior of sunglasses lenses after the long periods of exposure to solar radiation will be carried out to contribute to the redefinition, if necessary, of the parameters of the Brazilian standard regarding lenses stress after solar exposition. Lenses are being exposed towards geographic north, and total exposure time is recorded. It is expected to verify whether the requirements of the ISO 12312-1:2013 and ABNT NBR ISO 12312-1:2015 standards are still met or whether new certification items need to be provided for ensuring sunglasses protection for population.

References

ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS. NBR ISO 12312-1: Proteção dos olhos e do rosto – óculos para proteção solar e óculos relacionados – parte 1: óculos para proteção solar para uso geral. Rio de Janeiro, 2015. 26 p.

INTERNATIONAL STANDARD ORGANIZATION. ISO 12312-1: Eye and face protection – sunglasses and related eyewear – part 1: Sunglasses for general use. August. 2013. 23 p.

MASILI, M., VENTURA, L. Equivalence between solar irradiance and solar simulators in aging tests of sunglasses. Biomedical Engineering Online (Online), p. 86–98, n. 2016.

MAGRI, R., MASILI, M., DUARTE, F. O., VENTURA, L. Building a resistance to ignition testing device for sunglasses and analysing data: a continuing study for sunglasses standards. Biomedical Engineering Online (Online), 16:114, 2017.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Gomes, L.M., Loureiro, A.D., Momesso, G.A., Masili, M., Ventura, L. (2019). Automated Sunglasses Lens Exposure Station and the Preliminary Effects of Solar Exposure. In: Lhotska, L., Sukupova, L., Lacković, I., Ibbott, G. (eds) World Congress on Medical Physics and Biomedical Engineering 2018. IFMBE Proceedings, vol 68/3. Springer, Singapore. https://doi.org/10.1007/978-981-10-9023-3_46

Download citation

DOI: https://doi.org/10.1007/978-981-10-9023-3_46

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-9022-6

Online ISBN: 978-981-10-9023-3

eBook Packages: EngineeringEngineering (R0)