Abstract

The major problem in permanent Magnet Synchronous Motor (PMSM) drive systems are the nonlinear behavior which arises mainly from motor dynamics and load characteristics. So, the speed control technique should be adaptive and robust for successful industrial applications. The conventional proportional integral derivative (PID) controllers used to control speed of the drive are tuned mainly using Ziegler-Nichols’ (Z-N) tuning technique. Since, PID controller works well under linear operating condition and underperforms when nonlinearity arises. So Artificial Intelligence (AI) techniques are being implemented to achieve better performance i.e. Adaptive Neuro Fuzzy Inference System (ANFIS), Modified Particle Swarm Optimization (MPSO). This paper proposes novel design of ANFIS and MPSO- AI techniques based PID speed controller which has been incorporated in PMSM drive to improve its dynamic performance. A model of PMSM drive is simulated under various operating conditions to analyze its performance in terms of transient response specification such as rise time, settling time, peak overshoot and peak time. The results obtained give much better performance as compared to conventionally used Z-N technique.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

- Permanent Magnet Synchronous Motor (PMSM)

- Proportional integral derivative controller (PID)

- Ziegler-Nichols (Z-N)

- Adaptive neuro fuzzy inference system (ANFIS)

- Modified Particle Swarm Optimization (MPSO)

1 Introduction

PMSM drives have emerged as efficient variable speed drive systems in the recent trend of industrial applications giving stiff competition to the classical brushed DC and induction motor (IM) drives in the low to medium power range. The replacement of electrically excited field windings by constant flux producing permanent magnets in PMSMs have led to elimination of brushes, slip rings and rotor copper losses resulting in higher efficiencies. Although PMSMs are more expensive as compared to IMs but with high-energy magnet material (Nd-Fe-B), offer higher efficiency, higher torque to inertia ratio, higher power density reduced size and high performance in wide range of speed. Owing to these advantages PMSMs are being widely used in electric vehicles, audio equipment, household appliances, medical instruments, robotics, textiles and chemical industries [1, 2]. Due to the presence of non-linearity in the system the conventional approach of PID tuning is not very efficient with the dynamic conditions of a system because of varying parameters and complicated environmental applications [3]. The Zeigler and Nichols (Z-N) tuning method is one of the most widely used method for tuning of PID controller [4]. ANFIS based speed controller is a good tool to deal with complicated, non-linear and ill-defined systems [5]. Another evolutionary computation technique [PSO] was first presented by Kennedy and Eberhart in 1995 [6] for optimize the gain of PID controller. PSO has some demerits as the rate of convergence, problem of local extreme, premature and halt condition in searching process. In order to overcome these defects MPSO have been incorporated [7,8,9,10,11,12]. The objective of this paper is to use the MPSO algorithm in order to obtain optimal values of gains for PID speed controller for improved performance of PMSM drive. By incorporating AI techniques such as ANFIS and MPSO for tuning the conventionally used PID speed controller, an improvement in the performance of PMSM in terms of transient response under various operating conditions has been presented in this paper.

2 Design of ANFIS Based Speed Controller

The FIS to be used in ANFIS based speed controller consists of input block, output block and their respective membership functions. Figure 1 explains the development of fuzzy inference system using ANFIS edit GUI toolbox [13].

In this PMSM motor drive, there are two inputs and one output. The inputs are the speed error (e) and change in speed error (ce) and the value of du is taken as output from the ANFIS based speed controller. Algorithm of ANFIS based Speed Controller.

The block diagram representing the ANFIS based controller for the speed control of the PMSM is shown in Fig. 2 [5].

Basically, the ANFIS controller includes four processes as.

(a) Fuzzification (b) Knowledge base (c) Neural network (d) Defuzzification.

The process of designing ANFIS based speed controller involves the following steps as.

Step 1: The data of the two inputs e, ce and the output du are collected and fed as a loading data to the ANFIS edit GUI toolbox. The training data obtained is shown in Fig. 3.

Step 2: The required FIS is generated using the grid partition. The normalized membership functions, 3 in number for each, of the two inputs are shown in Fig. 4. The 3 membership functions for each input have been taken in order to reduce the computational burden.

Step 3: The control of the speed is done by the ANFIS based speed controller; the following rules are used and summarized in Table 1. The structure of ANFIS developed with all the 5 layers is shown in Fig. 5.

The abbreviations in Table are as follows.

NB - Negative Big, PB - Positive Big, Z - zero.

Step 4: The loaded training data with the generated FIS is trained using the hybrid method with the following parameters given in Table 2.

2.1 Incorporation of ANFIS Based Speed Controller in PMSM

The ANFIS based speed controller is obtained using the algorithm of ANFIS. It is incorporated in the PMSM drives. As shown in Fig. 6 the conventional PID speed controllers in the drives have been replaced by this ANFIS based speed controller.

The PMSM has to meet the load requirement and disturbances due to speed. The number of output membership functions are equivalent to the number of rules in Sugeno based ANFIS based speed controller. The Sugeno based FIS gives a singleton output [13] unlike the most commonly used Mamdani based FIS.

3 Methodology of Proposed Modified PSO

The Modified PSO have certain advantages over Particle Swarm Optimization technique, it comes with the advantages that shares the optimal information in the group to improve the overall convergence and prevent the prematurely condition. When each group is divided, the group which has maximum population at the center is preferred. It shows a particle subgroup as a central subgroup, and the other subgroups are neighborhoods to the central subgroups, it can communicate with other subgroup near to it and other subgroups cannot share the information with each other. By using MPSO technique the information can transmit faster and improving efficiency of the algorithm. Accordingly, the distance of two vectors was obtained by the space position of each particle. The Lmax denoted as the maximum distance of any two particles. Meanwhile \( \left| {\left| {{\text{X}}_{\text{i}} \left( {\text{k}} \right) - {\text{X}}_{\text{i}} \left( {\text{k}} \right)} \right|} \right|/{\text{L}}_{ \hbox{max} } \) was also calculated. Each particle updates its status according to Eqs. (1, 2) as follows

Fitness function is used to evaluate every new position. In MPSO technique, the value of weight w adjust the properly, which prevent algorithm from getting into a local optimization. In this algorithm, a quasi-linear speed-weights way is used in the iterative process. This way used is illustrated as follows:

k denotes current iterate time; K denotes max iterate time.

The searching procedure of the implemented MPSO-PID controller is described in flowchart given in Fig. 7.

The optimized values of PID controller gains are shown in Table 3.

4 Model of PMSM and Results

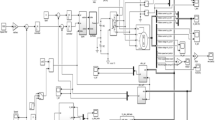

The model for speed control of PMSM using AI technique is as shown in Fig. 8. Matlab R2013a is used for simulation of the model and time required for the simulation is 0.5 s. The reference value of speed being used in MATLAB model is 1000 r.p.m.

The motor speed (given by feedback path) is compared with reference speed with the help of comparator which is fed to the PID controller. These controllers improve the transient parameters. The output of controller is fed to the dq to abc transformation. The inverter circuit is fed by the dq to abc transformation. The output of inverter circuit is fed to Permanent Magnet Synchronous Motor (PMSM). The output of PMSM is taken with the help of Bus Selector. The output of bus selector is Current, Rotor Speed and Electromagnetic torque. The Rotor speed is fed back to the comparator to achieve the desired speed which is required. The simulation is carried out under the different operating conditions such as starting, braking and load application and removal.

4.1 Starting Characteristics

The motor is started at no load with a reference speed of 1000 rpm. The stator winding currents possess low frequency at the time of starting. The motor tracks the reference speed of 1000 rpm. At this instant, the torque reaches it’s no load value (zero Nm) and the stator winding currents magnitudes and frequency settle down to their normal no load values. The starting characteristics for PMSM drive are shown in Figs. 9, 10 and 11 using Ziegler-Nichols method and AI controllers such as ANFIS and MPSO speed controller.

4.2 Speed Reversal Characteristics

The reference speed is reversed at t = 0.08 s to −1000 rpm. The rotor speed follows and tries to attain the reference value as seen from Figs. 12, 13 and 14.

The torque Tem also reduces, the speed settles down to its new reference value of −1000 rpm and the torque reverts to the no load value of zero Nm.

4.3 Load Application and Load Removal

Load application and removal of load are shown in Figs. 15, 16 and 17. When the sudden load is applied at t = 0.15 s. The developed torque follows the value of load torque. The rotor speed ωm decreases when the load is applied and increases, try to attain the reference value when the load is removed at t = 0.35 s.

The values of the transient response specifications under starting, speed reversal and load disturbance conditions obtained from the AI techniques and Z-N method of PMSM tuned PID speed controller as shown in Table 4.

5 Conclusion

The performance of the PMSM motor is improved by tuning PID parameters effectively along with AI technique i.e. ANFIS and MPSO. Further, these results are compared with those of Z-N method. The proposed controller has significantly improved the transient response of the drive by optimizing gains of PID controller as compared to Z-N tuned method. Further, the proposed method incorporated in PMSM motor is robust, efficient and easy to implement. In this paper, the performance of PID speed controller with and without AI tuning has been compared and the obtained results clearly demonstrate the difference between the two waveforms obtained from simulation of PMSM model. Under various operating conditions, the analysis and comparison between the improved static and dynamic characteristics in terms of rise time, peak overshoot and settling time are demonstrated which are helpful in selection of PMSM drive for particular industrial applications.

References

Krishnan, R.: Permanent Magnet Synchronous and Brushless DC Motor Drives. CRC Press/Taylor & Francis Group, Boca Raton/Milton Park (2010)

Bose, B.K.: Modern Power Electronic and Drives. The University of Tennessee, Knoxville (2001)

Pan, T.-H., Li, S.-Y.: Adaptive PID control for nonlinear systems based on lazy learning. Control Theory Appl. (2009)

Ogata, K.: Modern Control Engineering, 4th edn. Prentice Hall of India, New Delhi (2002)

Jain, L.C., Martin, N.M.: Fusion of Neural Networks, Fuzzy Systems and Genetic Algorithms: Industrial Applications. CRC Press, Boca Raton (1998)

Kennedy, J., Eberhart, R.: Particle swarm optimization. In: Proceedings of the IEEE International Conference on Neural Networks, vol. 4, pp. 1942–1948 (1995)

Jeong, S., Hasegawa, S., Shimoyama, K., Obayashi, S.: Development and investigation of efficient GA/MPSO-hybrid algorithm applicable to real-world design optimization. IEEE Comput. Intell. Mag. 777–784 (2009)

Shayeghi, H., Mahdavi, M., Bagheri, A.: Discrete MPSO algorithm based optimization of transmission lines loading in TNEP problem. Energy Convers. Manag. 51, 112–121 (2010)

Duan, Z., Zhang, C., Hu, Z., Ding, T.: Design for multi-machine power system damping controller via particle swarm optimization approach. In: International Conference, SUPERGEN 2009 (2009)

Shoorehdeli, M.A., Teshnehlab, M., Sedigh, A.K.: Training ANFIS as an identifier with intelligent hybrid stable learning algorithm based on particle swarm optimization and extended Kalman filter. Fuzzy Sets Syst. 160, 922–948 (2009)

Karakuzu, C.: Fuzzy controller training using particle swarm optimization for nonlinear system control. ISA Trans. 47, 229–239 (2008)

Catalão, J.P.S., Pousinho, H.M.I., Mendes, V.M.F.: Hybrid wavelet-MPSO-ANFIS approach for short-term wind power forecasting in Portugal. IEEE Trans. Sustain. Energy 2, 50–59 (2011)

ANFIS and ANFIS editor GUI - User’s Guide. The MathWorks. www.mathworks.com

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Yadav, D., Verma, A. (2018). Comparative Performance Analysis of PMSM Drive Using ANFIS and MPSO Techniques. In: Bhattacharyya, P., Sastry, H., Marriboyina, V., Sharma, R. (eds) Smart and Innovative Trends in Next Generation Computing Technologies. NGCT 2017. Communications in Computer and Information Science, vol 827. Springer, Singapore. https://doi.org/10.1007/978-981-10-8657-1_12

Download citation

DOI: https://doi.org/10.1007/978-981-10-8657-1_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-8656-4

Online ISBN: 978-981-10-8657-1

eBook Packages: Computer ScienceComputer Science (R0)